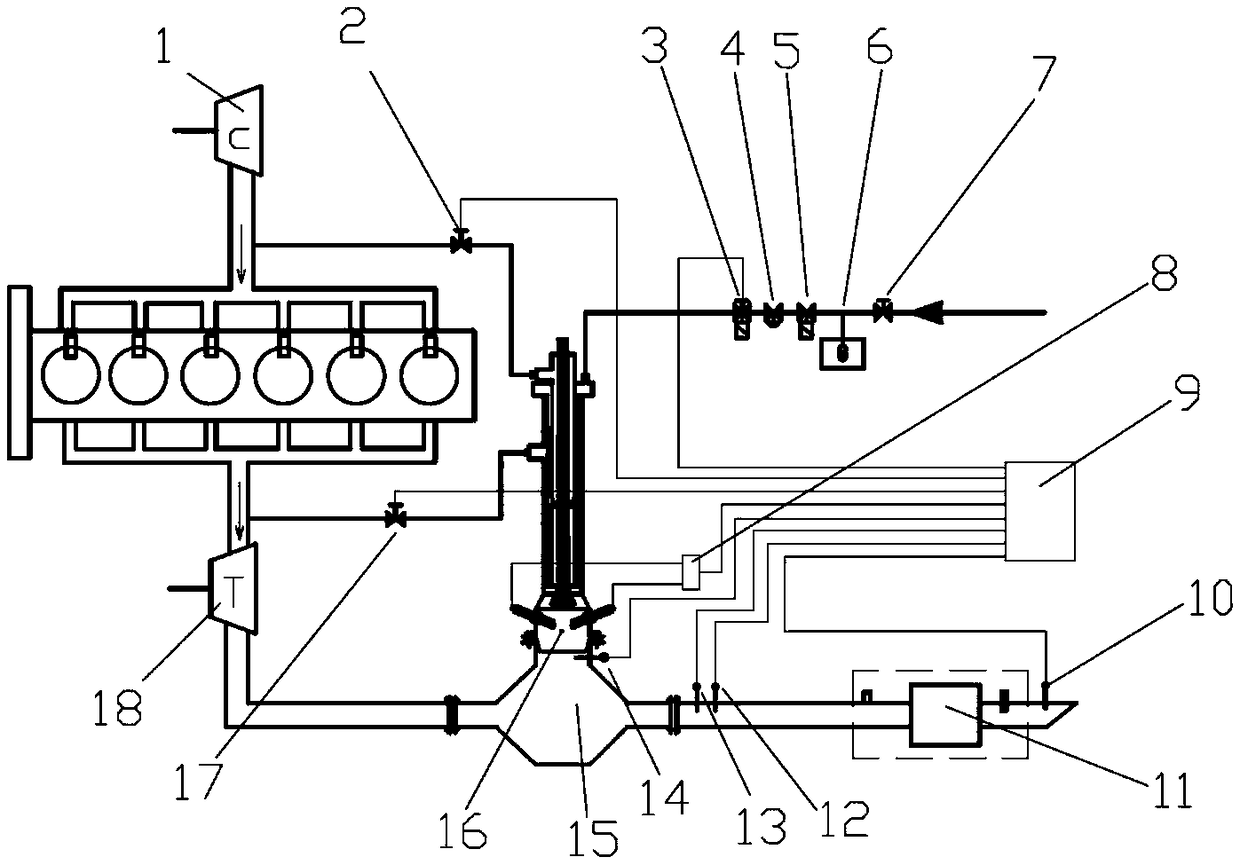

Auxiliary heating device and heating method for vehicle scr system

An SCR system and auxiliary heating technology, which is applied in the direction of exhaust devices, mufflers, machines/engines, etc., can solve the problems of exhaust pipe sediment blockage and low conversion efficiency of SCR system, so as to optimize the emission of soot and improve Catalytic efficiency, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

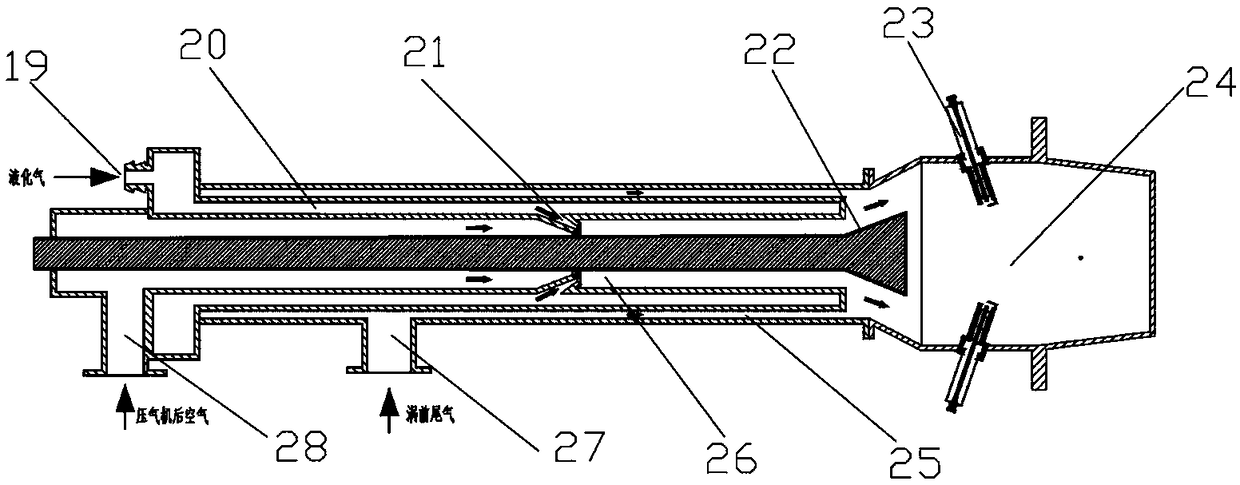

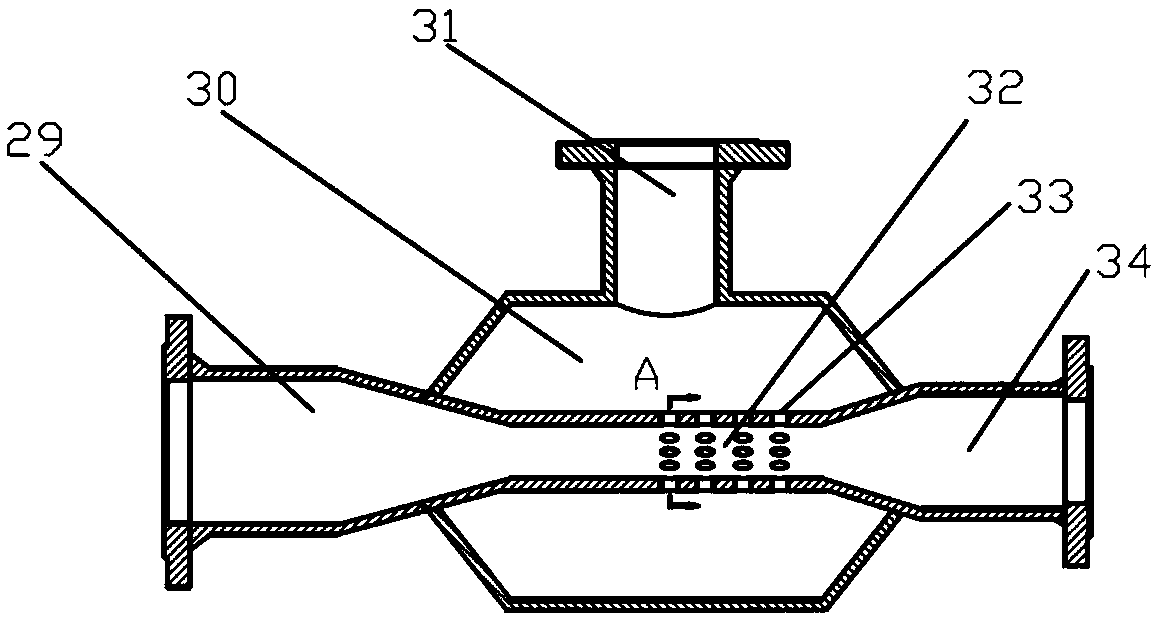

[0036] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. An auxiliary heating device for a vehicle SCR system provided by the present invention has the following structure: the air compressor 1 is connected to the air inlet 28 of the combustion device 16 through the first proportional solenoid valve 2, and the intake end of the exhaust gas turbine 18 is connected to the air inlet 28 of the combustion device 16 through the third proportional solenoid valve 2. The solenoid valve 17 is connected to the exhaust gas inlet 27, the outlet end of the exhaust gas turbine 18 is connected to the exhaust gas inlet 29 of the mixing device, and the liquefied gas input port is connected to the liquefied gas inlet 19 of the combustion device 16 through the second proportional solenoid valve 3;

[0037] Outside the guide rod 22, an air cavity 26, a liquefied gas cavity 20, and a waste gas cavity 25 are sequentially ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com