Propulsion hydraulic system of hard rock roadheader test bench

A technology of hard rock roadheader and hydraulic system, applied in mechanical equipment, fluid pressure actuating device, servo motor, etc., can solve problems such as less research, and achieve the effects of reducing cost, suppressing eccentric load, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

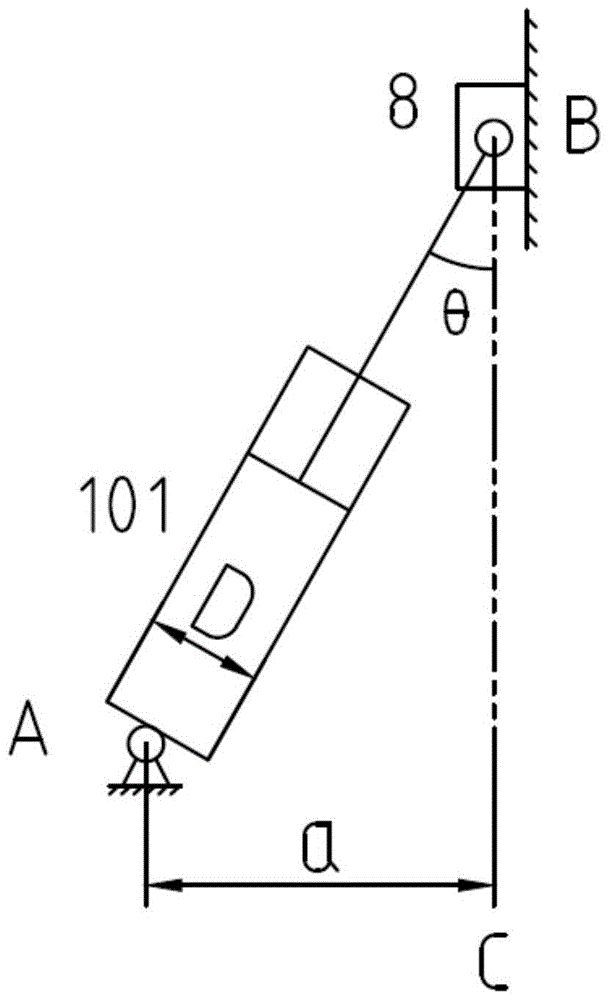

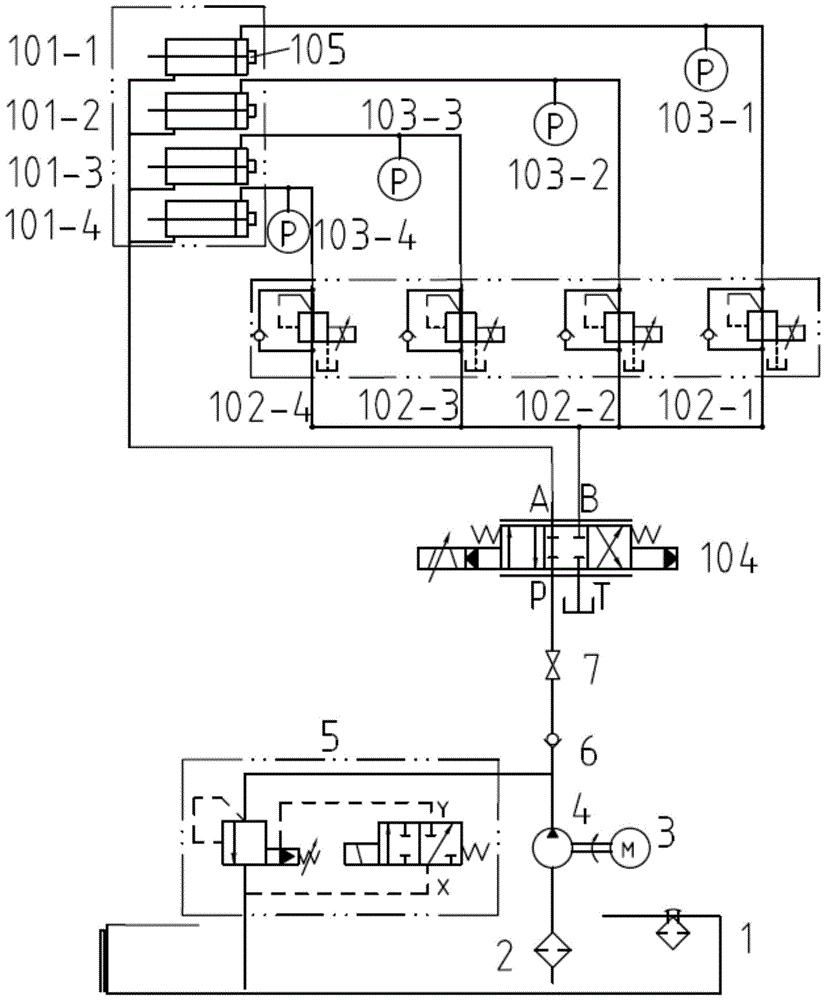

[0020] refer to figure 1 , set the distance between the two hinges A and B at the initial moment as X 0 , the cylinder rod displacement of the propulsion cylinder is S, in the figure: the vertical distance from the hinge A to the guide rail axis C of the main beam 8 is a, the angle between the propulsion cylinder 101 and the main beam 8 is θ, and the diameter of the rodless cavity of the propulsion cylinder 101 is D.

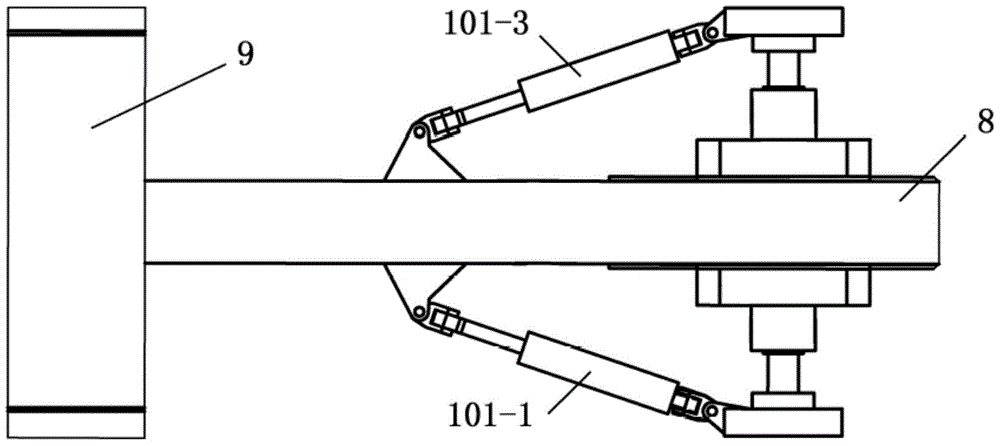

[0021] refer to figure 2 , illustrates the connection relationship between the propulsion cylinder 101 and the main beam 8, the cutter head 9, and the like. Among the figure: the main beam 8 is connected with the cutter head 9, and the piston rod of the propulsion cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com