Metal element improved biochar-based nitrate radical adsorbent and preparation method thereof

A technology for improving biochar and metal elements, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve problems such as poor adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a metal element-improved biochar-based nitrate adsorbent, characterized in that it comprises the following steps:

[0044] 1) Preparation of straw material: crush 50-250g of straw, pass through a 40-100 mesh sieve, soak in deionized water for 24 hours, and then wash repeatedly with deionized water until the supernatant is colorless. The cleaned straw powder is placed in an oven, and dried at 80°C-120°C for 12-24h.

[0045] 2) Preparation of mixture A1 of straw material and metal salt solution

[0046] Prepare 50-250 mL of metal salt solution with a molar concentration of 0.5-2.0 mol / L, including but not limited to magnesium chloride, calcium chloride, and aluminum chloride solutions. The straw powder prepared above is mixed with the metal salt solution, soaked for 1h-4h, centrifuged to remove the supernatant, and dried in an oven at 60-80°C for 12-24h. Let the impregnated straw material obtained at this time be A1.

[0047] 3) Preparation of me...

Embodiment 1

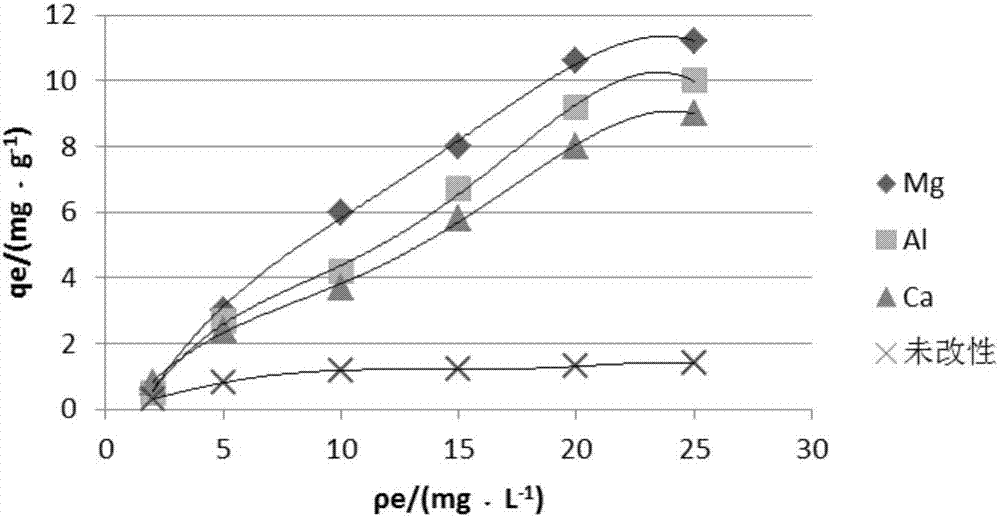

[0049] Embodiment 1 isothermal adsorption test

[0050] In order to obtain the adsorption performance of the adsorption material prepared by the present invention on nitrate, especially the parameters of the adsorption capacity, an isothermal adsorption test was carried out in this embodiment.

[0051] The preparation method of the adsorbent (that is, the aforementioned A2) is the same as before, using wheat straw as a precursor to prepare metal element-improved biochar. In order to determine the maximum adsorption capacity of biochar on nitrate nitrogen and related parameters, the Langmuir model and Freundlich model were used in this example to fit the isothermal adsorption data.

[0052] From the parameters obtained by fitting the two equations, it can be found that the adsorption process conforms to the assumption of the Langmuir model, that is, the adsorption process is monomolecular layer adsorption; the adsorbate is adsorbed on a specific adsorption site on the surface o...

Embodiment 2

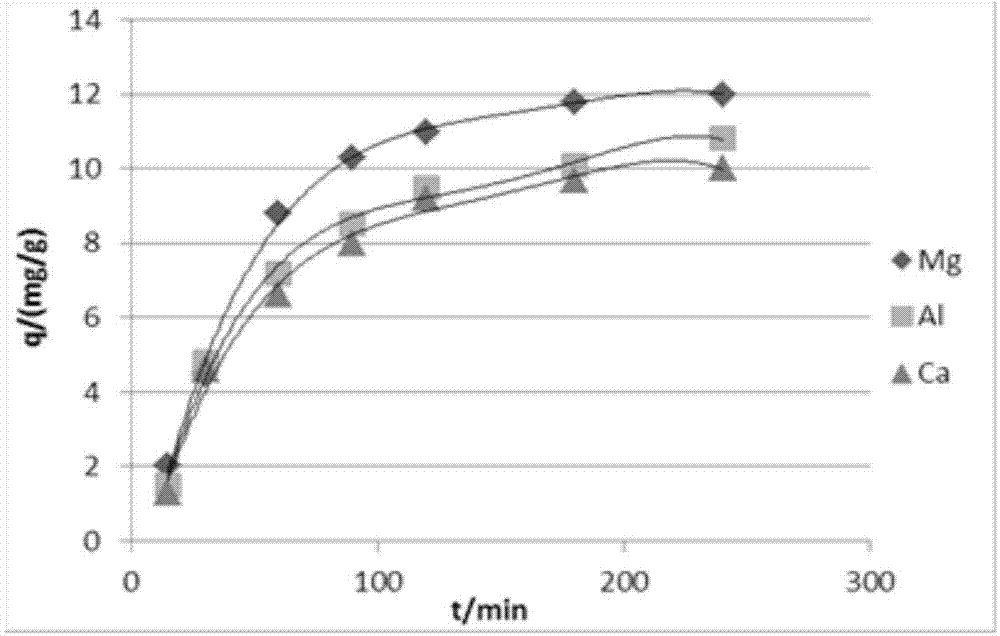

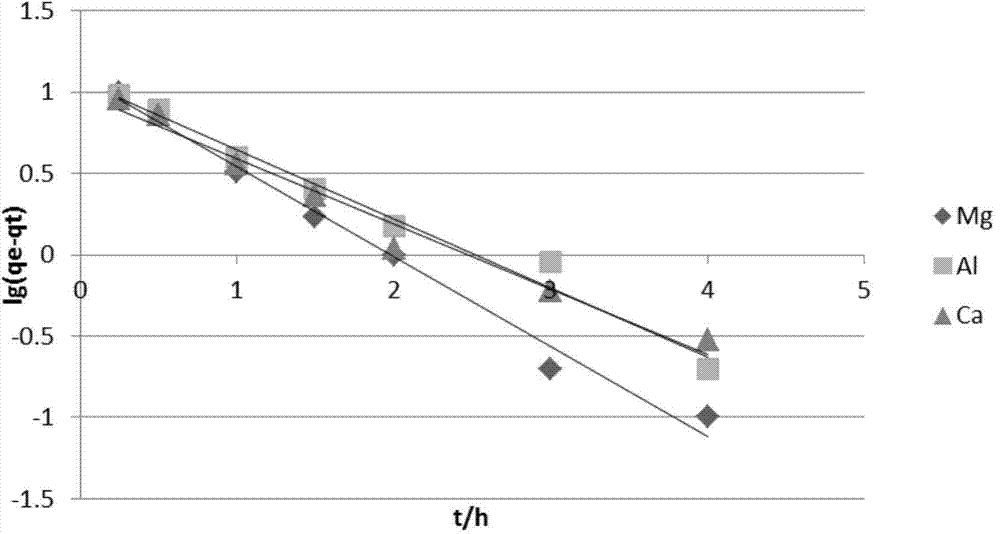

[0054] Embodiment 2 adsorption kinetics test

[0055] Under isothermal conditions, the adsorption kinetic curve of modified wheat straw to nitrate nitrogen was studied. The experimental results are shown in figure 2 . It can be seen from the figure that the adsorption process of various biochars can be roughly divided into three stages. The first stage is rapid adsorption (0-60min). The adsorbate quickly passes through the water film to reach the surface of the adsorbent, causing the adsorption amount to rise sharply. This stage should be a fast physical process; the second stage is the stage of decreasing adsorption speed (60 minutes). -120min), the adsorption amount increases slowly with time at this stage, and the adsorbate diffuses in the pores; the third stage is the adsorption equilibrium stage (120-240min), the adsorption reaches equilibrium, and the adsorption amount no longer increases with time. The saturated adsorption capacities of the three kinds of biochars wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com