Potato chip frying machine

A French fries machine and French fries technology, applied in the direction of oil/fat baking, etc., can solve the problems of low efficiency, trouble, poor taste, etc., and achieve the effects of easy drying, avoiding sticking, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

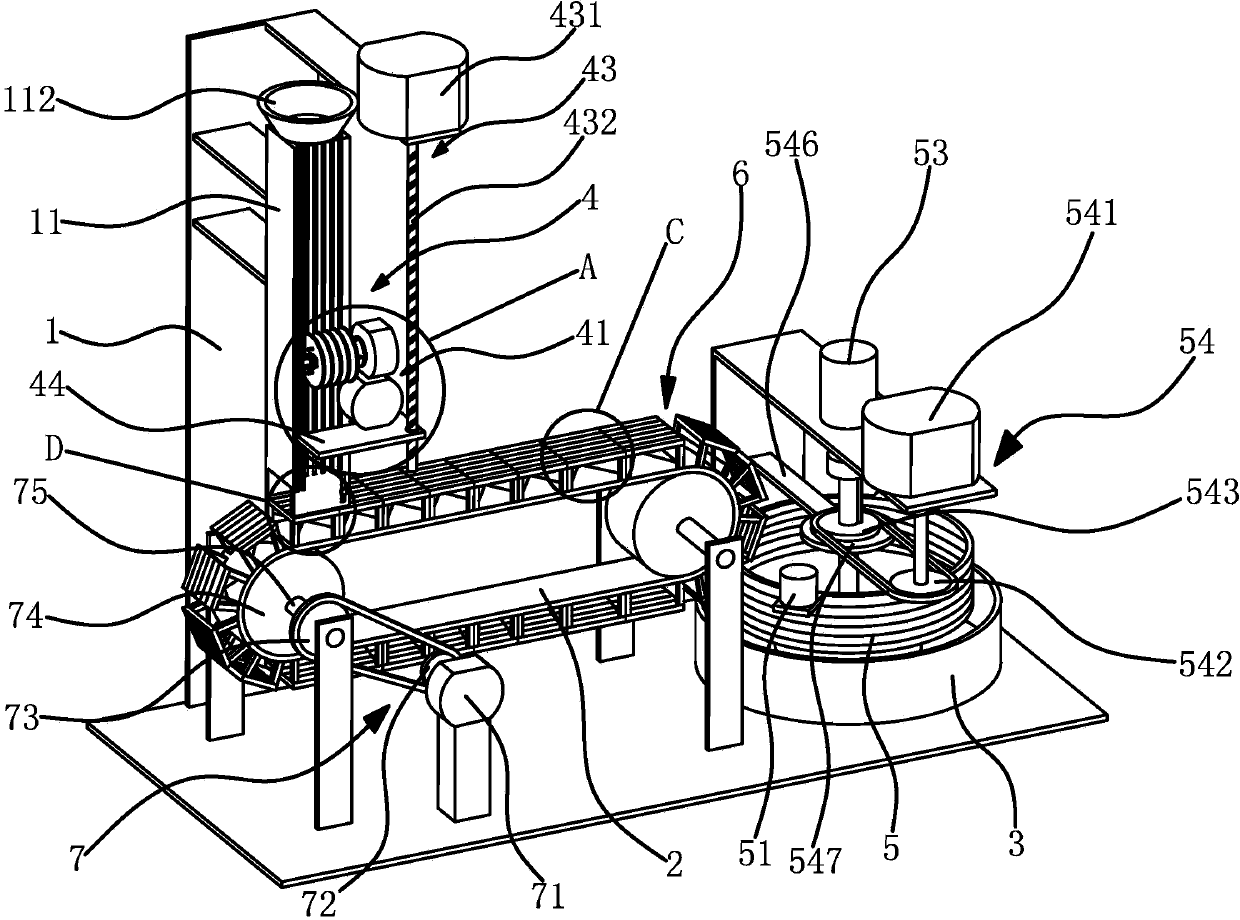

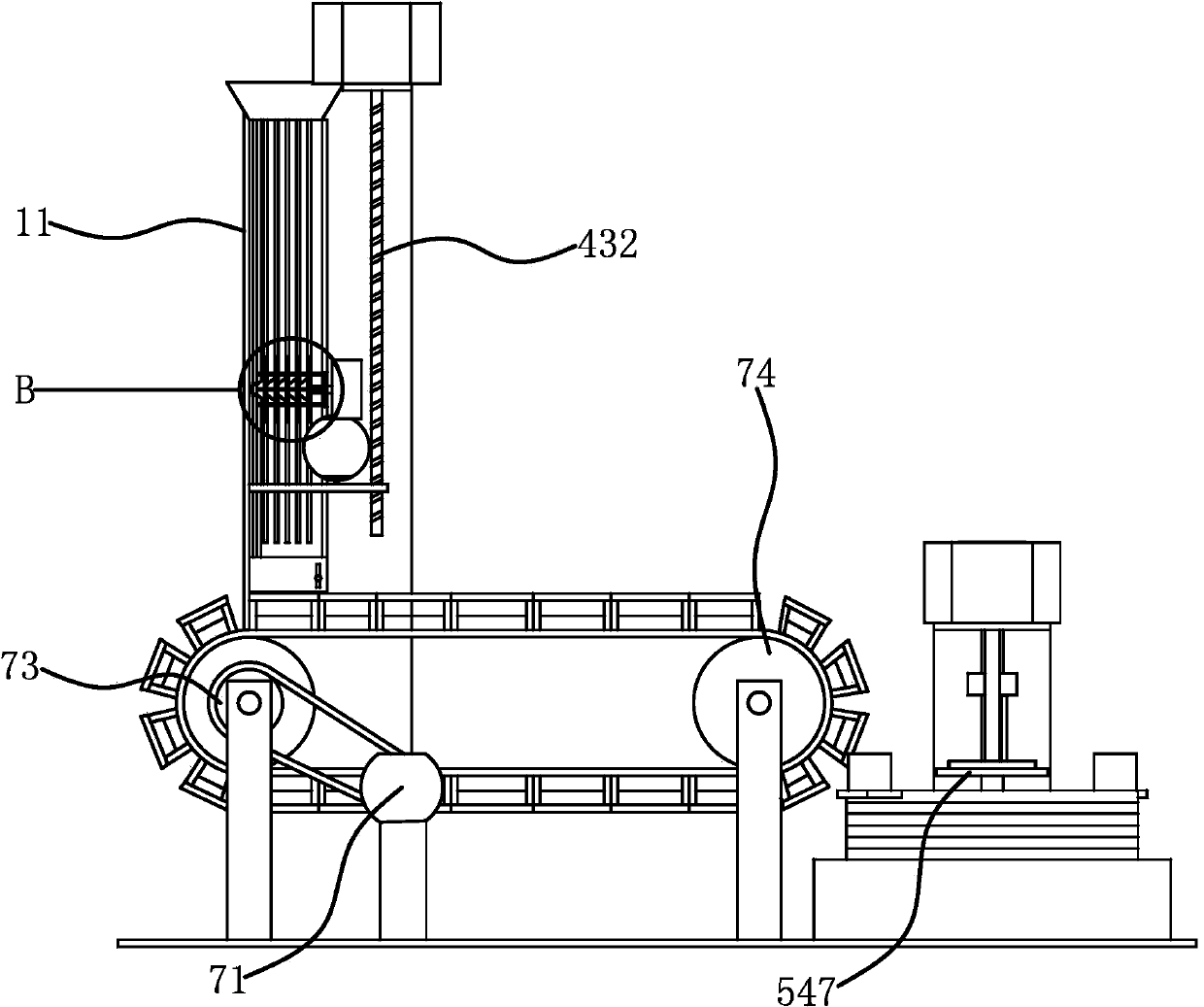

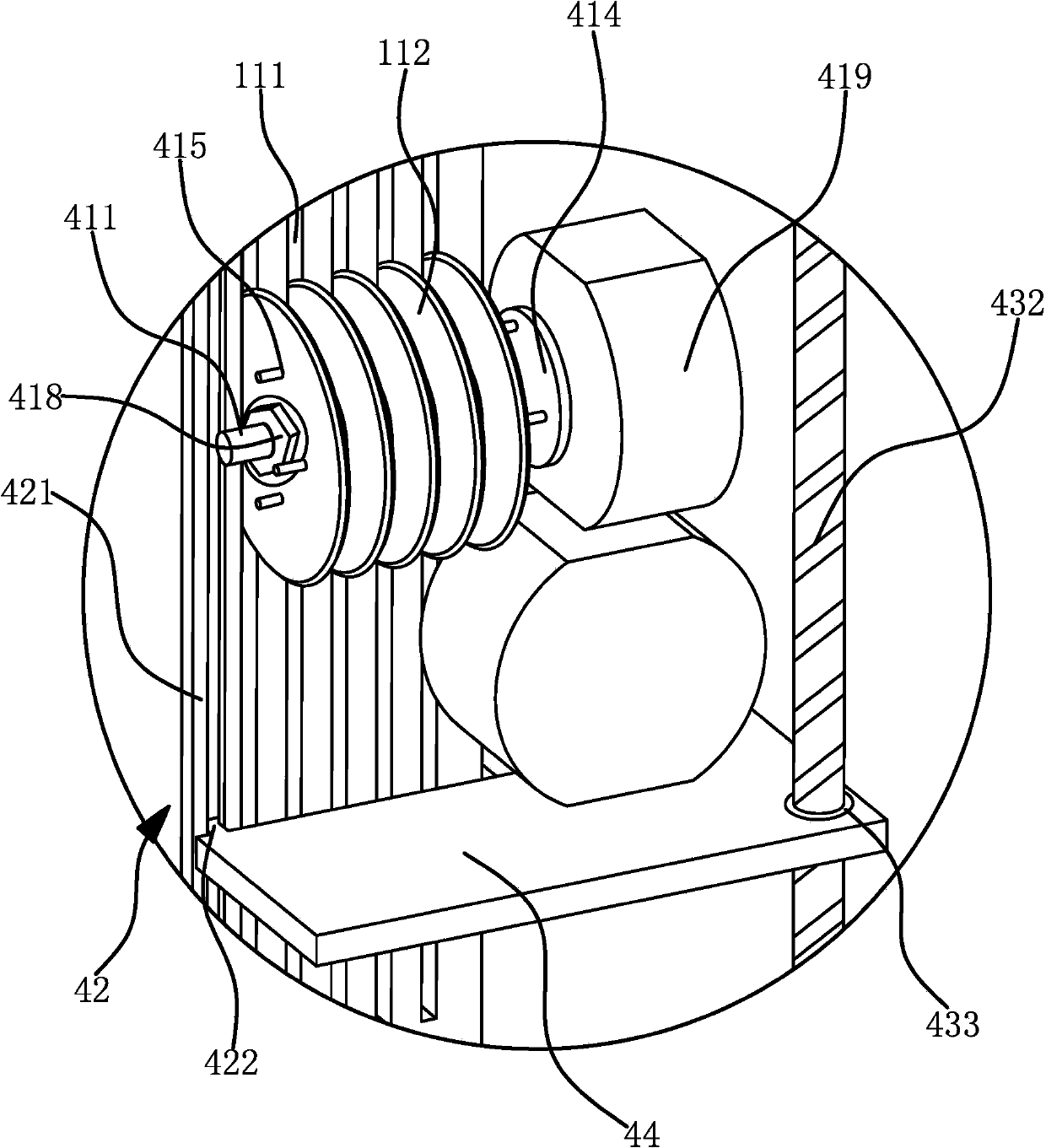

[0032] Such as figure 1 as shown, figure 2 Shown, a kind of French fries machine comprises frame 1, and frame 1 can be set up on the ground, and frame 1 is provided with a conveyer belt 2, and this conveyer belt 2 is connected with a drive mechanism-7, and drive mechanism-7 can Drive conveyor belt 2 to convey. A feed channel 11 is vertically provided above the input end of the conveyor belt 2, the lower end of the feed channel 11 is opposite to the upper side of the conveyor belt 2, a feed tray 112 is provided at the upper end, and an oil cylinder 3 is provided below the output end of the conveyor belt 2. 3 is used to hold edible oil, and edible oil is heated. The feeding channel 11 is provided with a cutting device 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com