3D laser printer with leveling function and light-curing printing method thereof

A 3D printer and laser technology, applied in the field of 3D printing, can solve the problems of printing failure, burr or unevenness, deformation and other problems on the printing surface, and achieve the effect of reasonable smoothing process and excellent printing surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

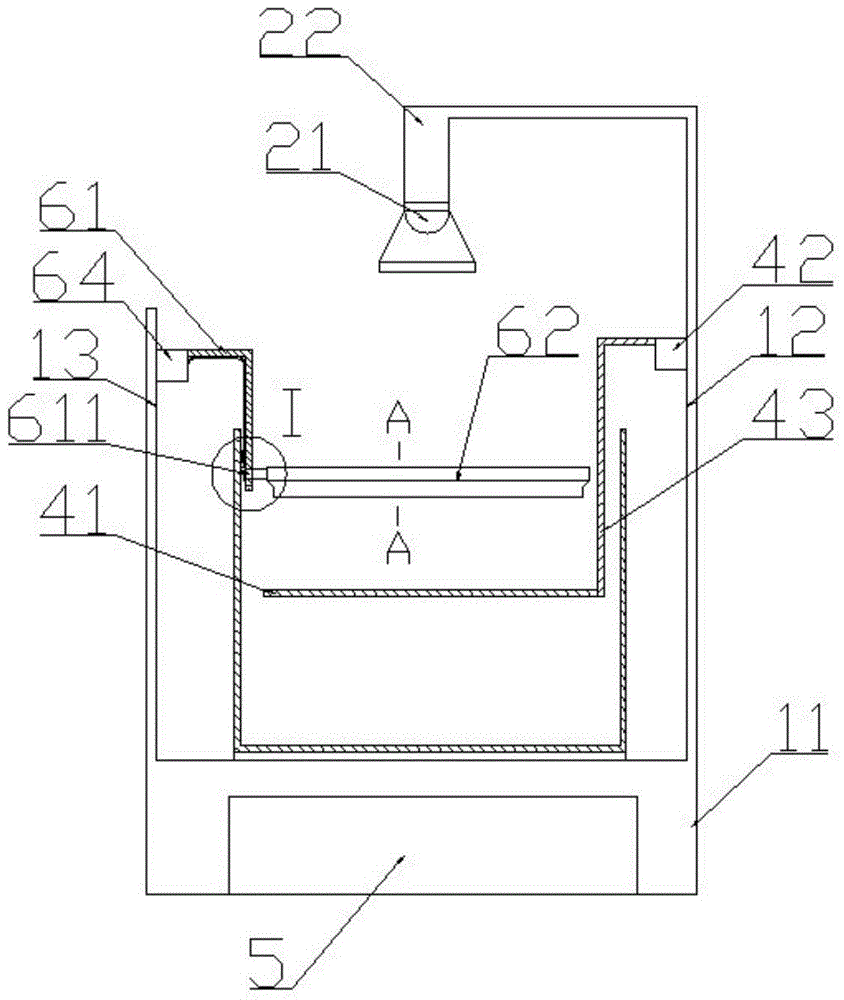

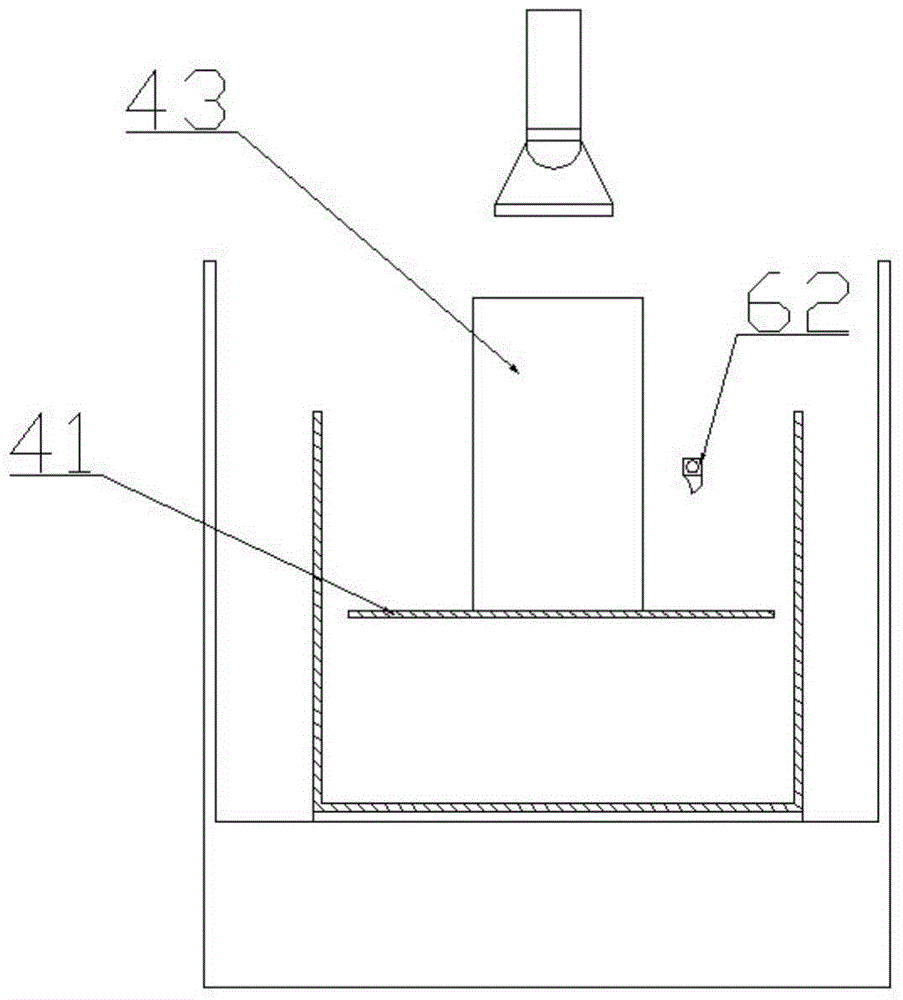

[0058]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. In the embodiments, parts of the same configuration are given the same reference numerals and descriptions are omitted.

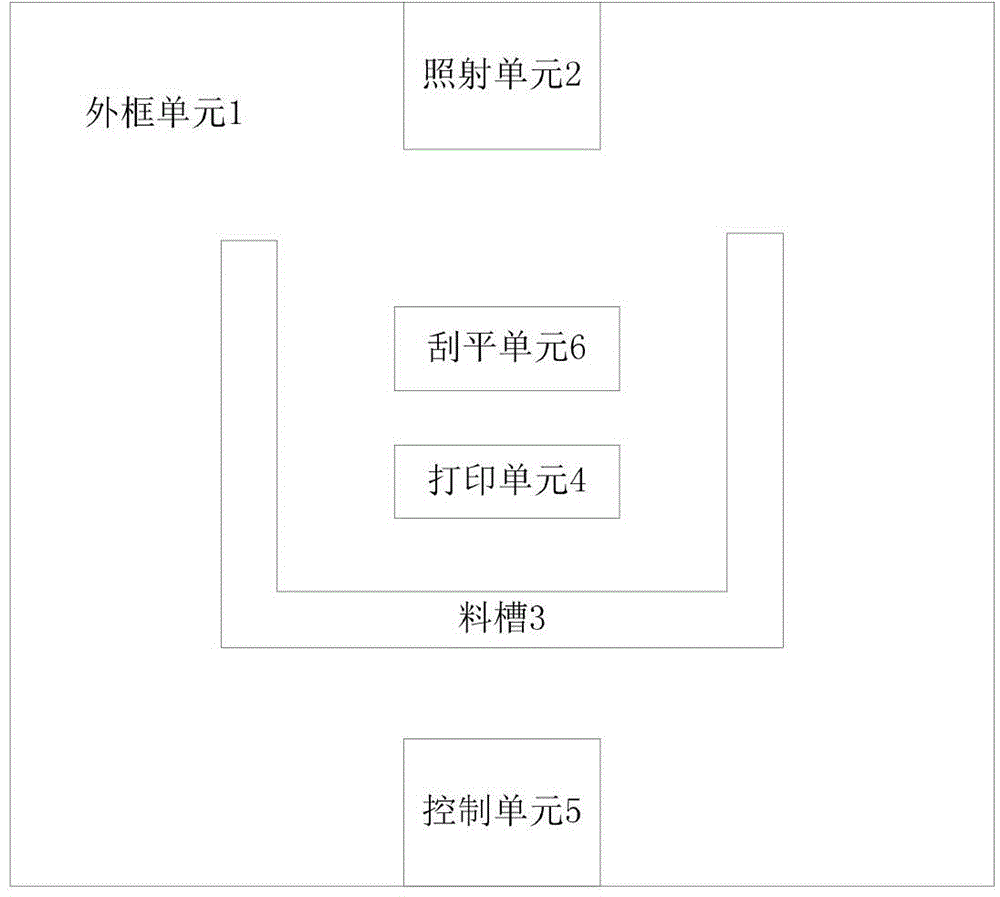

[0059] refer to figure 1 As shown, it is a structural and functional block diagram of Embodiment 1 of a laser 3D printer with a scraping function according to the present invention. As shown in the figure, the 3D printer includes an outer frame unit 1 , an irradiation unit 2 , a trough 3 , a printing unit 4 , a control unit 5 and a scraping unit 6 .

[0060] The outer frame unit 1 constitutes the basic skeleton structure of the 3D printer.

[0061] The material trough 3 is arranged on the outer frame unit 1, and is used to carry the printing stock solution for photo-curing 3D printing.

[0062] The irradiation unit 2 is arranged on the outer frame unit 1 and is located above the material tank 3 for providing the laser light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com