Coal tar dehydration method and coal tar dehydration device

A dehydration device and a technology for coal tar, applied in the field of coal tar dehydration, can solve the problem of high moisture content of coal tar, and achieve the effects of low separation energy consumption, mild operating conditions and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

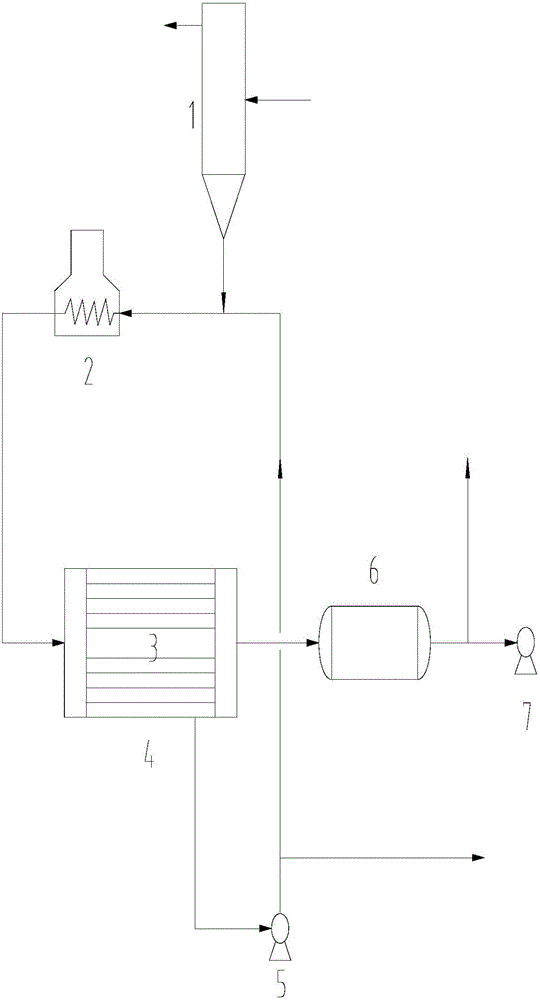

[0024] Such as figure 1 As shown, the coal tar dehydration device of the present invention comprises a settling tank 1, a preheating furnace 2, a membrane separation device 4, a condenser 6, and a vacuum pump 7 connected in sequence, and the membrane separation device is also connected with a reflux pump 5, and the settling tank passes through The pipeline is connected to the preheating furnace, and the preheating furnace is connected to the membrane separation device through the pipeline. The membrane separation device is provided with a raw material inlet for adding crude coal tar, and a dehydrated coal tar outlet for discharging the dehydrated coal tar out of the membrane separation device. And the water vapor outlet that is used to extract the water vapor on the permeate side, the membrane separation device includes a plurality of membrane modules 3, the membrane module in this embodiment is a circular membrane tube, and the circular membrane tube includes a membrane tube s...

Embodiment 2

[0026] The difference between the coal tar dehydration device of this embodiment and the coal tar dehydration device of Embodiment 1 is that no return pump is included.

Embodiment 3

[0028] The difference between the coal tar dehydration device in this embodiment and the coal tar dehydration device in Embodiment 1 is that no condenser is included.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com