Preparation method of microcapsule aluminum hypophosphite flame retardant

A technology of aluminum hypophosphite and microcapsules is applied in the field of materials to achieve the effects of improved water resistance, improved safety and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

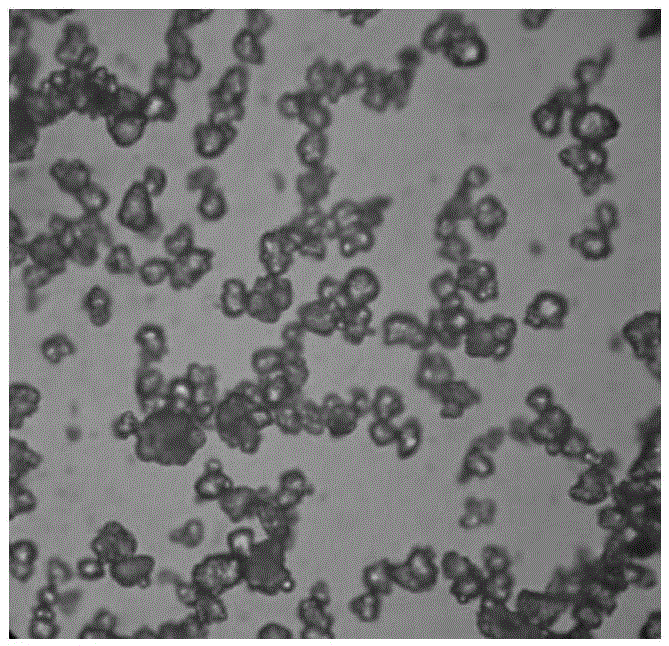

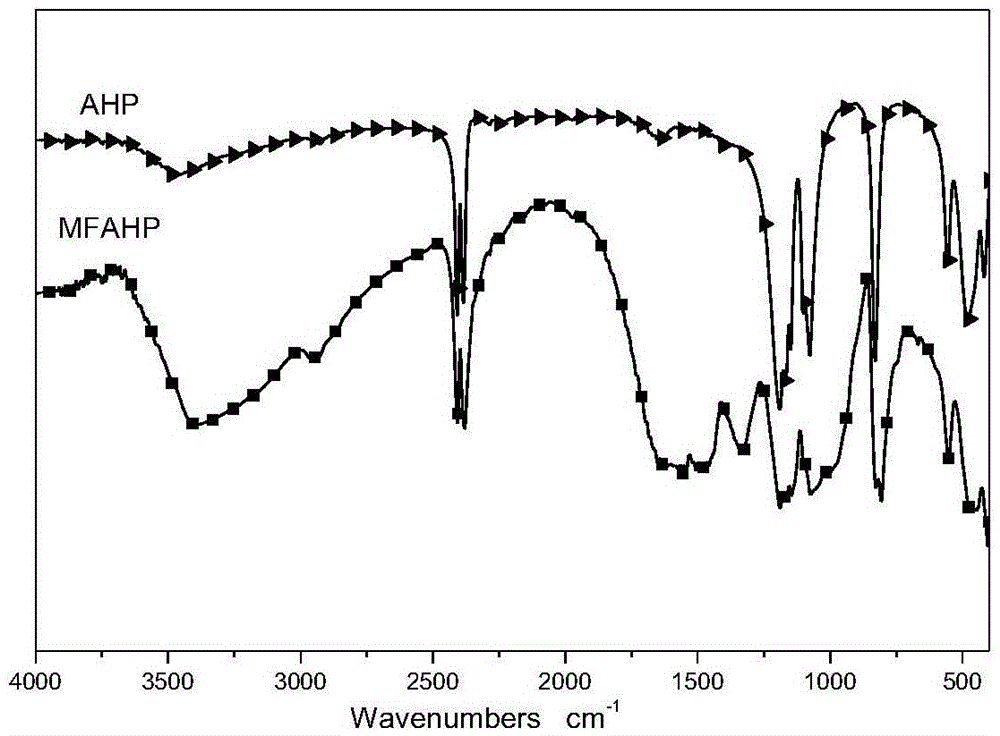

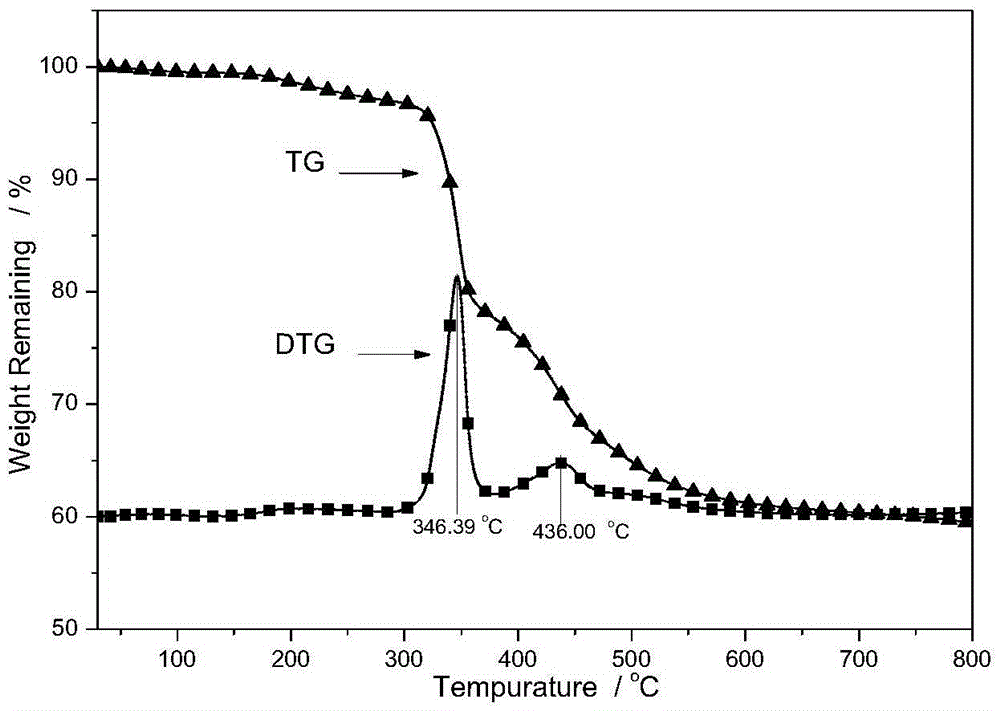

Image

Examples

Embodiment 1

[0028] A preparation method of microcapsule aluminum hypophosphite flame retardant, the steps are as follows:

[0029] Add melamine, 37% formaldehyde solution and water into the reaction kettle with a mass ratio of 1:2:10, adjust the pH in the kettle to 8 with 1% aqueous sodium hydroxide solution, and react for 25 minutes at a temperature of 50°C , adding polyethylene glycol with 0.1 times the mass of melamine, and then reacting for 80 minutes to end the reaction to obtain a modified melamine resin prepolymer solution;

[0030] Add inorganic aluminum hypophosphite and water into the reaction kettle at a mass ratio of 1:8 at room temperature, then add 0.3% of aluminum hypophosphite quality surfactant sodium dodecylbenzene sulfonate, and fully stir for 25 minutes to make aluminum hypophosphite Disperse evenly; then, raise the temperature to 60°C, slowly add the modified melamine resin prepolymer solution in the first step, which is 6 times the mass of aluminum hypophosphite, int...

Embodiment 2

[0031] A preparation method of microcapsule aluminum hypophosphite flame retardant, the steps are as follows:

[0032] Add melamine, 37% formaldehyde solution and water into the reaction kettle at a mass ratio of 1:4:8, adjust the pH inside the kettle to 9 with triethylamine, react at 80°C for 10 minutes, add 0.2 times The polyvinyl alcohol of melamine quality, finishes reaction after reacting again 40min, obtains modified melamine resin prepolymer solution;

[0033] Add inorganic aluminum hypophosphite and water into the reaction kettle at a mass ratio of 1:6 at room temperature, then add 0.5% aluminum hypophosphite quality surfactant hexadecyltrimethylammonium bromide, fully stir for 20min, and make the secondary The aluminum phosphate is dispersed evenly; then, the temperature is raised to 90°C, and the modified melamine resin prepolymer solution in the first step, which is 4 times the mass of aluminum hypophosphite, is slowly added to the reaction kettle, and the pH is adj...

Embodiment 3

[0035] A preparation method of microcapsule aluminum hypophosphite flame retardant, the steps are as follows:

[0036] Add melamine, 37% formaldehyde solution and water into the reaction kettle with a mass ratio of 1:1:11, adjust the pH in the kettle to 10 with triethanolamine, and react for 15 minutes at a temperature of 70°C, then add 0.3 times of melamine quality urea, and then finish the reaction after 40 minutes of reaction to obtain a modified melamine resin prepolymer solution;

[0037] Add inorganic aluminum hypophosphite and water into the reaction kettle at a mass ratio of 1:4 at room temperature, then add 1% aluminum hypophosphite quality surfactant sodium lauryl sulfate, and stir thoroughly for 30 minutes to disperse aluminum hypophosphite evenly Then, the temperature was raised to 75°C, and the modified melamine resin prepolymer solution in the first step, which was 2 times the mass of aluminum hypophosphite, was slowly added to the reactor, and the pH was adjuste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com