Scraper mechanism for paste mixer

A technology of paste mixing machine and scraper, which is applied to mixers, mixers with rotating stirring devices, chemical/physical/physicochemical processes, etc. It can solve the problems of slow temperature drop, improve quality, and achieve better mixing effects. The effect of increasing the temperature cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

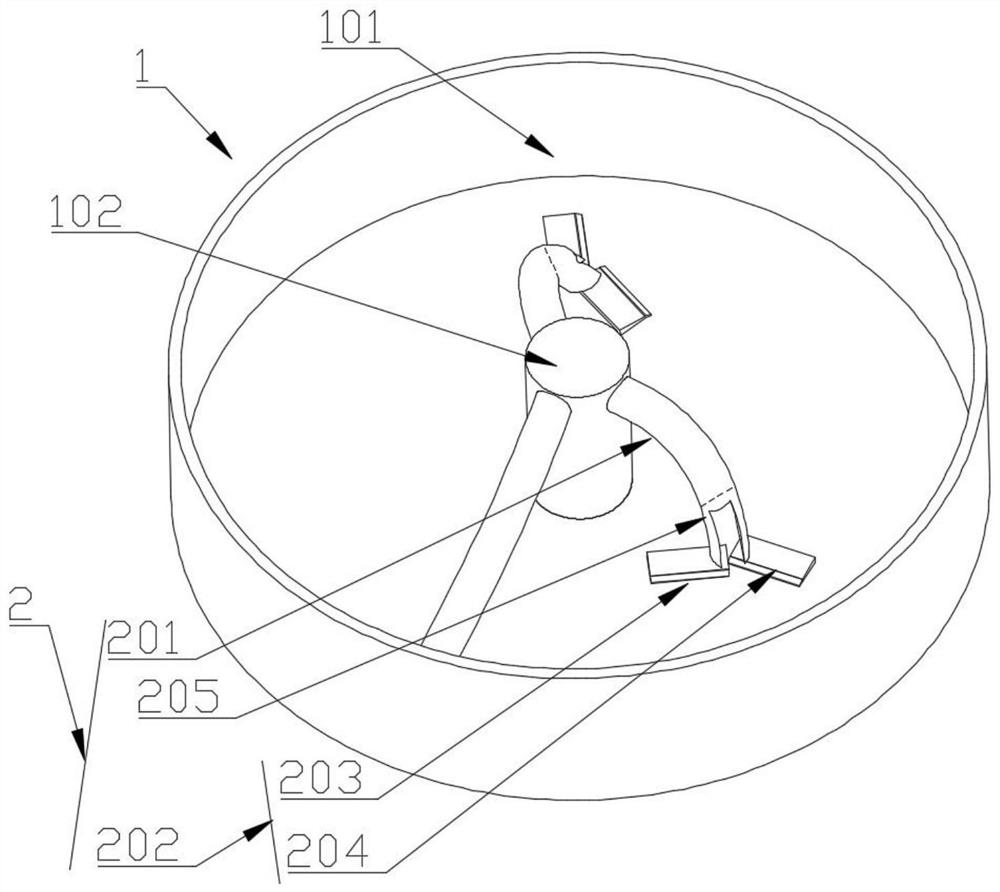

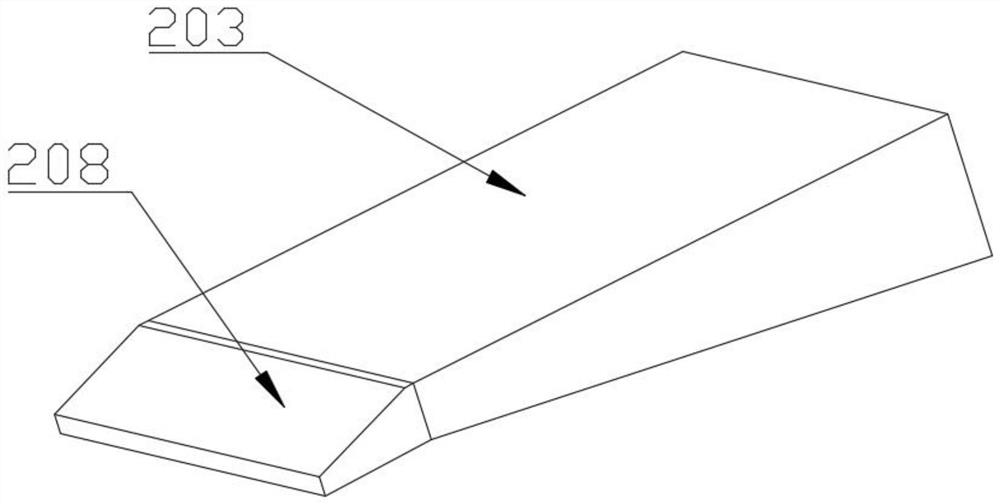

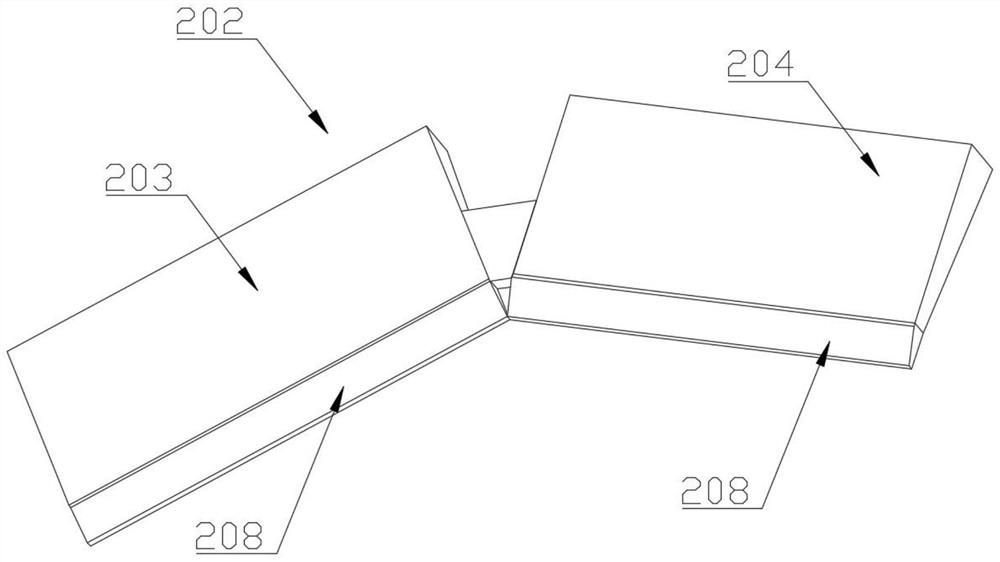

[0031] see Figure 1-2 As shown, the present invention is a scraper mechanism for a paste combining machine, including a paste combining machine 1; the paste combining machine 1 includes a stirring housing 101 and a rotating shaft 102; a scraper mechanism 2 is fixedly installed on the top of the rotating shaft 102; the scraper mechanism 2 Including a fixed shaft 201 and a scraper 202; the scraper 202 includes a scraper A203 and a scraper B204; the end of the fixed shaft 201 is provided with a bifurcated shaft 205; the two forks of the bifurcated shaft 205 are respectively fixed with a scraper A203 and a scraper B204; wherein, by The scraper mechanism carries out the structural design of scraper A203 and scraper B204, so that the scraping effect on the lead paste on the bottom of the pot is higher and the scraping is more thorough, and then the temperature in the paste mixing process can be stably lowered, thereby improving The quality of the paste.

[0032] Preferably, the sc...

Embodiment 2

[0035] see Figure 1-4 As shown, the present invention is a scraper mechanism for a paste combining machine, including a paste combining machine 1; the paste combining machine 1 includes a stirring housing 101 and a rotating shaft 102; a scraper mechanism 2 is fixedly installed on the top of the rotating shaft 102; the scraper mechanism 2 Including a fixed shaft 201 and a scraper 202; the scraper 202 includes a scraper A203 and a scraper B204; the end of the fixed shaft 201 is provided with a bifurcated shaft 205; the two forks of the bifurcated shaft 205 are respectively fixed with a scraper A203 and a scraper B204; wherein, by The scraper mechanism carries out the structural design of scraper A203 and scraper B204, so that the scraping effect on the lead paste on the bottom of the pot is higher and the scraping is more thorough, and then the temperature in the paste mixing process can be stably lowered, thereby improving The quality of the paste.

[0036] Preferably, the sc...

Embodiment 3

[0040] see Figure 1-6 As shown, the present invention is a scraper mechanism for a paste combining machine, including a paste combining machine 1; the paste combining machine 1 includes a stirring housing 101 and a rotating shaft 102; a scraper mechanism 2 is fixedly installed on the top of the rotating shaft 102; the scraper mechanism 2 Including a fixed shaft 201 and a scraper 202; the scraper 202 includes a scraper A203 and a scraper B204; the end of the fixed shaft 201 is provided with a bifurcated shaft 205; the two forks of the bifurcated shaft 205 are respectively fixed with a scraper A203 and a scraper B204; wherein, by The scraper mechanism carries out the structural design of scraper A203 and scraper B204, so that the scraping effect on the lead paste on the bottom of the pot is higher and the scraping is more thorough, and then the temperature in the paste mixing process can be stably lowered, thereby improving The quality of the paste.

[0041] Preferably, the sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com