Straight axle environmental protective IC engine

An internal combustion engine, direct shaft technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of low effective power utilization, reduce the service life of machinery, pollute the environment, etc., to improve the effective power utilization and use Longevity, environmental protection, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

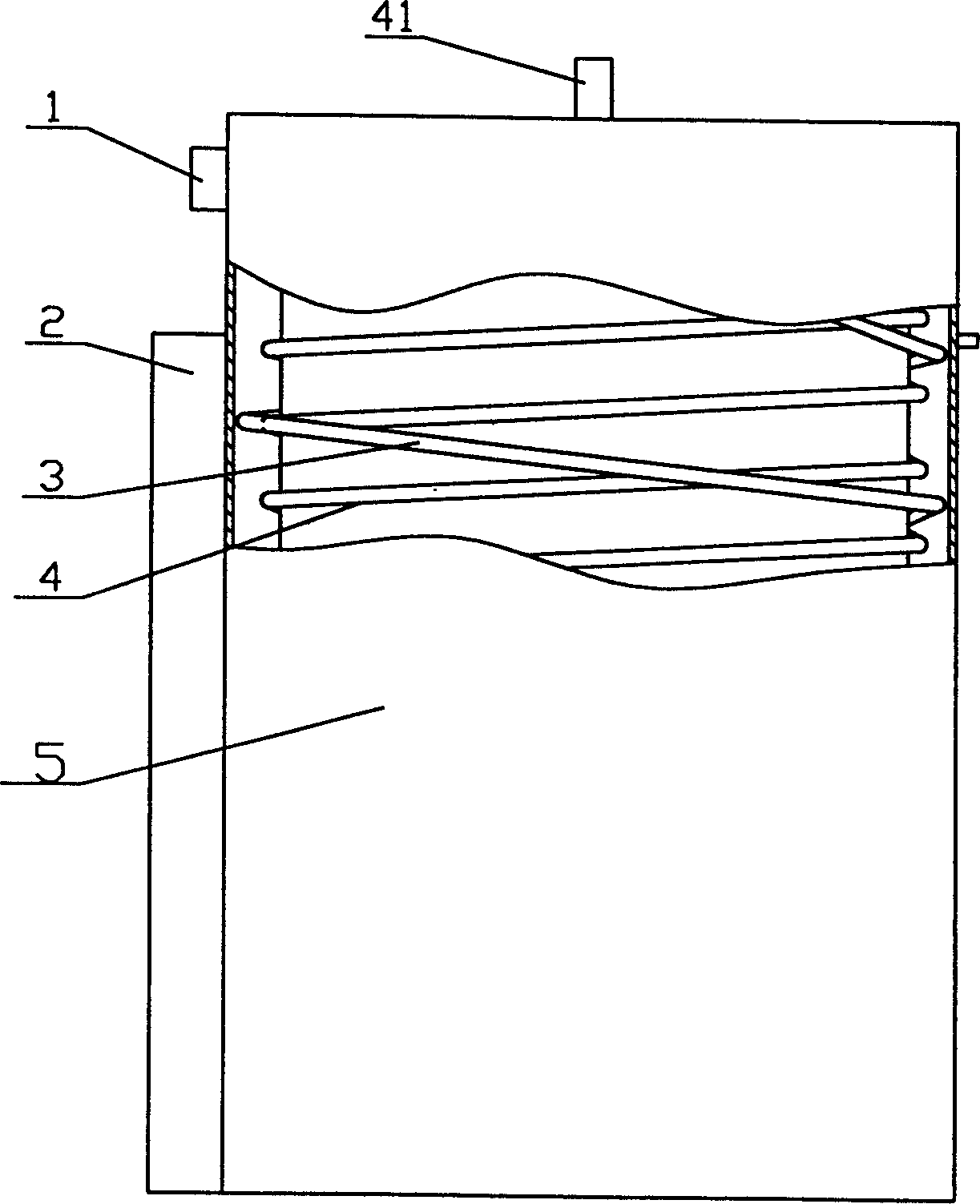

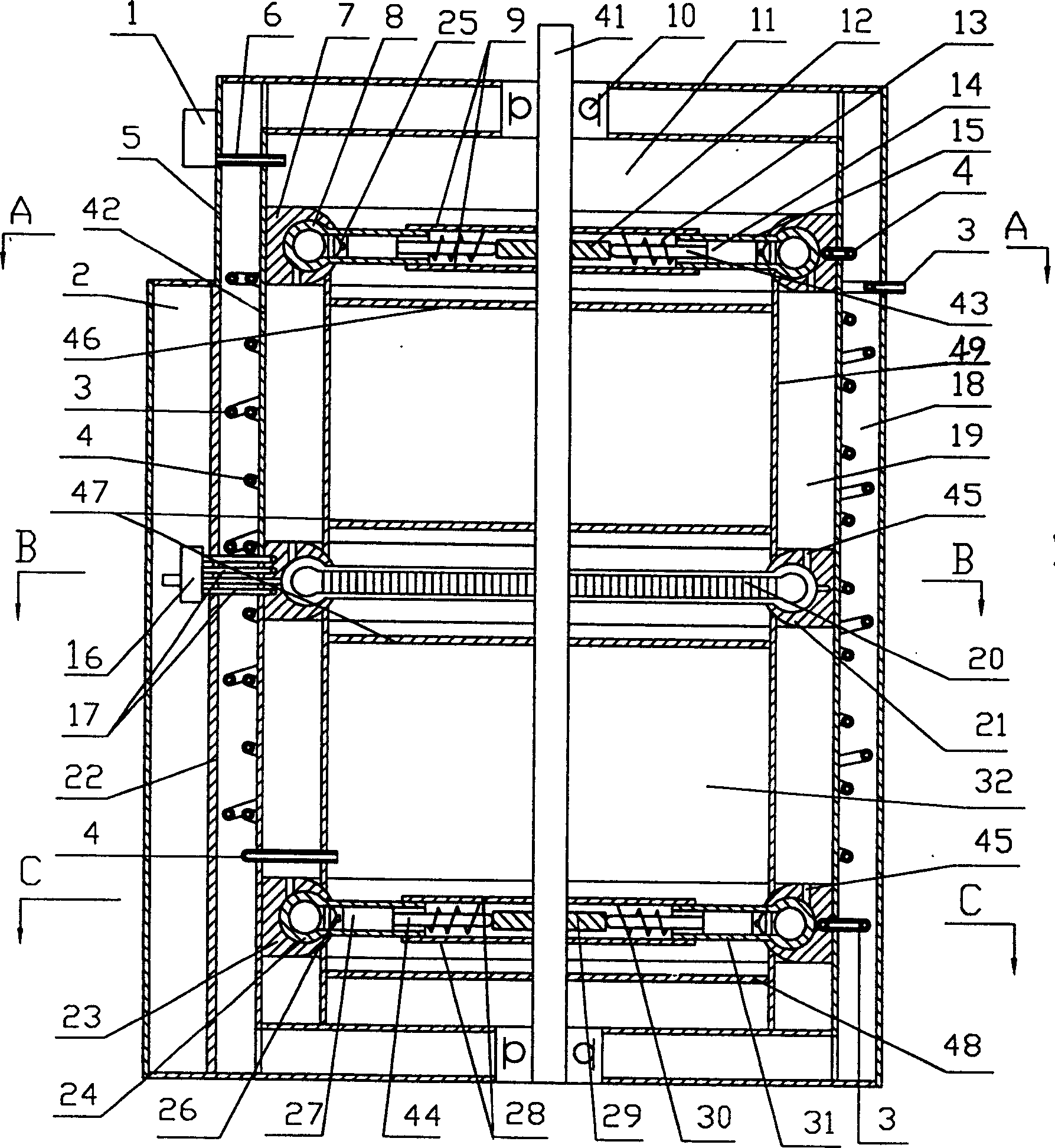

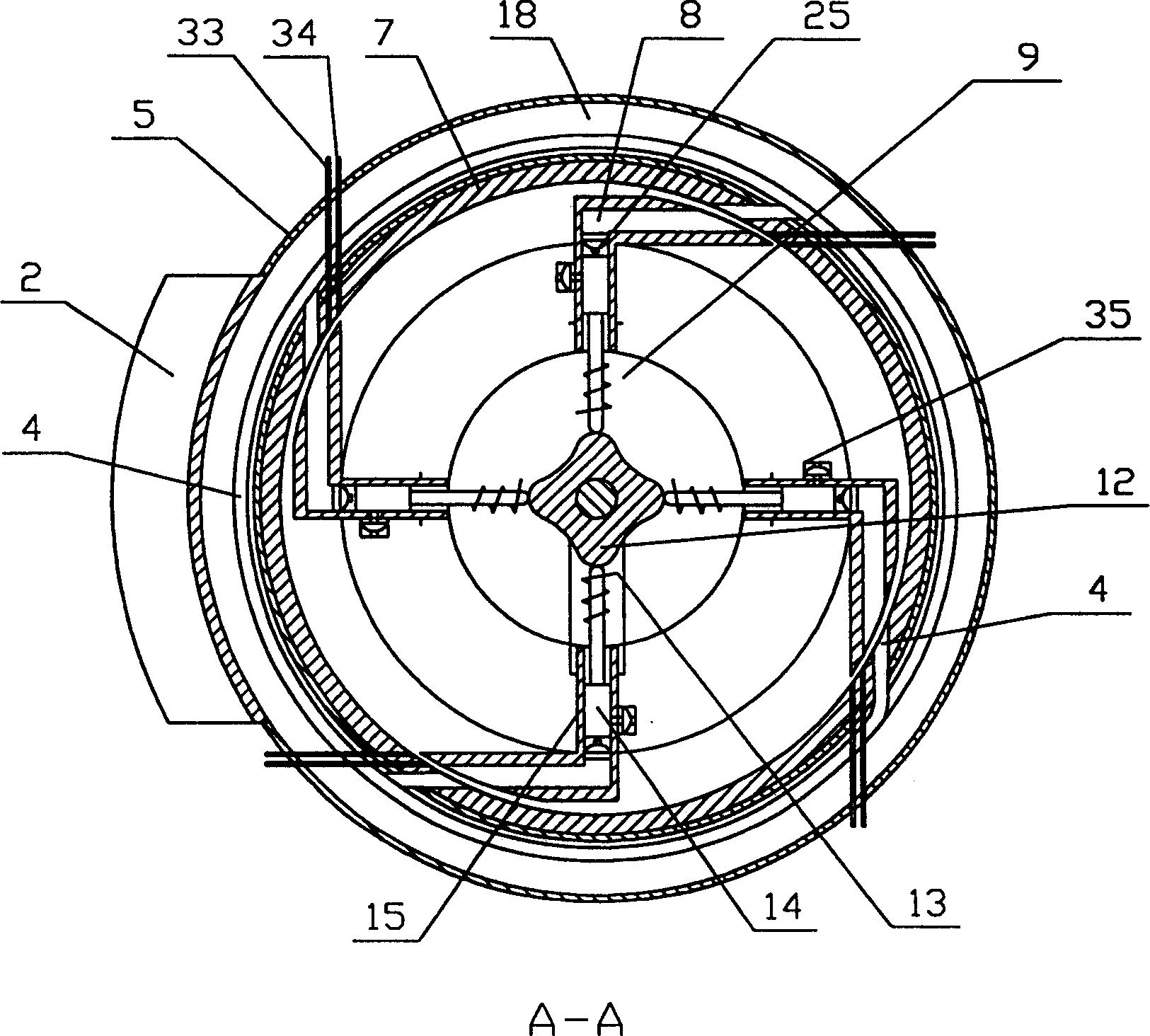

[0018] What the present invention provides is the embodiment that the right and left annular bodies each have four cylinder blocks. Above-mentioned air filter 1 is equipped with on the right upper part of described body 5, and above-mentioned air filter intake pipe 6 is equipped with in the bottom of air filter 1, and the other end of air filter intake pipe 6 stretches into air cavity 11. The body 5 is provided with the above-mentioned cylindrical inner wall 42, and forms a water chamber 18 with the inner side of the body 5. There should be a certain gap between the water level in the water chamber 18 and the body wall. The inner side of the cylindrical inner wall 42 is fixedly equipped with the above-mentioned right ring body 7, middle ring body 21 and left ring body 23, and the cross section inside the right ring body 7, middle ring body 21 and left ring body 23 is a semicircle, and has a section It is circular and the inner side is an open annular hollow, and the right ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com