Filter plate and heating device with same

A heating device and filter plate technology, which is applied in the field of civil heating devices and heating devices, can solve the problems of unfavorable heating device pipeline cleaning, unstable furnace top temperature, insufficient ignition point of coal-fired gas, etc., to reduce the risk of polluting indoor air, Conducive to continuous good work and the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

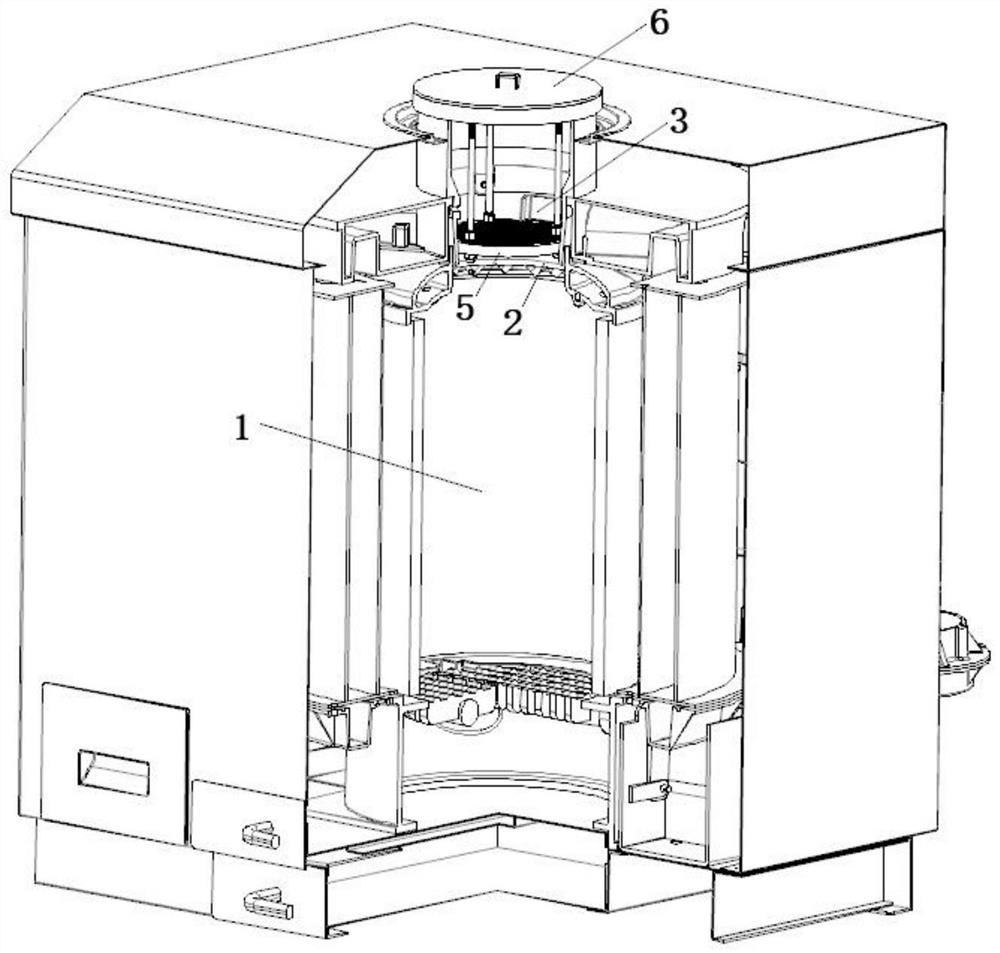

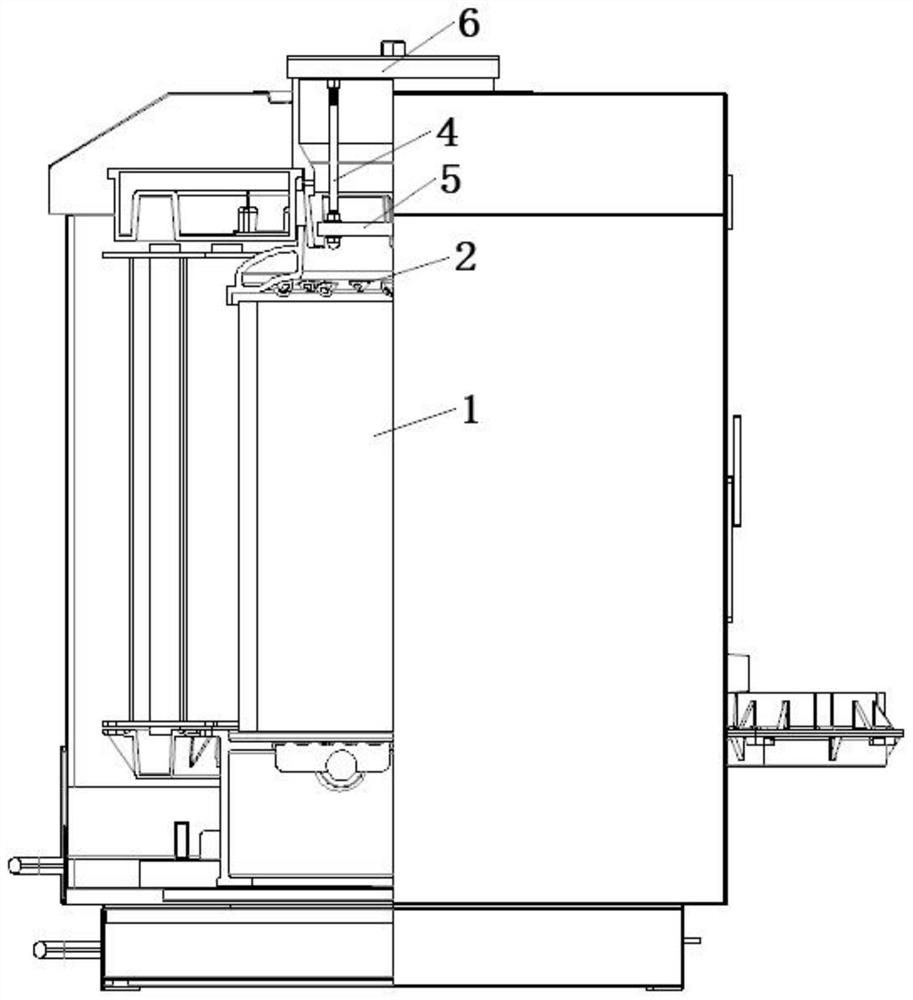

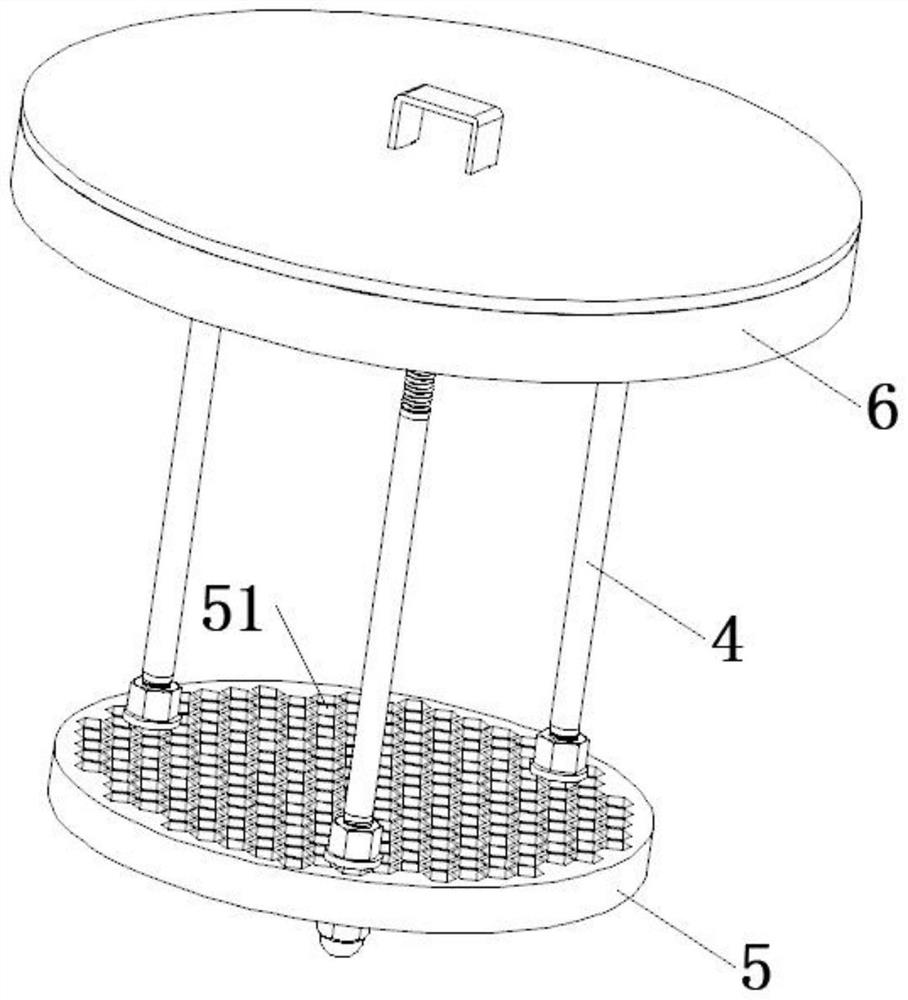

[0035] Such as Figure 1-6 As shown, the heating device is equipped with a filter plate 5. The filter plate includes evenly distributed filter holes 51. The filter holes are suitable for absorbing the smoke dust and tar in the furnace 1. The filter plate is resistant to the high temperature at the top of the flame zone. The filter plate is placed on the top of the furnace. Located above the flame zone and between the smoke outlet, the filter plate is located above the upper air distribution device 2 . The whole filter plate is a flat plate. The filter plate is detachably connected to the bottom of the furnace cover 6, and the filter plate and the furnace cover are detachably connected by connecting rods 4. The filter plate in this embodiment can be a honeycomb ceramic plate.

Embodiment 2

[0037] Different from Example 1, as Figure 7 As shown, the size of the opening of the filter hole near the flame zone is larger than that of the side near the smoke exhaust port.

Embodiment 3

[0039] Different from Example 1, as Figure 8 As shown, the filter plate as a whole is a convex plate with a raised part in the middle, and the raised part is one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com