Continuous vacuum frying oil removing machine

A vacuum frying and deoiling machine technology, applied in oil/fat roasting and other directions, can solve the problems of prolonged shelf life, inability to further reduce processing costs, limitation of processing varieties, etc., to reduce the damage of nutrients, improve repeated utilization, The effect of compaction and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, further describe structure and working process of the present invention by embodiment:

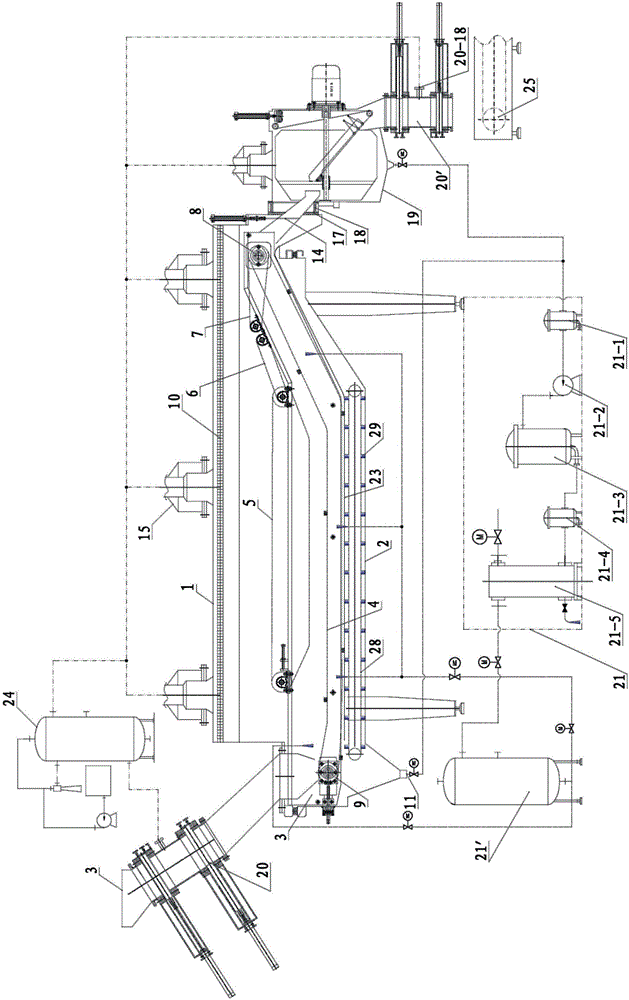

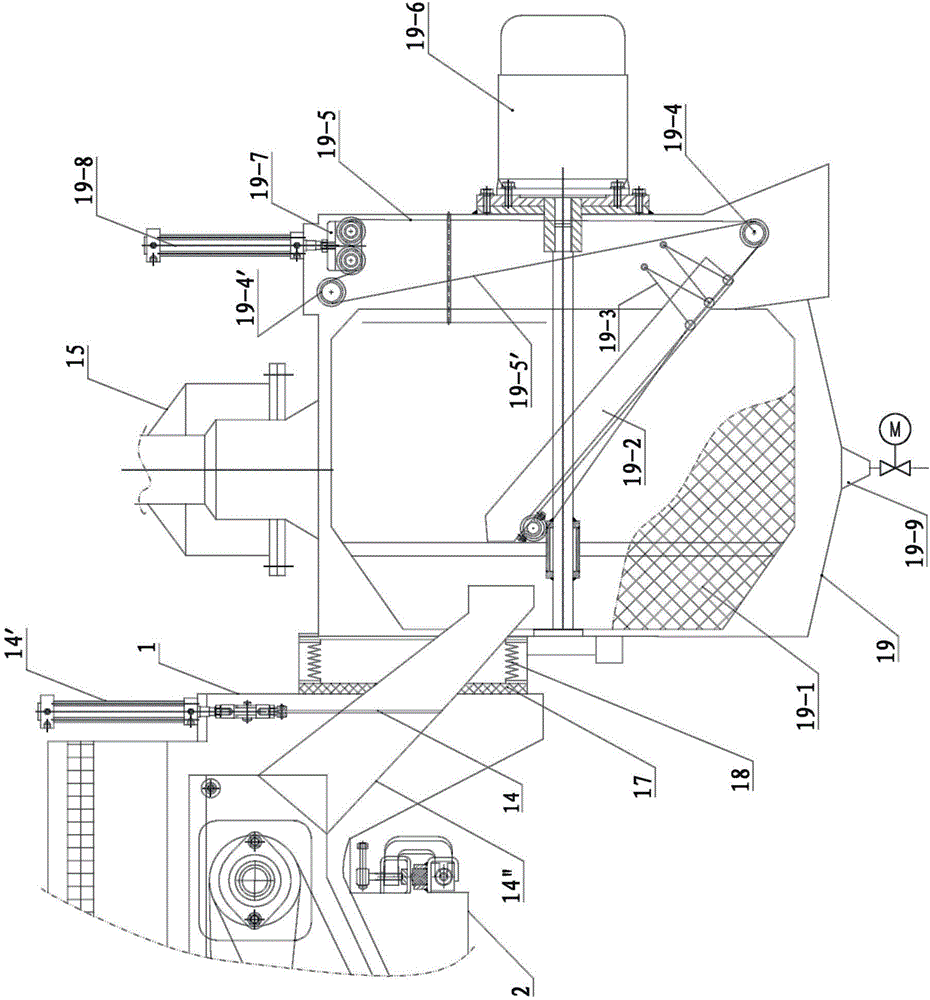

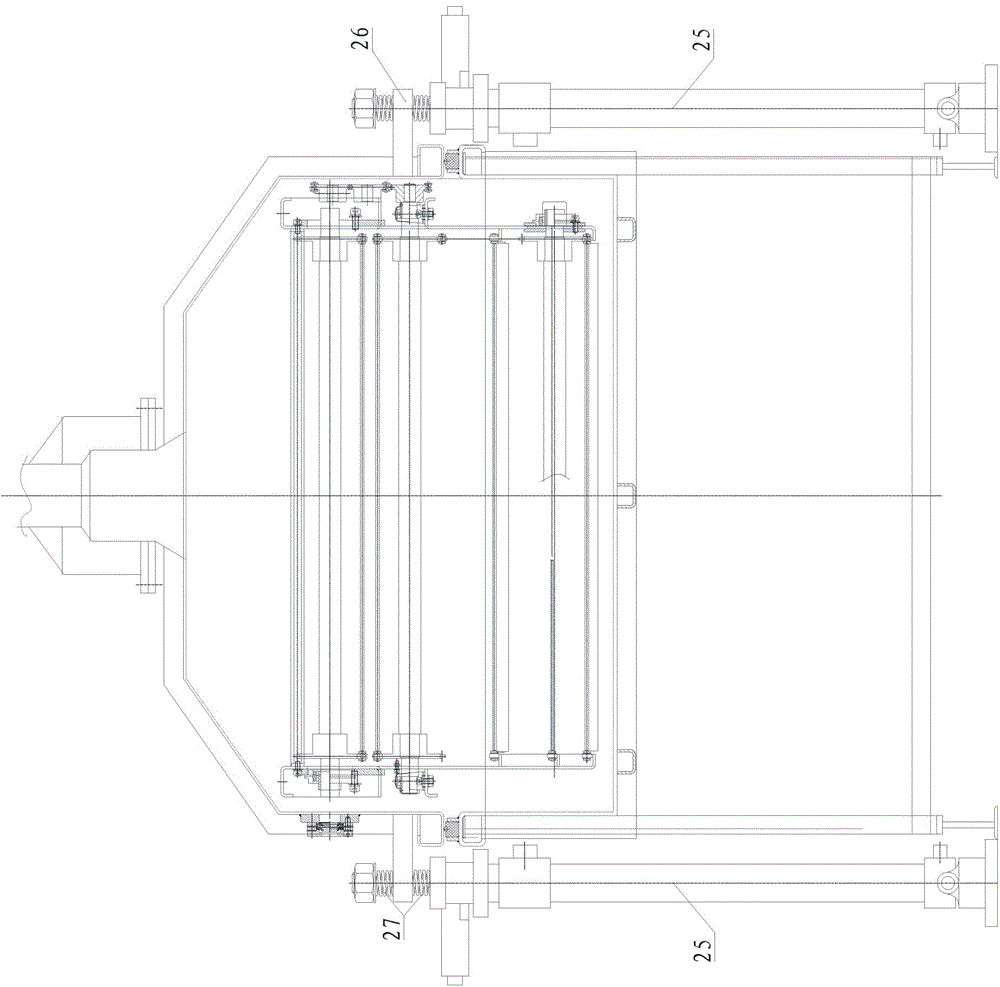

[0034] figure 1 It is a schematic diagram of the overall structure of a continuous vacuum frying and deoiling machine of the present invention, which is suitable for vacuum frying processing equipment with various varieties and large output.

[0035] Its working process is: the bulk material enters through the feed port (3) of the feed sealing device (20), and the air in the bulk material is evacuated to a certain level in the feed sealing device (20) through the pre-vacuum port (20-18). After the vacuum degree is reached, the bulk material falls from the outlet (20-12) of the feeding sealing device (20) onto the material conveying mesh belt (4) in the frying chamber, and after a period of dehydration, the material floats upwards. The floating material runs forward under the drive of the pressing mesh belt (5), and the material after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com