Method for preparing cathode materials of power lithium ion secondary batteries

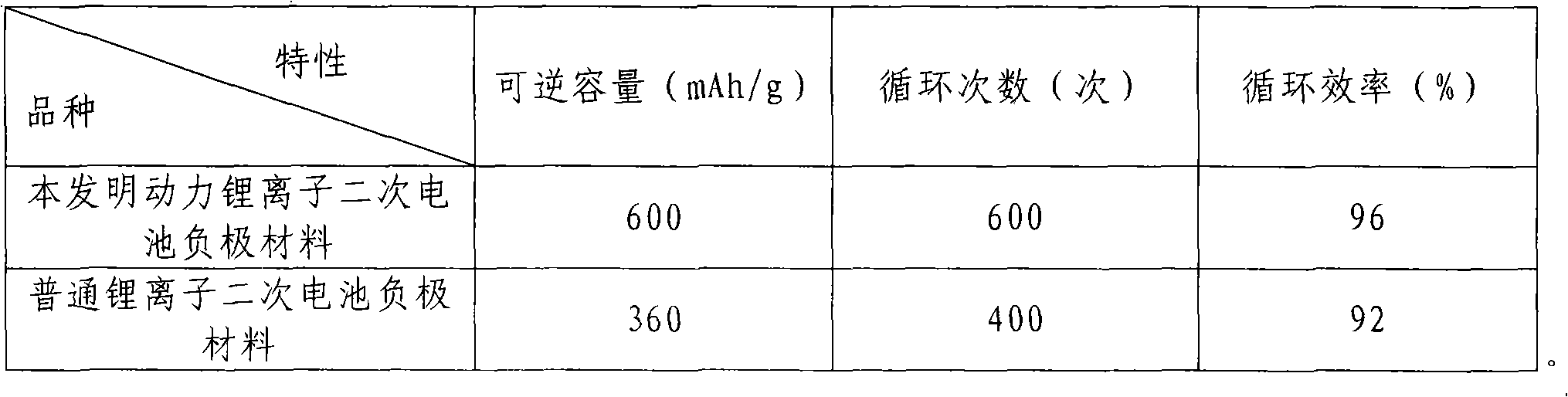

A secondary battery and negative electrode material technology, applied in the direction of electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of complex manufacturing process, less cycle times, environmental pollution, etc., and achieve complete pyrolysis, no shrinkage pores, and a state of fusion uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0012] The preparation method is as follows: use qualified phenolic resin, wash with water, and dry at 50°C to obtain qualified raw materials, add the processed raw materials and additives into the carbonization furnace in a ratio of 50:1, vacuumize, and press 3-5 ℃ / min heating to 600-800℃, keep the temperature for 3-5 hours, then cool down to room temperature naturally, use a pulverizer to pulverize the obtained solid matter to 35um and finer sections, and classify the 5-30um powder with a classifier, The powder is added with a coating agent at a ratio of 1:100 and then stirred in a stirred tank for 2-3 hours. The temperature of the tank is controlled at 90-100°C. After that, the resulting mixture is placed in an oven and heated at a heating rate of 5-10°C / min. to 300°C, keep the temperature constant for 2-3 hours, then heat the material to 700°C in a vacuum state at a heating rate of 10-15°C / min, and keep the temperature constant for 2-3 hours. ℃ / min heating rate to 2800 ℃, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cycle efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com