Roll pulverizer with dust suction function

A pulverizer and pulverizing chamber technology, which can be used in swirling devices, devices whose axial directions of swirling can be reversed, grain processing, etc., and can solve problems such as pulverizing dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

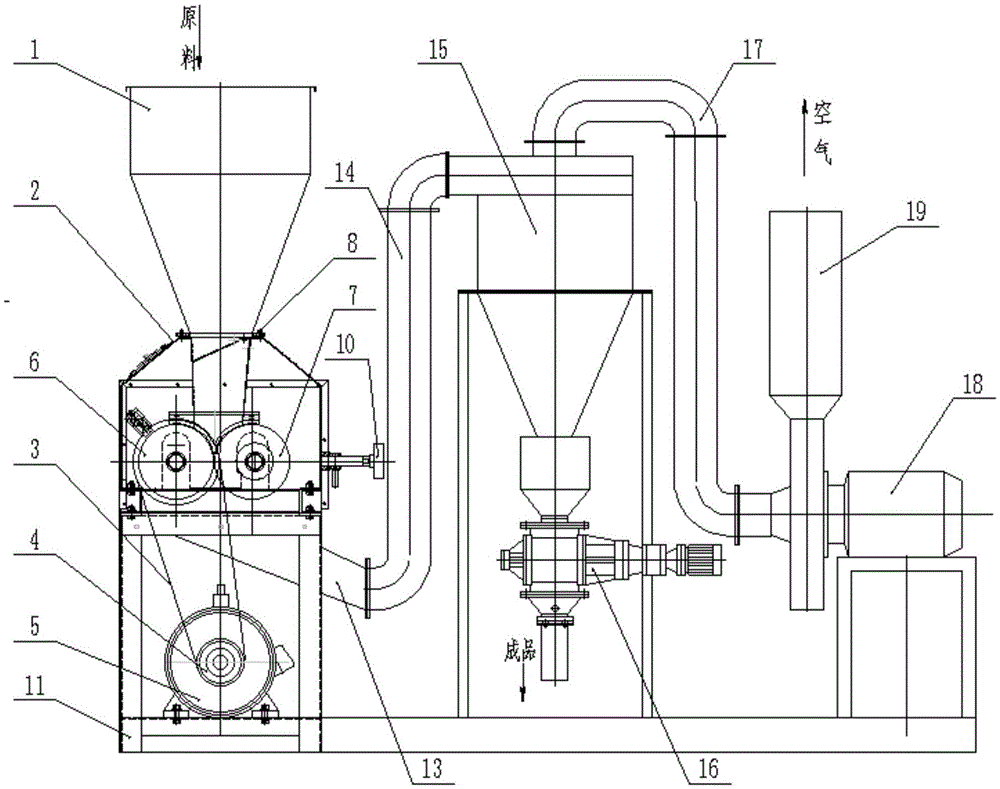

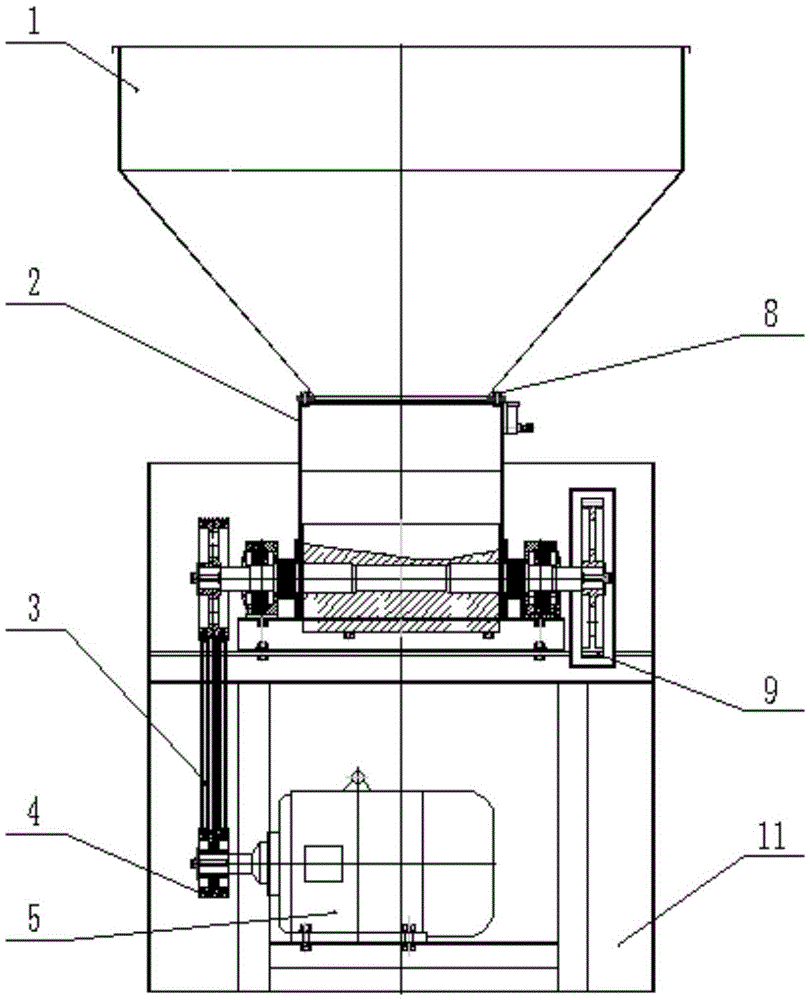

[0021] Such as Figure 1-Figure 2 Shown, dust-absorbing pair of roller pulverizers, it is by feeding hopper 1, crushing chamber 2, frame 11, pulverizes out hopper 13, collection pipe 14, cyclone collector 15, blower fan 16, induced draft fan 18, muffler 19 and so on.

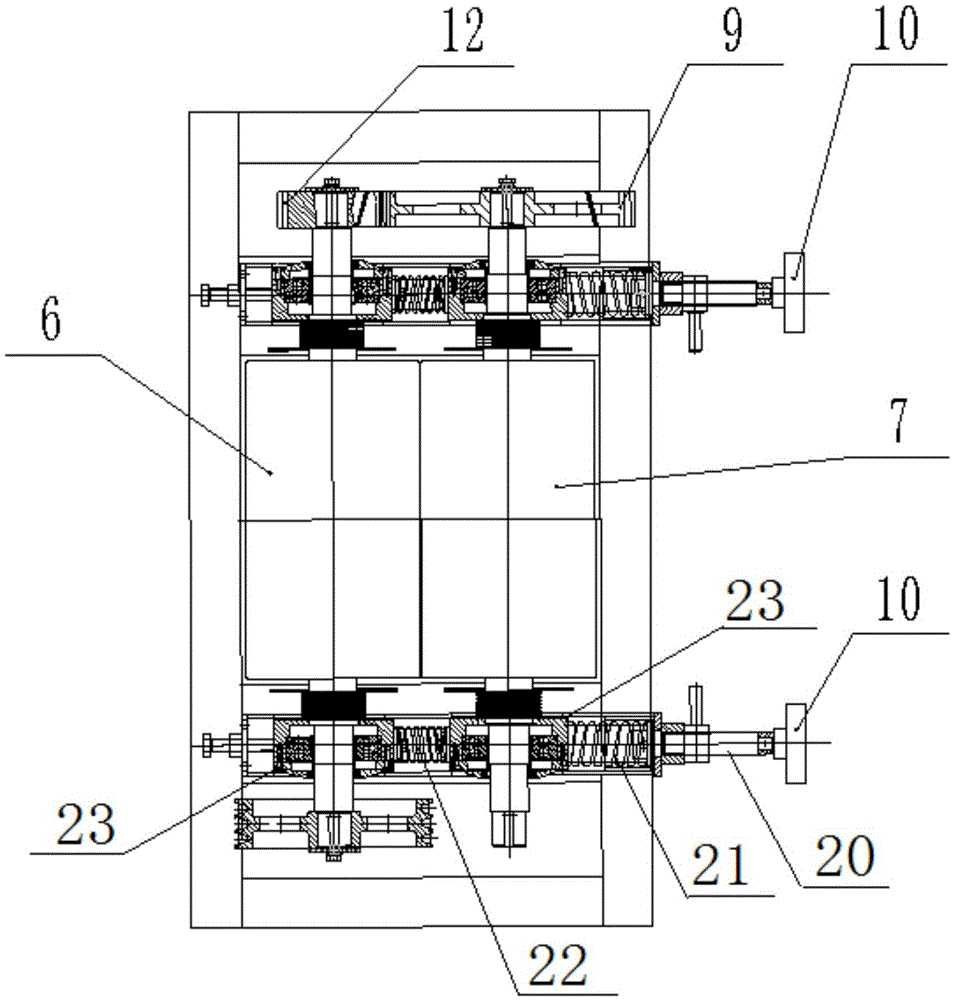

[0022] The feed hopper 1 is installed above the crushing chamber 2 through connecting bolts 8, and the crushing chamber 2 is fixed on the frame 11. Two driving rollers 6 and driven rollers 7 with different rotational speeds and opposite directions of rotation are installed in the crushing chamber 2. The power that driving roller 6 rotates is provided by the motor 5 that is fixed on frame 11 below, and motor 5 transmits power to driving roller 6 by belt pulley 4 and transmission belt 3 that are connected with it.

[0023] After the material is crushed in the crushing chamber 2, the finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com