Tunnel type pyrolysis gasifying device and pyrolysis gasification method

A pyrolysis gasification, tunnel-type technology, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of low operability, low production efficiency, time-consuming and labor-intensive operation of feeding and discharging materials, and achieve metal recovery rate. High efficiency, improved productivity, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

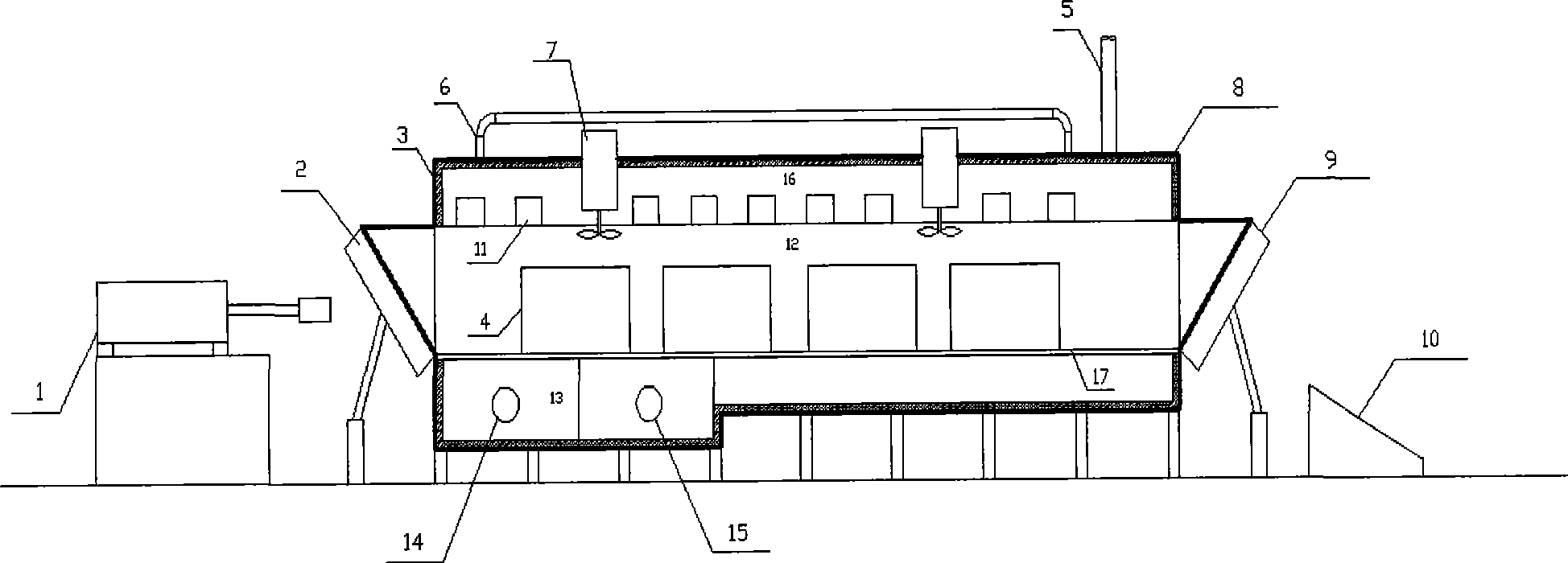

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Such as figure 1 As shown, the present invention is a tunnel-type pyrolysis gasification device. A feed platform, a pyrolysis furnace body, and a discharge platform are arranged in sequence from the feed end. Sealed furnace doors are arranged on both sides of the pyrolysis furnace body. There is a pyrolysis chamber 12, a combustion chamber 13, and a flue 16 between the pyrolysis chamber and the inner wall of the furnace. The upper part of the furnace body is provided with a smoke exhaust port 5 and a pyrolysis gas pipeline 6. The lower part of the furnace body is provided with a pyrolysis gas pipeline. Burner 14 and fuel burner 15, whole body of heater is square, and refractory fiber 8 is also laid outside body of heater. Wherein, the fuel burner 15 can be fuel oil or gas, and fuel oil is used as an example for description in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com