Patents

Literature

30results about How to "Move forward at a constant speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spraying method for plant protection unmanned aerial vehicle (UAV)

InactiveCN104881037AMove forward at a constant speedHigh speedPosition/course control in three dimensionsRADIUSAirplane

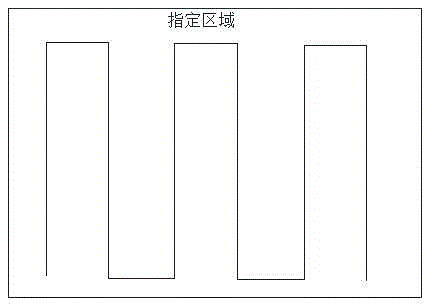

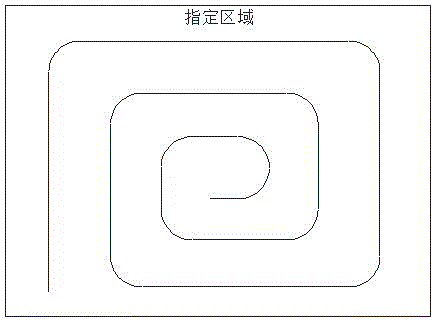

The invention discloses a spraying method for a plant protection unmanned aerial vehicle (UAV). The spraying method includes a method in which an aircraft body carries a spray unit, flies to a designated area and spraying a soup downward, and also comprises executing steps of a flight route of the aircraft body which are an S1 step of dividing the designated area into at least one rectangular area; an S2 step of performing spiral rotation flight along the surrounding of one rectangular area, with an interval of adjacent flight paths as the spraying radius; and an S3 step of stopping spraying the soup after the aircraft body flies to the central portion of the rectangular area, or flying straightly toward a closest side of the rectangular area to another rectangular area. The invention is capable of reducing the turning of the aircraft body and reducing the loss.

Owner:SHENZHEN XIANGNONG INNOVATION TECH CO LTD

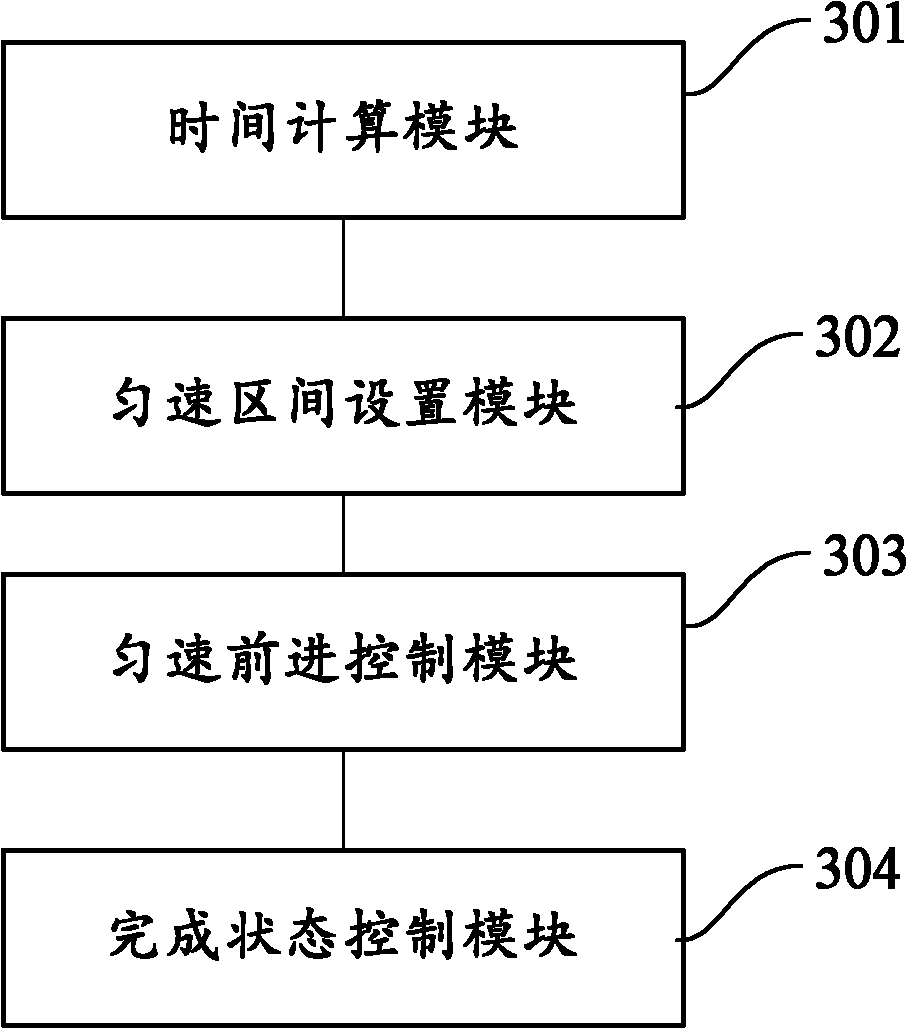

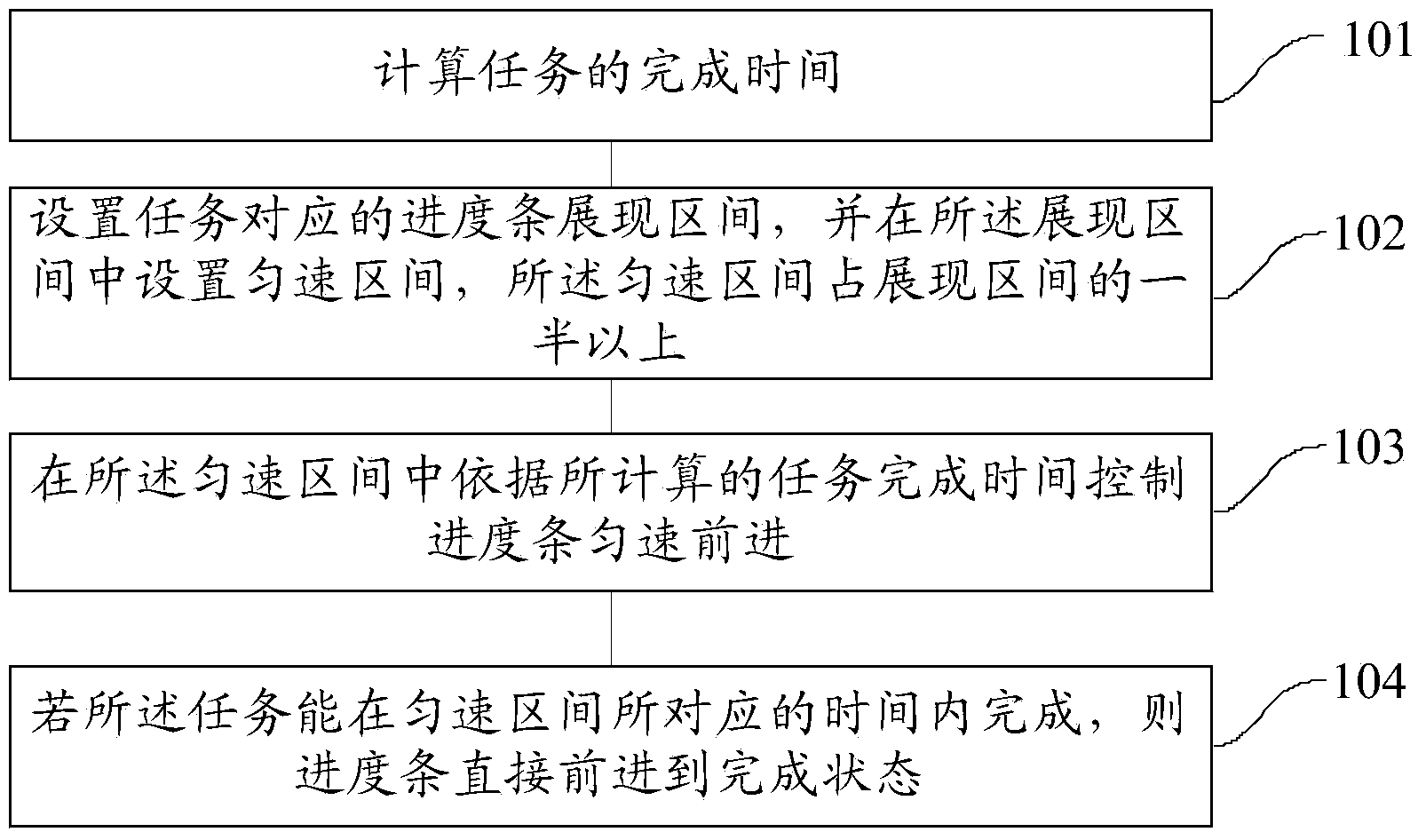

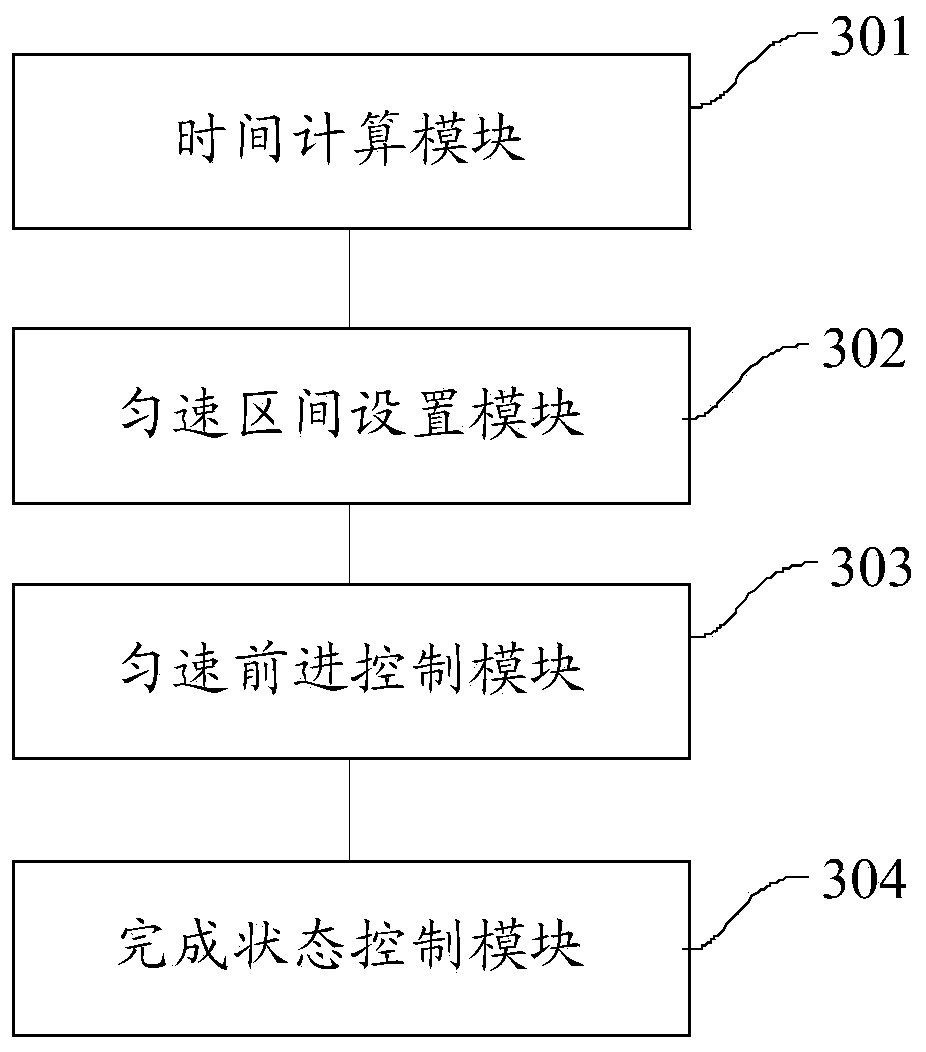

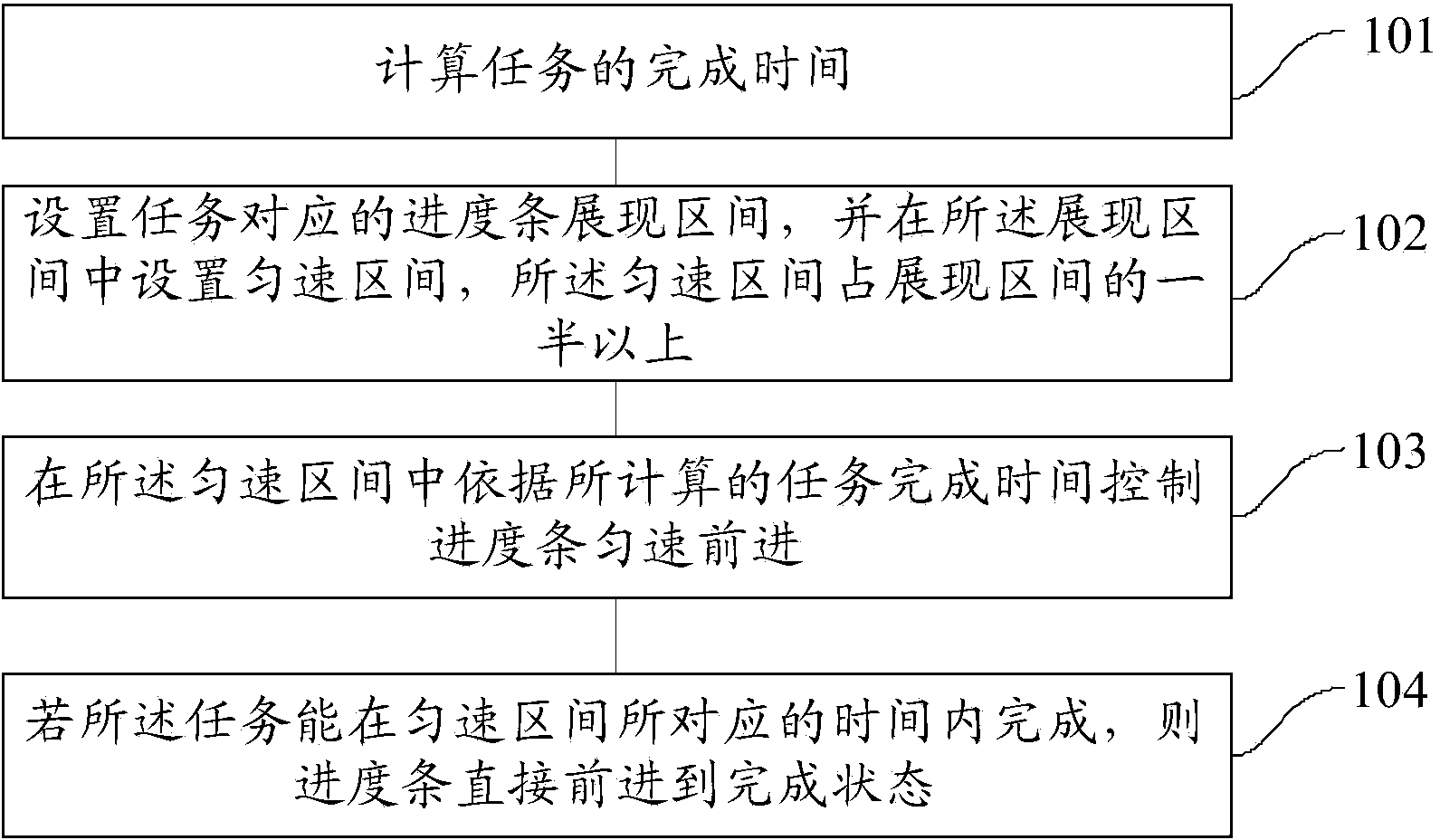

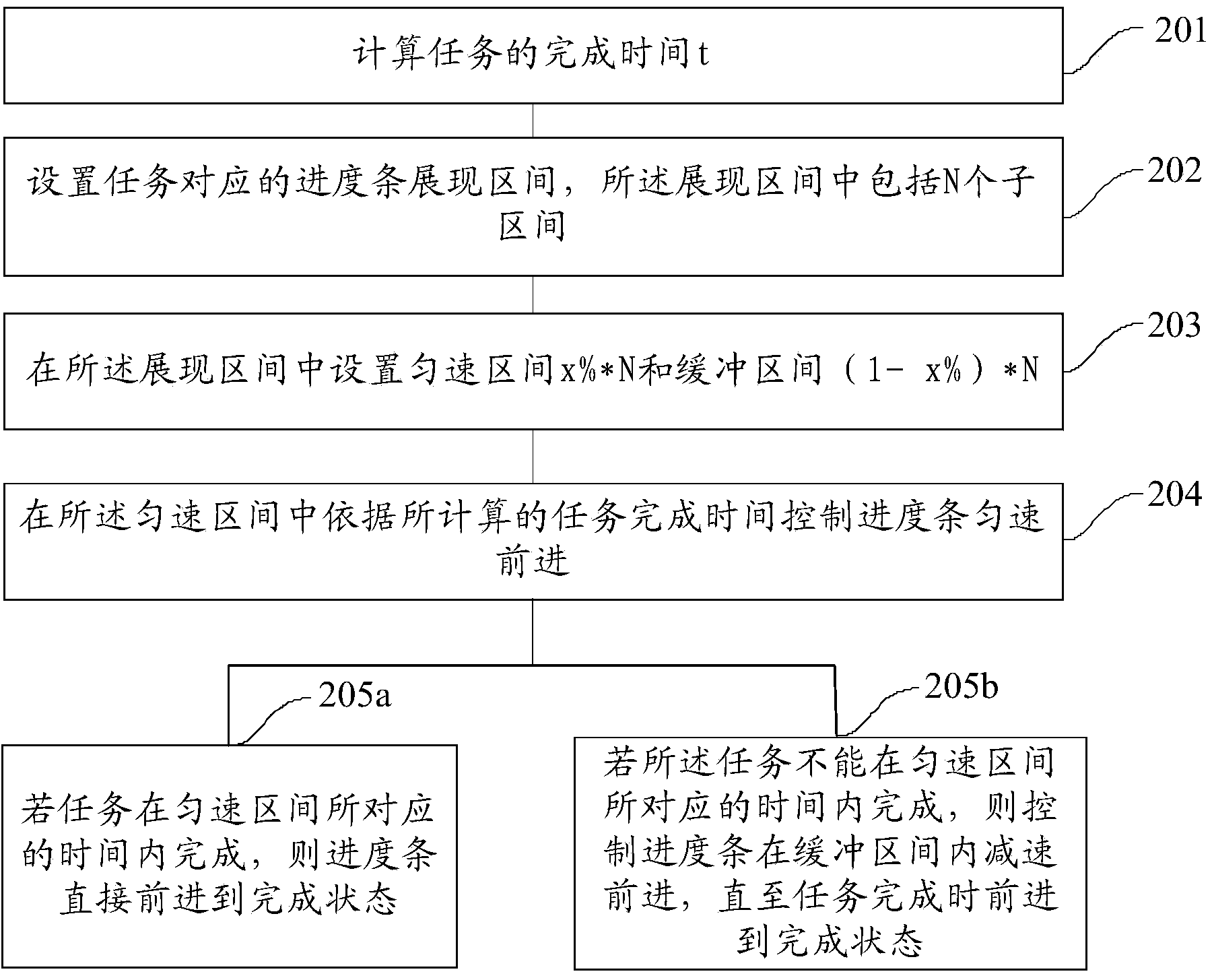

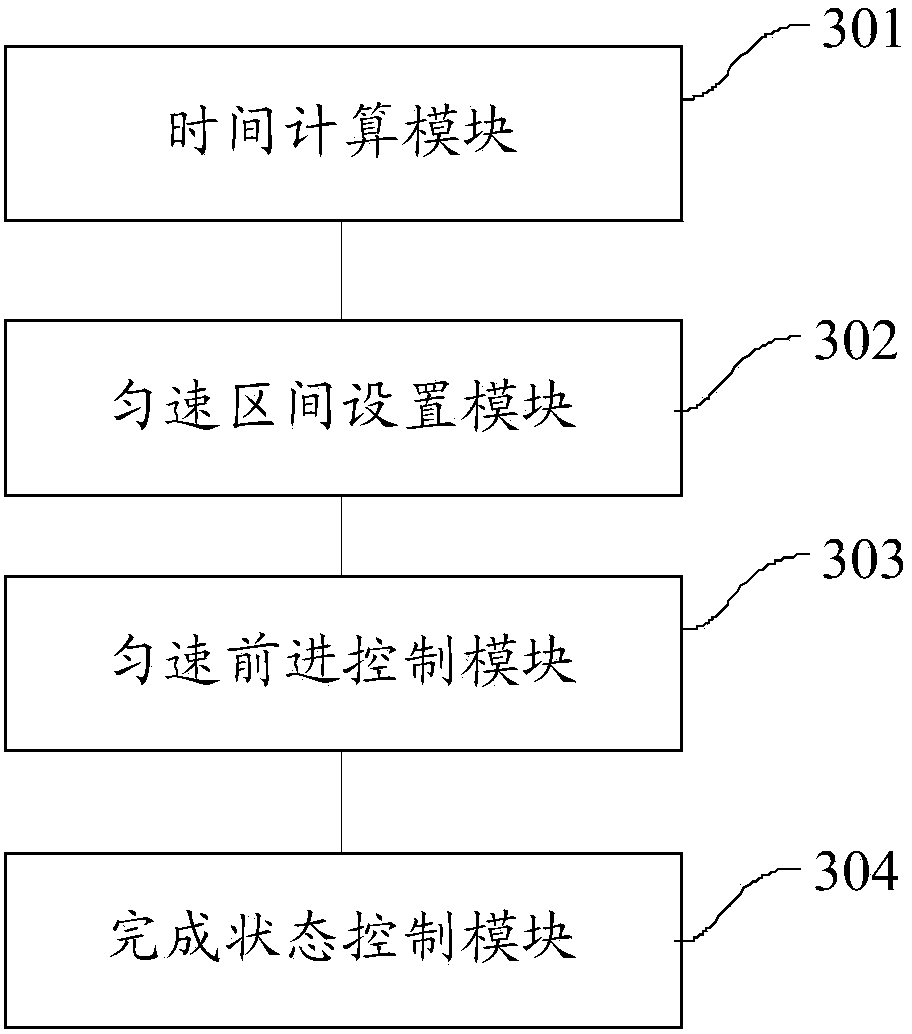

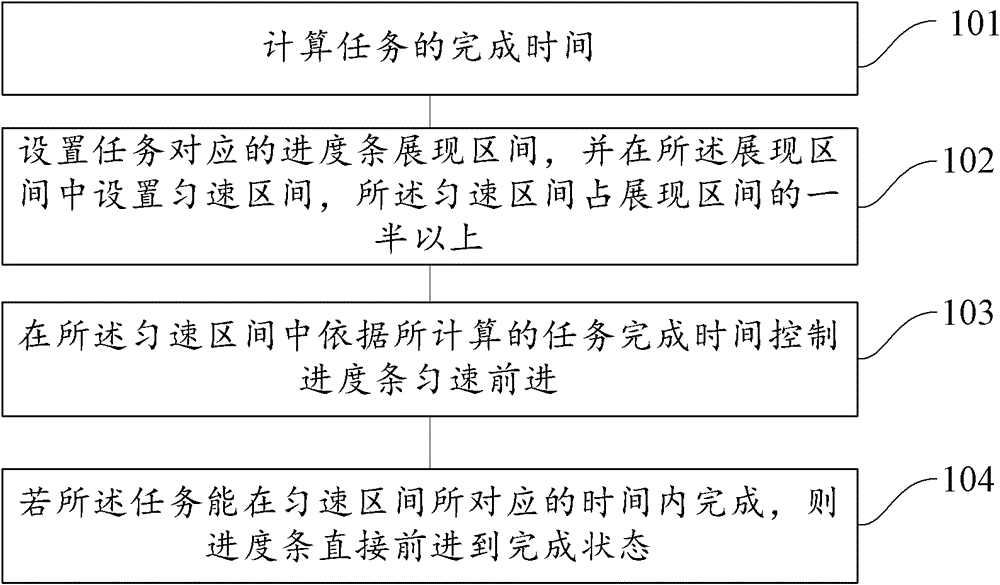

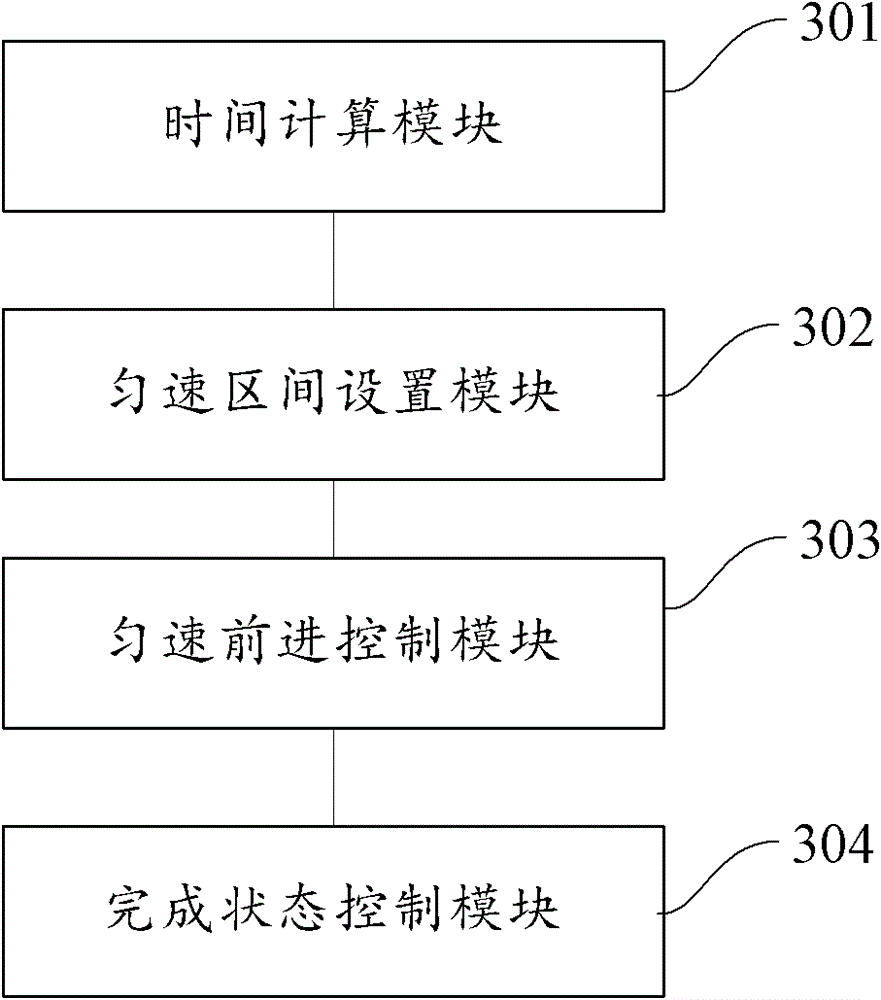

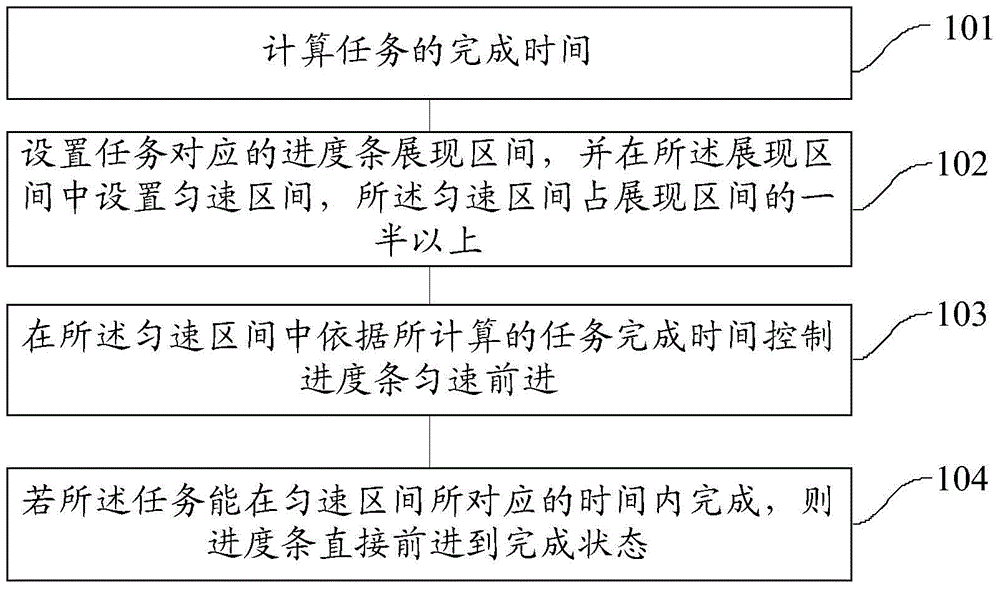

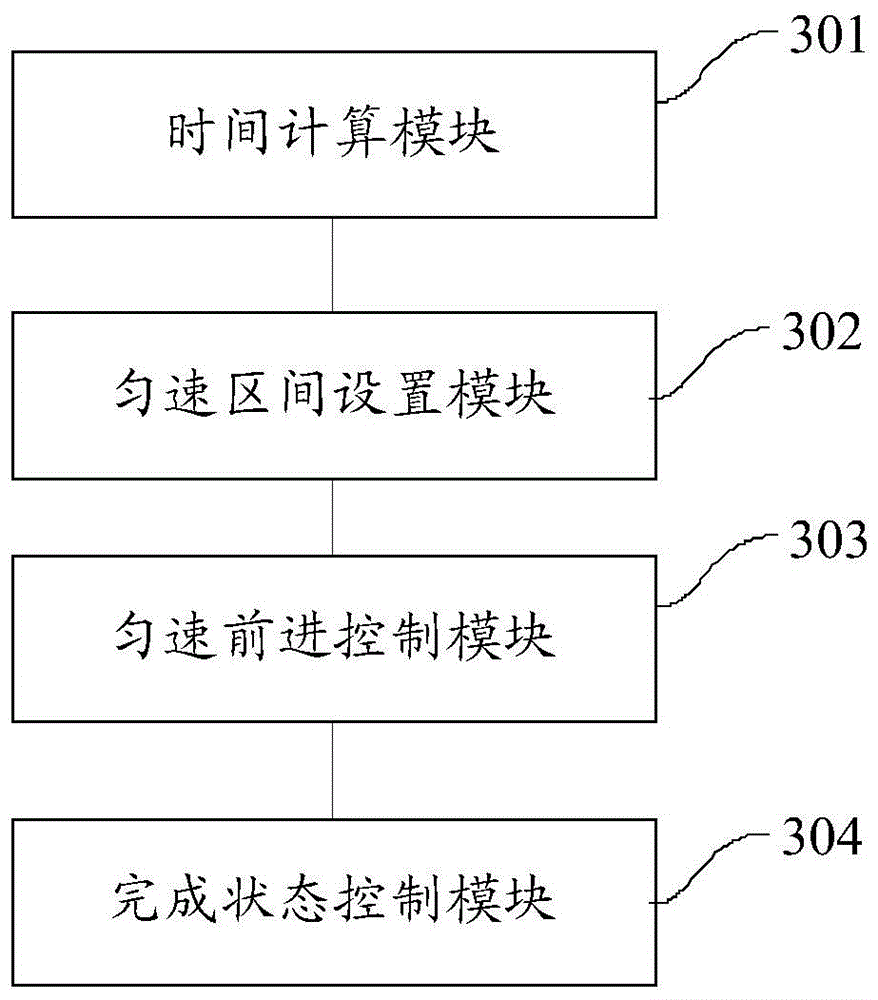

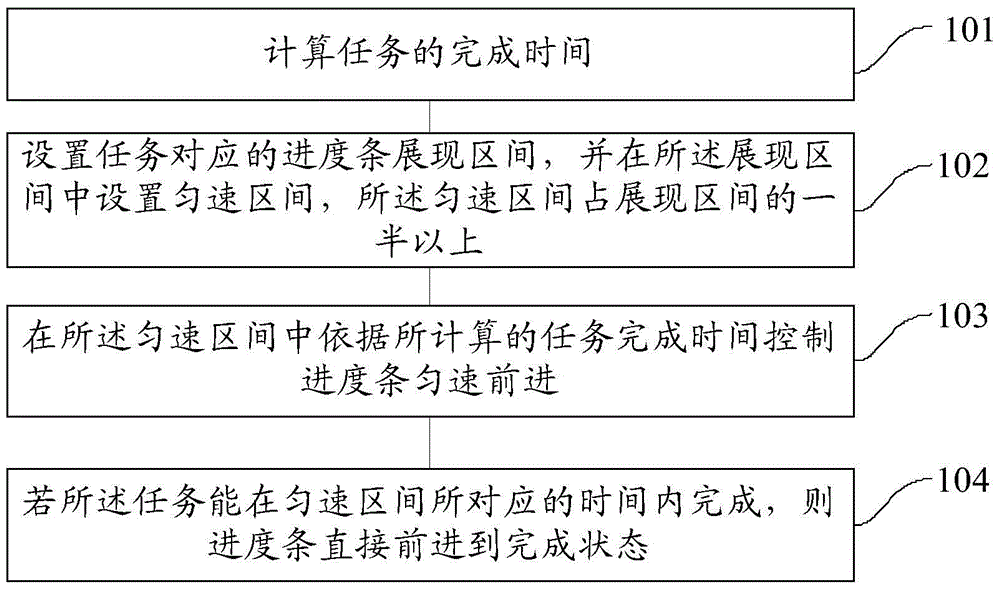

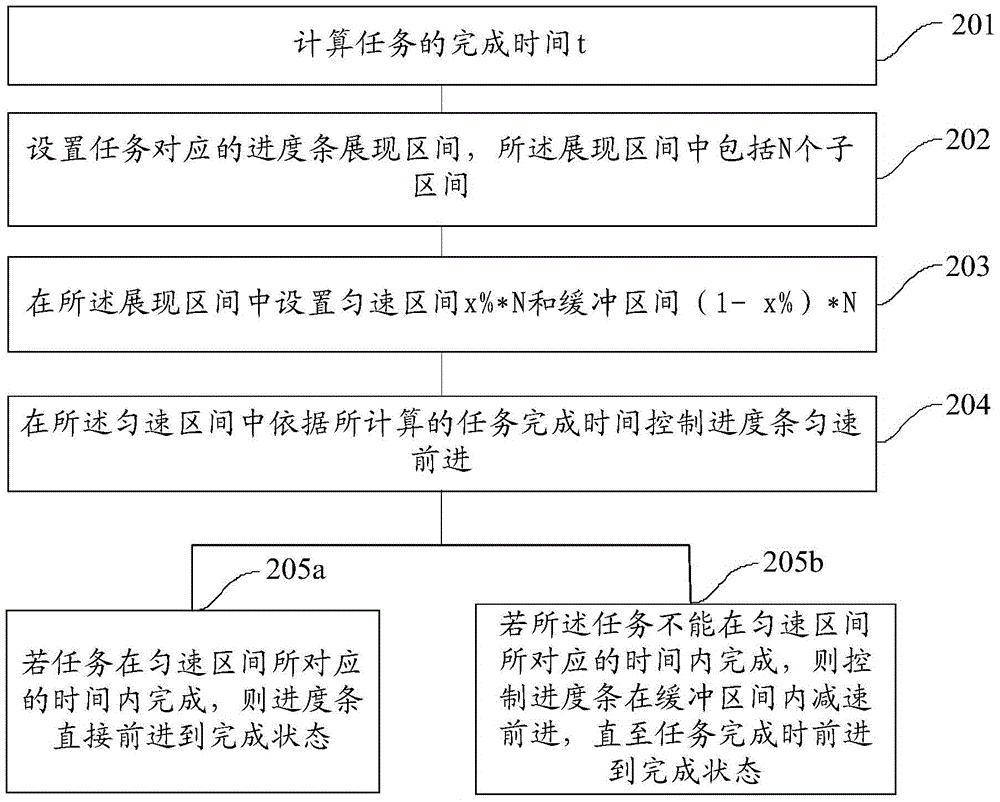

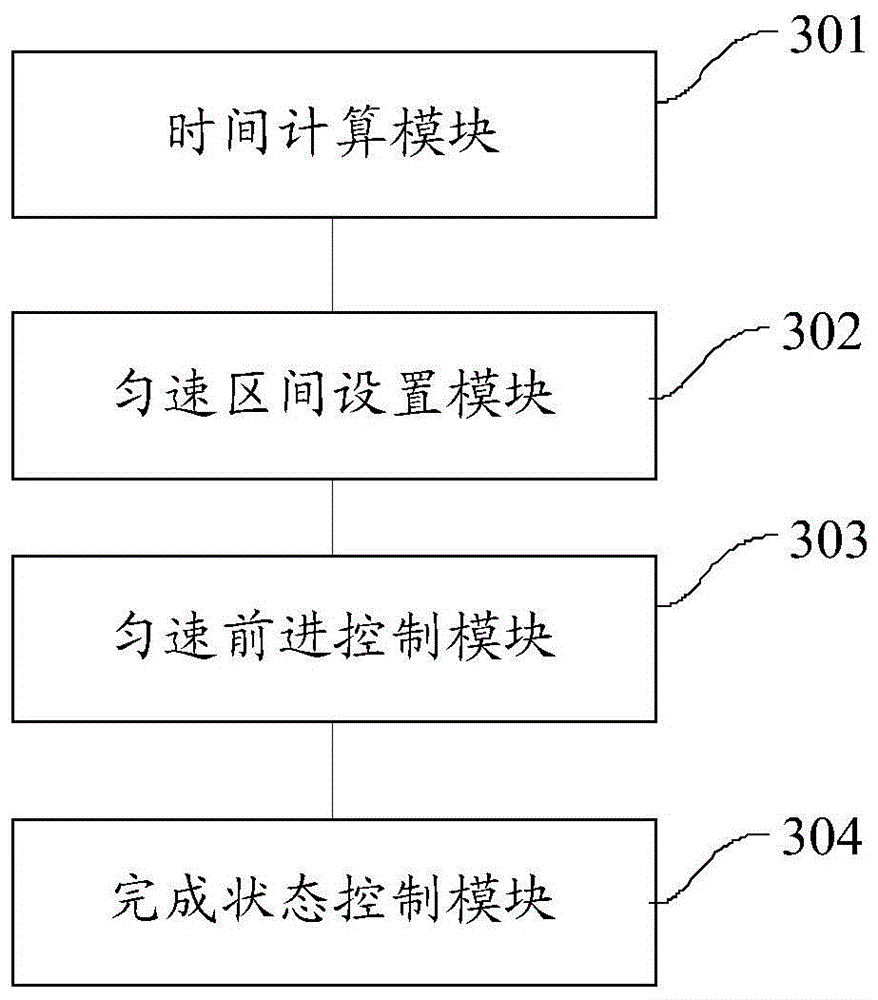

Method and device for showing progress bar

ActiveCN102141953ASolve abnormal problemsGood experienceHardware monitoringEngineeringConstant speed

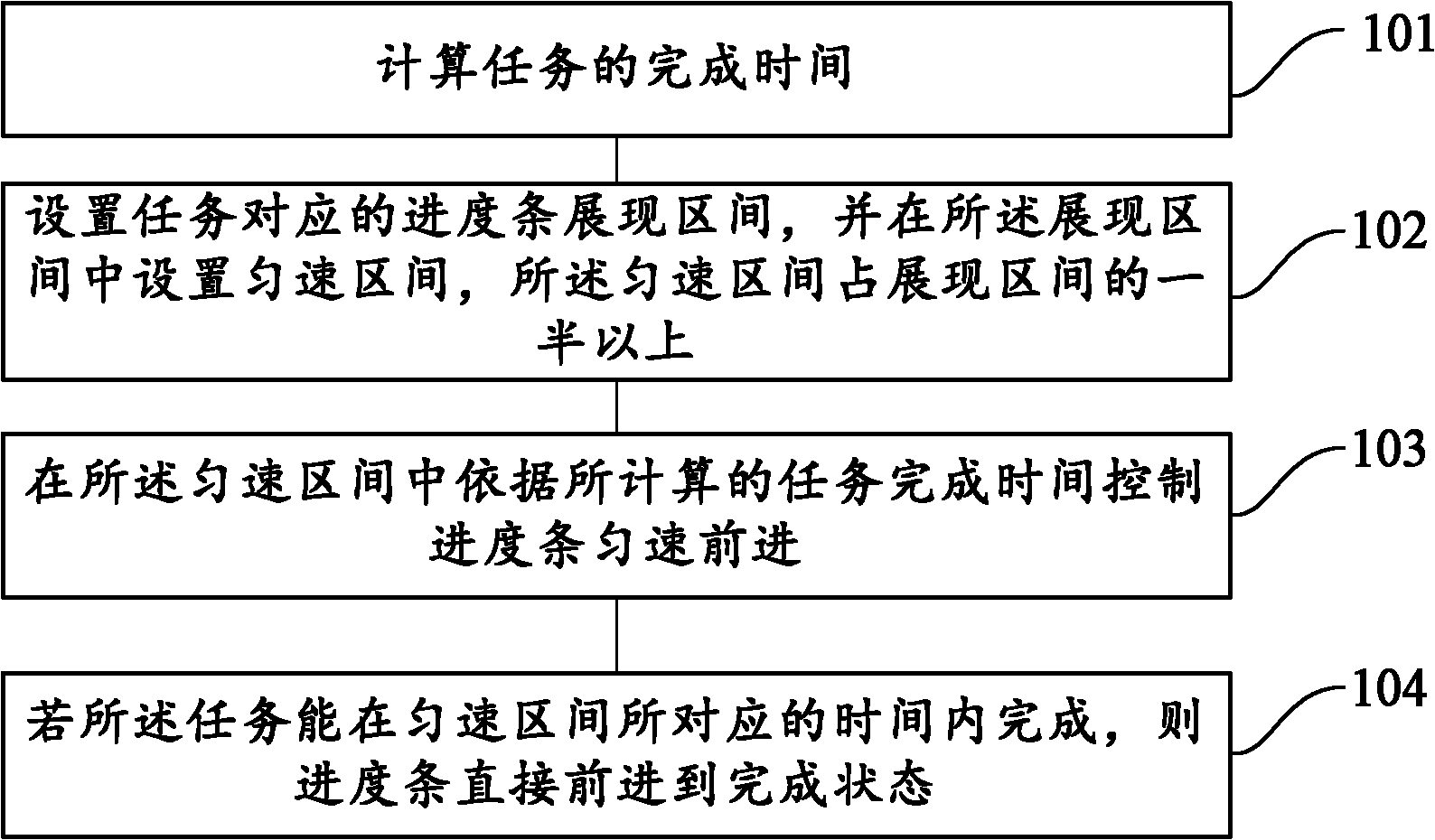

The invention provides a method for showing a progress bar. The method comprises the following steps of: calculating a finish time of a task; setting a constant-speed region in the progress bar corresponding to the task, wherein the length of the constant-speed region is over half the total length of the progress bar; and controlling the progress bar to move forward at a constant speed in the constant-speed region according to the finish time of the task. By the method, the progress bar can move forward smoothly at the constant speed, so the problems that the progress bar has to wait for the finish of a subtask and stops moving forward, and the progress bar moves forward alternatively between slow and fast under most conditions can be solved.

Owner:BEIJING QIHOO TECH CO LTD

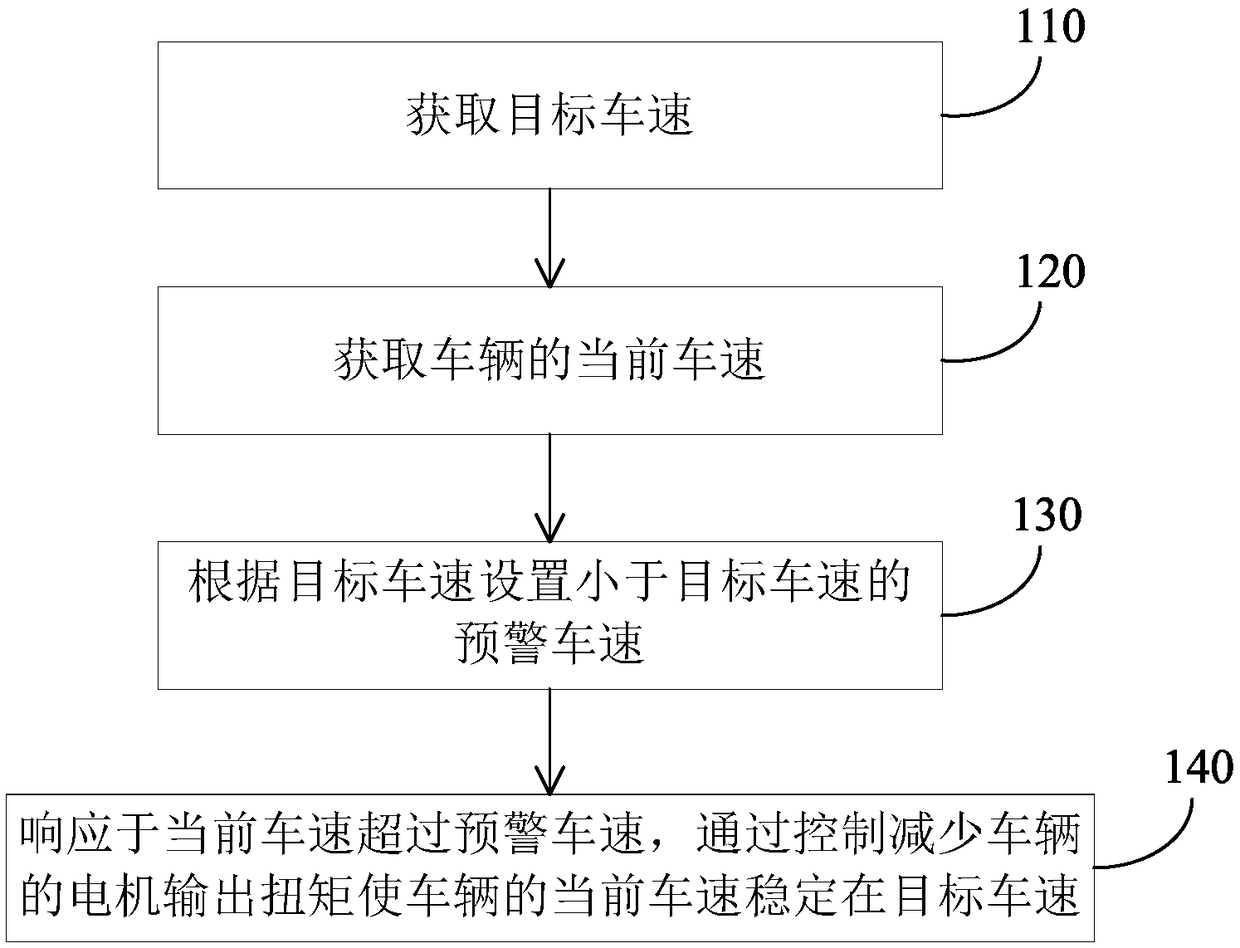

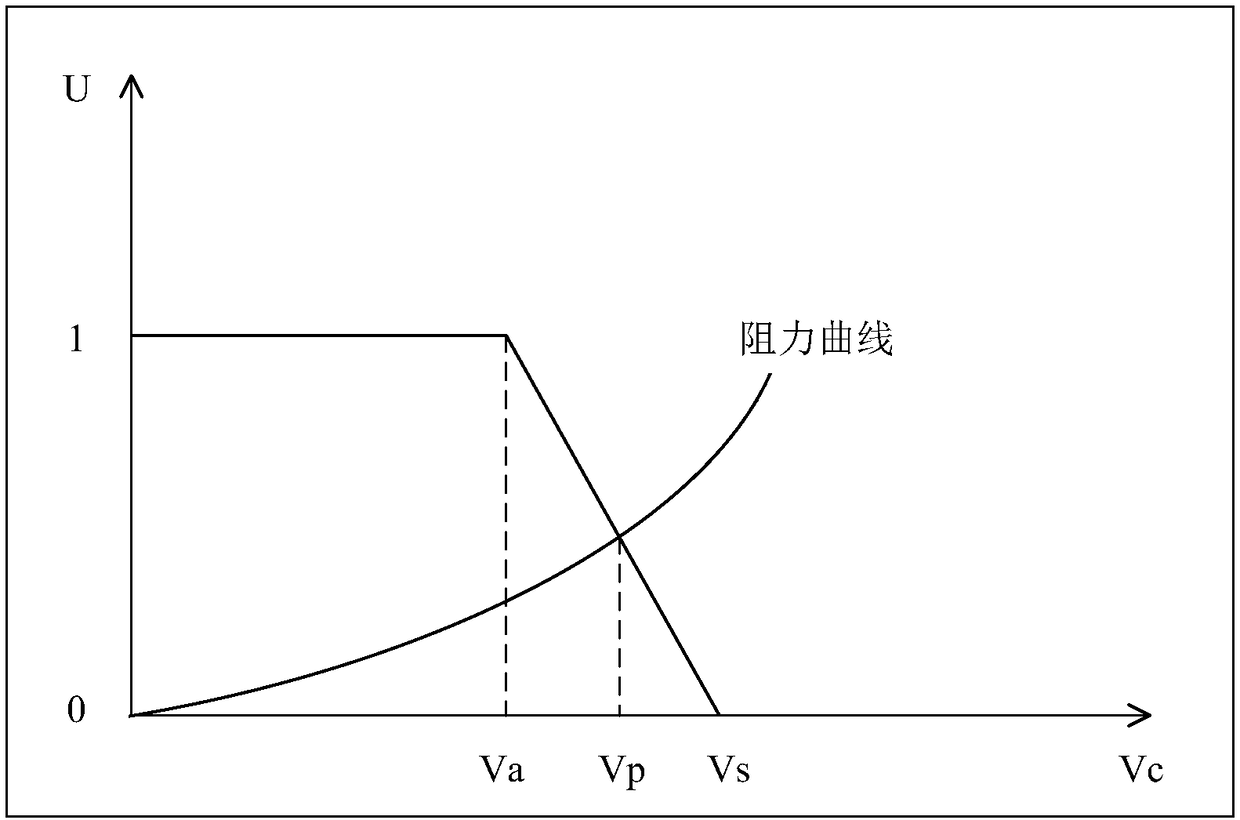

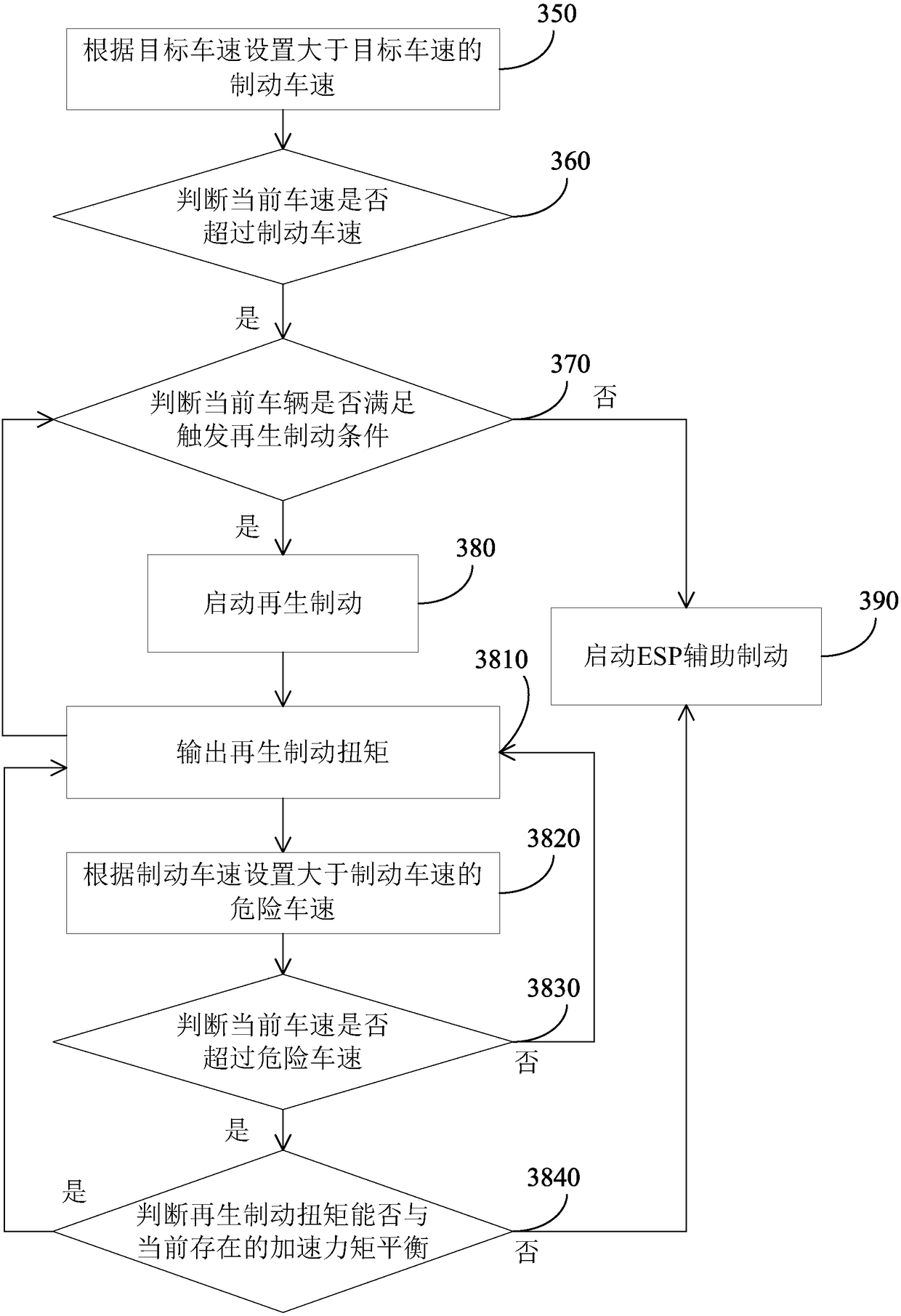

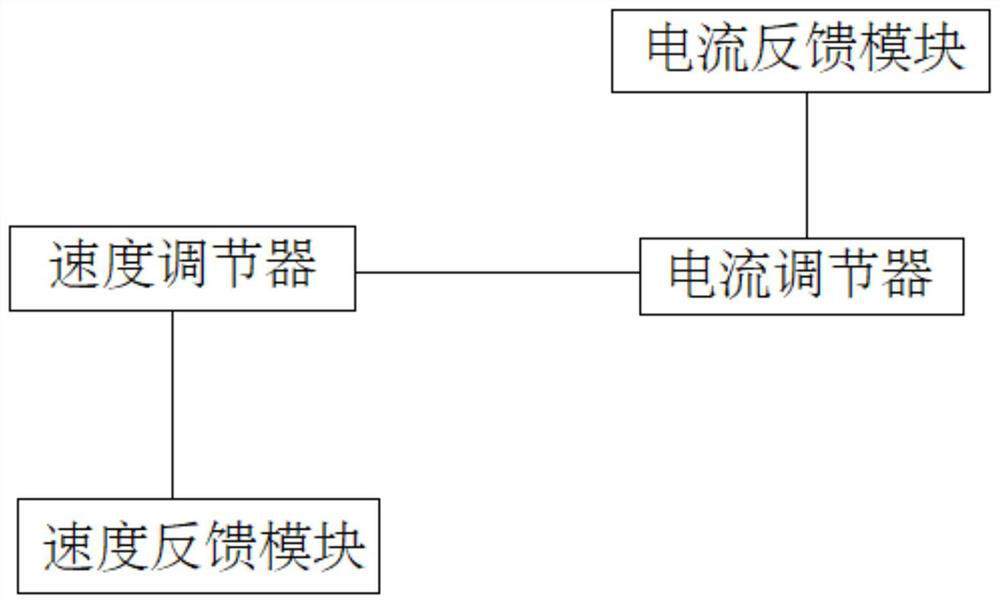

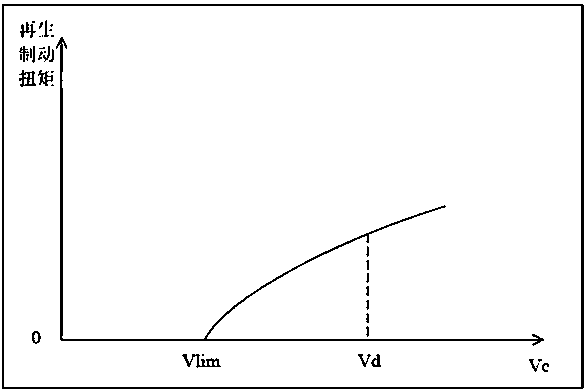

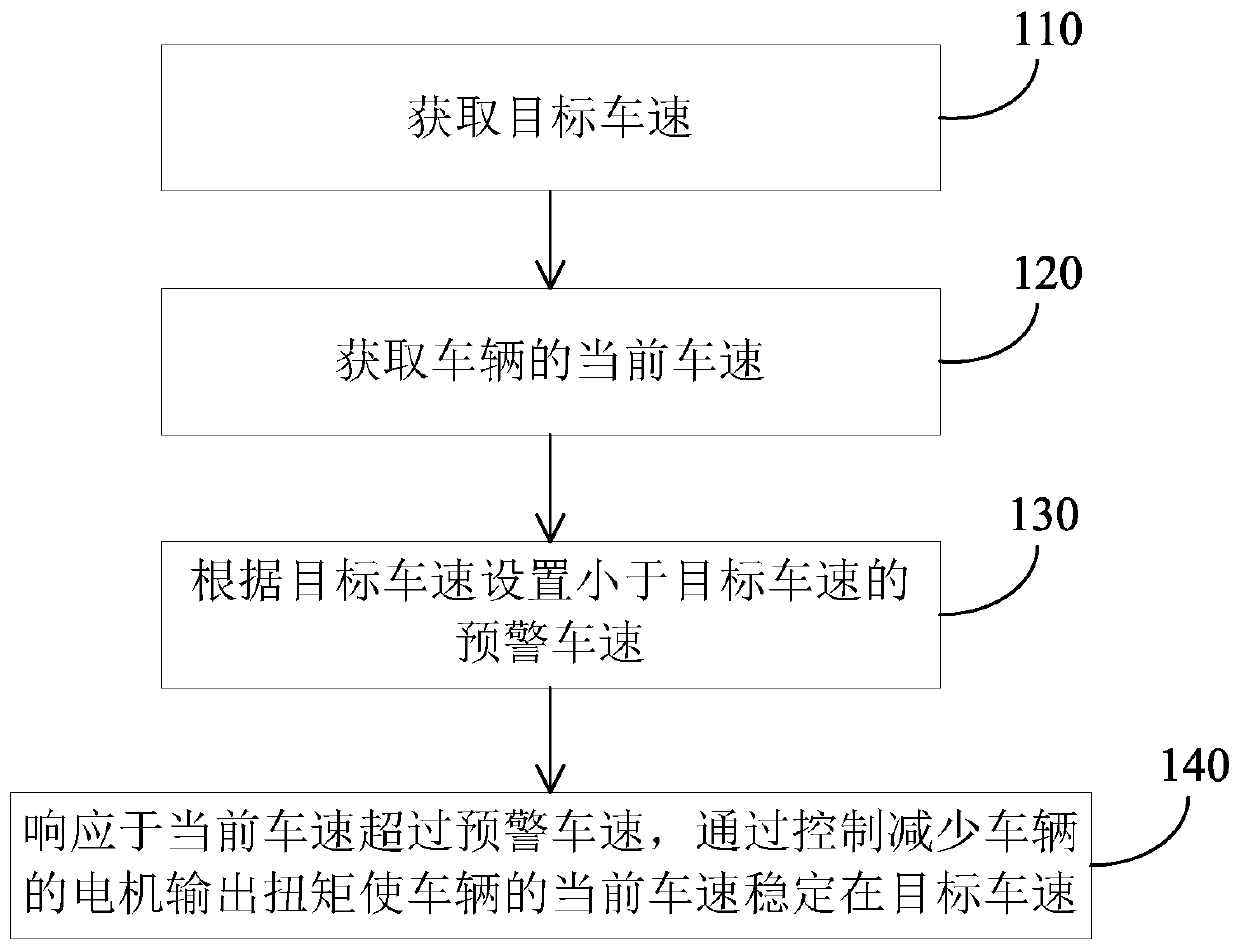

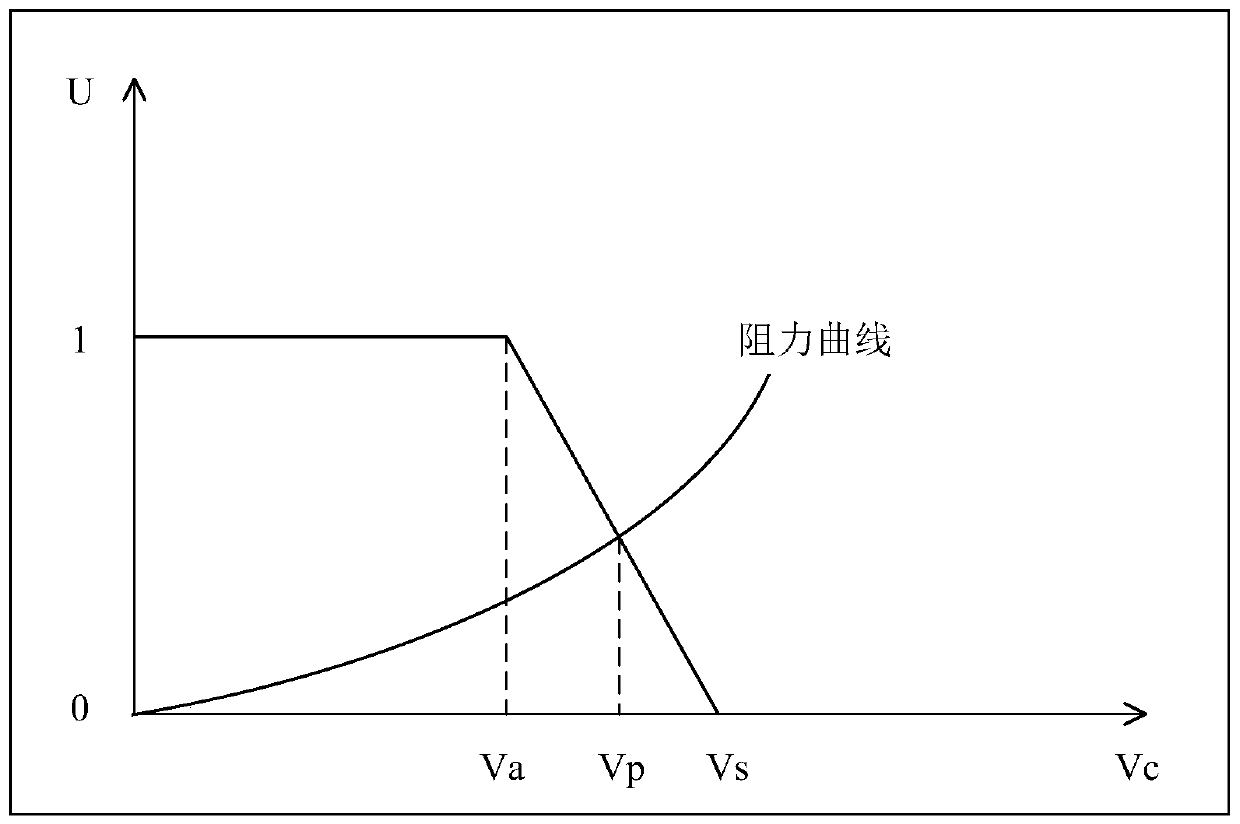

Vehicle speed control method and system used for electric vehicle

ActiveCN108437793AReduce output torqueGuaranteed stabilitySpeed controllerVehicle fittingsSpeed control systemControl system

The invention provides a vehicle speed control method used for an electric vehicle. The method specifically includes the steps that the target vehicle speed is obtained; the current vehicle speed of the vehicle is obtained; the early warning vehicle speed smaller than the target vehicle speed is set according to the target vehicle speed; and a response is made when the current vehicle speed exceeds the early warning vehicle speed, and the motor output torque of the vehicle is controlled to be reduced, so that the current vehicle speed of the vehicle is stabilized at the target vehicle speed. The invention further provides a vehicle speed control system capable of achieving the provided vehicle speed control method and the electric vehicle. The motor output torque is controlled so that thevehicle speed can be controlled, the vehicle speed is stabilized at an expected value, traveling safety can be guaranteed, and meanwhile the driving and riding experience feeling is not reduced.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

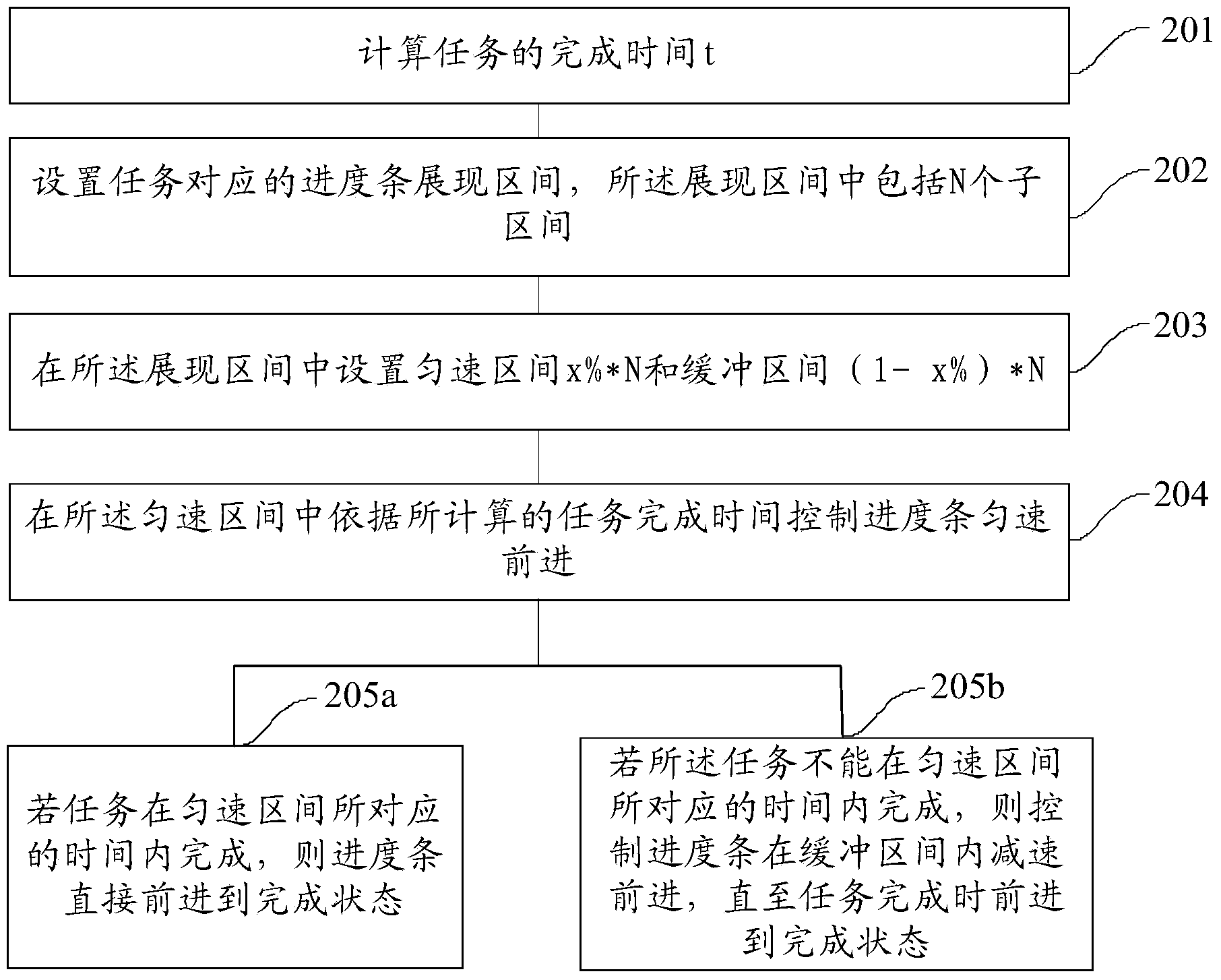

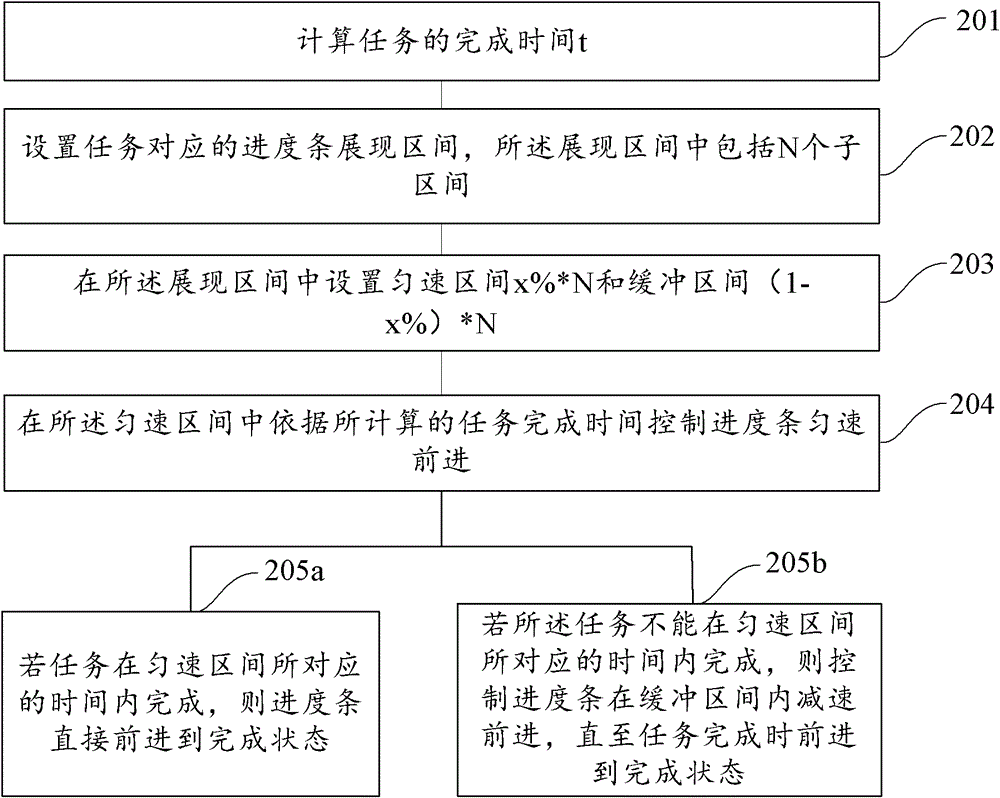

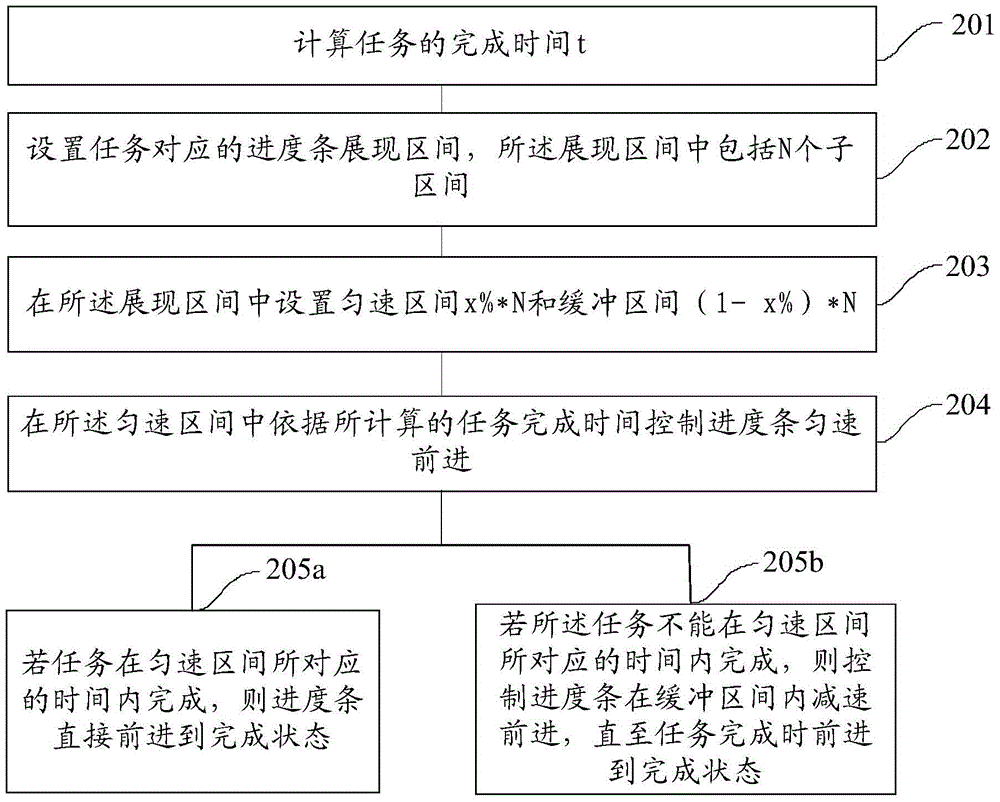

Progress bar implementation method and device

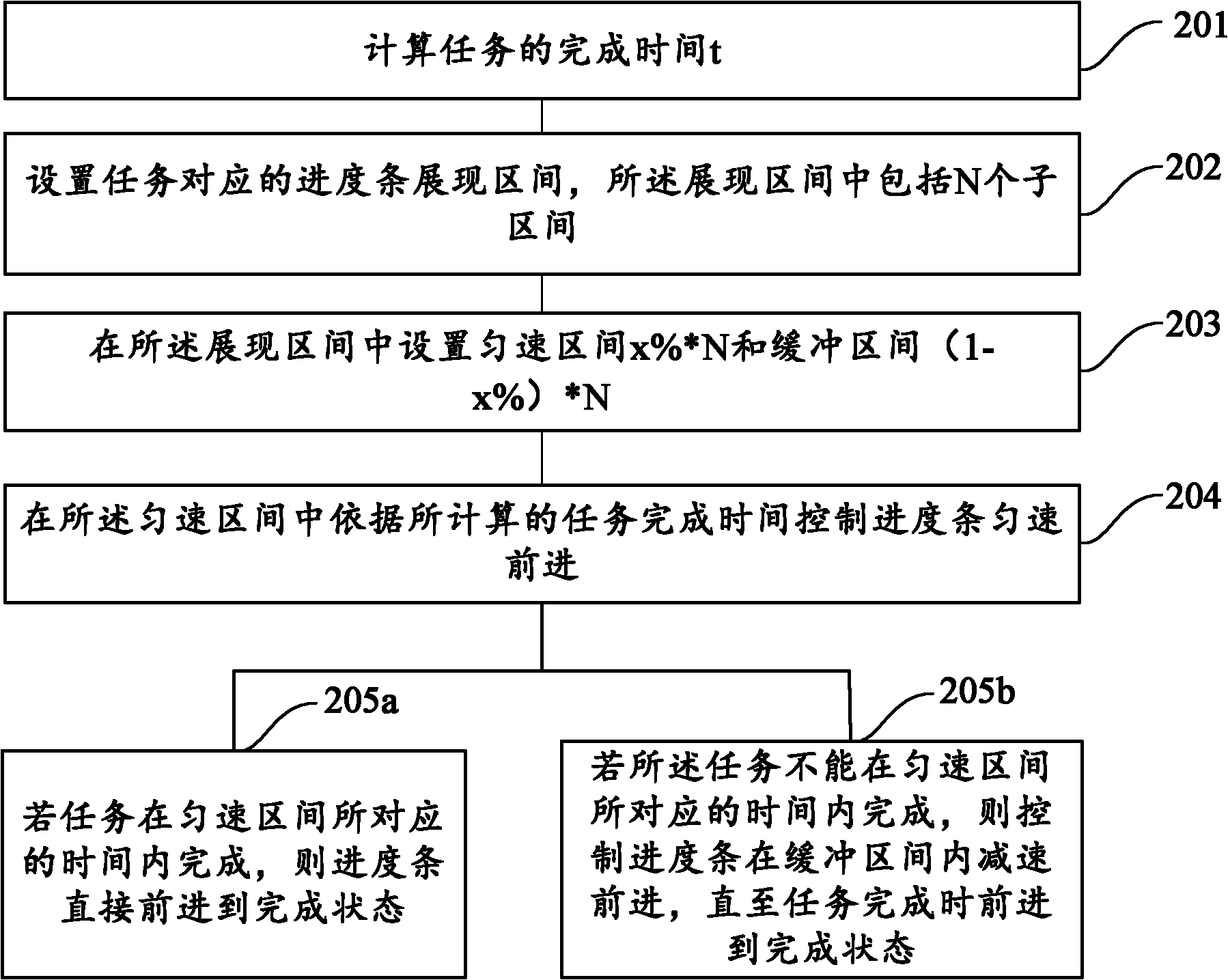

ActiveCN103488555ASolve the problem of pausing forwardSolve the problem of fast and slow progressHardware monitoringSpecific program execution arrangementsTask completionCompletion time

The invention provides a progress bar implementation method. The method includes calculating completion time of a task, setting a constant-speed range in a progress bar corresponding to the task, and controlling the progress bar to advance at a constant speed according to the task completion time in the constant speed range which accounts for more than half of the total length of the progress bar. Through the method, the progress bar can advance smoothly at the constant speed, and the problems that the progress bar halts when waiting for subtasks to be completed in the advance process as well as that the progress bar advances quickly sometimes and slowly sometimes in most circumstances are solved.

Owner:BEIJING QIHOO TECH CO LTD

Progress bar setting method and device

ActiveCN103530145ASolve abnormal problemsGood experienceHardware monitoringProgram loading/initiatingMoving speedMechanical engineering

The invention provides a progress bar setting method including the following steps of calculating task finishing time, arranging a constant speed interval in a progress bar corresponding to a task, wherein the constant speed interval accounts for more than half of the total length of the progress bar, and controlling the progress bar to move forward in the constant speed interval at a constant speed according to the task finishing time. By means of the progress bar setting method and device, the progress bar can move forward smoothly at a constant speed, and the problems that the progress bar stops moving in the moving process due to the fact that the progress bar waits until subtasks are finished, and the moving speed of the progress bar is not constant on most situations are solved.

Owner:BEIJING QIHOO TECH CO LTD

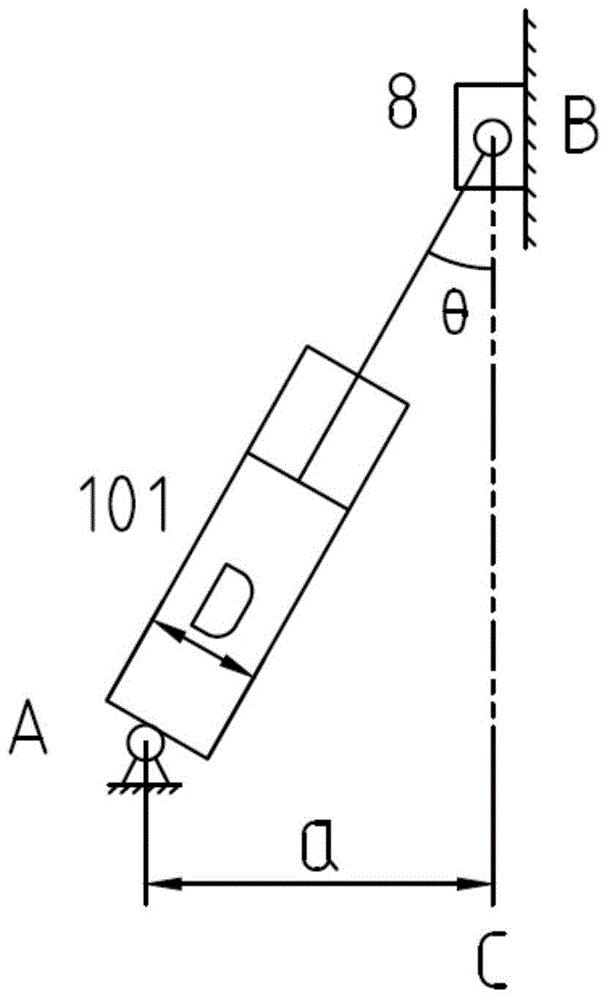

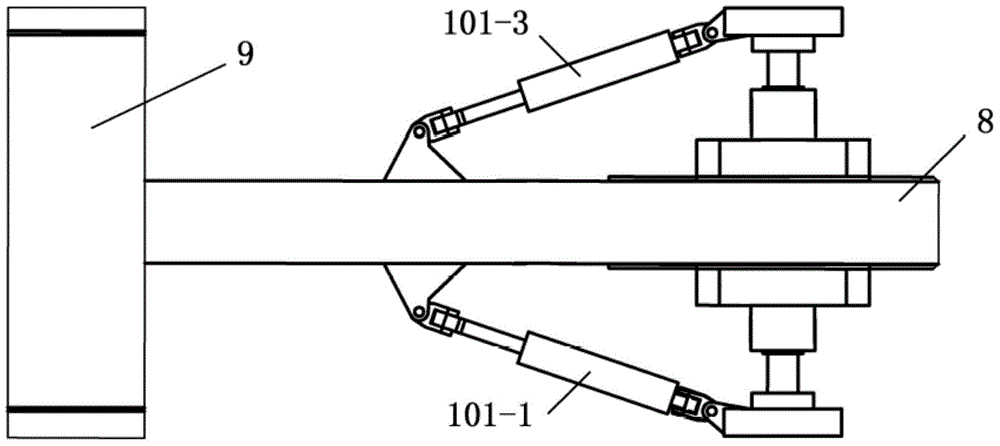

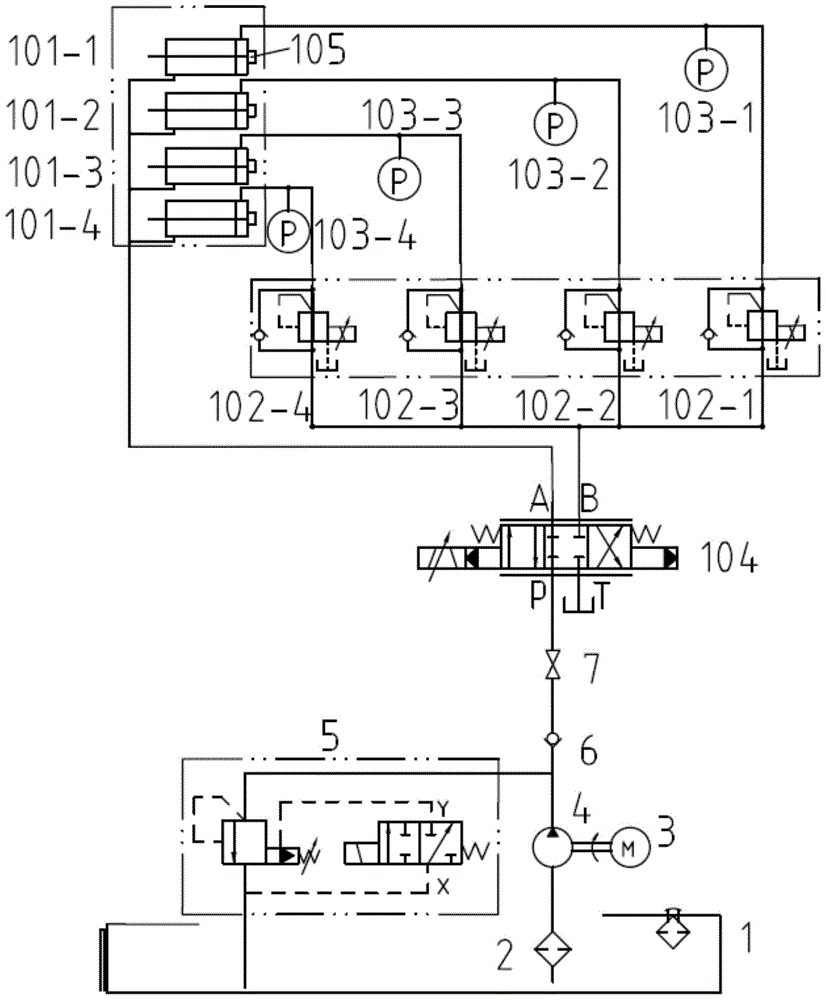

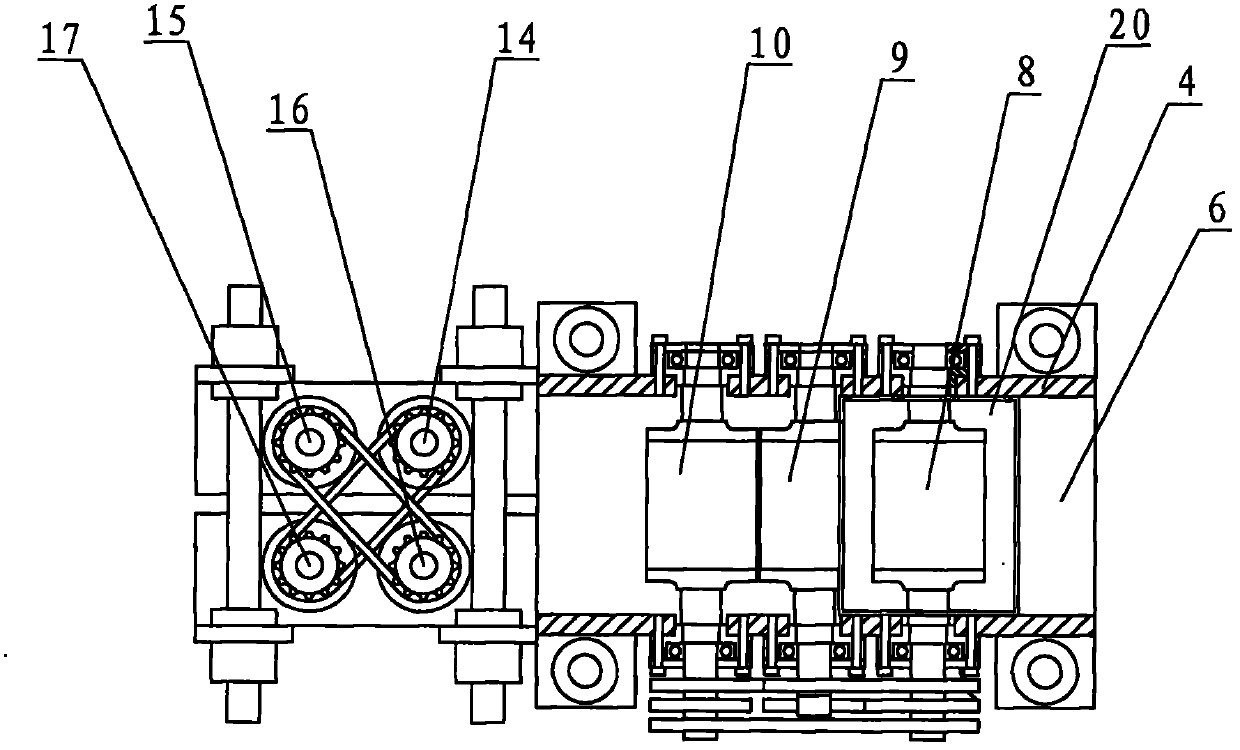

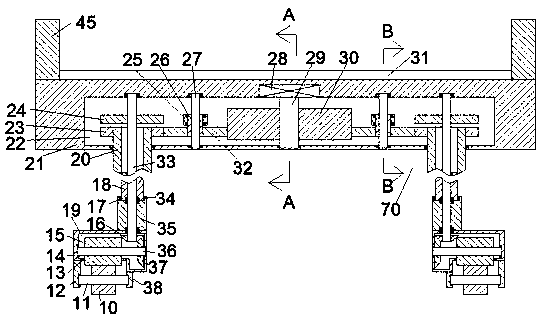

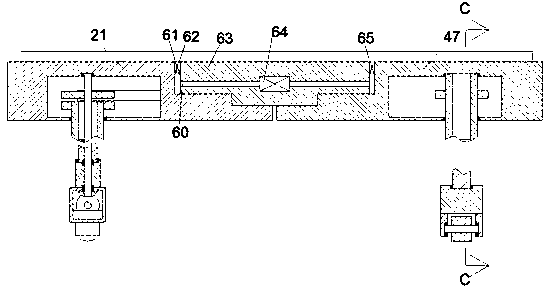

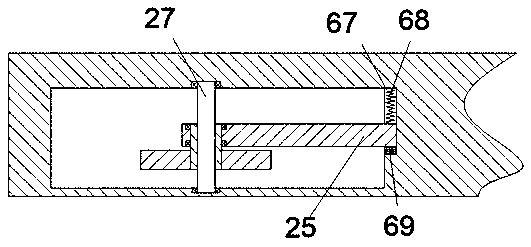

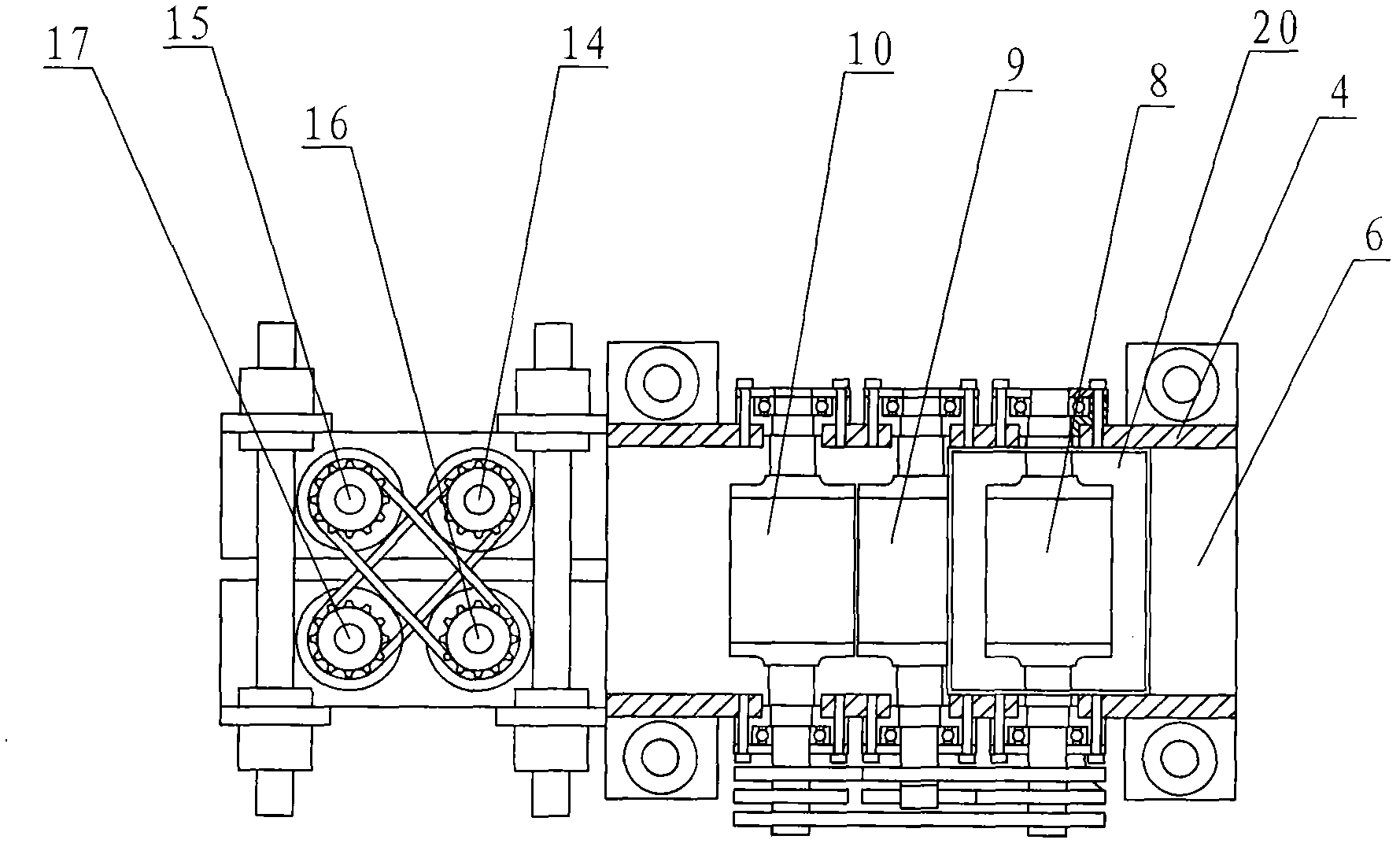

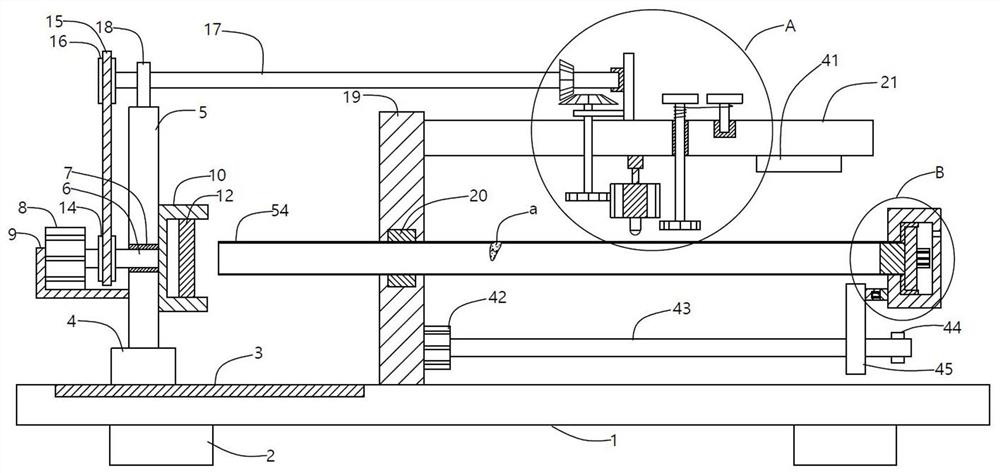

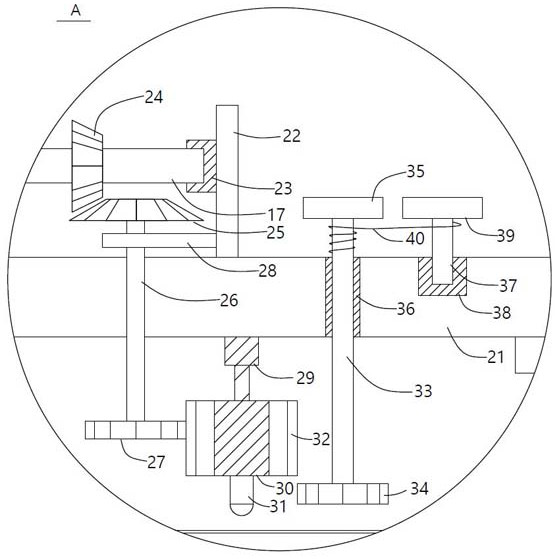

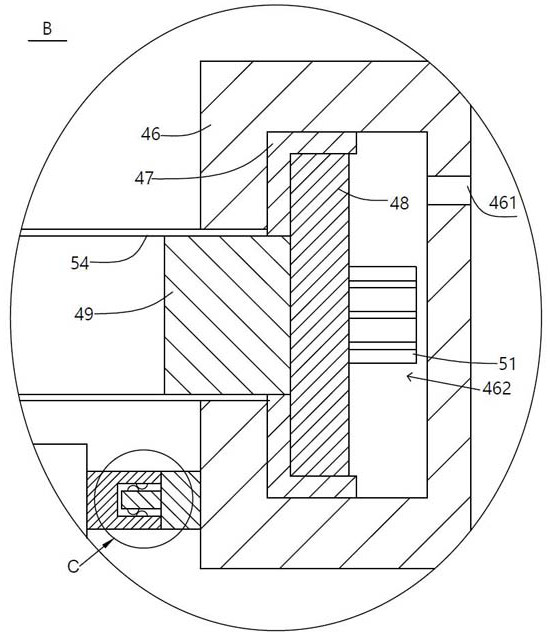

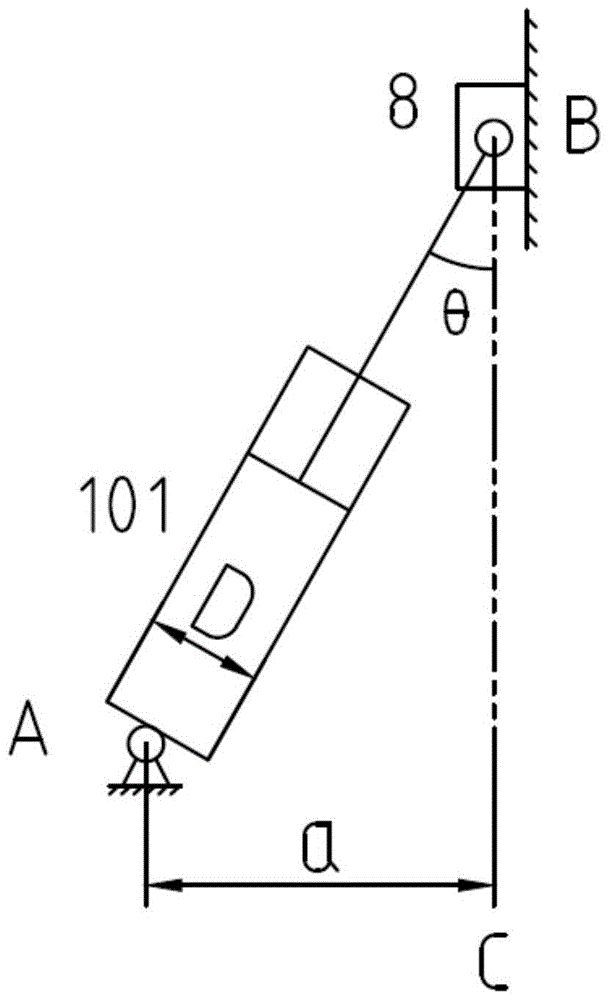

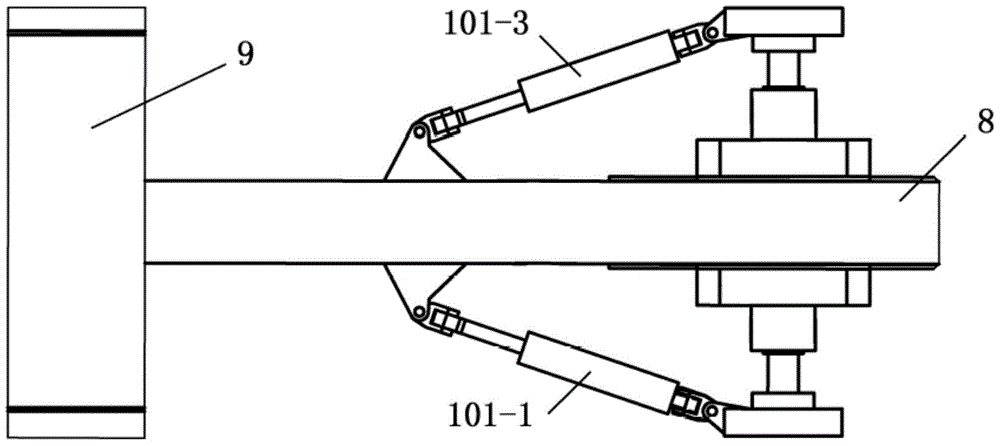

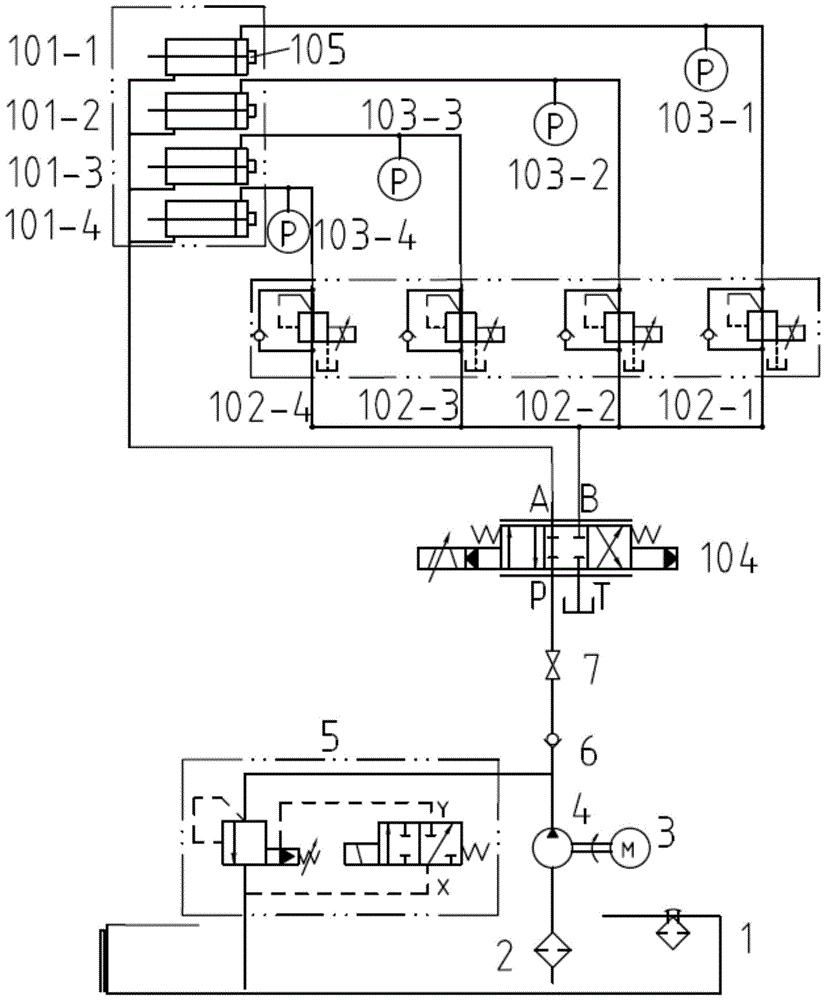

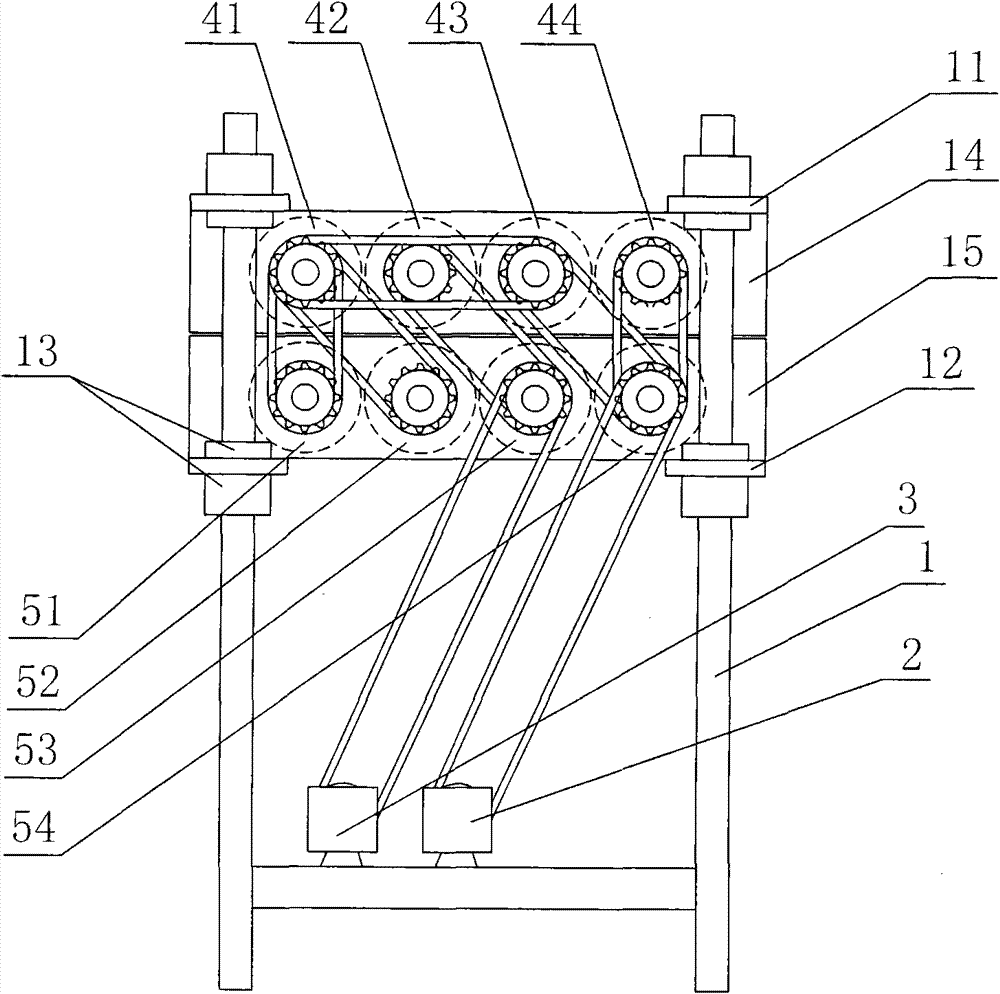

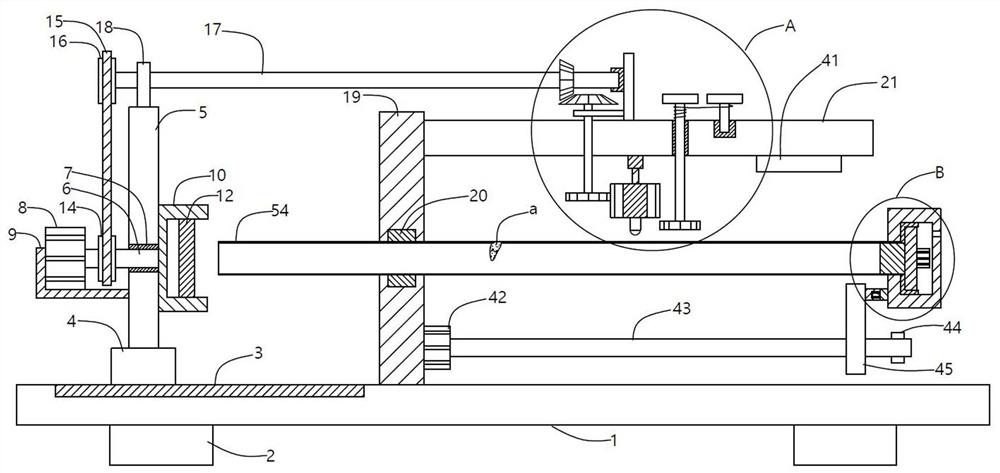

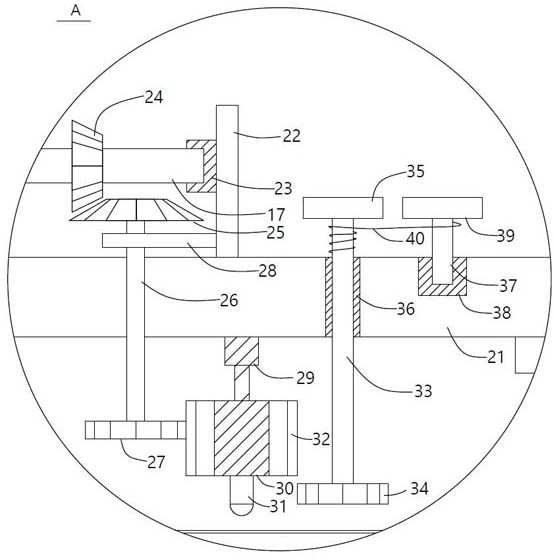

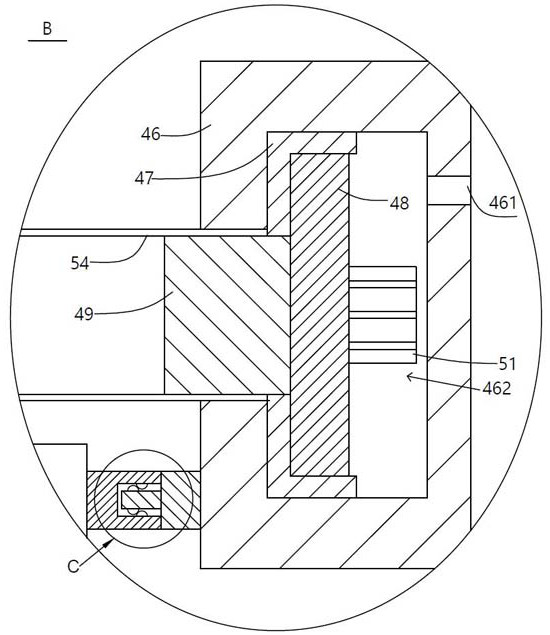

Experimental table propelling hydraulic system of hard rock boring machine

ActiveCN105020187APropel at a constant speedMove forward at a constant speedServomotorsElectro hydraulicFuel tank

The invention discloses an experimental table propelling hydraulic system of a hard rock boring machine. The experimental table propelling hydraulic system comprises an oil feeding pipeline, wherein one end of the oil feeding pipeline is communicated with an oil tank; the other end of the oil feeding pipeline is sequentially connected with a filter, a constant delivery pump, a one-way valve and a stop valve; an oil outlet of the stop valve is connected with a first opening of a three-position four-way electro-hydraulic servo valve; a fourth opening of the three-position four-way electro-hydraulic servo valve is connected with inlets of first, second, third and fourth one-way proportional pressure reducing valves; each of oil outlets of the first, second, third and fourth one-way proportional pressure reducing valves is connected with a pressure sensor and a rodless cavity of a propelling cylinder; rod cavities of four propelling cylinders are connected with a third opening of the three-position four-way electro-hydraulic servo valve respectively; a displacement sensor is arranged in each of the four propelling cylinders; and a second opening of the three-position four-way electro-hydraulic servo valve is connected with the oil tank. With the adoption of the system, main beam constant-speed propelling can be realized, unbalance loading is restrained when the main beam is loaded in an unbalanced mode, and steering is matched when the main beam is steered.

Owner:TIANJIN UNIV

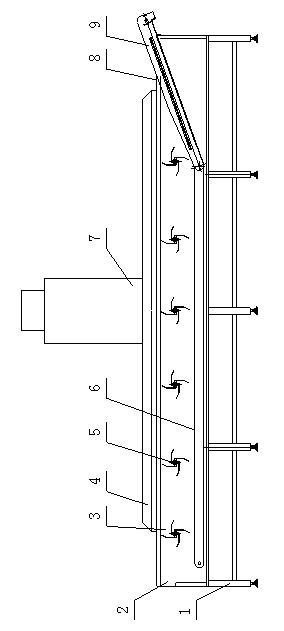

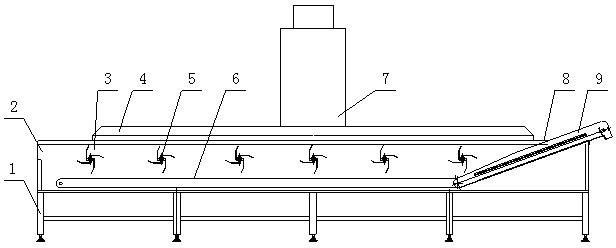

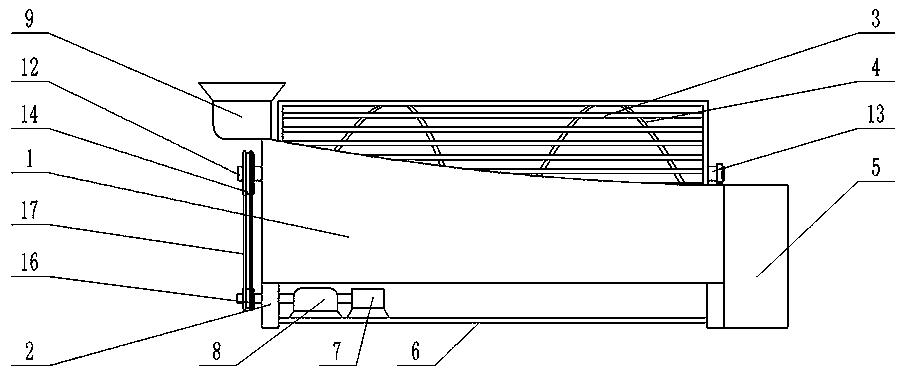

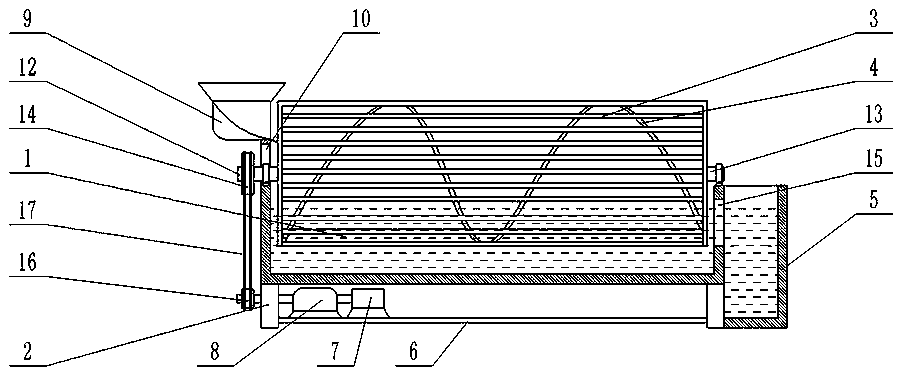

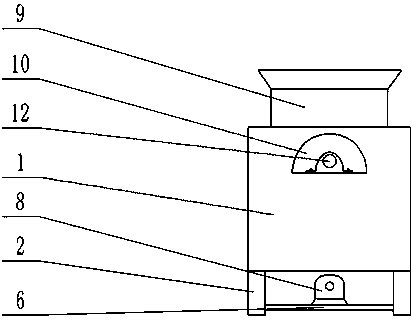

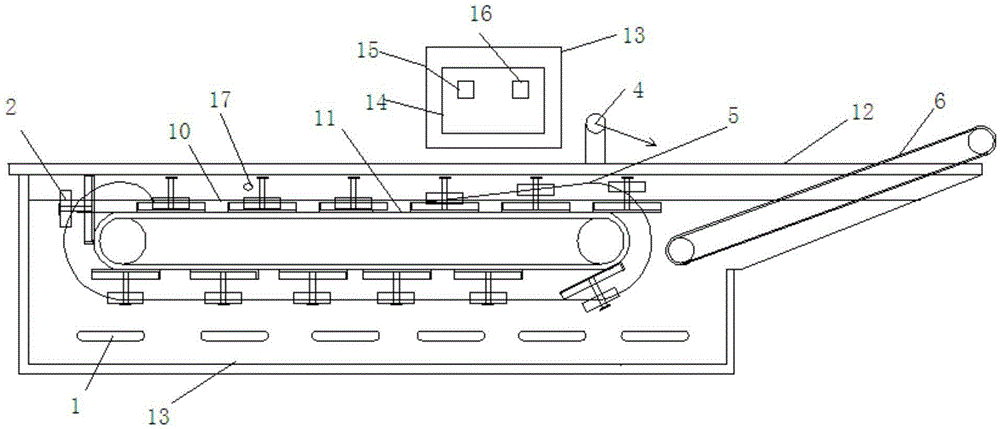

Continuous frying device of potato flake/chip

InactiveCN101999611AUniform and constant temperatureImprove the frying effectFood preparationProduction lineHeating oil

The invention relates to a continuous frying device of potato flake / chip, comprising a frame and a frying pan, wherein the cover body on upper part of the frying pan is provided with a smoke outlet, and the continuous frying device of potato flake / chip is characterized in that the exterior of the frying pan is equipped with a heating oil path system, the interior of the frying pan is spacedly equipped with a set of rotary vanes, one end of the frying pan is provided with a feeding port while the other end is provided with a discharging port, the discharging port is equipped with a lifting machine and the conveyor mesh belt of the lifting mechanism is extended to the feeding port from the bottom within the frying pan. The continuous frying device of potato flake / chip provided by the invention has the advantages that the structure is simple, the design is scientific and logic, the constant temperature control of oil can be realized, the material can be prevented from adhering, the time of frying can be accurately controlled, the continuous production purpose can be realized and the device is suitable for producing in a large batch of a high-speed production line.

Owner:SHENGCHANGDA MACHINERY TIANJIN

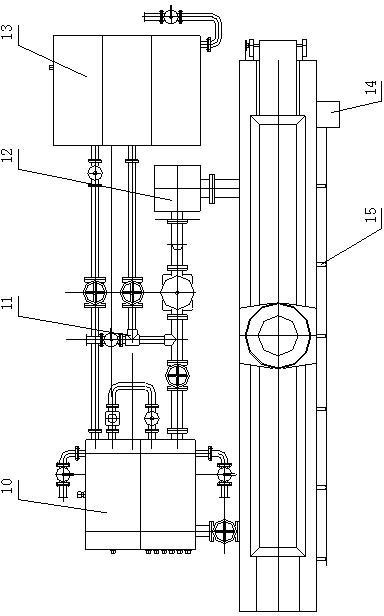

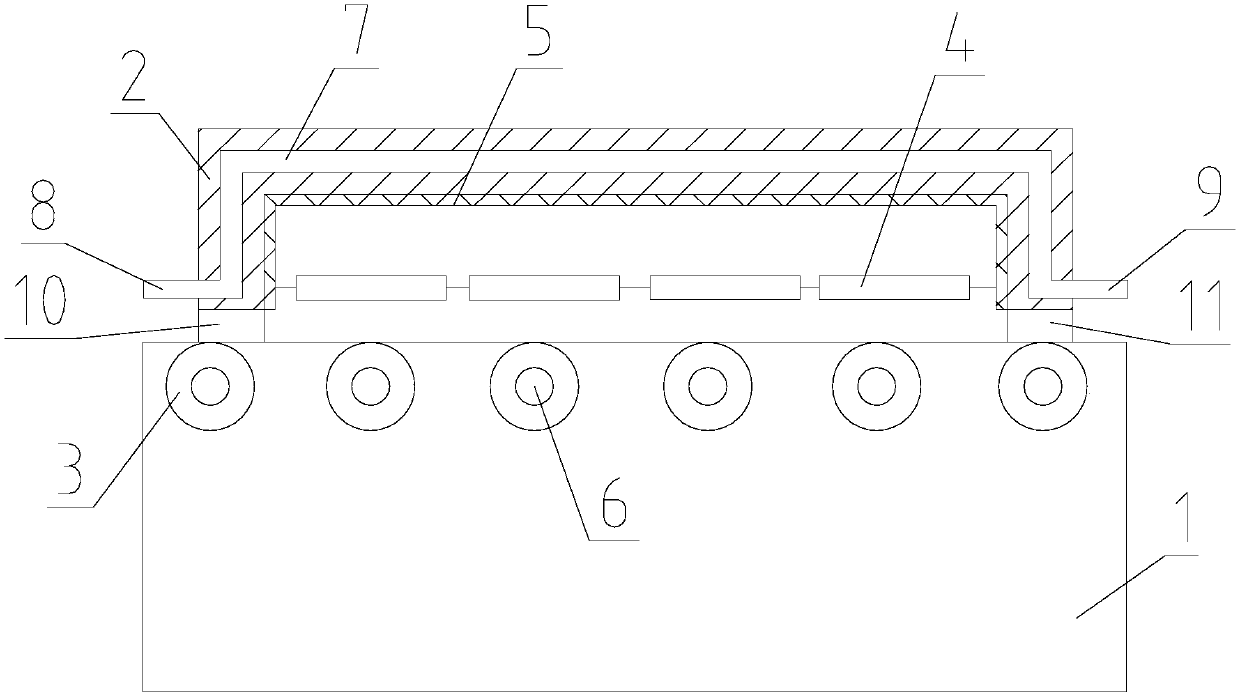

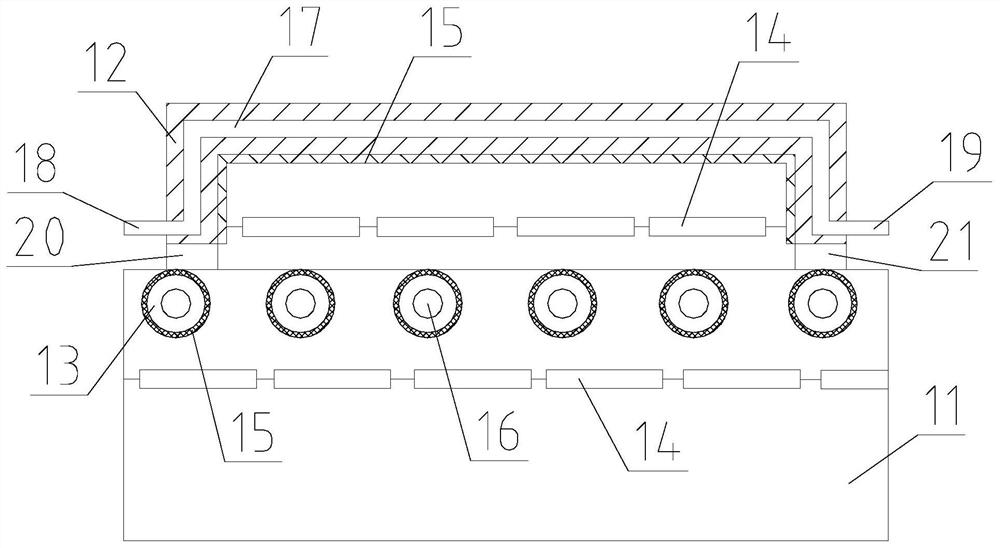

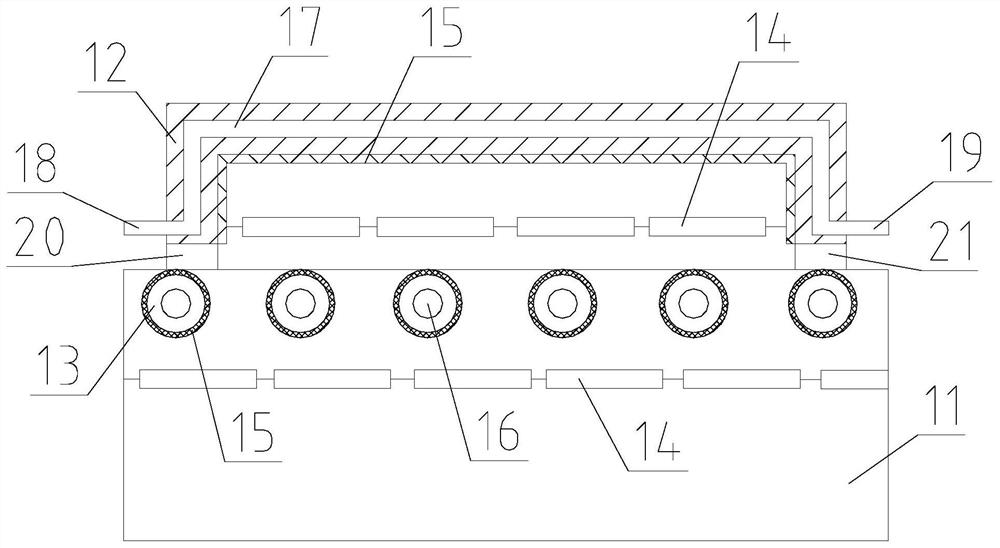

PVC decorative sheet drying device

PendingCN108044848APrevent high temperature burntTimely coolingFlat articlesEngineeringMechanical engineering

The invention relates to a PVC decorative sheet drying device. The PVC decorative sheet drying device comprises a substrate, a protective cover and heaters; the protective cover is a cavity of which the bottom is opened; the protective cover is connected to the upper portion of the substrate in a covering manner; a plurality of heaters are arranged inside the cavity of the protective cover; a transporting structure for moving a PVC decorative sheet is arranged inside the substrate; a cooling structure is arranged inside the protective cover; one side of the protective cover is provided with afeeding opening for the PVC decorative sheet to enter the protective cover; and the other side of the protective cover is provided with a discharging opening for the PVC decorative sheet to leave awayfrom the protective cover. The PVC decorative sheet drying device provided by the invention has the beneficial effects that the cooling structure is arranged inside the protective cover so that the PVC decorative sheet can be effectively prevented from being damaged due to baking at a high temperature.

Owner:湖北银座新材料股份有限公司

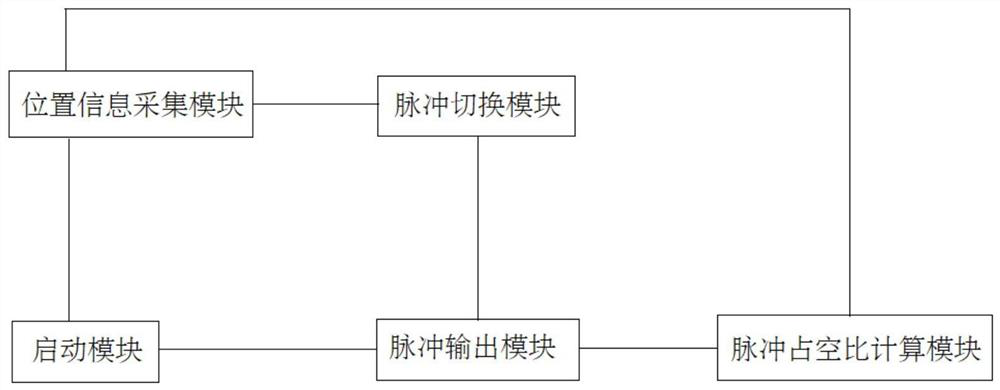

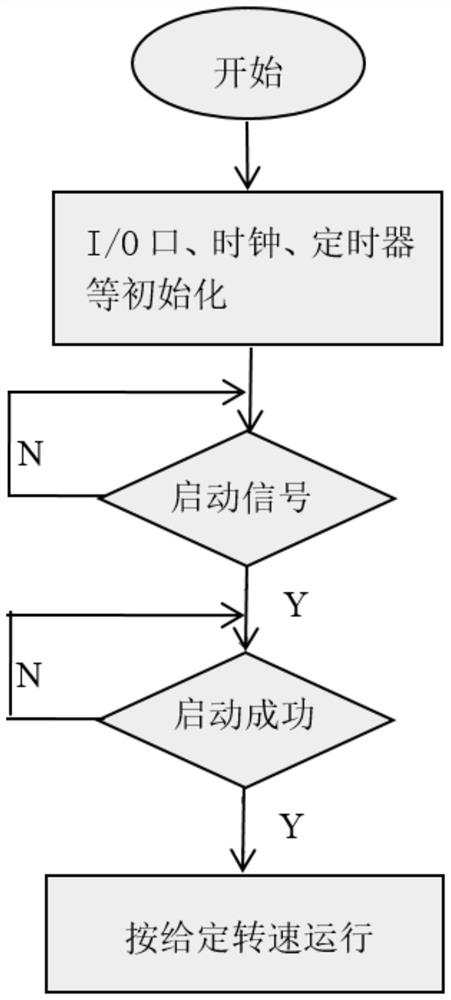

Controller of single-phase direct-current permanent magnet brushless motor, control method and motor power system

PendingCN111969905AControl startControl runabilityElectric motor controlCurrent controllersBrushless motorsSquare waveform

The invention discloses a controller and a control method of a single-phase direct-current permanent magnet brushless motor used by a near space airship motor power system. The controller comprises aposition signal acquisition module, a pulse duty ratio calculation module, a pulse switching module and a pulse output module. The position signal acquisition module is connected with the pulse switching module, the pulse output module is connected with the pulse duty ratio calculation module and the pulse switching module, the pulse output module comprises two timers, the two timers respectivelygenerate two paths of pulse square waves, and the duty ratio of the pulse square waves output by the timers is adjusted according to the pulse duty ratio; and the pulse switching module is used for determining whether to switch the pulse output state or not according to the rotor position information and the current pulse output state. The processor judges the position of the motor rotor by inputting the level signals of the level of the output port so as to control the starting and running of the motor.

Owner:北京空天高科技有限公司

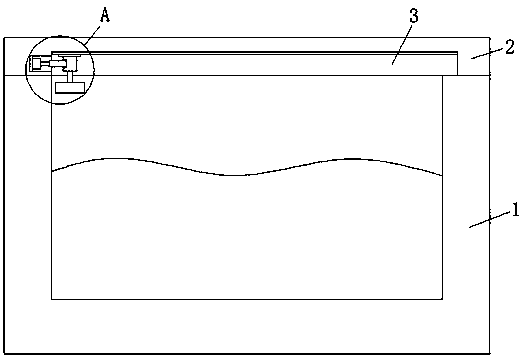

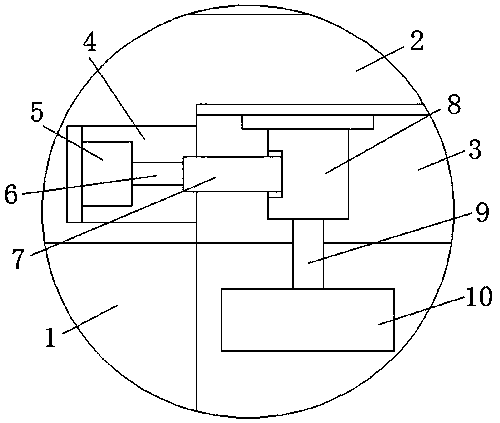

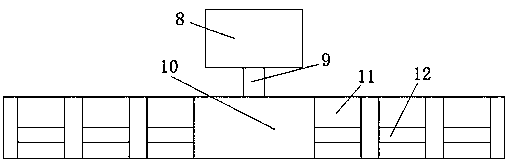

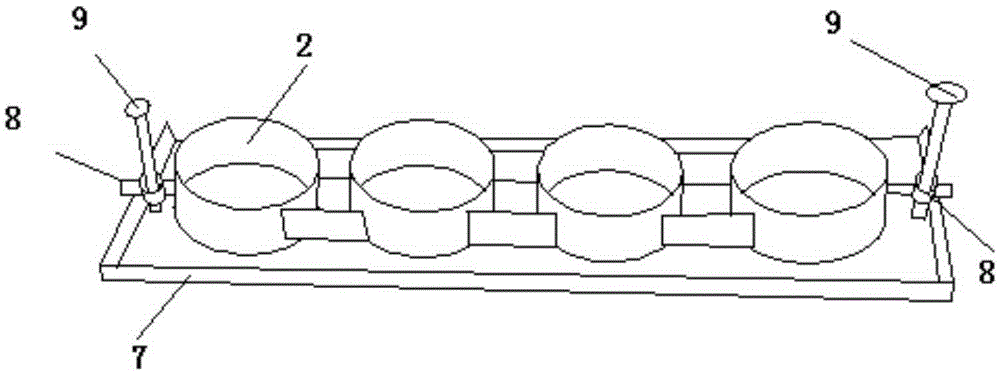

Fodder feeding device for soft-shelled turtle culture

InactiveCN107751107AMove forward at a constant speedServe evenlyAnimal husbandryMotor driveEngineering

Owner:成都市回归甲鱼养殖有限公司

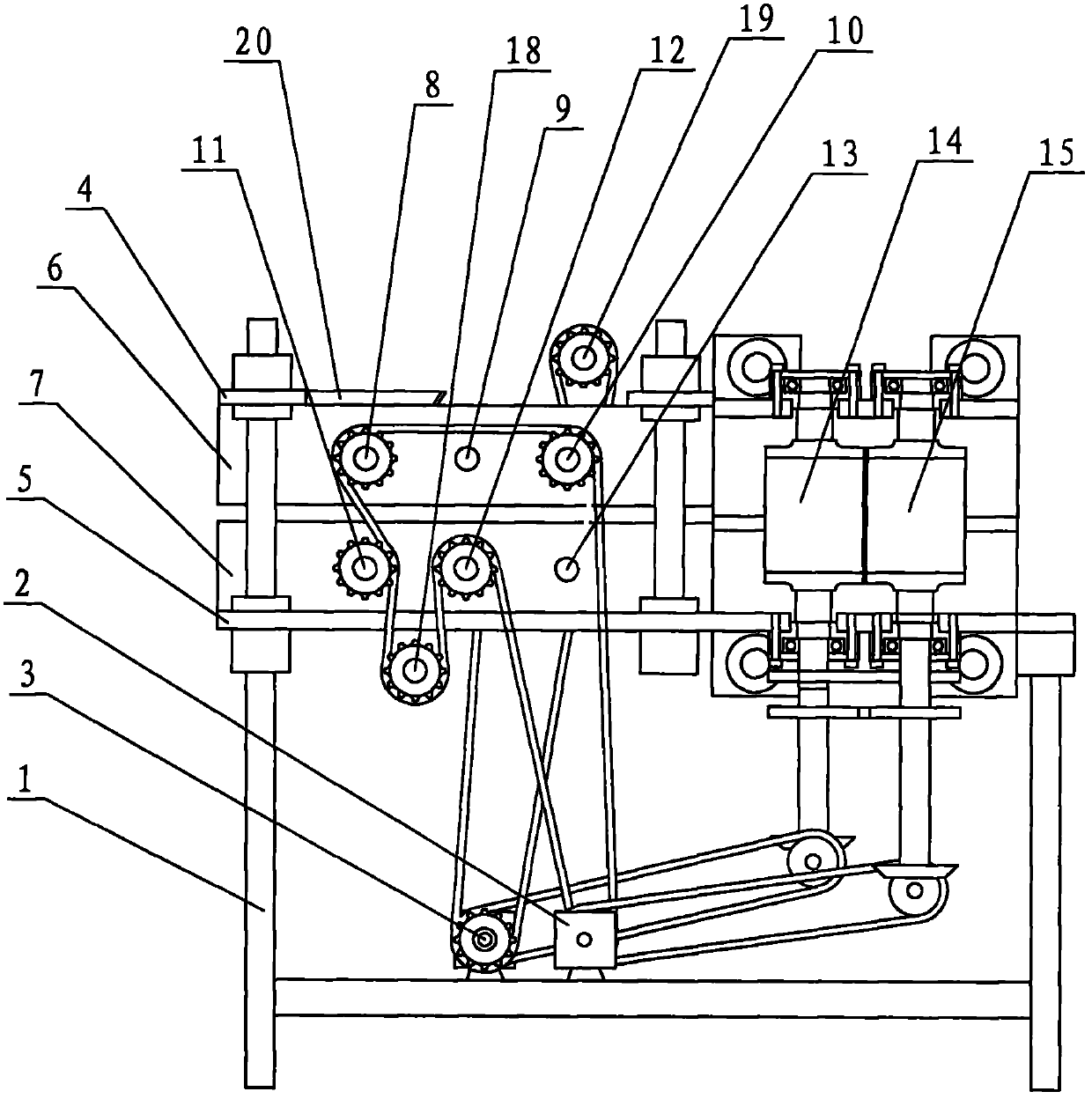

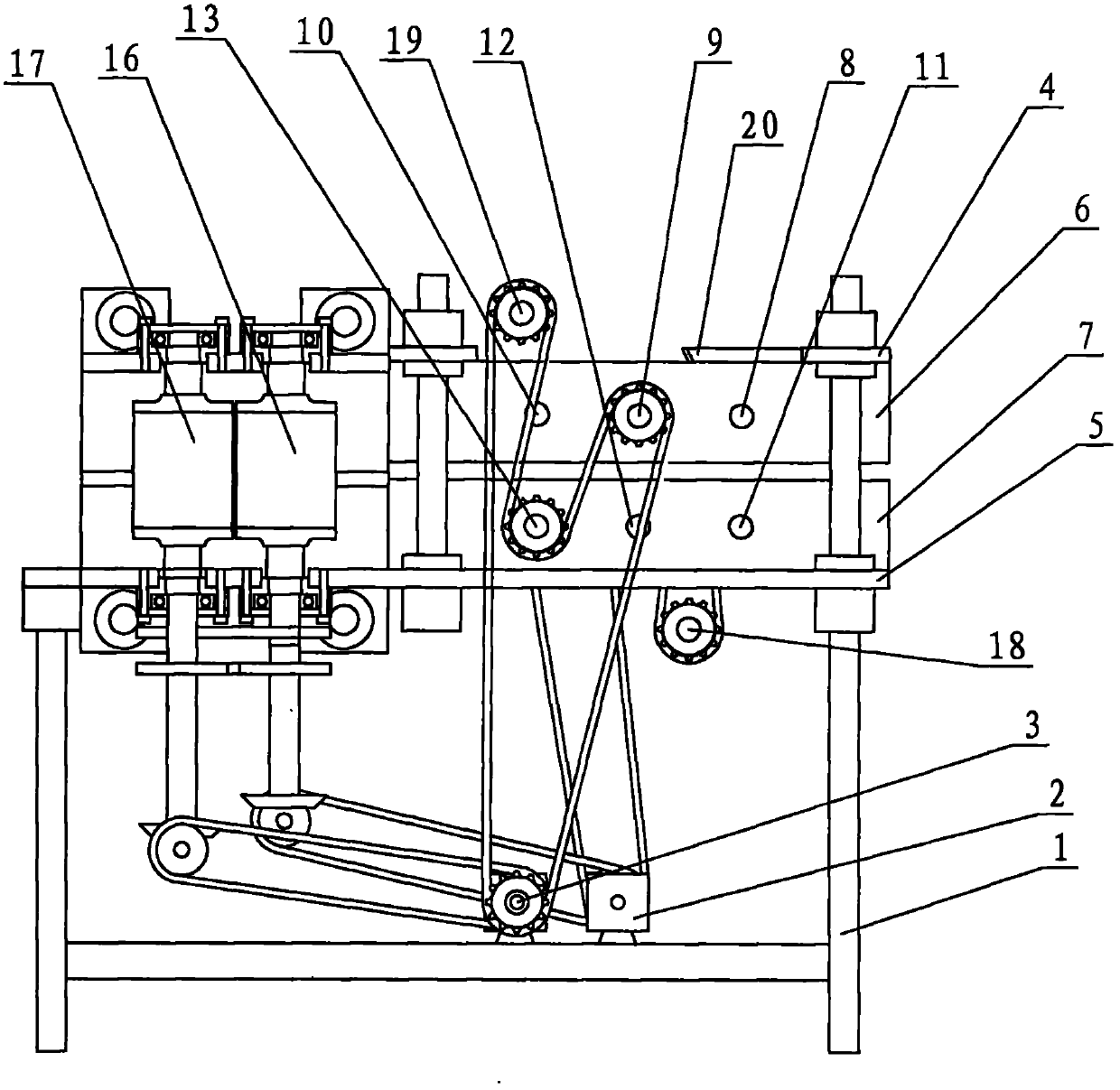

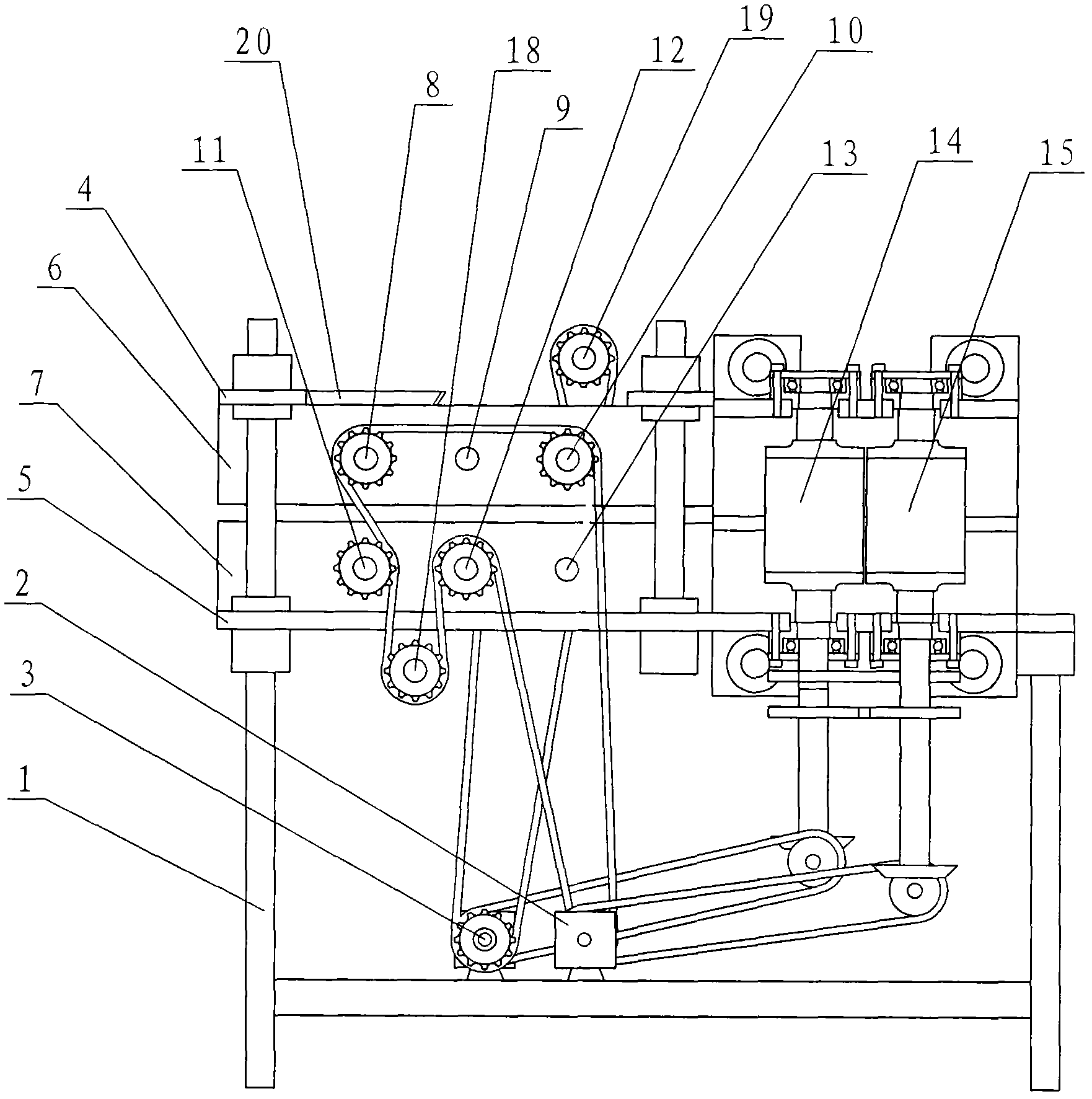

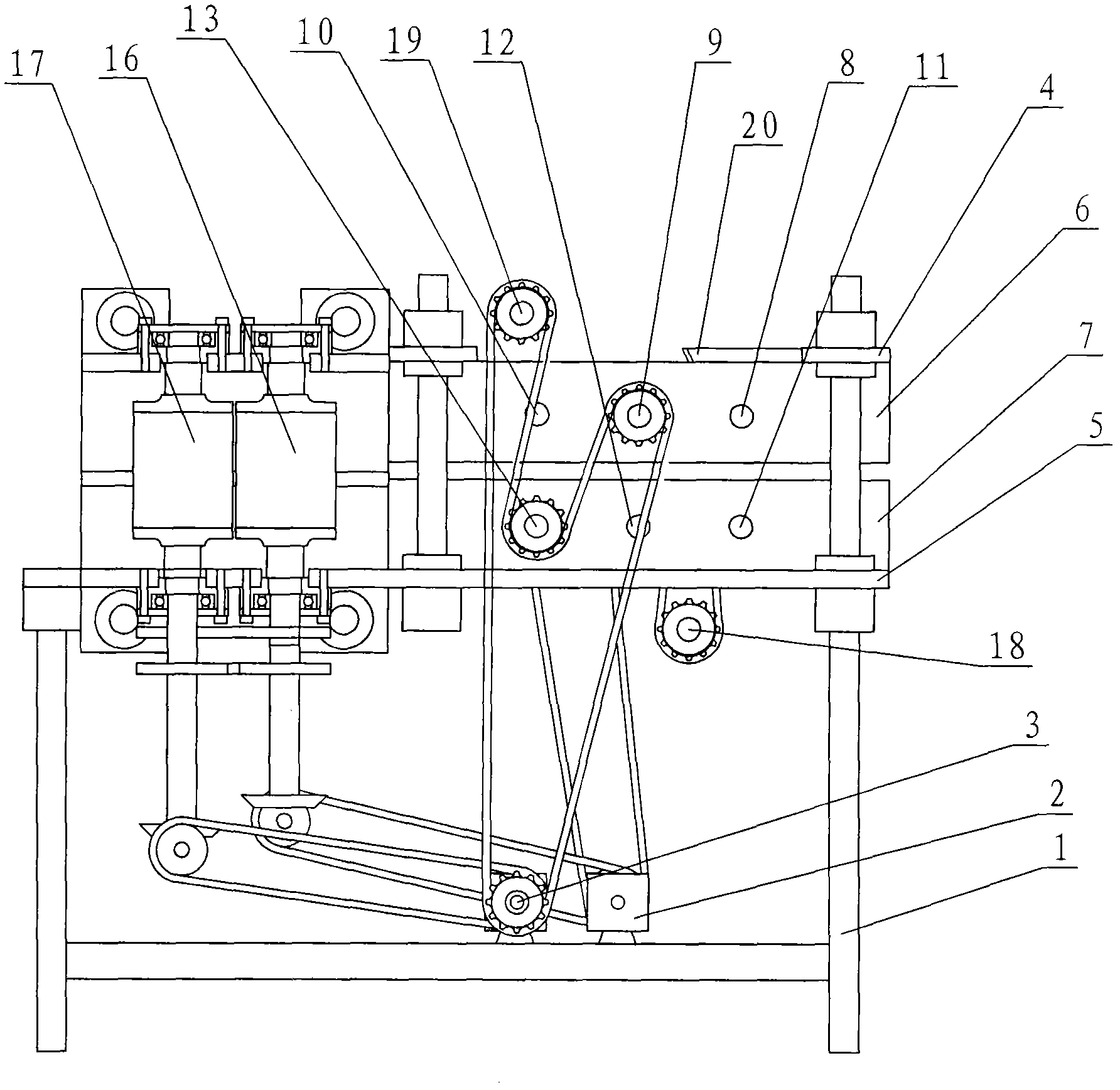

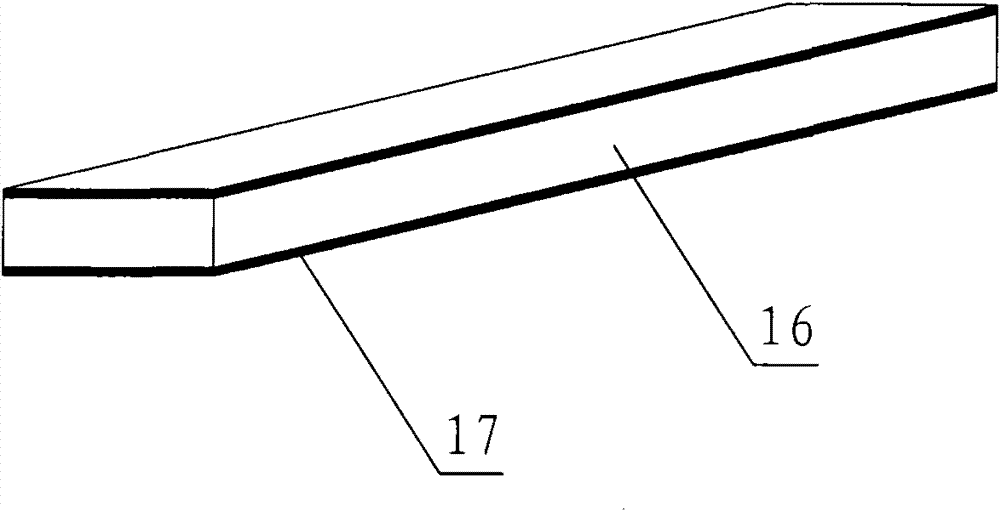

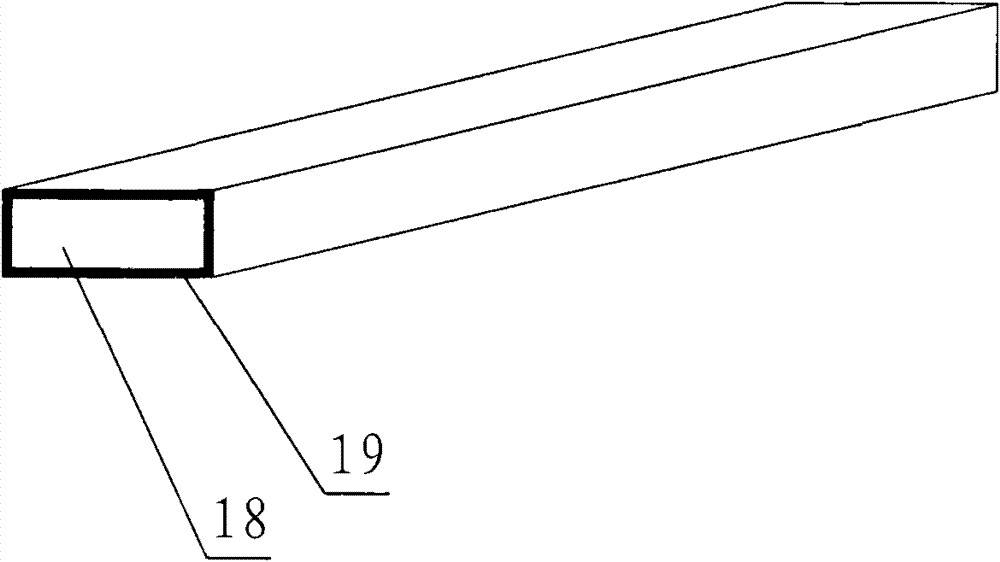

Processing equipment for woodware

InactiveCN102166771AControl feed rateMove forward at a constant speedWood compressionEngineeringMechanical engineering

The invention discloses processing equipment for woodware, which is characterized in that: an upper connecting plate is coupled with three upper rollers; a lower connecting plate is coupled with lower rollers which have the same number as the upper rollers and correspond to the upper rollers one to one; a longitudinal pressing plate device is arranged on the same worktable at an inlet end or an outlet end and consists of at least two left rollers and at least two right rollers; and a coating groove is formed on each roller. The invention has the advantages that: the equipment can press the horizontal and vertical surfaces of the woodware, and has a shaping effect on a floor simultaneously, the processing quality of the equipment is ensured, the equipment can paint the woodware while rolling the woodware, a paint can fully infiltrate into pipe holes of the woodware due to friction between the rollers and the surface of the woodware, and can be adhered to the surface of the woodware more firmly, and higher sealing property is achieved.

Owner:佛山市南海纵华家具有限公司

Method and device for showing progress bar

ActiveCN102141953BSolve the problem of pausing forwardSolve the problem of fast and slow progressHardware monitoringProgress barEngineering

The invention provides a method for showing a progress bar. The method comprises the following steps of: calculating a finish time of a task; setting a constant-speed region in the progress bar corresponding to the task, wherein the length of the constant-speed region is over half the total length of the progress bar; and controlling the progress bar to move forward at a constant speed in the constant-speed region according to the finish time of the task. By the method, the progress bar can move forward smoothly at the constant speed, so the problems that the progress bar has to wait for the finish of a subtask and stops moving forward, and the progress bar moves forward alternatively between slow and fast under most conditions can be solved.

Owner:BEIJING QIHOO TECH CO LTD

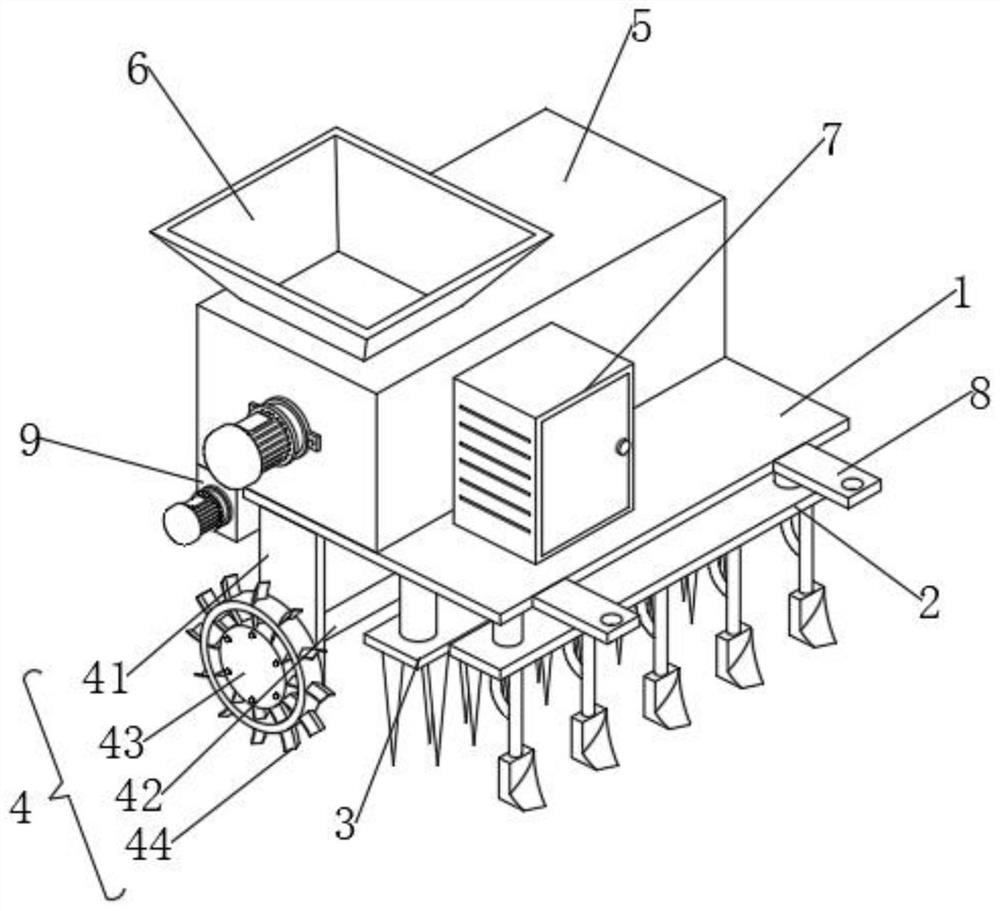

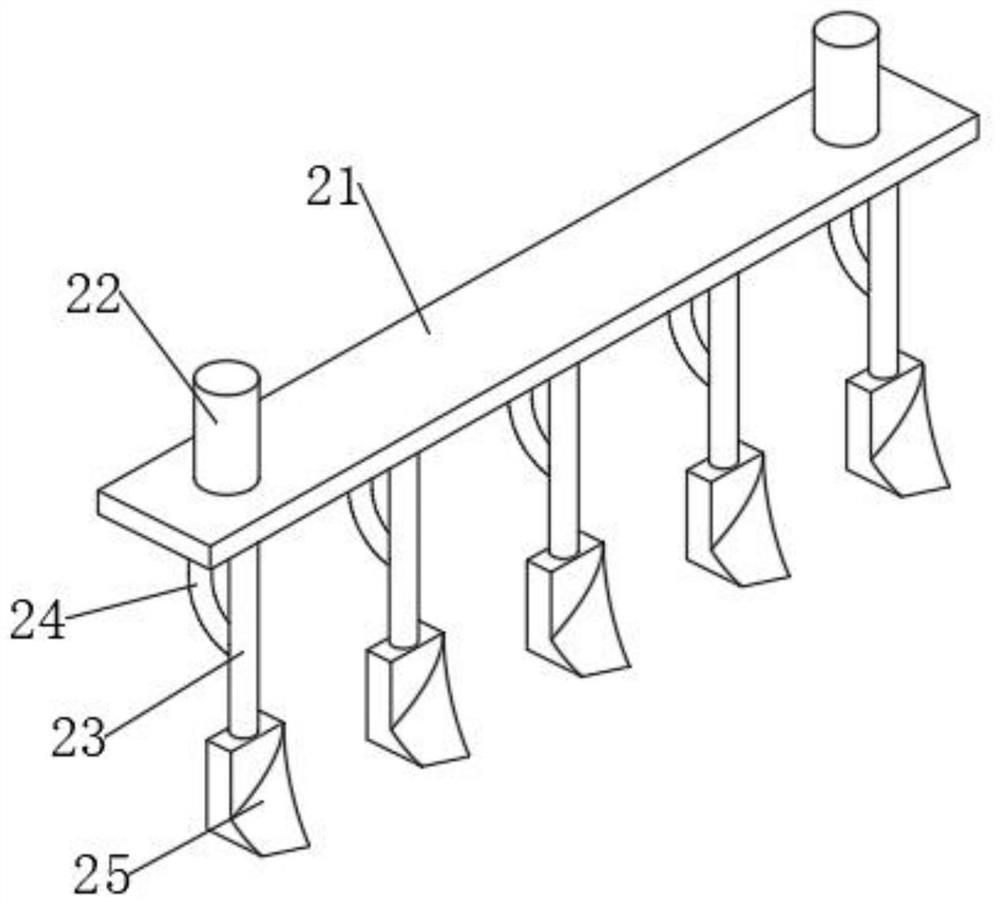

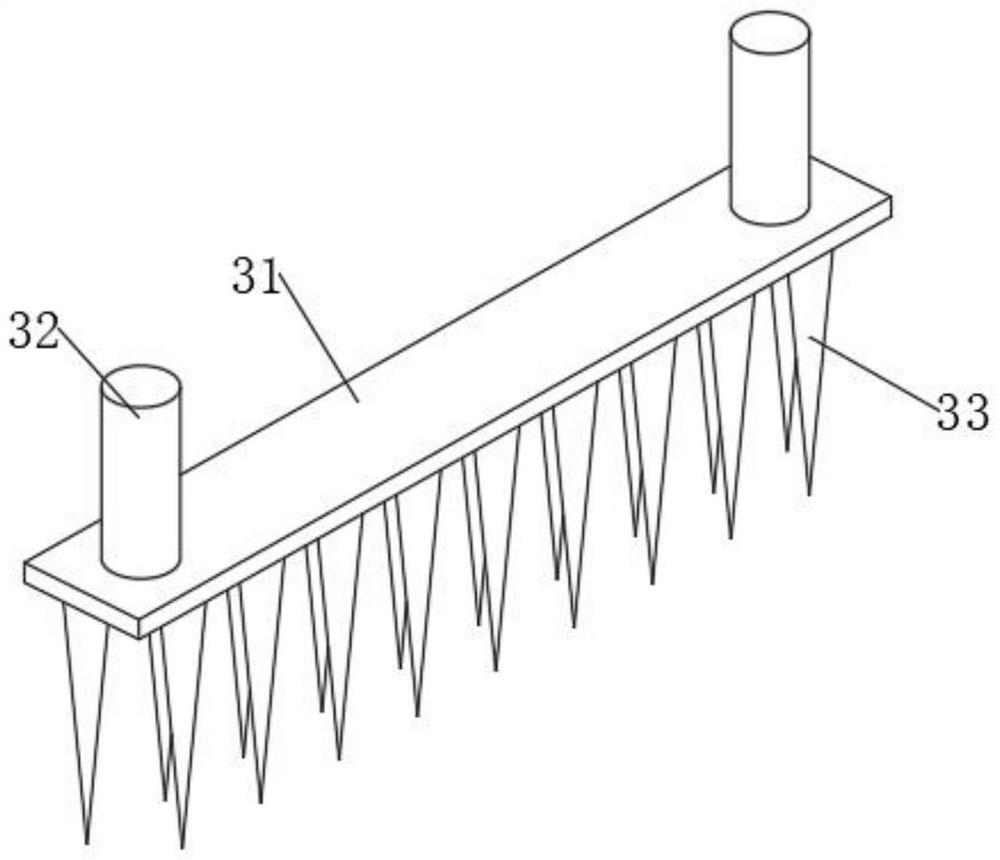

Fertilizing device capable of uniformly fertilizing for bamboo reed planting

InactiveCN112136393AImprove gripImprove stabilitySpadesFertiliser distributersAgricultural engineeringMechanical engineering

Owner:NAN COUNTY WEIYE MACHINERY MFG

Forming mechanism of PVC plate

ActiveCN111746009ADry fastGuaranteed symmetryFlat articlesMetal working apparatusMolding machineStructural engineering

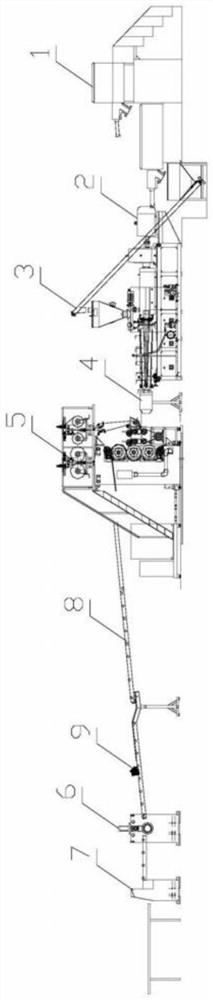

The invention relates to a forming mechanism of a PVC plate. The forming mechanism comprises a mixer, an extruder, a feeder, a mold, a laminating calender, a tractor and a plate shearing machine whichare sequentially connected end to end, wherein the laminating calender and the tractor are connected through a bracket; a material uniformizing device is arranged between the feeder and the mold andused for uniformly spreading materials discharged from the feeder; a drying device is arranged on the front section of the bracket and used for drying the plate output from a discharge port of the laminating calender; a trimming and slitting device is arranged on the rear section of the bracket and comprises two side guide plates which can get close to or away from each other and a trimming mechanism; the side guide plates are used for centering and guiding before trimming of the PVC plate; and the trimming mechanism is used for symmetrically cutting two side edges of the PVC plate. The forming mechanism has the benefits as follows: the material uniformizing device spreads and compacts the materials, and the materials have no holes and are uniform after entering the mold; the drying devicecan quickly dry the materials; and the symmetric side guide plates can center and guide the PVC plate, and the trimming mechanism can guarantee cutting symmetry.

Owner:湖北佳美智能科技有限公司

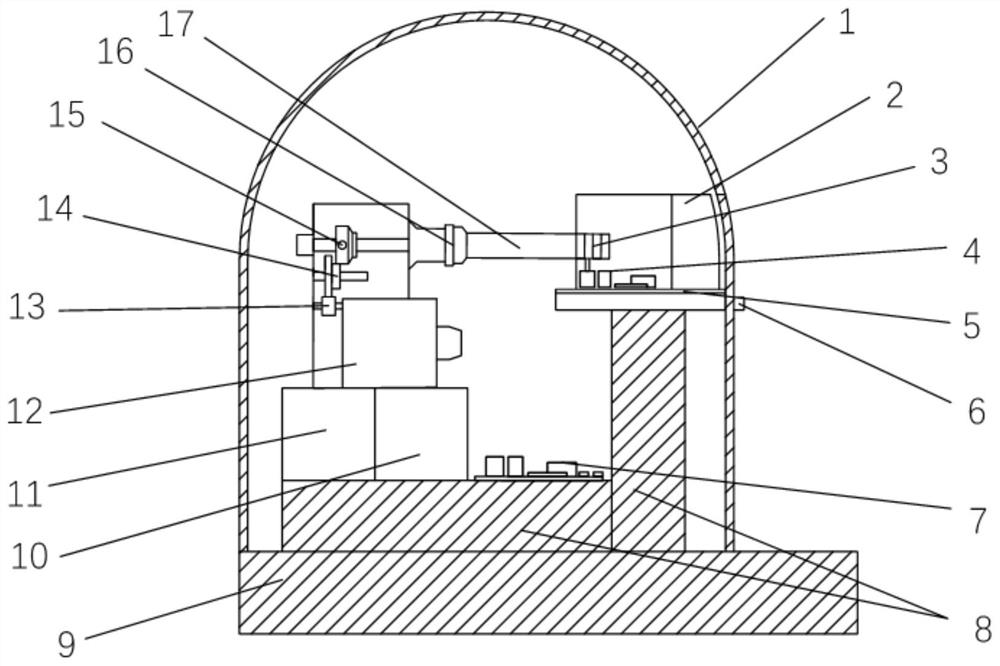

Yoga type intelligent scoliosis measuring instrument

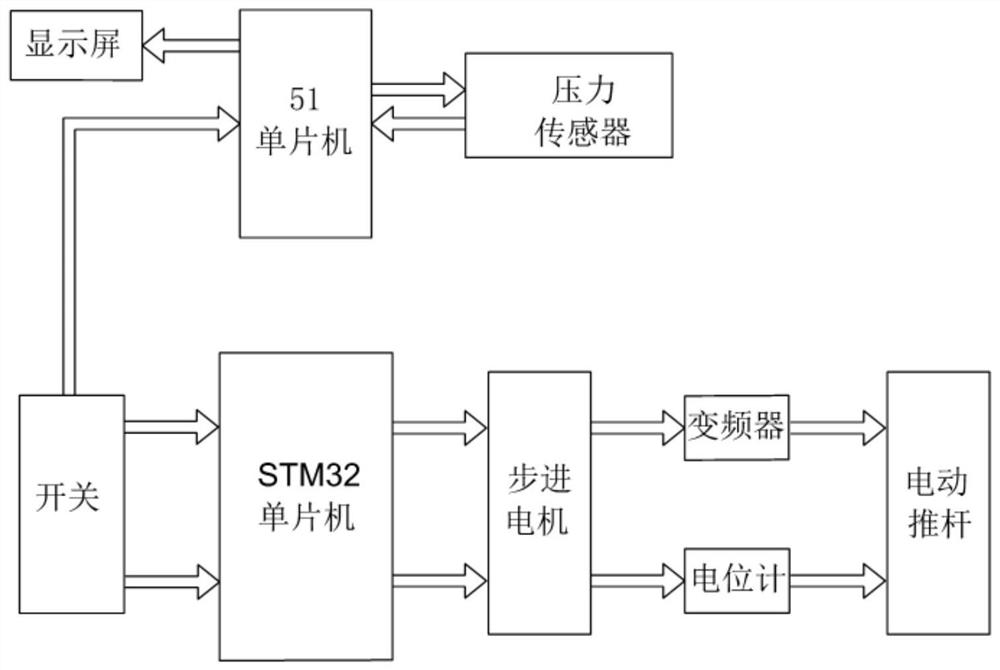

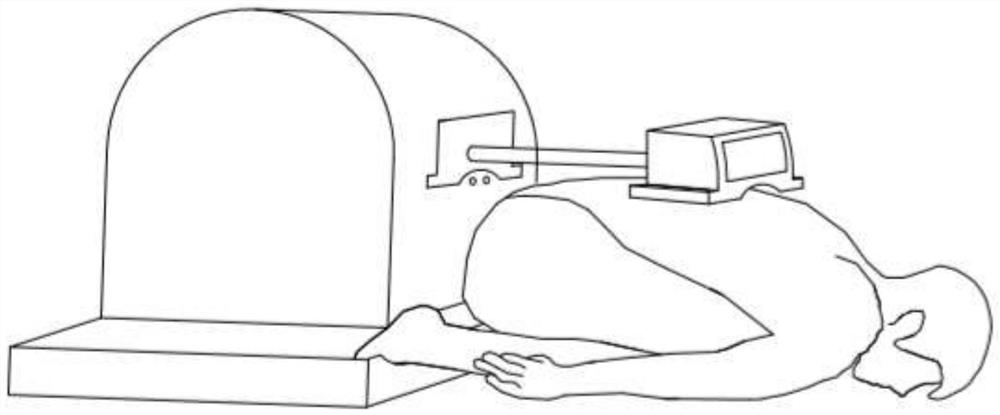

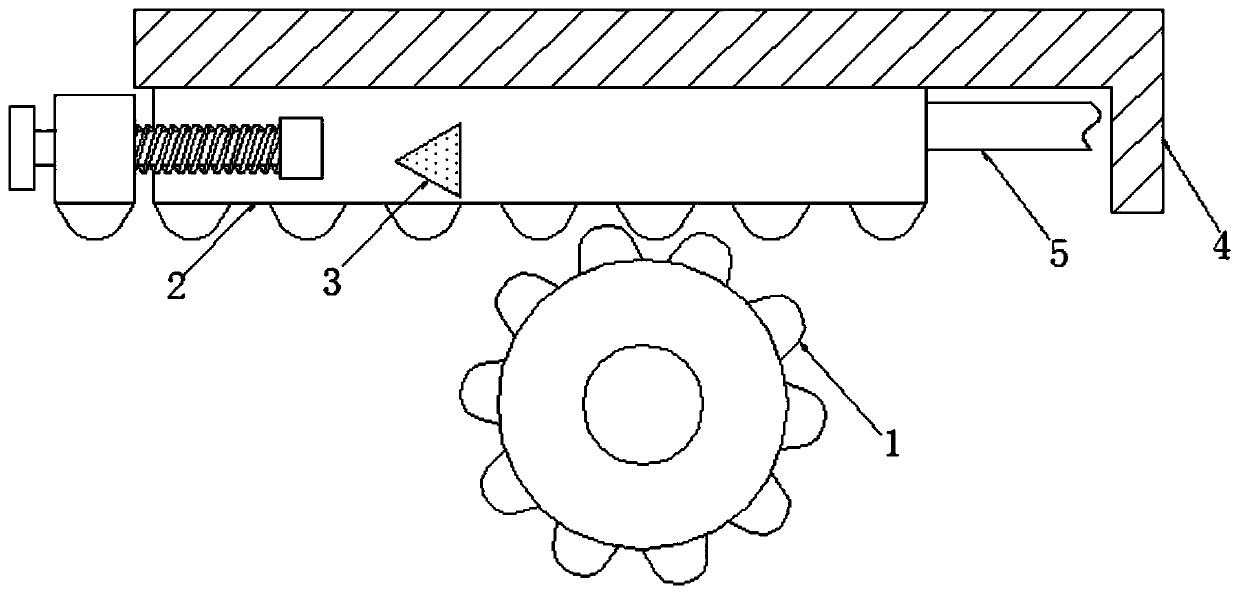

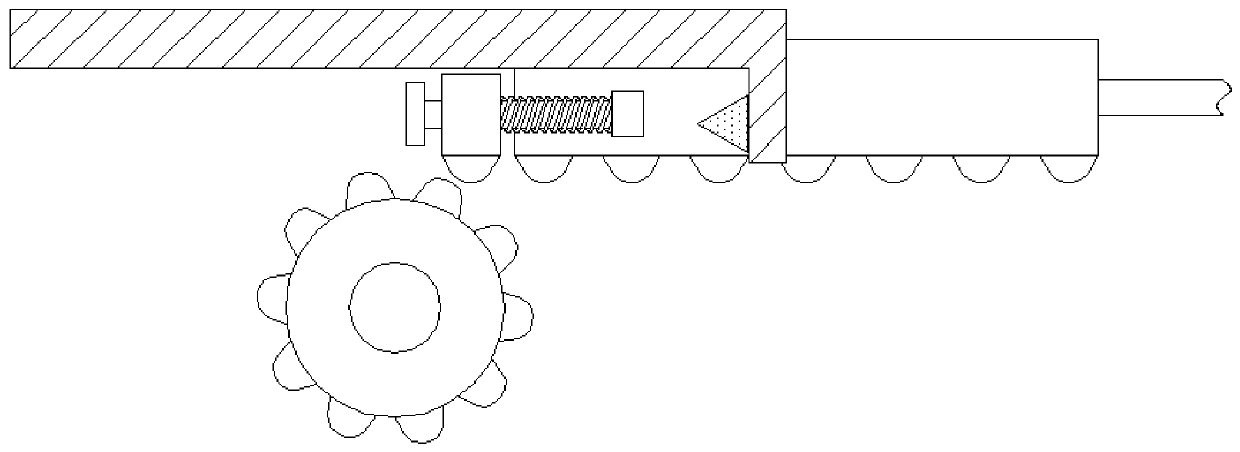

ActiveCN111643059ASimple structureClear division of laborDiagnostic recording/measuringSensorsFrequency changerSTM32

The invention discloses a yoga type intelligent scoliosis measuring instrument. The instrument comprises a shell, a main control system, a secondary control system, an electric push rod mechanism, a pressure measuring system, an led display screen and a supporting mechanism. A main control unit comprises an STM32 single-chip microcomputer and a reset button connected with the STM32 single-chip microcomputer. A secondary control unit comprises a 51 single-chip microcomputer and a reset button connected with the 51 single-chip microcomputer. The electric push rod mechanism comprises a potentiometer, a frequency converter, a stepping motor, a gear, a speed reducer and a telescopic rod. After the instrument is started, the STM32 single-chip microcomputer of the main control system receives a signal and drives the stepping motor to work; and the 51 single-chip microcomputer of the secondary control system receives a starting signal at the same time and drives a flexible pressure sensor to work, and the sensor receives a pressure signal and transmits the pressure signal back to the secondary control system, so that intelligent measurement and scoliosis evaluation are achieved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

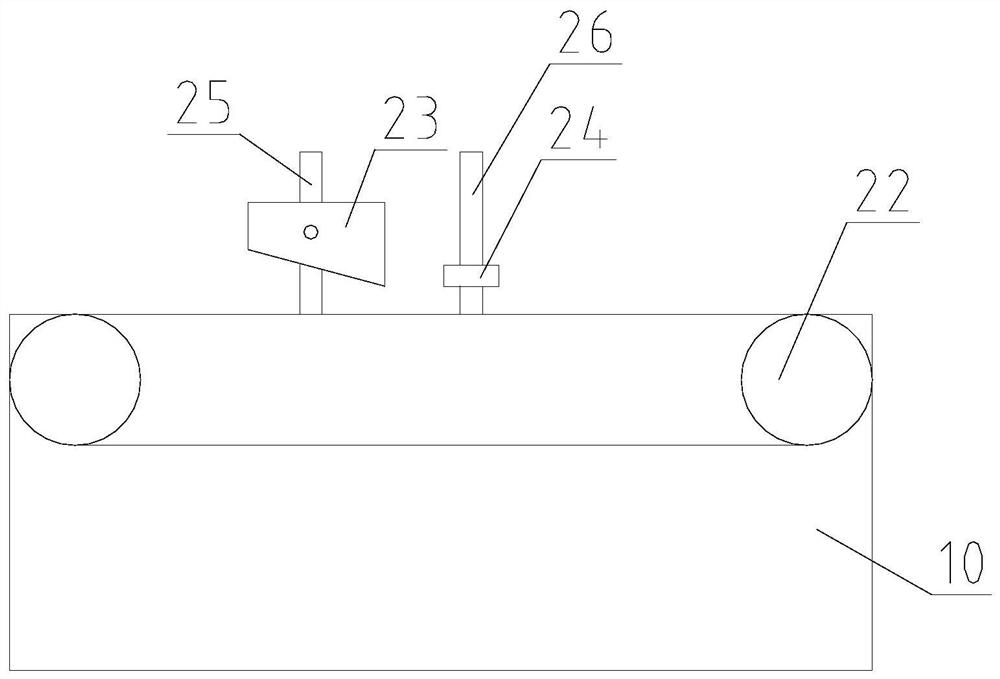

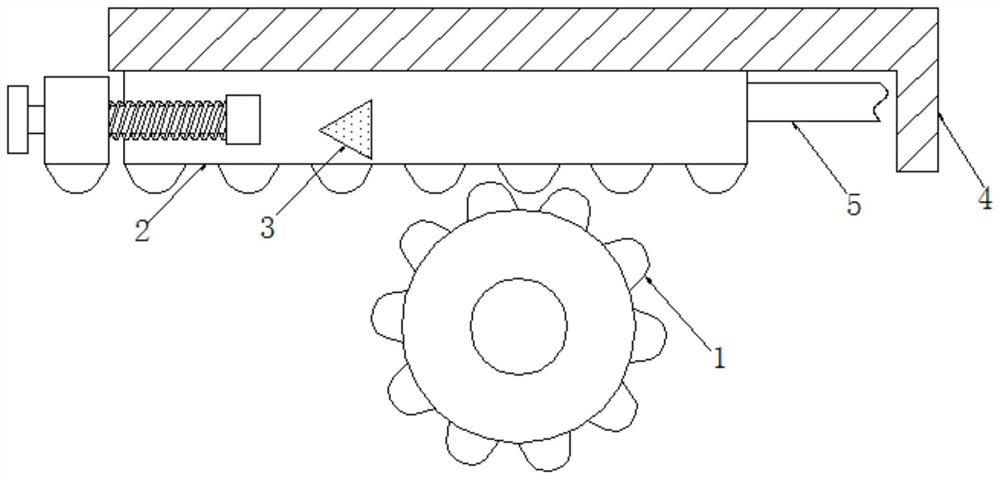

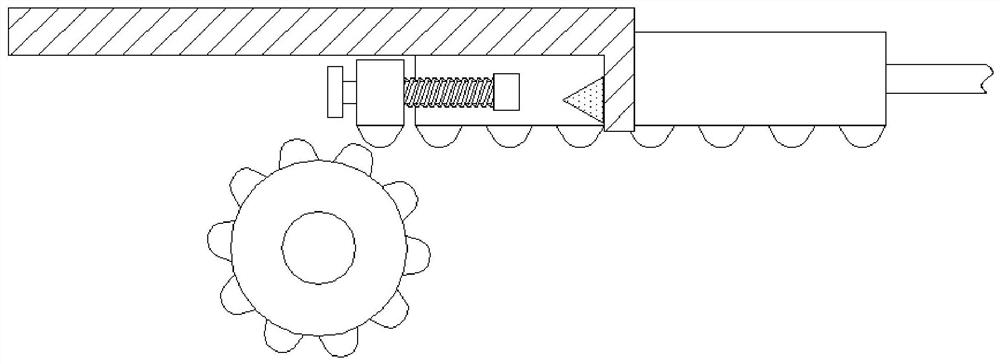

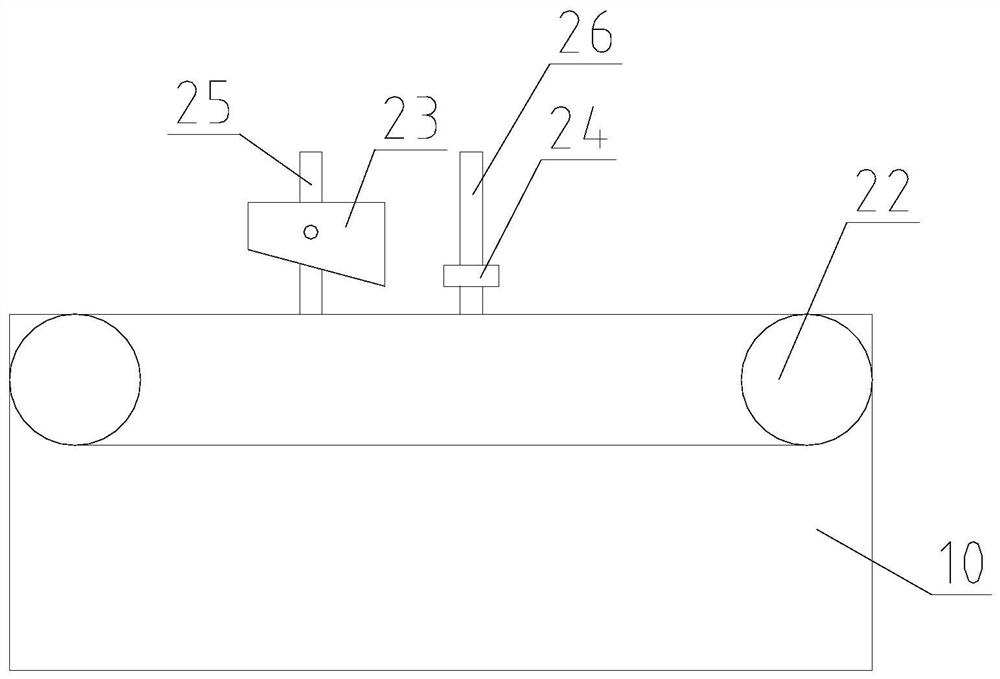

Transmitting equipment for processing roller ball pens, capable of performing automatic fixing and pushing

ActiveCN110921287ARotation does not affectEasy to operateConveyorsMetal working apparatusGear wheelControl engineering

The invention relates to the technical field of stationery, and discloses transmitting equipment for processing roller ball pens, capable of performing automatic fixing and pushing. The transmitting equipment for processing roller ball pens, capable of performing automatic fixing and pushing comprises a first gear, wherein a first toothed bar is movably connected to the top of the first gear; thefirst gear rotates to enable a push rod to move rightwards to a preset position, then the push rod stops moving without influencing the own rotating of the first gear, so that a subsequent grasping operation is facilitated, and the shoving operation cannot be influenced; the push rod moves rightwards to enable a moving block to move upwards to get close to materials, and besides, a second clampingblock on the upper side of the rotating rod is close to the materials to perform joint grasping, so that multi-direction grasping is realized, stable moving of the materials is guaranteed, and subsequent operations are facilitated; and a second rotating disk rotates to enable a second toothed bar to drive a second gear to be in reciprocating rotating, the second rotating disk synchronously rotates, and the materials are sequentially pushed by a first push block and a second push block, so that the uniformity of the pushing frequency is guaranteed, and the materials are advanced at a uniform speed. Through the adoption of the transmitting equipment for processing roller ball pens, capable of performing automatic fixing and pushing disclosed by the invention, space is effectively saved, andhigher working efficiency is achieved.

Owner:上海永力笔业有限公司

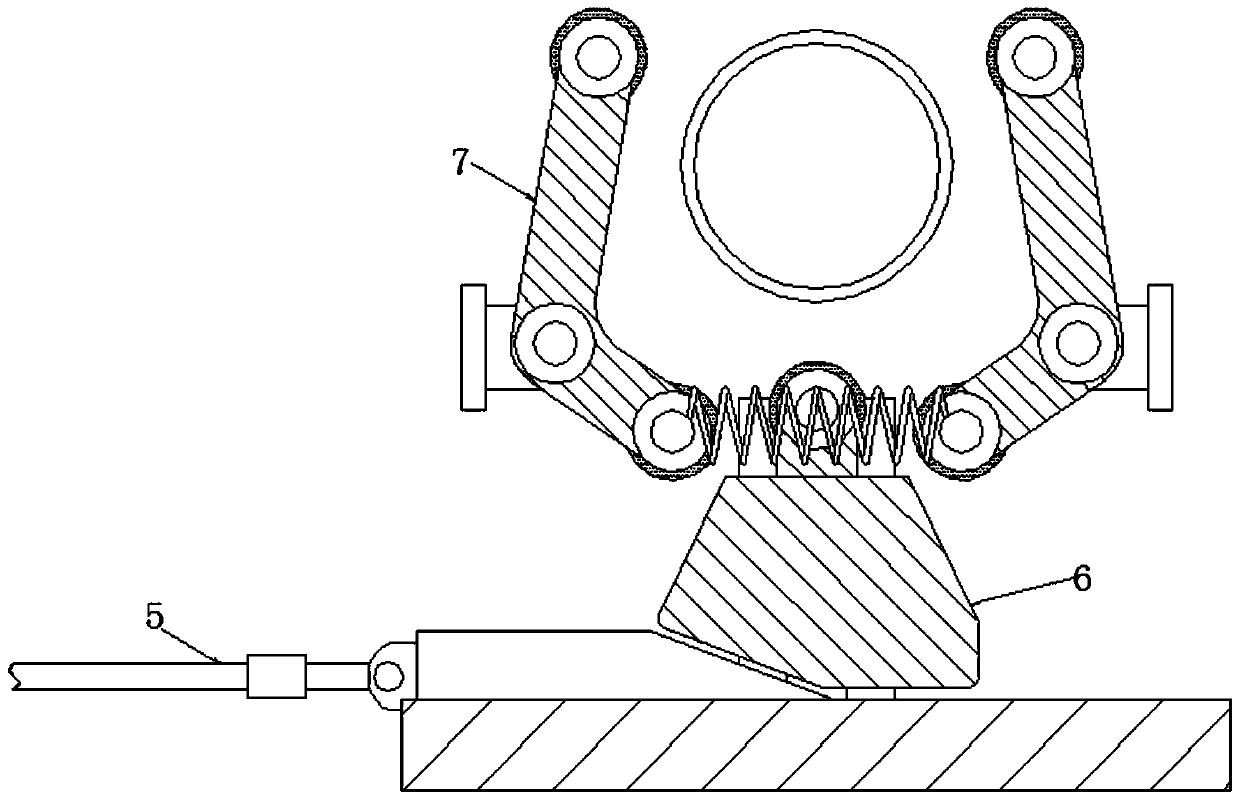

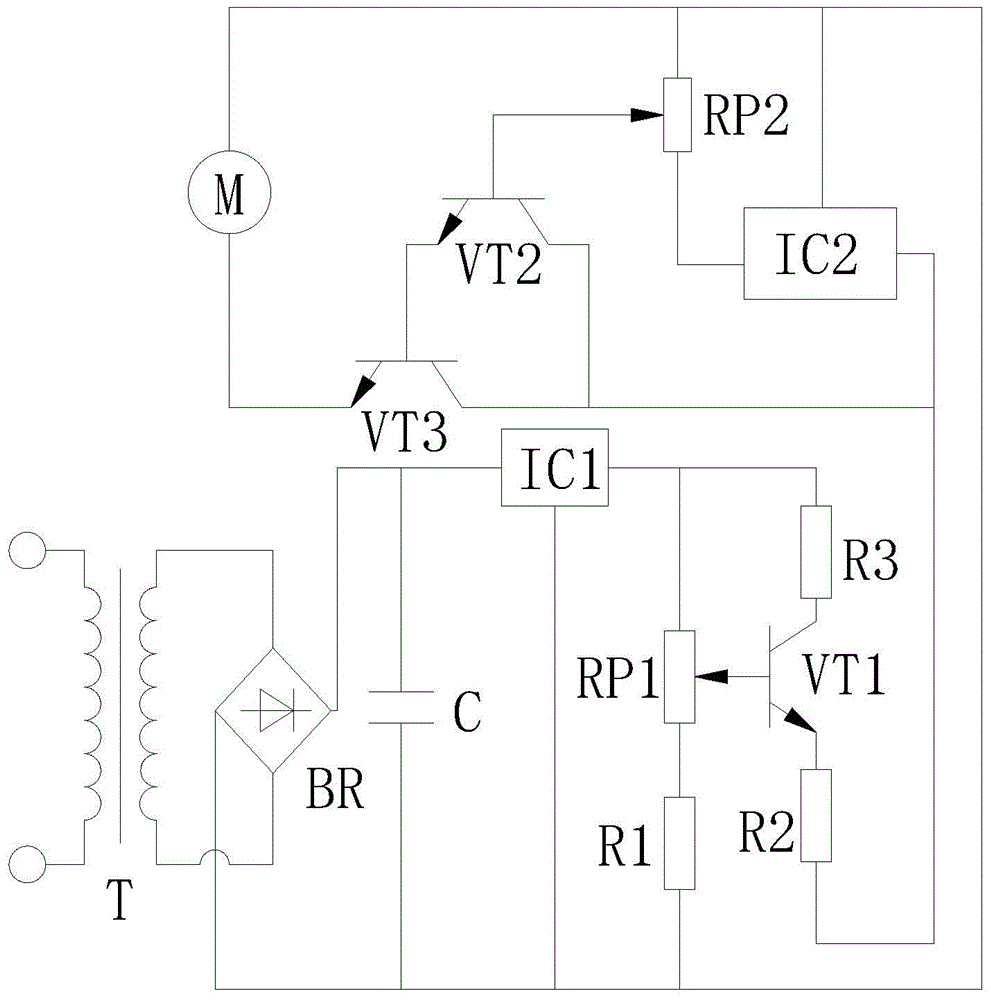

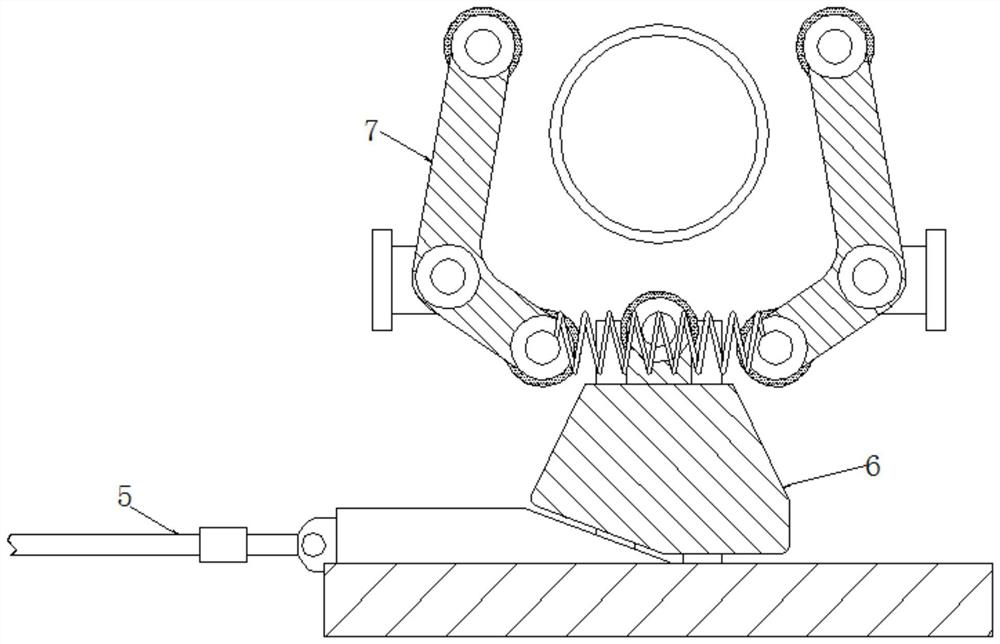

Speed stabilizer of welder welding head walking mechanism in long-distance pipeline

InactiveCN104668821AMove forward at a constant speedGuarantee welding qualityWelding/cutting auxillary devicesPipeline systemsPower flowTransformer

The invention discloses a speed stabilizer of a welder welding head walking mechanism in a long-distance pipeline. The speed stabilizer comprises first to third resistors, first to third triodes, a first potentiometer, a second potentiometer, a three-terminal regulator, an integrated voltage stabilizer, a capacitor, a transformer, a motor and a bridge rectifier circuit, wherein two ends of a primary winding of the transformer are respectively connected with two poles of an alternating-current power supply; and two ends of a secondary winding of the transformer are respectively connected with an alternating-current input end of the bridge rectifier circuit. The first potentiometer of the speed stabilizer of the welder welding head walking mechanism in the long-distance pipeline can control constant current output by the three-terminal regulator; and the current enters the integrated voltage stabilizer via the first triode, and is magnified to be accessed into the motor via the second triode and the third triode after the voltage stabilization through the integrated voltage stabilizer, so that the current is not changed due to the change of external voltage, the walking device of a welder can keep advance with uniform speed, and the welding quality is guaranteed.

Owner:CHENGDU XIONGGU JIASHI ELECTRICAL

A water-based pen processing conveying equipment that automatically fixes and pushes

ActiveCN110921287BRotation does not affectEasy to operateConveyorsMetal working apparatusGear wheelEngineering

Owner:上海永力笔业有限公司

A forming mechanism for pvc sheet

ActiveCN111746009BMove forward at a constant speedCause scratchesFlat articlesMetal working apparatusMolding machineEngineering

The invention relates to a molding mechanism for PVC boards, comprising a mixing machine, an extruder, a feeder, a mould, a film-coated calender, a tractor and a shearing machine connected in sequence from end to end, a film-coated calender and a traction machine. The machines are connected by brackets; there is a leveling device between the feeder and the mold to evenly spread the materials from the feeder; The plate output by the optical machine outlet; the rear section of the bracket is equipped with a trimming and slitting device. The trimming and slitting device includes two side guides and a trimming mechanism that can be close to or far away from each other. The side guides are used for PVC sheets. Centering guide before trimming, the trimming mechanism is used to symmetrically cut both sides of the PVC sheet. Beneficial effects: the material leveling device flattens and compacts the material, and the material enters the mold without holes and is uniform; the drying device can quickly dry the material; the symmetrical side guide plate can guide the centering of the PVC board, and the edge trimming mechanism can ensure Symmetry of the cut.

Owner:湖北佳美智能科技有限公司

Potato cleaning device

InactiveCN110269265AImprove cleaning efficiencySave human effortFood treatmentEngineeringCylindrical lens

The invention discloses a potato cleaning device. The device is characterized by comprising a barrel body, supporting legs, a cylindrical cage, conveying ribs, a material collecting bin, a bottom plate, a motor, a speed reducing box and a feeding hopper, wherein the upper end of the cylinder body is in an opening shape, a containing groove is formed in the outer wall of the left side of the barrel body, the feeding hopper is connected to the top of the barrel body, and the three conveying ribs are arranged on the inner side face of a cavity of the cylindrical cage at equal intervals; a support at one end of the cylindrical cage is fixedly connected with a driving short shaft, and a support at the other end of the cylindrical cage is fixedly connected with an auxiliary short shaft; the driving short shaft penetrates through the left side of the barrel body and is arranged on the containing groove through a bearing block, and the end of the driving short shaft is connected with a driven belt wheel; the auxiliary short shaft is arranged on the top of the right side of the barrel body through a bearing block, and the outer wall of the right side of the barrel body is hermetically connected with the material collecting bin and is provided with a discharge opening communicated with the material collecting bin; the output end of the motor is connected with the input end of the speed reducing box, and the output end of the speed reducing box is sleeved with a driving belt wheel; the driving belt wheel is connected with the driven belt wheel through a belt. The device has the advantages of being simple in structure, high in efficiency and low in production cost.

Owner:黄元进

Medical automatic adjusting stretcher

InactiveCN111110461AMove forward at a constant speedAvoid secondary damageStretcherBilateral symmetryDriving mode

The invention discloses a medical automatic adjusting stretcher. The stretcher comprises a front baffle and a rear baffle which are arranged on the left side and the right side respectively, an upperbaffle is arranged on the upper end face of the rear portion of the front baffle and the upper end face of the front portion of the rear baffle, armrests are fixedly installed on the upper end face ofthe upper baffle in a bilateral symmetry mode, cushions located in the armrests are arranged on the upper end faces of the upper baffle, the front baffle and the rear baffle, and the front and rear end faces of the upper baffle, the front baffle and the rear baffle form upper grooves which are symmetrical front and back. The stretcher can be adjusted according to the height of a patient, so thatmedical staff can conveniently perform transportation on the patient. Moreover, when the patient is transferred, the stretcher can be moved to a sickbed conveniently and quickly by adjusting the height of the stretcher, and the patient can advance at a constant speed by adopting an automatic driving mode.

Owner:ZIBO HAIRUI MEDICAL EQUIP CO LTD

Processing equipment for woodware

InactiveCN102166771BControl feed rateMove forward at a constant speedWood compressionEngineeringHorizontal and vertical

The invention discloses processing equipment for woodware, which is characterized in that: an upper connecting plate is coupled with three upper rollers; a lower connecting plate is coupled with lower rollers which have the same number as the upper rollers and correspond to the upper rollers one to one; a longitudinal pressing plate device is arranged on the same worktable at an inlet end or an outlet end and consists of at least two left rollers and at least two right rollers; and a coating groove is formed on each roller. The invention has the advantages that: the equipment can press the horizontal and vertical surfaces of the woodware, and has a shaping effect on a floor simultaneously, the processing quality of the equipment is ensured, the equipment can paint the woodware while rolling the woodware, a paint can fully infiltrate into pipe holes of the woodware due to friction between the rollers and the surface of the woodware, and can be adhered to the surface of the woodware more firmly, and higher sealing property is achieved.

Owner:佛山市南海纵华家具有限公司

Progress bar realization method and device

ActiveCN103488555BSolve the problem of pausing forwardSolve the problem of fast and slow progressHardware monitoringSpecific program execution arrangementsTask completionProgress bar

The invention provides a method for realizing a progress bar, comprising: calculating the completion time of a task; setting a constant speed interval in the progress bar corresponding to the task, and the constant speed interval accounts for more than half of the total length of the progress bar; in the constant speed interval according to The task completion time controls the progress bar to advance at a constant speed. The invention can make the progress bar advance at a constant speed and smoothly, and solve the problem that the progress bar is suspended when waiting for the completion of subtasks during the progress process, and in most cases, the progress bar advances fast and sometimes slow.

Owner:BEIJING QIHOO TECH CO LTD

Progress bar setting method and device

ActiveCN103530145BSolve the problem of pausing forwardSolve the problem of fast and slow progressHardware monitoringProgram loading/initiatingCompletion timeTask completion

The present invention provides a method for setting a progress bar, comprising: calculating the completion time of a task; setting a constant speed interval in the progress bar corresponding to the task, and the constant speed interval accounts for more than half of the total length of the progress bar; The progress bar is controlled to advance at a constant speed according to the completion time of the task. The invention can make the progress bar advance at a constant speed and smoothly, and solve the problem that the progress bar is paused while waiting for the completion of subtasks during the progress bar, and in most cases, the progress bar advances fast and sometimes slow.

Owner:BEIJING QIHOO TECH CO LTD

A vehicle speed control method and system for an electric vehicle

ActiveCN108437793BReduce output torqueGuaranteed stabilitySpeed controllerVehicle fittingsSpeed control systemControl system

The invention provides a vehicle speed control method used for an electric vehicle. The method specifically includes the steps that the target vehicle speed is obtained; the current vehicle speed of the vehicle is obtained; the early warning vehicle speed smaller than the target vehicle speed is set according to the target vehicle speed; and a response is made when the current vehicle speed exceeds the early warning vehicle speed, and the motor output torque of the vehicle is controlled to be reduced, so that the current vehicle speed of the vehicle is stabilized at the target vehicle speed. The invention further provides a vehicle speed control system capable of achieving the provided vehicle speed control method and the electric vehicle. The motor output torque is controlled so that thevehicle speed can be controlled, the vehicle speed is stabilized at an expected value, traveling safety can be guaranteed, and meanwhile the driving and riding experience feeling is not reduced.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

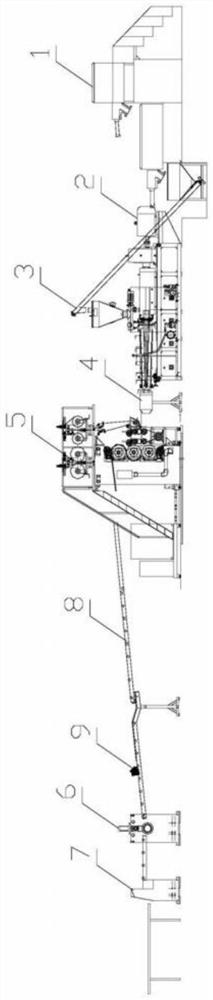

Tool clamp for pipeline laser cutting machine and pipeline laser cutting machine

ActiveCN114523219AAvoid affecting product qualityAvoid failureMetal working apparatusLaser beam welding apparatusMarking outLaser cutting

The invention provides a tool clamp for a pipeline laser cutting machine and the pipeline laser cutting machine. The tool clamp comprises a bottom plate, and a grinding wheel is fixedly arranged in a bearing frame; a cleaning sponge is embedded in a clamping groove which is formed in the clamping plate and used for containing a pipeline, a storage box is hinged to a piston shaft of the air cylinder, a marking pen is arranged at the bottom of the storage box in a communicating mode, a linkage rod and a rope winding column are hinged to the interior of the transverse plate, and a marking rope is wound between the linkage rod and the rope winding column. A pipeline defect detector is fixedly arranged at the bottom of the transverse plate; a positioning block is arranged on the nut block in a buckled mode and can drive the pipeline to rotate. According to the tool clamp for the pipeline laser cutting machine and the pipeline laser cutting machine, the end of a pipeline can be polished, whether defects exist in the pipeline or not can be detected, the utilization rate of the pipeline is higher, and the tool clamp is very worthy of popularization.

Owner:中交三航(南通)海洋工程有限公司

Propulsion hydraulic system of hard rock roadheader test bench

ActiveCN105020187BPropel at a constant speedMove forward at a constant speedServomotorsElectro hydraulicFuel tank

The invention discloses an experimental table propelling hydraulic system of a hard rock boring machine. The experimental table propelling hydraulic system comprises an oil feeding pipeline, wherein one end of the oil feeding pipeline is communicated with an oil tank; the other end of the oil feeding pipeline is sequentially connected with a filter, a constant delivery pump, a one-way valve and a stop valve; an oil outlet of the stop valve is connected with a first opening of a three-position four-way electro-hydraulic servo valve; a fourth opening of the three-position four-way electro-hydraulic servo valve is connected with inlets of first, second, third and fourth one-way proportional pressure reducing valves; each of oil outlets of the first, second, third and fourth one-way proportional pressure reducing valves is connected with a pressure sensor and a rodless cavity of a propelling cylinder; rod cavities of four propelling cylinders are connected with a third opening of the three-position four-way electro-hydraulic servo valve respectively; a displacement sensor is arranged in each of the four propelling cylinders; and a second opening of the three-position four-way electro-hydraulic servo valve is connected with the oil tank. With the adoption of the system, main beam constant-speed propelling can be realized, unbalance loading is restrained when the main beam is loaded in an unbalanced mode, and steering is matched when the main beam is steered.

Owner:TIANJIN UNIV

Board and board processing equipment

The invention discloses a board and board processing equipment, which has the advantages that a lower roller on one end of the equipment is simultaneously connected with an upper roller on the end and another upper roller adjacent to the upper roller by a driving wheel to form a first platen device; an upper roller on the other end of the equipment is simultaneously connected with a lower roller on the end and a lower roller adjacent to the lower roller by a driving wheel to form a last platen device; the first platen device and the last platen device have low rotation speed, but one lower roller in the middle and one upper roller adjacent to the upper roller which is opposite to the lower roller in the middle are connected by a driving wheel to form a middle platen device; the rotation speeds of the adjacent platen devices are high and low alternately, thus, the one surface of the board on some processing point only is quickly polished under the press of the roller; and the upper surface, the lower surface, the back side and the front side of the quick roller are all provided with quick rollers, thus ensuring that the board can not be driven by the roller with high rotation speedduring feeding so as to better control the board feeding speed and cause the board to advance at constant speed. In addition, relatively shorter boards also can be processed.

Owner:韩付芹

a frying machine

The invention relates to the frying machinery field and specifically relates to a frying machine. The frying machine comprises a main frame, a frying tank and a conveying chain. The frying machine is characterized in that the frying tank is mounted on the main frame and a heating tube is mounted at the bottom of the frying tank; the conveying chain is mounted at a side close to the frying tank inside the main frame, a separator is mounted on the conveying chain and a cylinder is mounted on the separator; a hot oil tank is mounted on the top support of the main frame, a power distribution box is fixed on the outer surface of the hot oil tank, a thyristor and a frequency converter are mounted in the power distribution box, respectively, the thyristor is connected with the heating tube, and the frequency converter is connected with the tachometer of the conveying chain; an oil injection tube is mounted at a side close to the outer surface of the hot oil tank, and a transmission chain is mounted at a side close to the conveying chain adjacent to the oil injection tube. The factor of poor conveying effect of the previous frying machine is overcome; the frying machine is not only convenient to operate and capable of realizing large-scale frying process, and also capable of saving oil and non-sticky to pan; the fried cakes are regular and beautiful in appearance.

Owner:PENGLAI JINGLU FISHERY

Fixtures for pipe laser cutting machines and pipe laser cutting machines

ActiveCN114523219BAvoid affecting product qualityAvoid failureMetal working apparatusLaser beam welding apparatusMarking outEngineering

The invention provides a tooling fixture for a pipeline laser cutting machine and a pipeline laser cutting machine, including a bottom plate, a grinding wheel is fixedly arranged in the bearing frame; a clamping slot for placing a pipeline is provided in the clamping plate A cleaning sponge is embedded in the center, a storage box is hinged on the piston shaft of the cylinder, and a marker pen is connected to the bottom of the storage box, and a linkage rod and a rope winding column are hinged in the horizontal plate. A marking rope is wound between the linkage rod and the rope winding column, and a pipeline defect detector is fixedly installed on the bottom of the horizontal plate; a positioning block is mounted on the nut block, and the positioning block can drive the pipeline to rotate. The invention provides a tooling fixture for a pipeline laser cutting machine and a pipeline laser cutting machine, which can polish the end of the pipeline, and can also detect whether there is a defect in the pipeline, so that the availability of the pipeline is higher, which is very worthwhile promote.

Owner:中交三航(南通)海洋工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com