Combined oil mist purifying unit of air conditioner

A combined air-conditioning and oil mist technology, applied in air-conditioning systems, heating methods, mechanical equipment, etc., to achieve the effect of reducing pollution, convenient process operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

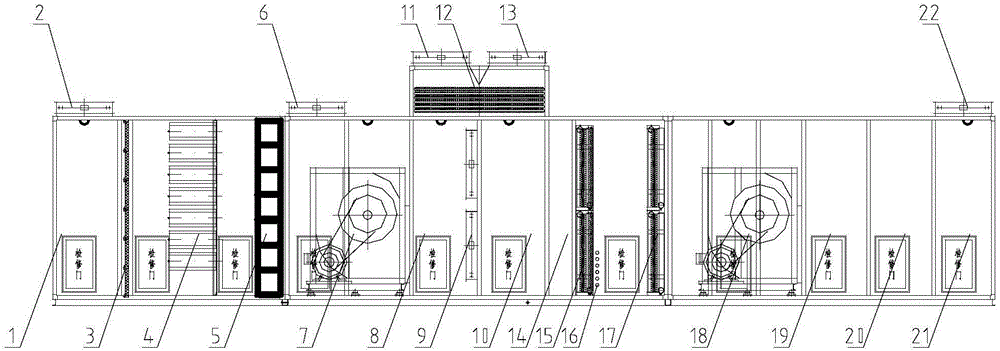

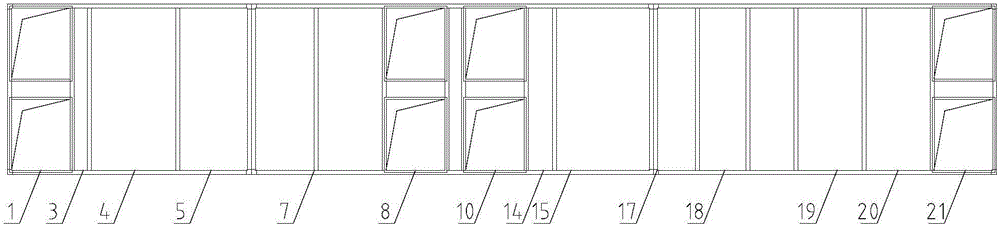

[0034] see figure 1 and figure 2 , the combined air conditioning oil mist purification unit in the figure includes return air section 1, return air valve 2, metal oil mist filter section 3, high-efficiency oil mist filter section 4, odor purification section 5, bypass valve 6, and return fan section 7. Exhaust air adjustment section 8, air mixing valve 9, fresh air adjustment section 10, exhaust valve 11, heat recovery section 12, fresh air valve 13, air filter section 14, surface cooling section 15, auxiliary electric heater 16, heating section 17. Fan section 18, flow equalization section 19, muffler section 20, air supply section 21, air supply valve 22.

[0035] Among them, the return air section 1, the metal oil mist filter section 3, the high-efficiency oil mist filter section 4, the odor purification section 5, the bypass valve 6, the return fan section 7, and the exhaust air adjustment section 8 constitute the return air filter section, in which the return air The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com