Unpowered sludge dehydration device

A sludge dewatering and power technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of large volume, high mechanical maintenance cost and high cost, and achieve the effect of small volume, good dewatering effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

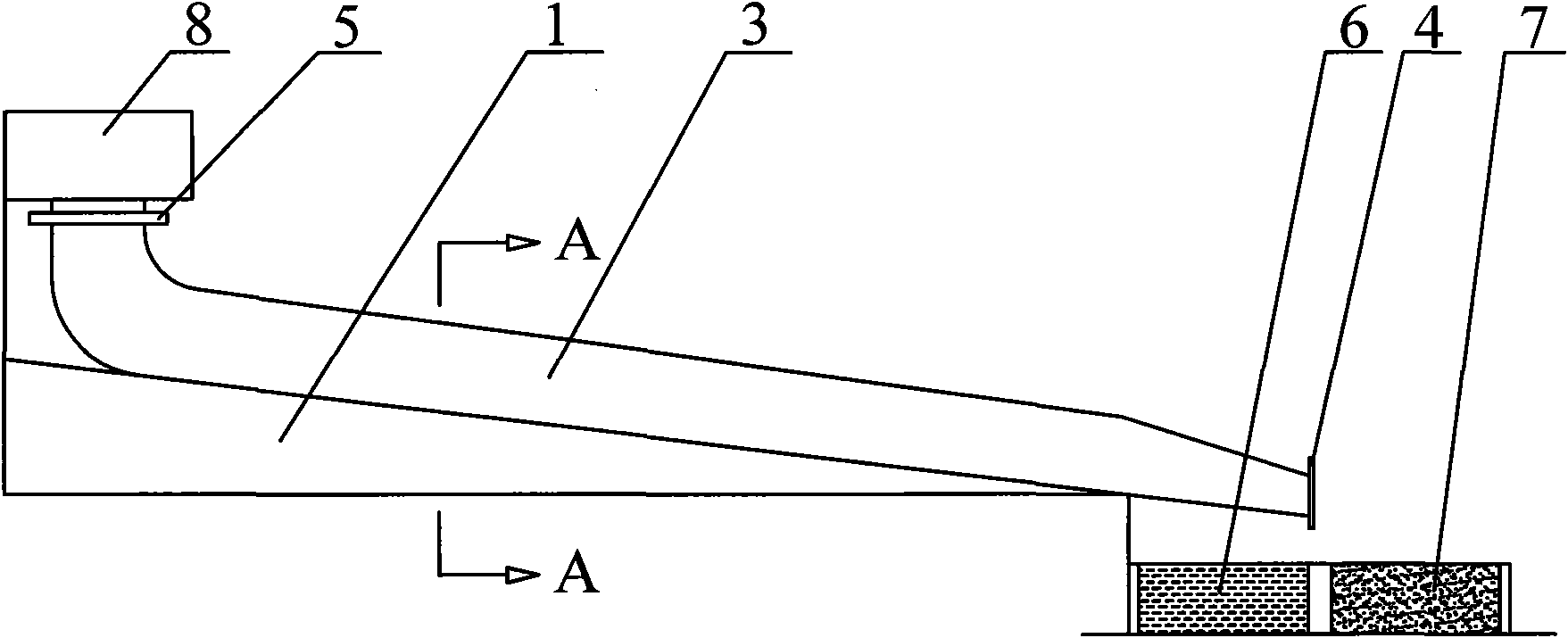

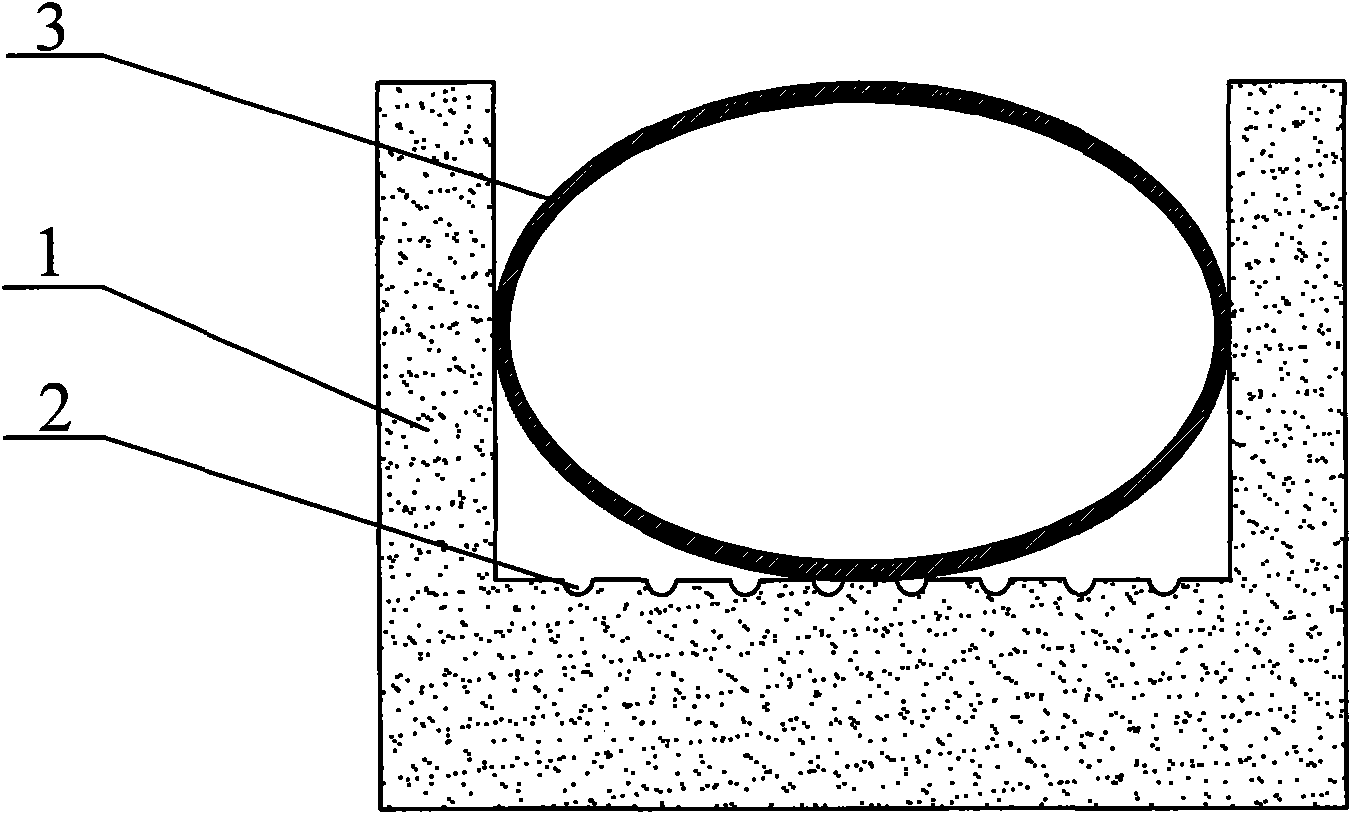

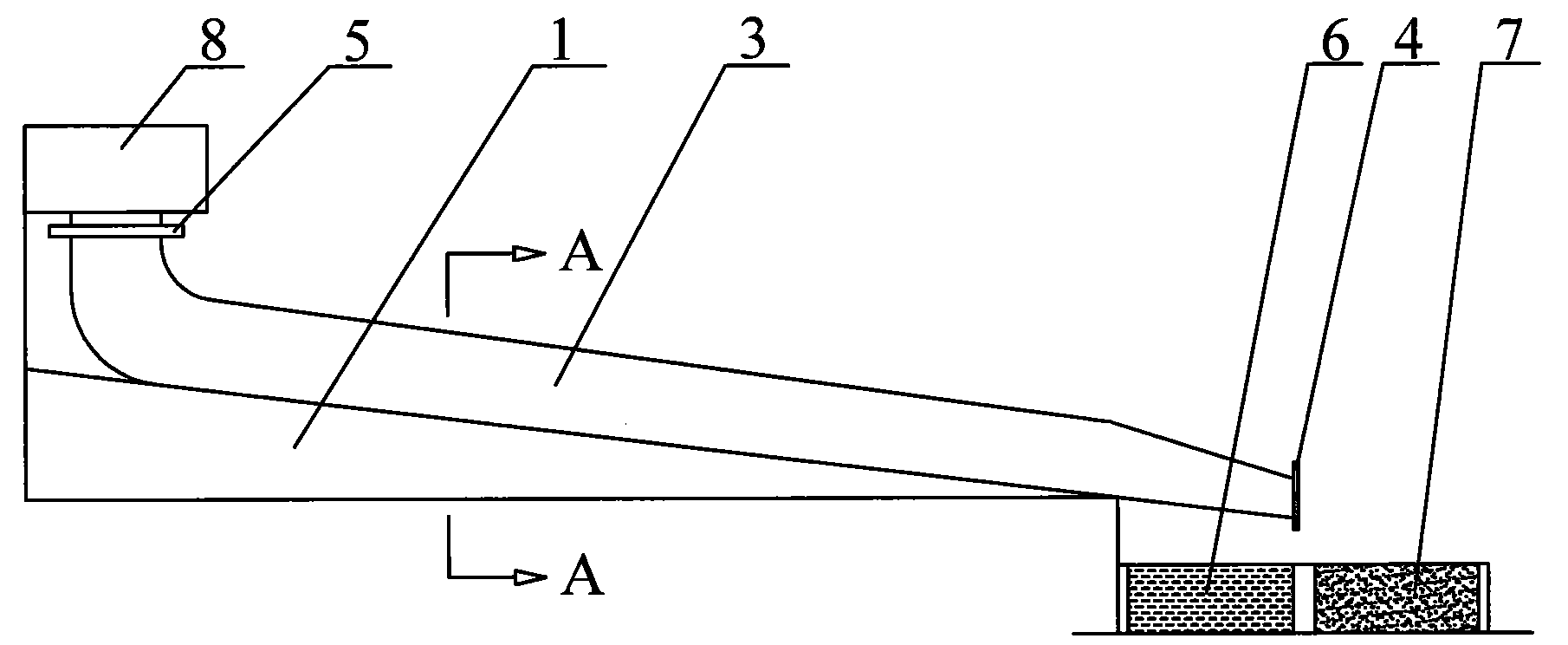

[0013] As shown in the figure: the unpowered sludge dewatering device includes a liquid flow tank 2 set on the upper surface of the bottom of the dewatering tank 1. The upper surface of the tank bottom of the dewatering tank 1 is inclined to the horizontal plane. Dehydration woven bag 3 is placed on the top surface of the tank bottom of dehydration tank 1, the length direction of dehydration woven bag 3 is consistent with the length direction of dehydration tank 1, the outlet end of dehydration woven bag 3 extends out of dehydration tank 1, and the dehydration weaving The inlet height of the bag 3 is higher than the outlet height of the dehydration woven bag 3, and the inlet end of the dehydration woven bag 3 is arranged above the high end of the dehydration tank platform 1, and a tie belt body 4 is arranged at the outlet of the dehydration woven bag 3. A water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com