Method for top-driving casing job of drilling apparatus

A casing and drilling technology, which is applied to the field of casing running by a top drive drilling device, can solve the problems of low casing running efficiency, inability to rotate the casing string, and inability to circulate mud, etc., so as to improve production efficiency and safety. , The effect of reducing operating equipment and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Taking a casing with an outer diameter of 177.8 mm as an example, the invention will be further described in detail.

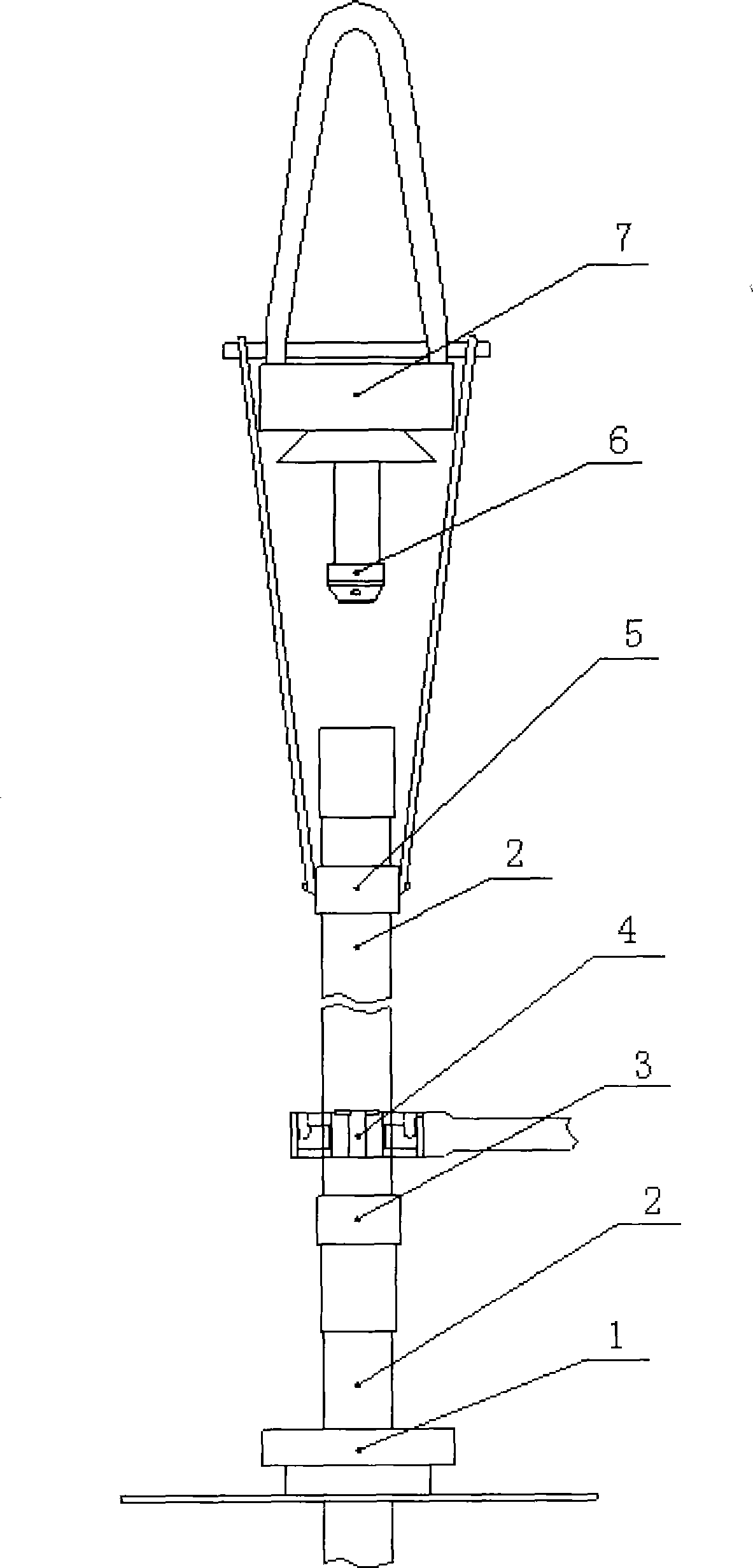

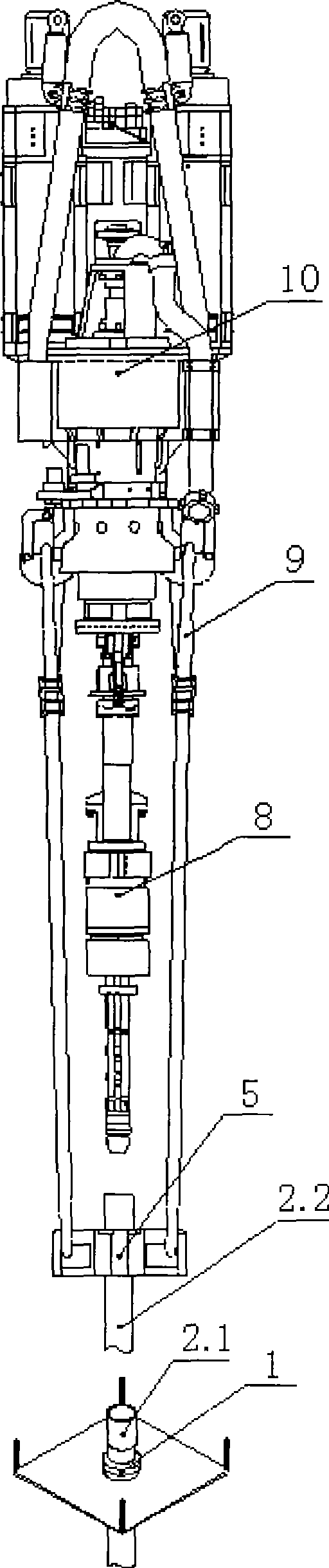

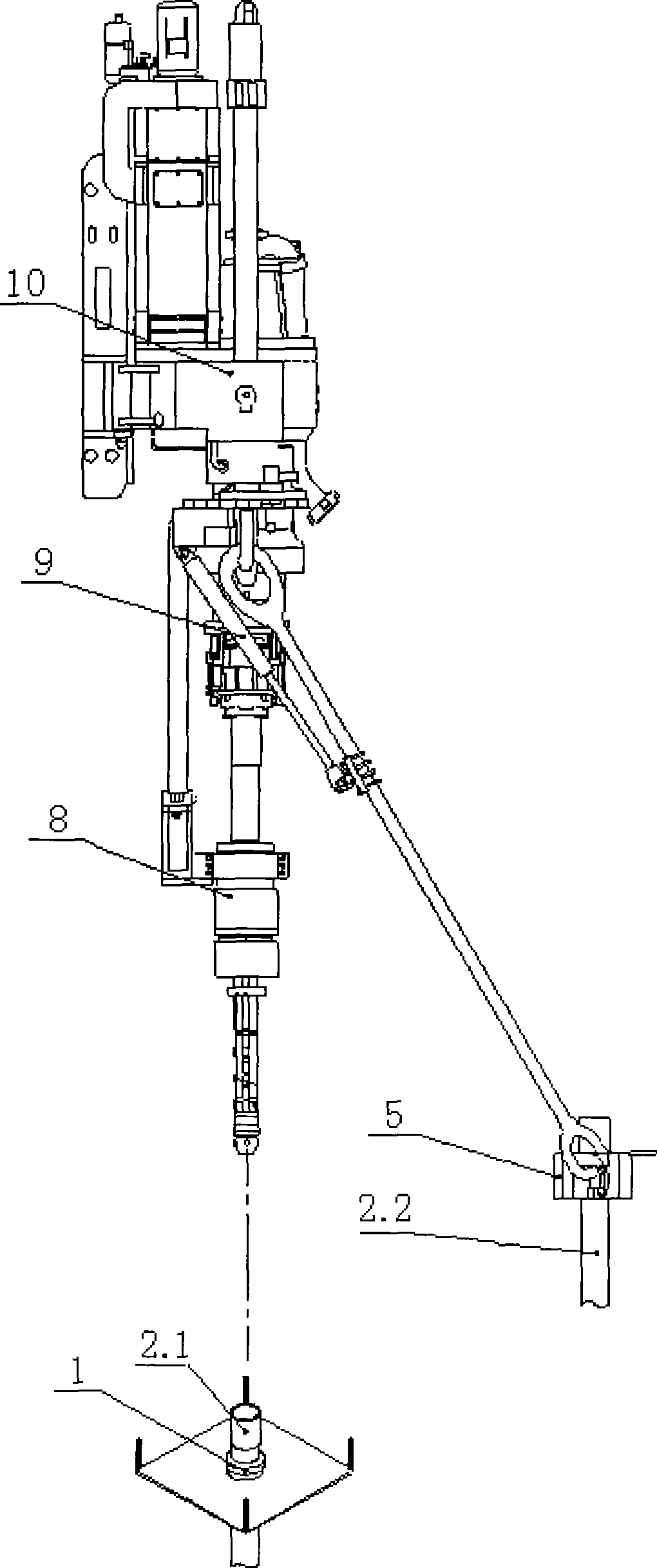

[0045] refer to figure 2 and image 3 . A new flow process of the method for casing operation with a top drive drilling device of the present invention is:

[0046] A. Connect the top drive casing running device 8 to the lower end of the main shaft of the top drive drilling device 10 .

[0047] At present, top drive drilling devices 10 have been sold in the market. For example, Beijing Petroleum Machinery Factory has mass-produced 2250kN, 3150kN, 4500kN, 6750kN, 9000kN and other series products. In addition, Chinese Patent Publication No. CN 101089356A provides "a hollow motor directly drives a top drive drilling device".

[0048] B. Connect the casing elevator 5 at the lower part of the top drive lifting ring 9, and use the casing elevator 5 to lift the single casing 2.2; the single casing 2.2 adopts a casing with an outer diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com