Method and device for preventing distillation scaling

A technology of distillation tower and distillation tray, which is applied in the direction of cleaning methods using tools, distillation separation, separation methods, etc., which can solve the problems affecting the stable and continuous operation of the ammonia distillation system, pollution, and increasing the operating cost of ammonia removal equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

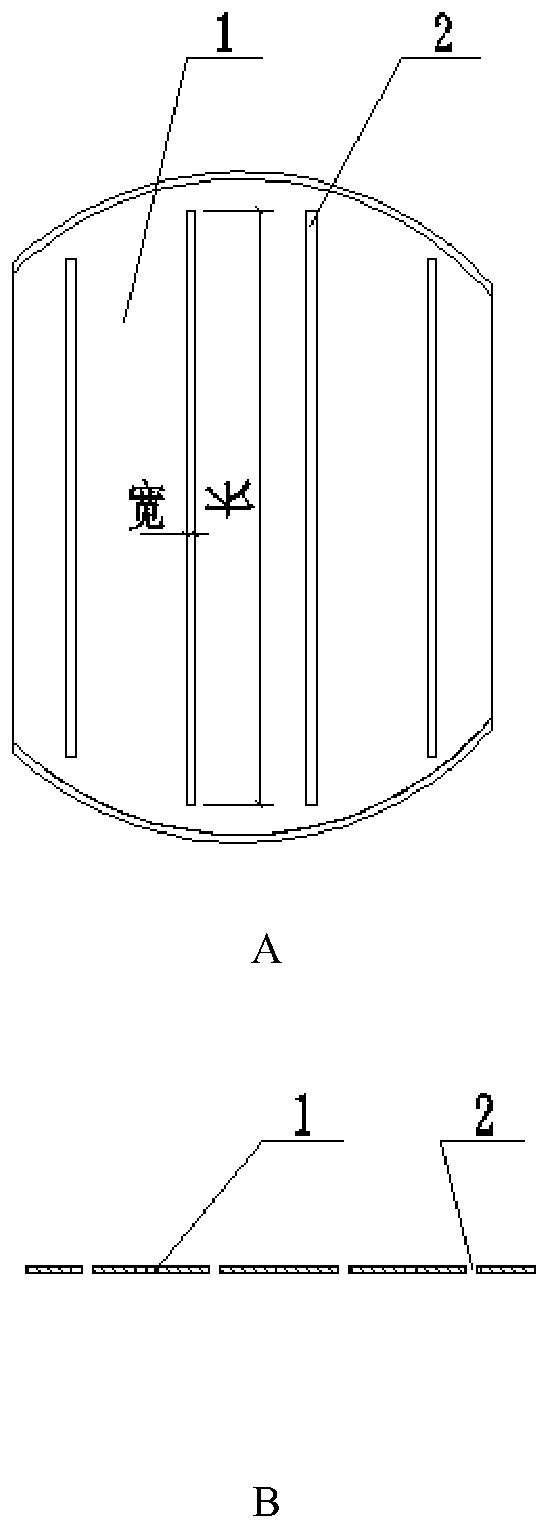

[0029] Such as figure 1 As shown, in one embodiment, the sieve of the distillation tray 1 provided by the present invention that can prevent distillation fouling is a bar-shaped sieve 2, and the width of the bar-shaped sieve 2 can be 2-20mm. The length of the shaped sieve 2 is adapted to the size of the tray, any two sieves are parallel, and the center distance between the sieves is between 30-80mm. The liquid to be deaminated moves horizontally from the left side of the figure to the right side, and the steam runs from the bottom of the tray to the top of the tray, and passes through the strip sieve holes. Heat transfer completes the deamination process.

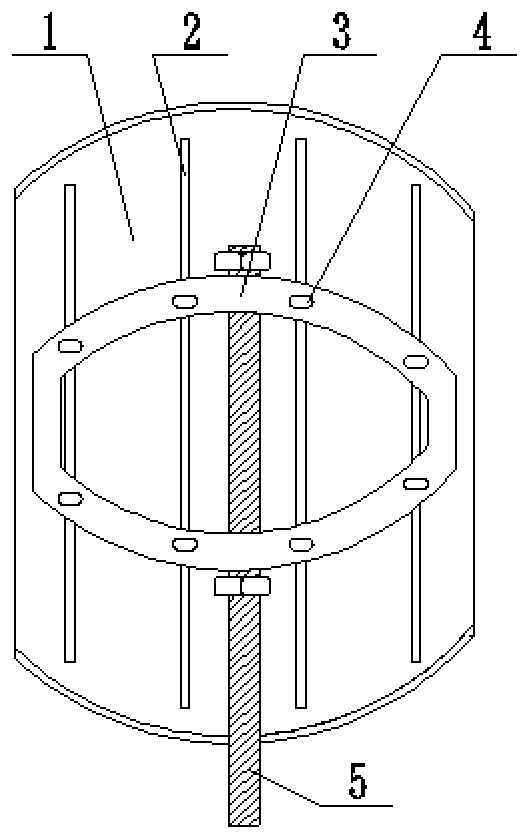

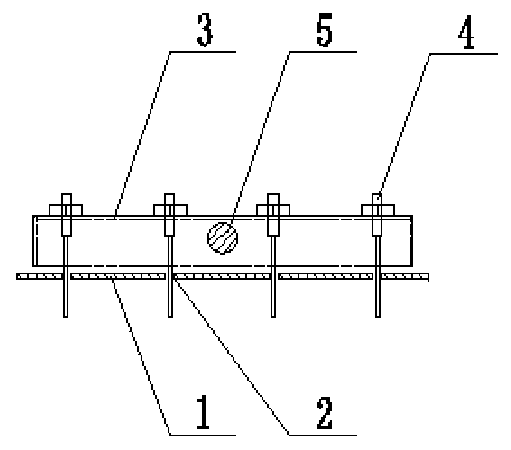

[0030] As shown in Figures 2 and 3, it contains the distillation trays that can prevent distillation fouling and a self-cleaning mechanism. The self-cleaning mechanism is a frame 3 that is rectangular or circular or has an arc or is only in the form of a bracket , such as an elliptical metal frame; the frame 3 is located ...

Embodiment 2

[0033] For a deammonization tower with a diameter of 350 mm, design a strip sieve hole and a self-cleaning mechanism with reference to Example 1. There are 4 strip sieves with a width of 3mm on the tray, the center distance of the strip sieves is 60mm, and the lengths of the strip sieves are 260mm, 310mm, 310mm, 260mm respectively; a 230mm width is set above the tray. Frame with circular arcs on both sides, the thickness of the frame is 30mm, the distance between the lower edge of the frame and the upper surface of the tray plate is 1mm; a metal sheet with a width of 2mm is connected to the frame, and the metal sheet is inserted into the bar-shaped sieve hole. The length of the metal sheet is (or depth) 75mm, the metal sheet completely penetrates the bar-shaped sieve hole, and there are two rows of metal sheets to ensure that the metal sheet can scrape the full length of the bar-shaped sieve hole when the frame is reciprocating; the frame is also connected with Shaft, the shaf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com