Frying machine

A frying machine and oil tank technology, which is applied in the direction of oil/fat baking, etc., can solve the problems of large temperature error, poor transmission effect, and short life of AC contactors, so as to improve the transmission effect and realize large-scale intensive frying Effect of processing and reducing labor cost operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

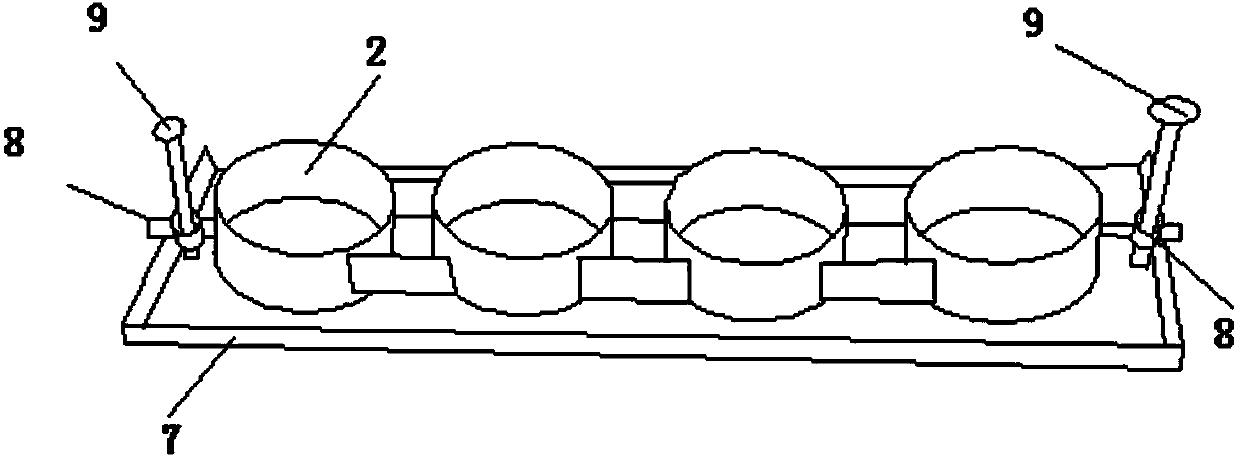

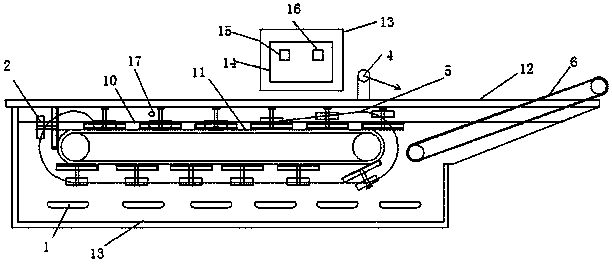

[0021] Such as figure 1 As shown, it is a schematic structural view of a frying machine, including a main frame 12, a frying tank 13, and a transmission chain 11. A frying tank 13 is installed on the main frame 12, and the bottom of the frying tank 13 is installed There is a heating pipe 1; a transmission chain 10 is installed on the side of the main frame 12 close to the frying tank 13, a partition 7 is installed on the transmission chain 11, and a cylinder 2 is installed on the partition 7; A hot oil tank 3 is installed on the top bracket of the main frame 12, and a power distribution box 14 is fixed on the outer surface of the hot oil tank 3, and a thyristor 15 and a frequency converter 16 are respectively instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com