Self-cleaning enhanced heat-transfer magnetic suspension spiral twisted tape in heat-transfer tube

A technology for strengthening heat transfer and heat transfer tubes, which is applied in the field of twisted belts for self-cleaning and enhanced heat transfer in heat transfer pipes, which can solve the problem of insignificant effect of field synergy to enhance heat transfer, short life of end rotating bearings, and scraping of spiral twisted belts. and other problems to achieve the effect of increasing service life, increasing strength, increasing radial flow and turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

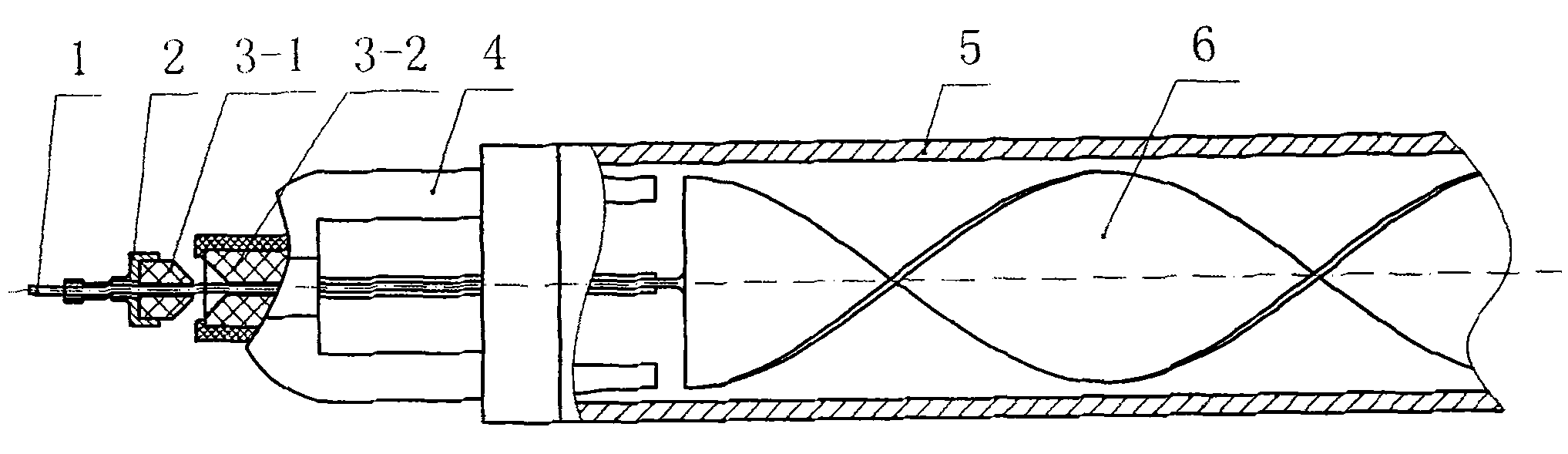

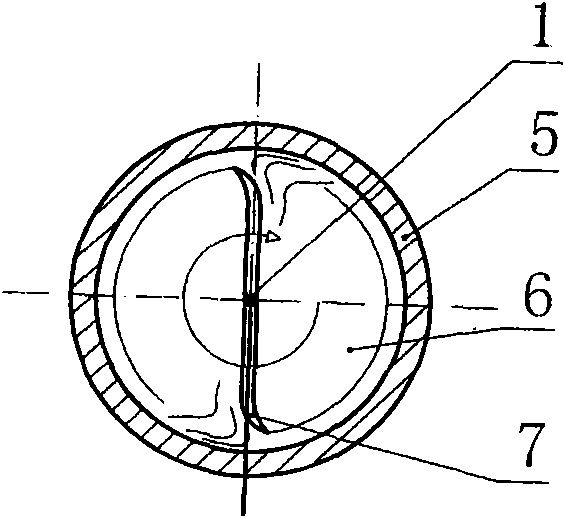

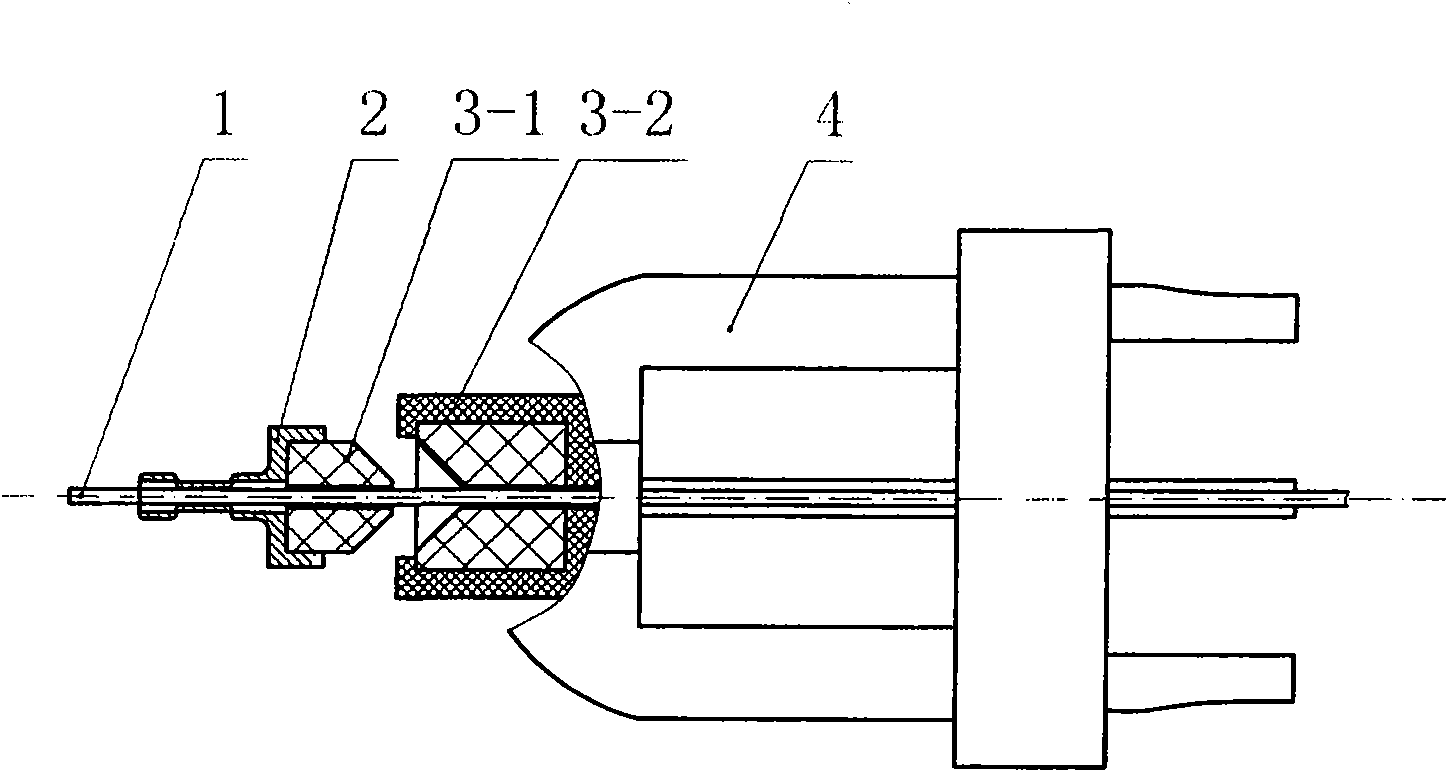

[0023] Such as Figure 1 to Figure 9 As shown, the present invention relates to an embodiment of the self-cleaning and enhanced heat transfer magnetic levitation helical twisted belt in the heat transfer tube, which includes a helical twisted belt 6 and an axial positioning device, and the rotation center of the helical twisted belt 6 has a reinforced The core of the skeleton axis, the part of the reinforcement skeleton axis core protruding from the helical twisted band is mandrel 1, and the diameter of the reinforced skeleton axis core can be less than, greater than or equal to the thickness of the helical twisted band. The axial positioning device is fixed on the liquid inlet end of the heat transfer tube 5, and is composed of a support frame 4 and a magnet positioning device. The magnet positioning device is in the form of a conical fit. The conical sleeve magnet 3-2 is formed, and the core conical magnet 3-1 and the external conical sleeve magnet 3-2 are both S poles or N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com