Roller washing machine washing clothes separately

A drum washing machine and separate washing technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of poor dehydration effect, difficulty in drying and high production cost of single-tub drum washing machines, and avoid secondary Contamination of clothing problems, fast drying, and the effect of less water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

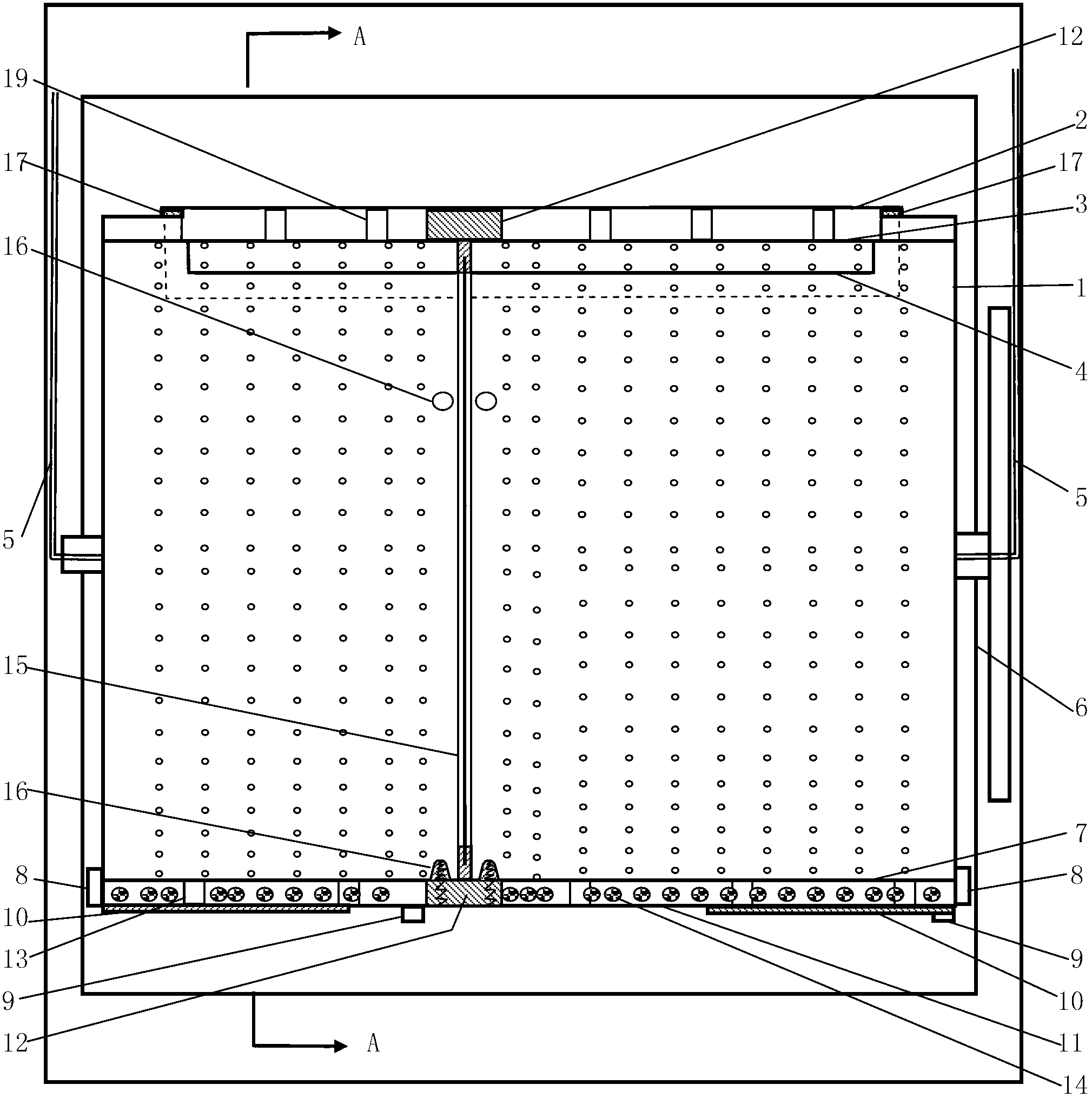

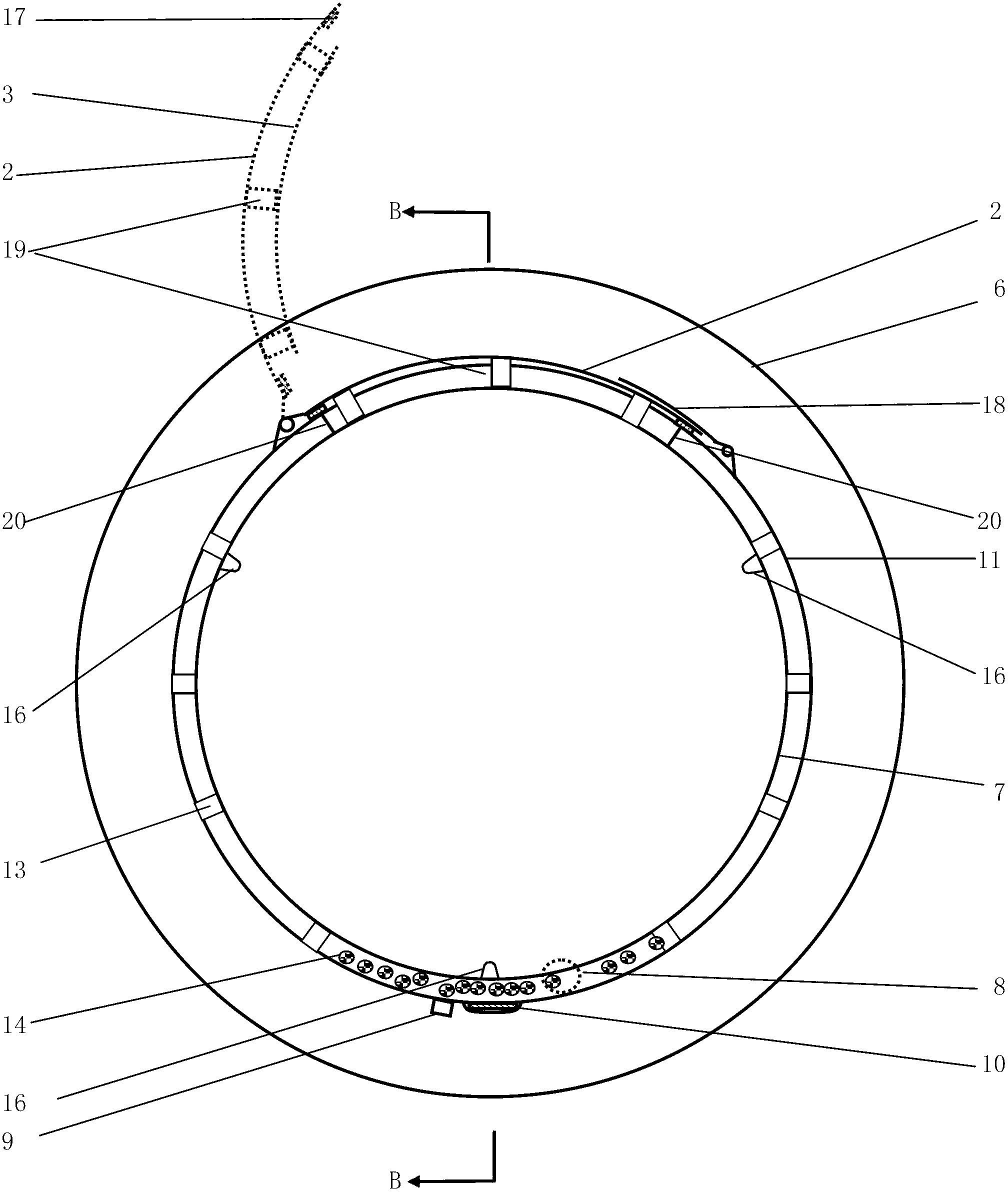

[0012] The present invention takes the top-opening type drum washing machine as an embodiment, as figure 1 , figure 2 shown in . Drum 1 is a composite drum composed of a closed outer drum 11 without dehydration holes and an inner drum 7 with dehydration holes. The two ends of the outer drum 11 and the inner drum 7 are fixedly connected together. The outer drum 11 and the inner layer drum 7 are all made of stainless steel, and a plurality of evenly distributed pillars 13 are arranged between the two layers of drums to strengthen the mechanical strength of the composite drum. A cleaning particle 14, the cleaning particle 14 is a stainless steel solid ball, its diameter is greater than the dehydration hole, about 0.3 to 0.8 cm, the number is selected according to its diameter, about 600 to 200. The drum cover consists of an outer layer cover 2 and an inner layer cover 3, such as figure 2 Shown by the dotted line in the center (the cylinder cover is in the open state), there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com