Band-type roasting machine cooling and hot wind returning system and band-type roasting machine cooling and hot wind returning method

A belt roasting machine, the technology of returning hot air, applied in lighting and heating equipment, furnace cooling, waste heat treatment and other directions, can solve the problem that the air volume and air pressure of the branch pipes cannot be effectively adjusted, and affect the roasting process of the belt machine. The effect of fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

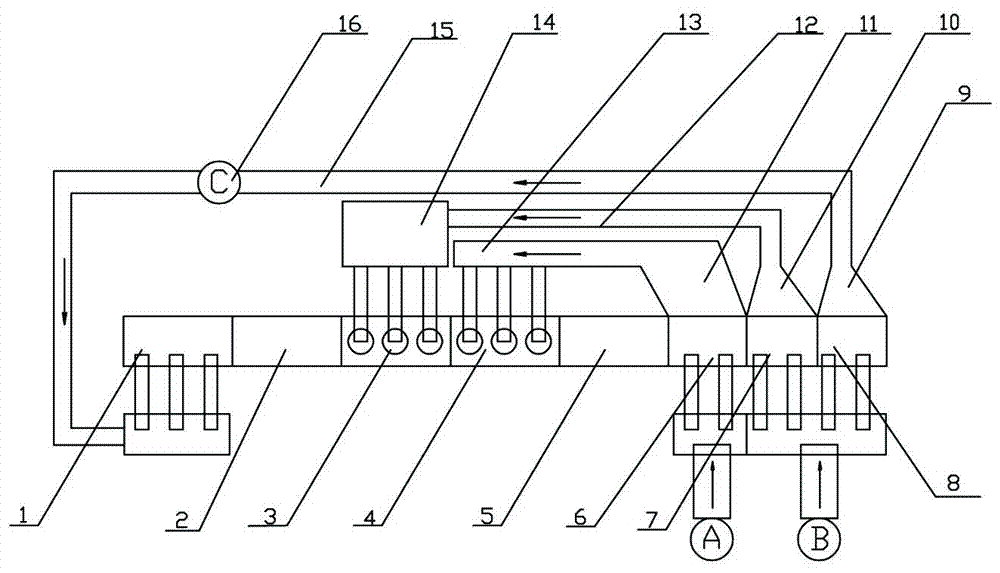

[0026] Such as figure 1 As shown, a belt roaster cooling and return hot air system of the present invention comprises that the material flow direction along the conveyor belt is divided into a blast drying section 1, a draft drying section 2, a preheating section 3, and a roasting section 4. , soaking section 5 and cooling section, it is characterized in that:

[0027] The cooling section is divided into cooling section 6, cooling section 7 and cooling section 8, and a partition wall is set between each cooling section, and a cooling fan A is installed at the bottom of the cooling section. There is a common fan B in the lower part;

[0028] A hot waste gas induction hood I11 is provided on the upper part of the cooling section 6, and the hot exhaust air induction hood I11 of the cooling section is connected to the sintering section 4 through the return hot air pipe I13 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com