Efficient washing equipment for textile thread materials

A kind of cleaning equipment and high-efficiency technology, which is applied in the direction of processing textile material equipment configuration, textile material processing, and processing textile material carriers, etc., can solve the problems of low cleaning efficiency and poor effect, and achieve high automation, uniform cleaning, and easy cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

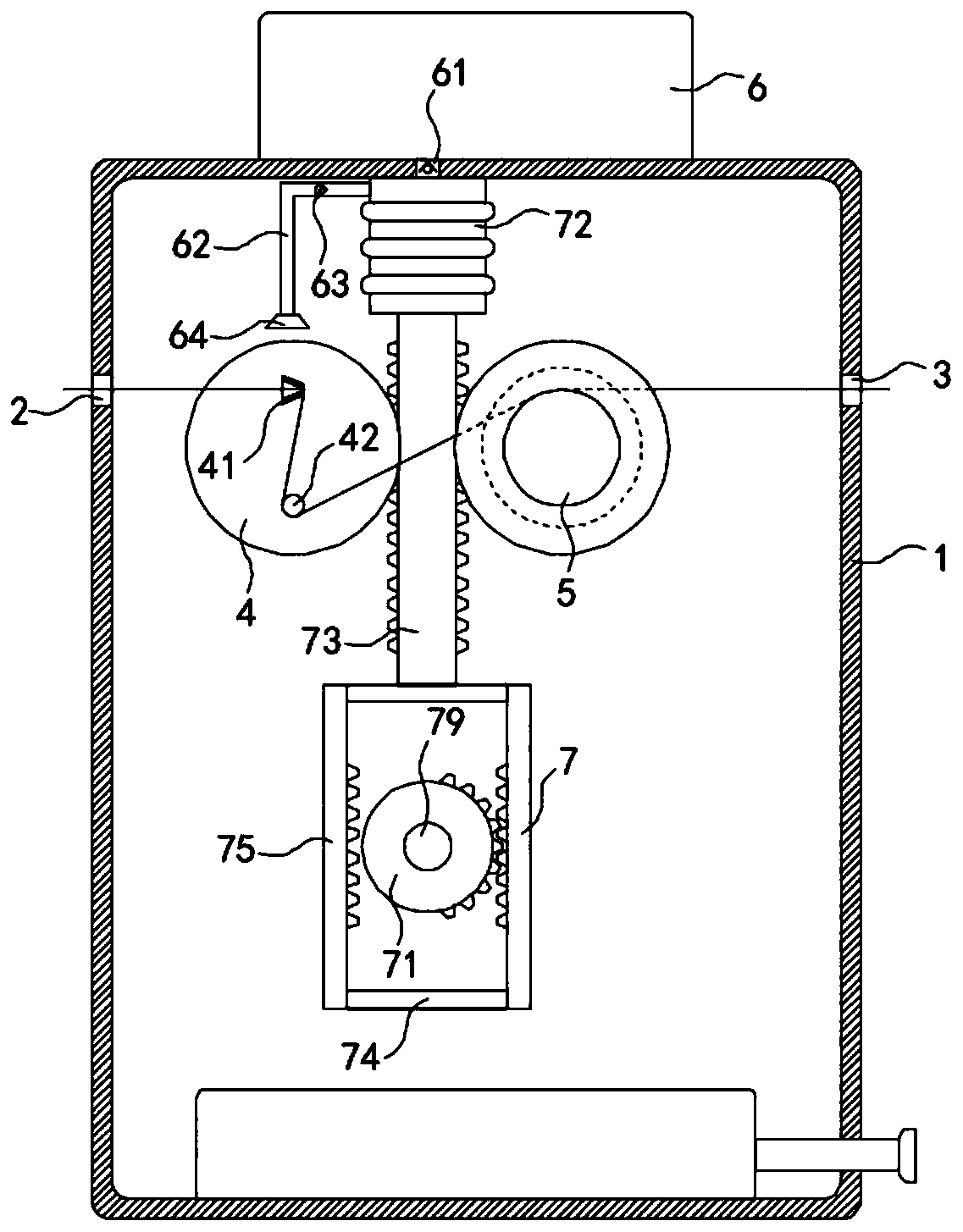

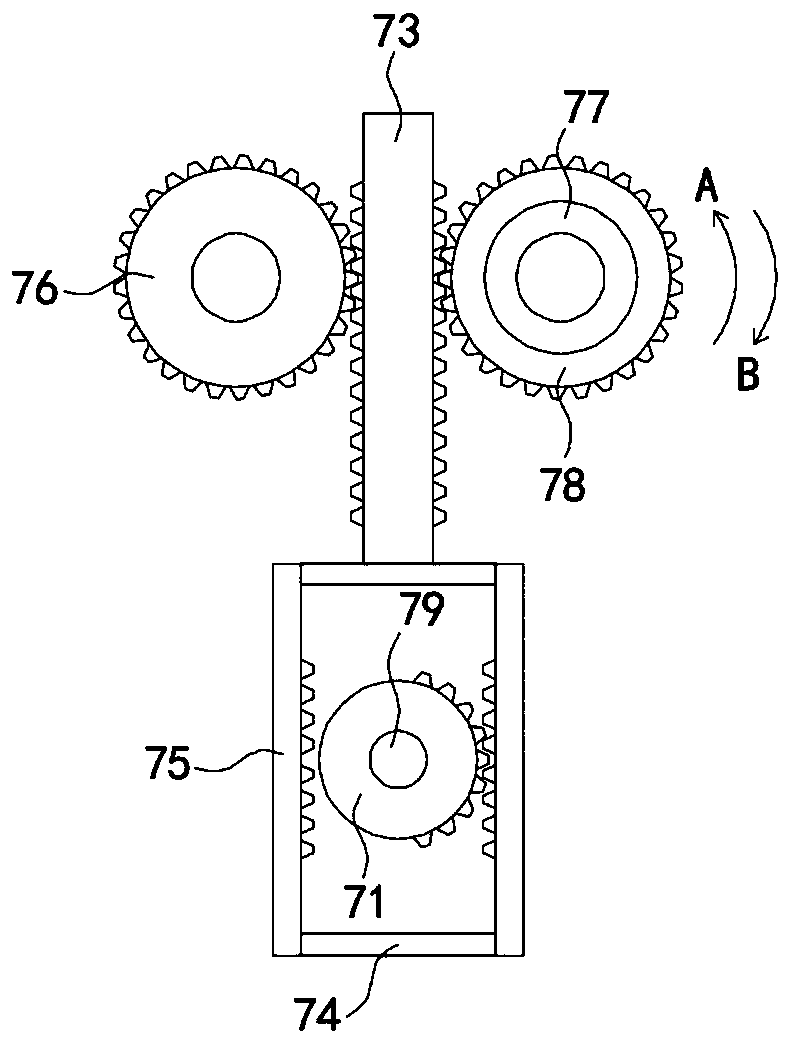

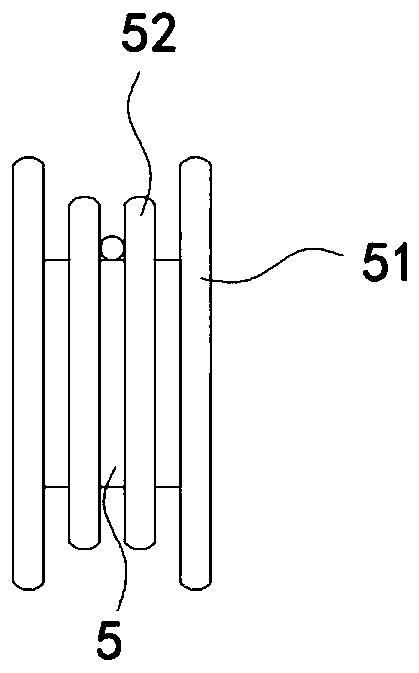

[0028] Such as Figure 1-4 As shown, a high-efficiency cleaning equipment for textile wires includes a box body 1, and the side walls on both sides of the box body 1 are respectively provided with inlet holes 2 and wire outlet holes 3, and the inner side walls of the box body 1 are rotatably connected with a turntable 4 and the push roller 5, it should be noted that both ends of the push roller 5 are fixedly connected to the limit plate 51, and the push roller 5 is slidingly sleeved with two clamping rings 52 made of magnetic materials, and the two clamping rings Different poles attract each other between 52. The surface of the turntable 4 is fixedly connected with a threading barrel 41. The threading barrel 41 is set in a conical shape with openings at both ends. The inner ring of the threading barrel 41 is fixedly connected with a graphite lubricating sleeve, which can reduce threading. The friction between the barrel 41 and the twine reduces the wear of the twine, so that t...

Embodiment 2

[0035] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that: the side wall of one of the second racks 75 is fixedly connected with a vertically arranged toggle plate 9 through a connecting rod, and the surface of the toggle plate 9 is fixedly connected There are a plurality of plectrums 91, and the plurality of plectrums 91 are arranged in equidistant arrays on the toggle plate 9. The plectrums 91 are made of nylon material, have good toughness and deformation ability, and can be used to vibrate the twine.

[0036] In this embodiment, the second rack 75 moves up and down, and then drives the toggle plate 9 to move up and down, and the twine is moved by a plurality of paddles 91 on the toggle plate 9, which drives the twine to vibrate, and shakes the water attached to the twine surface. In addition, it has a better drying and water removal effect and improves work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com