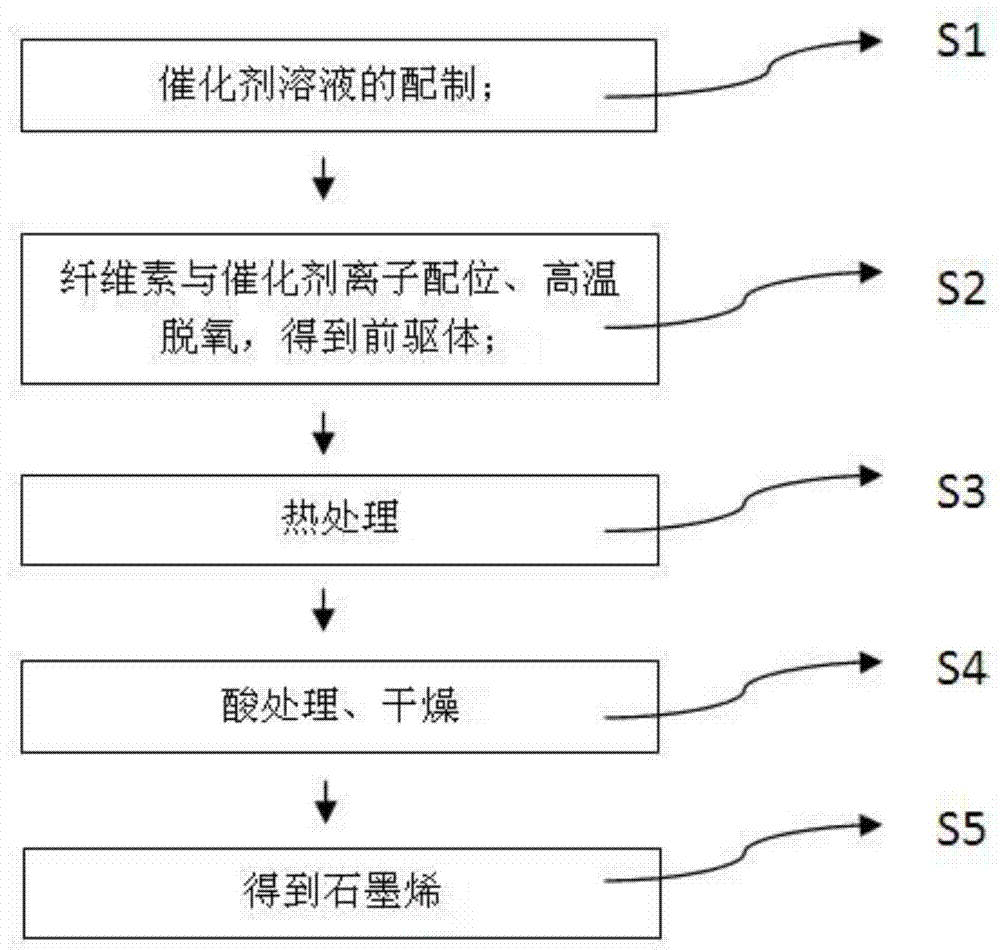

Method for preparing biomass graphene employing cellulose as raw material

A biomass graphene and cellulose technology, applied in graphene, chemical instruments and methods, material excitation analysis, etc., can solve the problems of complex graphene preparation process, complex equipment required for the reaction, poor production safety, etc. The effect of industrialized production, high production safety, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the method that present embodiment prepares biomass graphene with cellulose as raw material is to be finished by following steps:

[0029] Step 1: prepare catalyst solution: 18gFeCl 2 Add it into 100ml of distilled water and stir for 25 minutes to obtain a uniform catalyst solution, wherein the ratio of solute to solvent in the catalyst solution is 18:100;

[0030] Step 2: Preparing the precursor: adding cellulose to the catalyst solution obtained in Step 1, stirring for 2 hours, then reacting at 140°C for 10 hours, deoxidizing and drying to obtain a precursor, wherein the cellulose and solvent The mass ratio is 26:100;

[0031] Step 3: heat treatment: pre-carbonization: put the precursor obtained in step 2 into an environment of nitrogen, argon or hydrogen, heat it to 280°C at a heating rate of 10°C / min, and put the precursor obtained in step 2 into Pre-carbonization of the body for 3 hours; secondary carbonization: heat the pre-carbonized product for 6...

Embodiment 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cellulose described in step 1 is the cellulose extracted from soybean straw biomass.

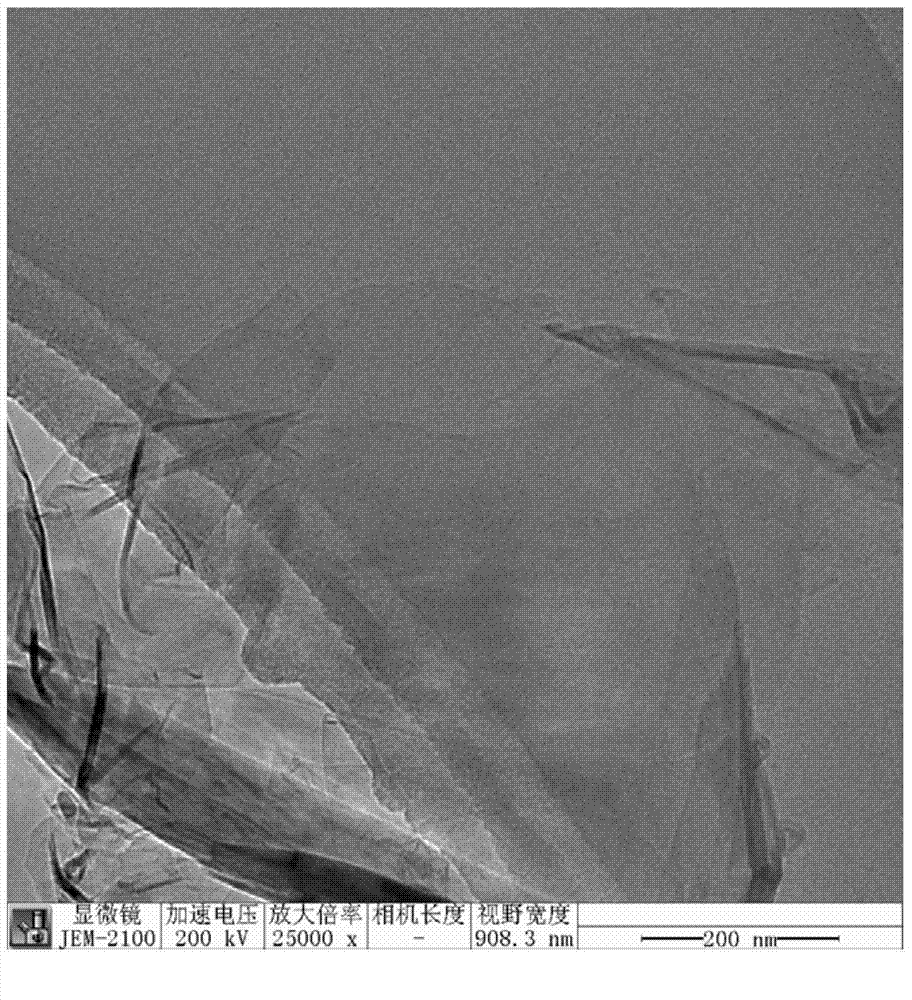

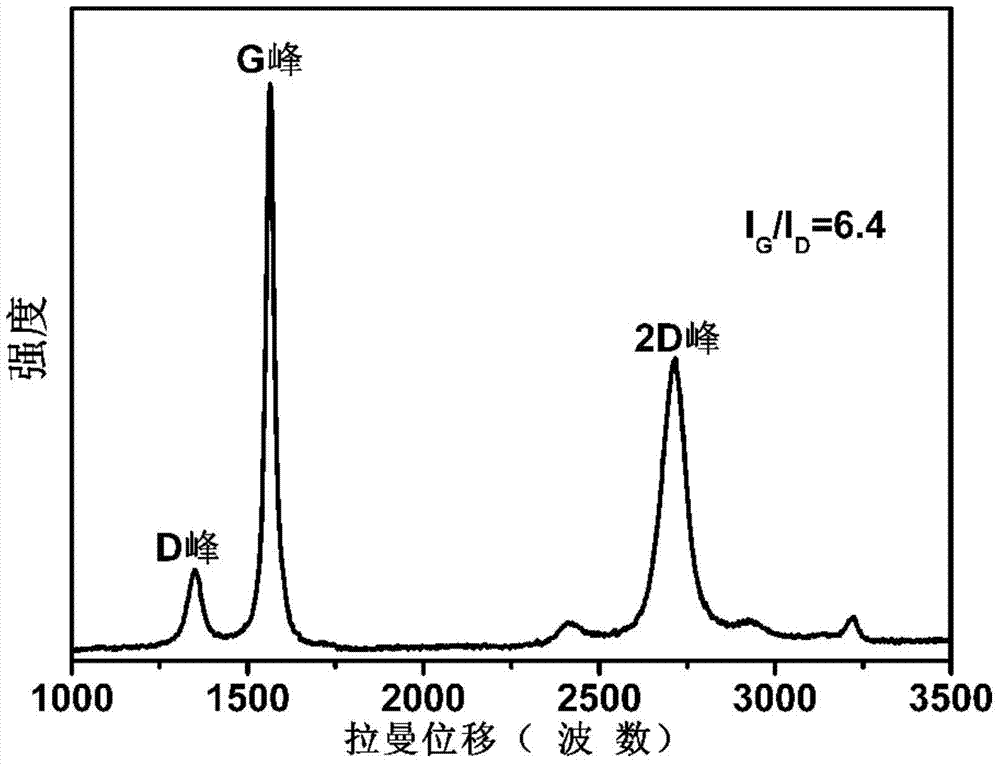

[0036] The transmission electron micrograph of the graphene that present embodiment 2 prepares is close to the transmission electron micrograph of embodiment 12, as figure 2 shown. The Raman spectrogram of the Graphene prepared in this embodiment 2 is similar to the Raman spectrogram of the Graphene prepared in Example 12, as image 3 shown.

[0037]The size of the graphene obtained in this embodiment is uniform, with a single-layer or multi-layer two-dimensional layered structure, the size is 0.5-2 μm, and the conductivity is above 25000-45000 S / cm; the yield of graphene in this embodiment is 99.9% or more.

Embodiment 3

[0038] Embodiment 3: the difference between this embodiment and embodiment 2 is: the catalyst described in step one is FeCl 2 with FeCl 3 A mix of both.

[0039] The transmission electron micrograph of the graphene that present embodiment 3 prepares is close to the transmission electron micrograph of embodiment 12, as figure 2 shown. The Raman spectrogram of the Graphene prepared in this embodiment 3 is similar to the Raman spectrogram of the Graphene prepared in Example 12, as image 3 shown.

[0040] The size of the graphene obtained in this embodiment is uniform, with a single-layer or multi-layer two-dimensional layered structure, the size is 0.5-2 μm, and the conductivity is above 25000-45000 S / cm; the yield of graphene in this embodiment is 99.9% or more.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com