High-precision batching device for ceramsite raw material

A high-precision, raw material technology, applied in the direction of selling raw material supply devices, liquid batching supply devices, unloading devices, etc., can solve the problem of inconvenient batching, and achieve the effect of improving accuracy, better scraping effect, and better practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

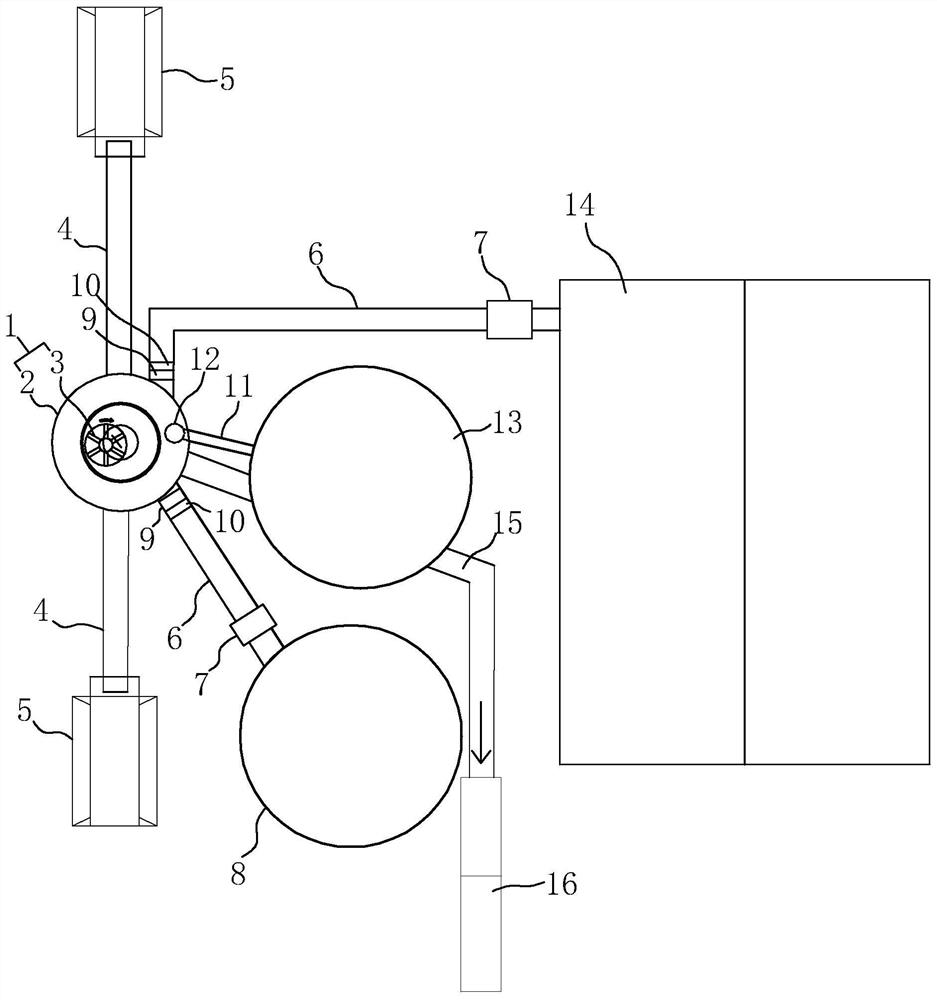

[0038] refer to figure 1 , a high-precision batching device for ceramsite raw materials, including a clay mixer 1 and a first feeding mechanism, a second feeding mechanism, a third feeding mechanism and a fourth feeding mechanism for conveying raw materials, wherein the clay mixer 1 is a high-speed inclined Type clay mixer, the clay mixer 1 includes a cylinder 2, the cylinder 2 is arranged obliquely, a stirring paddle 3 is arranged in the cylinder 2, and a feed inlet is arranged on the top of the cylinder 2, and the clay mixer 1 The bottom of the mixer is provided with a discharge port; each raw material is transported into the cylinder 2, and then the cylinder 2 and the stirring paddle 3 are rotated synchronously to achieve good mixing. After the stirring is completed, the mixture is discharged through the discharge port.

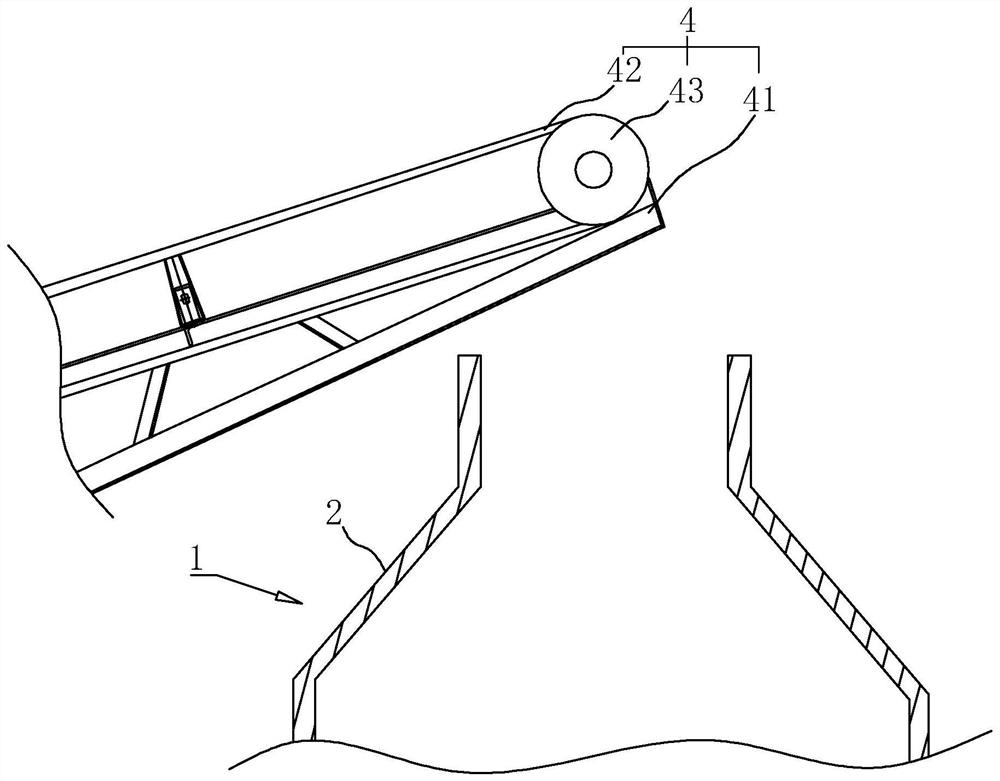

[0039] like figure 1 and figure 2 As shown, the first feeding mechanism is provided with two and symmetrically arranged on both sides of the clay mixer...

Embodiment 2

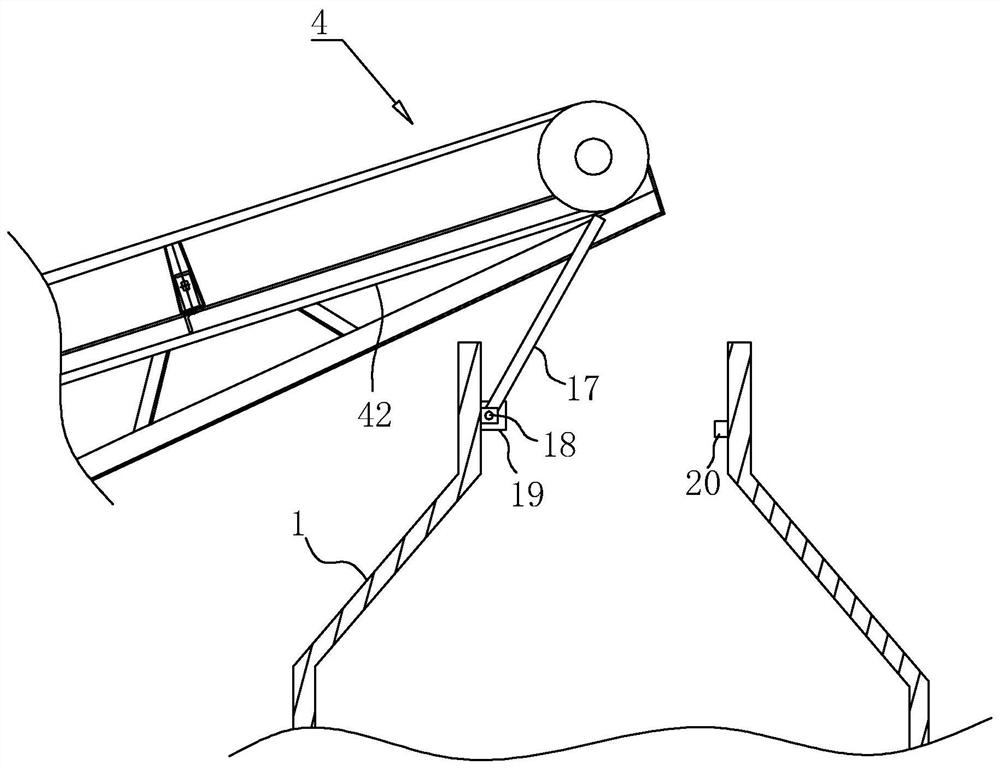

[0047] refer to image 3 , a high-precision batching device for ceramsite raw materials. The difference between this embodiment and Embodiment 1 is that the feed port of the clay mixer 1 is square and the inner wall is provided with a scraper 17, and the scraper 17 is inclined toward the clay mixing The middle part of the feeding port of the machine 1 is set, the belt 42 of the belt scale 4 includes the upper section of the load and the lower section of the no-load, and one end of the scraper 17 at an inclined height abuts against the surface of the lower section of the belt 42, so that it will stick to the belt during use. The clay attached to the belt 42 can be scraped off by the scraper 17 and enter the clay mixer 1 to ensure the accuracy of material delivery, and the clay scraped off by the inclined scraper 17 is not easy to fall on the scraper 17, and can be directly Drop into clay mixer 1.

[0048] like image 3 As shown, the side of the scraper 17 away from the belt 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com