Electrolysis device capable of automatically scraping away electrode impurities

A technology of electrolysis device and driving device, which is applied in the direction of water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of affecting electrolysis efficiency, low efficiency, electrode removal, etc., so as to ensure work efficiency , Realize the effect of automatic scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments.

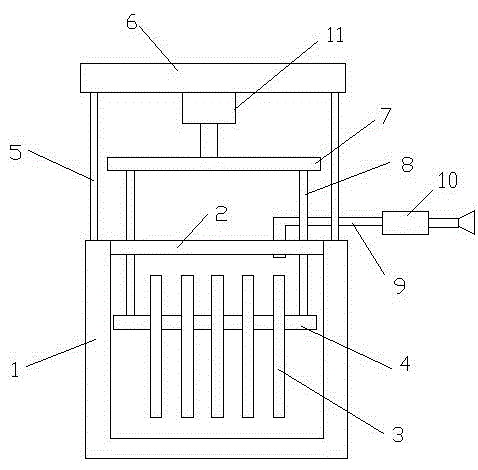

[0015] Such as figure 1 As shown, a kind of electrolysis device that can automatically scrape off the electrode impurities includes an electrolysis box 1 and a box cover 2, and a scraper 4 and a plurality of electrodes 3 are arranged in the electrolysis box 1, and the electrodes 3 all pass through the The scraper 4 is provided above the box cover 2 with a support plate 7 that can move up and down relative to it, and the support plate 7 and the scraper 4 are connected by a guide rod 8 passing through the box cover 2 .

[0016] An upper base plate 6 is fixed above the support plate 7 through a column 5 , and a drive device 11 for driving the support plate 7 to move up and down is arranged between the upper base plate 6 and the support plate 7 .

[0017] In this embodiment, the driving device 11 adopts a cylinder, which drives the support plate 7 to move up and down, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com