A whirlwind wind tunnel blanking cooling and dehumidification device

A technology of cooling, dehumidification, and cyclone, which is applied in the field of machinery, can solve the problems that the cooling and dehumidification effect cannot reach the ideal state, increase the use area of the production site, and affect the quality of finished fertilizers, etc., to achieve efficient cyclone treatment, efficient recovery, and fast cooling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

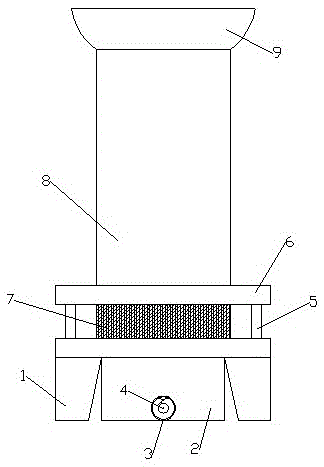

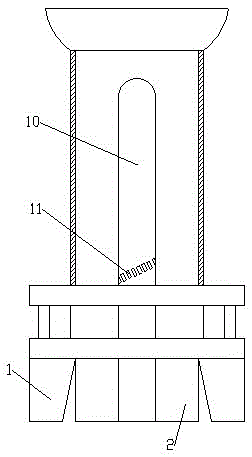

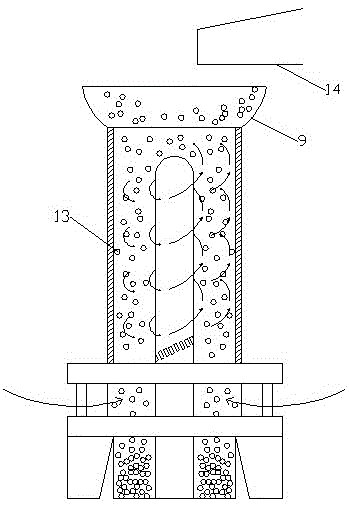

[0018] Such as figure 1 , 2 , 3, 4, and 5, a whirlwind wind tunnel blanking cooling and dehumidification device, including support 1, the upper and lower parts installed on the support 1, the blanking cylinder 8 of the cylindrical structure with openings, setting In the receiving bin 2 below the blanking barrel 8, a support rod 5 is fixedly installed above the support 1, a blanking bin support platform 6 is fixedly installed above the support rod 5, and a blanking bin support platform 6 is fixedly installed above There is a blanking barrel 8, the bottom of the blanking barrel 8 is connected to the top of the receiving bin 2, and a central cyclone pillar 10 with a cylindrical hollow structure is fixedly installed at the center of the blanking barrel 8, and the supporting platform 6 of the blanking bin At least four cyclone air outlets 11 are provided on the column wall of the upper central cyclone pillar 10, and the inside of the central cyclone pillar 10 communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com