Tool clamp for pipeline laser cutting machine and pipeline laser cutting machine

A technology of laser cutting machine and fixture, applied in the direction of manufacturing tools, household appliances, other household appliances, etc., can solve the problems of complicated operation, transfer pipes, repositioning pipes, etc., and achieve the effect of high availability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

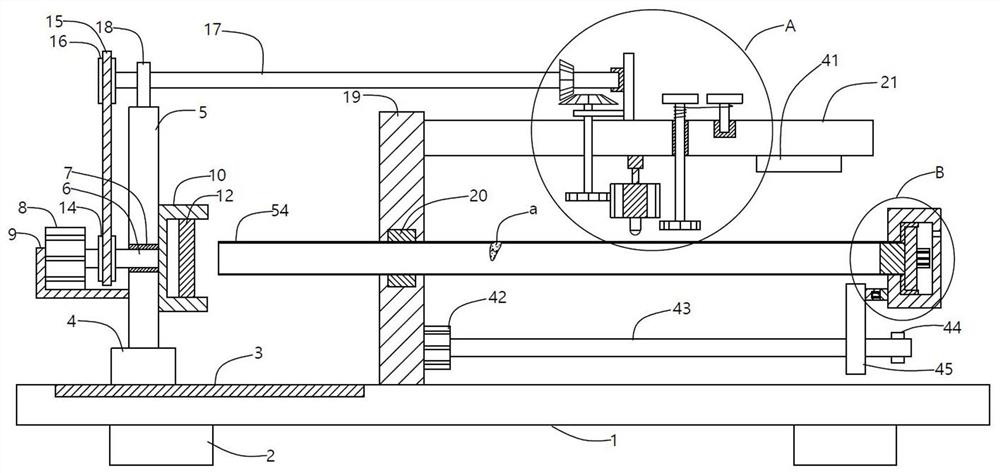

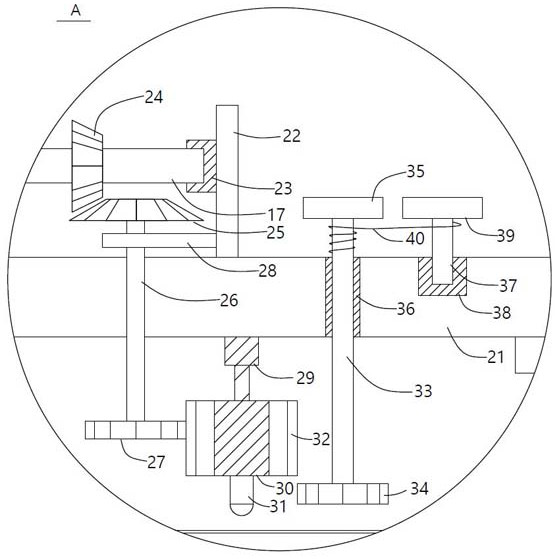

[0032] A tooling fixture for a pipeline laser cutting machine, comprising a base plate 1, a support base 2 is symmetrically fixed at the bottom of the base plate 1, and a support base 2 of a specific height can be flexibly set, thereby changing the height of the base plate 1, which is convenient for users to clamp The guide rail 3 is embedded in the top surface of the bottom plate 1, and the slider 4 is movably arranged on the guide rail 3. The slider 4 can slide along the guide rail 3, and then adjust the position. A support column 5 is fixedly arranged on the support column 5, a rotating rod 6 is hingedly arranged in the support column 5, one end of the rotating rod 6 is fixed on the output shaft of the first rotating motor 8, and the other end of the rotating rod 6 is fixed with a bearing frame 10, Therefore, when the first rotating motor 8 is started, the bearing frame 10 is driven to rotate by the rotating rod 6, and the bearing frame 10 is fixedly provided with a grinding...

Embodiment 2

[0037] A tooling fixture for a pipeline laser cutting machine, comprising a base plate 1, a support base 2 is symmetrically fixed at the bottom of the base plate 1, a guide rail 3 is embedded in the top surface of the base plate 1, and a slider is movably arranged on the guide rail 3 4. In order to prevent the sliding block 4 from sliding spontaneously, a locking structure can also be added on both sides of the sliding block 4, thereby making the position of the supporting column 5 more stable. The sliding block 4 is fixedly provided with a supporting column 5, and the supporting column 5 A rotating rod 6 is arranged through the middle hinge, a first annular bearing 7 is embedded in the support column 5, and the rotating rod 6 is hingedly arranged in the first annular bearing 7, so the rotating rod 6 can be in the first annular bearing 7. A stable rotation occurs in the middle, so that the rotation of the grinding wheel 12 is also more stable, to avoid shaking, one end of the r...

Embodiment 3

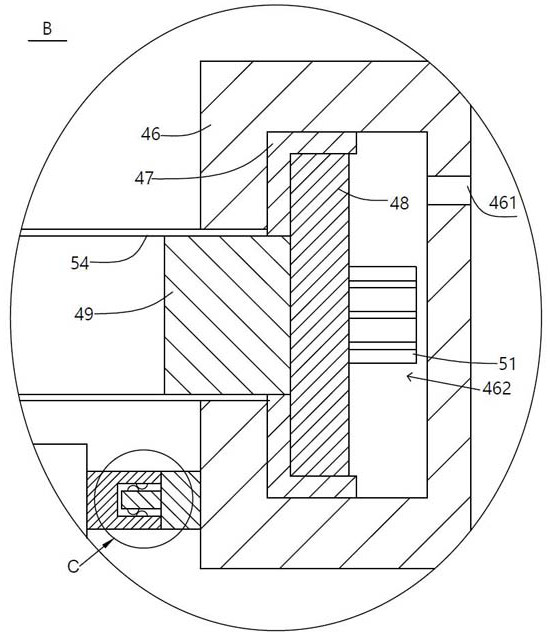

[0042] On the basis of the above-mentioned first or second embodiment, this embodiment further defines and further defines the specific structure of "the positioning block 46 is used for adsorbing and positioning the end of the pipe 54 and can drive the pipe 54 to rotate". It is disclosed, specifically: the positioning block 46 is provided with a ventilation hole 461 and an installation slot 462 that communicate with each other. The setting of the ventilation hole 461 enables the air in the external environment to freely enter and exit the installation slot 462, which is convenient for heat dissipation. The installation slot 462 is hingedly provided with The third annular bearing 47, the end plate 48 is fixedly arranged in the third annular bearing 47, so the end plate 48 can realize stable rotation in the third annular bearing 47, and the elastic inner support pad is fixedly arranged on the end plate 48 49. The diameter of the elastic inner support pad 49 is slightly larger th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com