Biomass hot blast stove

A hot blast stove and biomass technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of incomplete combustion of biomass fuel, unstable output, insufficient dust removal, etc., and achieve compact structure, Easy and fast installation, easy and transportation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

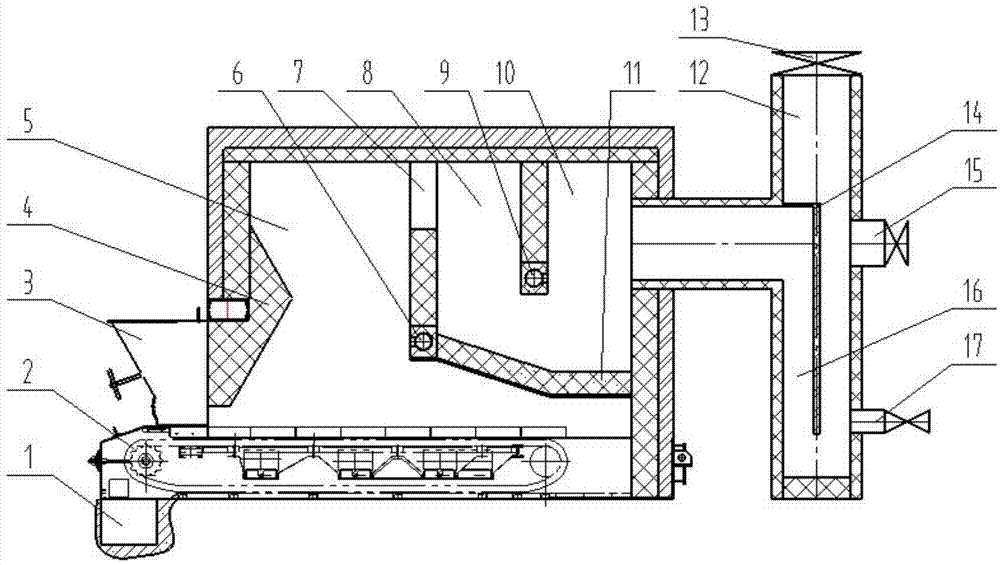

[0034] A biomass hot blast stove, comprising a hot blast stove body and an emergency discharge chimney 12, wherein the hot blast stove body is preferably in the shape of a cuboid, including a charging port 3, a fire grate 2, an ash pit 1, a front combustion chamber 5, and a rear combustion chamber 10 , the primary settling chamber 8, the primary air-cooled beam 6, the secondary air-cooled beam 9, and the chimney window 7. The emergency relief chimney 12 is preferably cylindrical, including a flame-retardant plate 14 , a tertiary settling chamber 16 , a tertiary air cooling port 17 , an emergency relief chimney outlet 15 , and an emergency relief smoke port 13 .

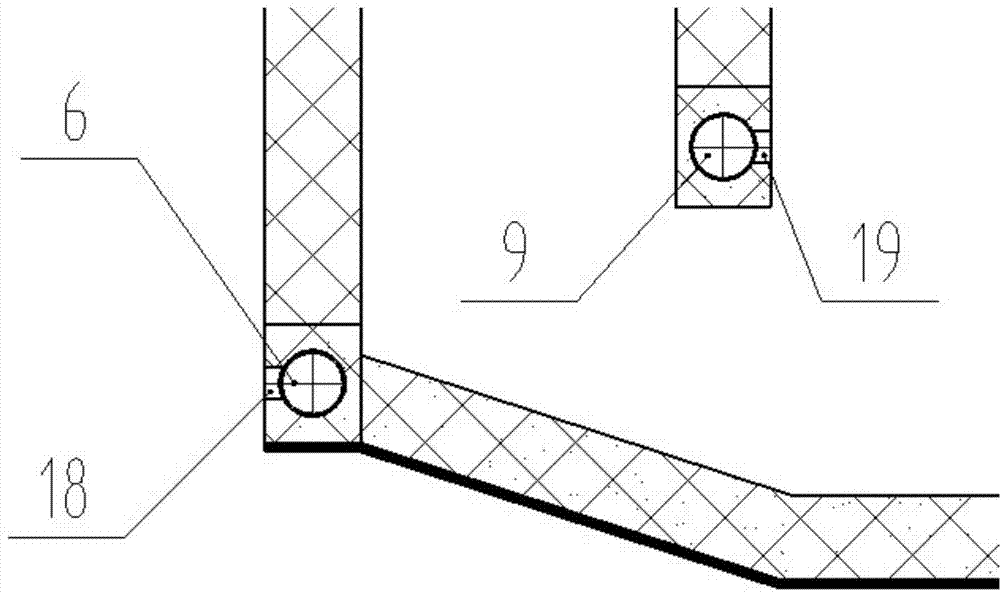

[0035] The primary air-cooled beam 6 is provided with a primary air-cooled port 18, and the secondary air-cooled beam 9 is provided with a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com