Granular crop grain drying device and method

A drying device and small particle technology, applied in drying, dryer, heating device and other directions, to achieve the effect of simple mechanical structure, reduced heat loss, simple and convenient software and hardware control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing:

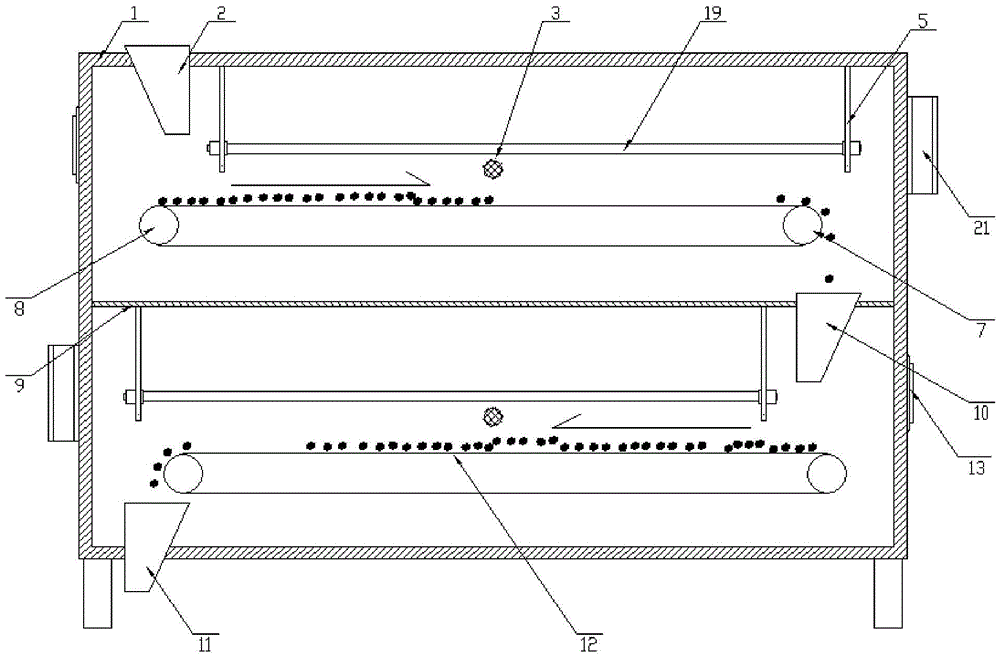

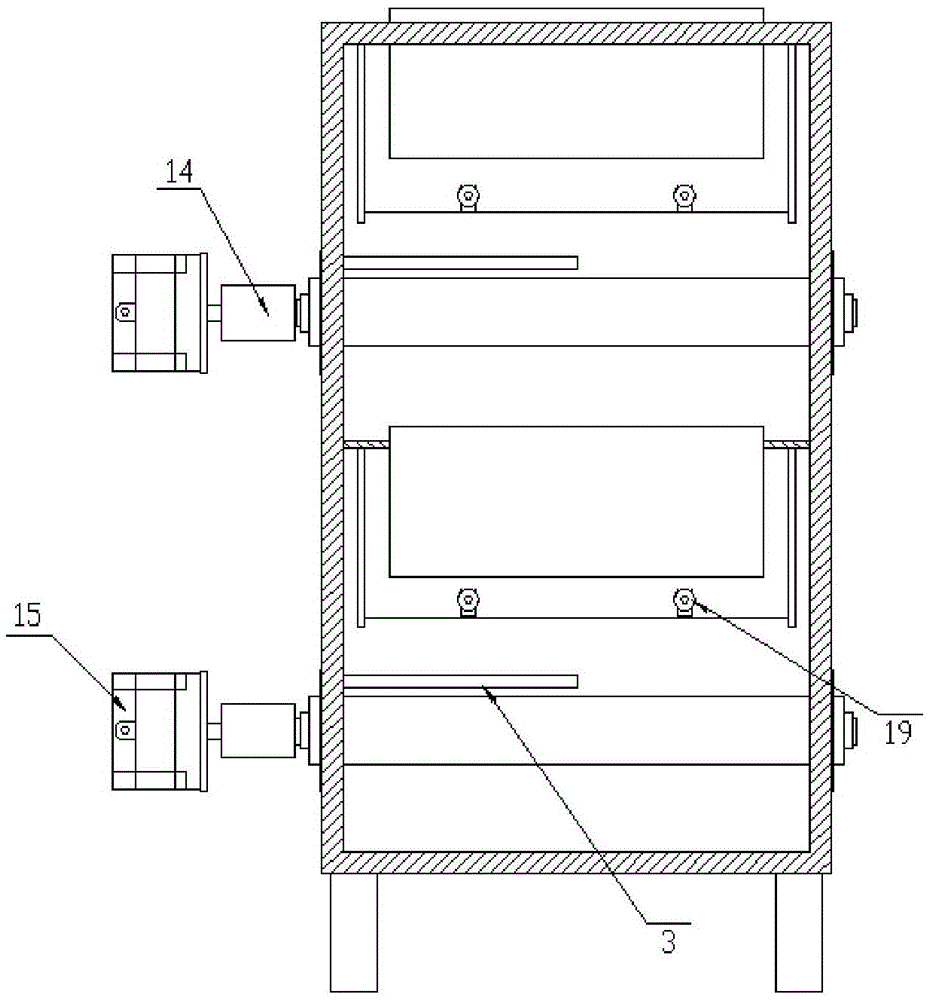

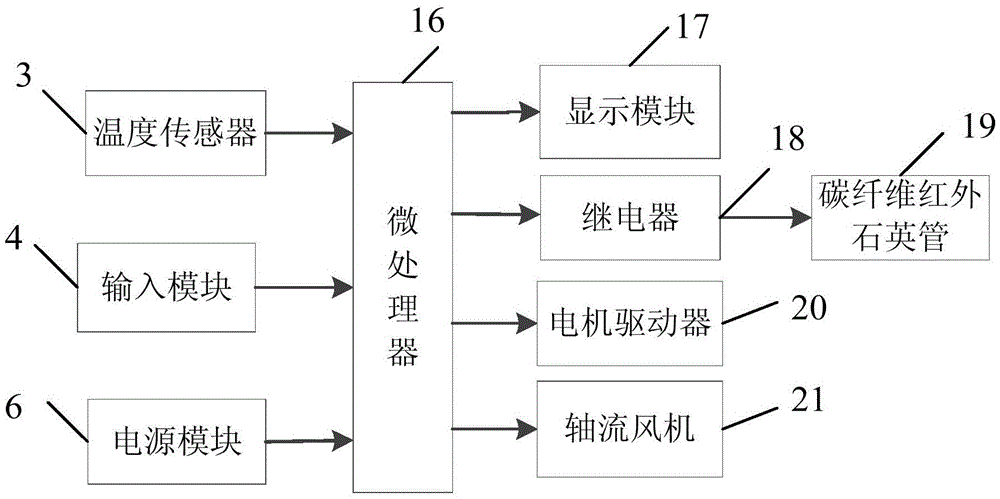

[0047] Such as Figure 1 to Figure 3 The shown small particle crop grain drying device includes a drying box 1 , a transmission mechanism, a drying mechanism, a moisture removal mechanism, a temperature sensor 3 , an input module 4 , a microprocessor 16 , a display module 17 and a power supply module 6 . A material inlet 2 is arranged on the top of the drying box 1 , and a material outlet 11 is arranged on the bottom of the drying box 1 . The transmission mechanism is used to support and transport the crop grains, the feed end of the transmission mechanism is located directly below the feed opening 2 , and the discharge end of the transmission mechanism is located directly above the discharge opening 11 . The drying mechanism is used for drying crop grains, and the drying mechanism is horizontally arranged above or below the transmission mechanism. The drying mechanism is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com