Preparation of low polyphosphate

A technology of oligomeric phosphate and monoalkyl dichlorophosphate, which is applied in the field of improvement of the preparation method of oligomeric phosphate, can solve the problems of low phosphorus content of diphosphate, poor flame retardant effect, etc. Simple operation, less corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

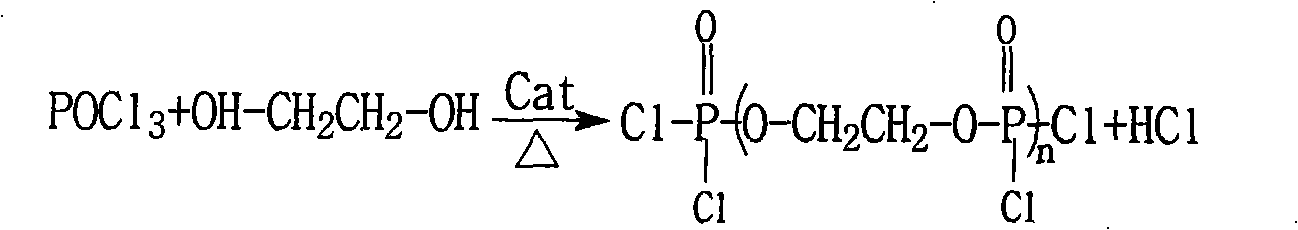

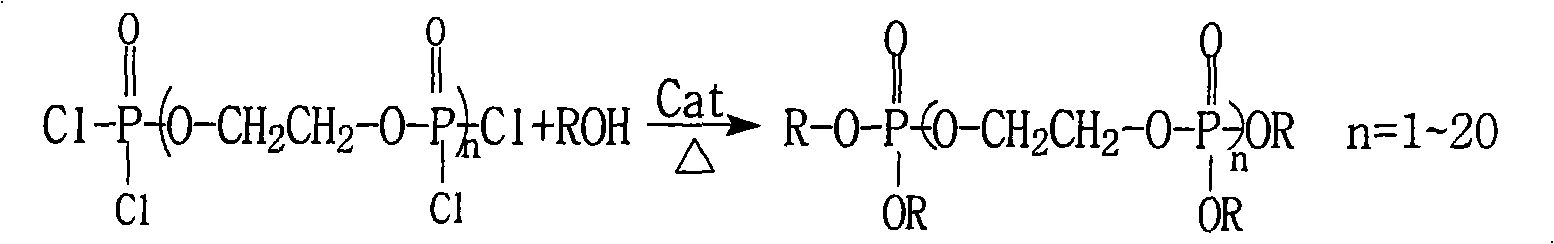

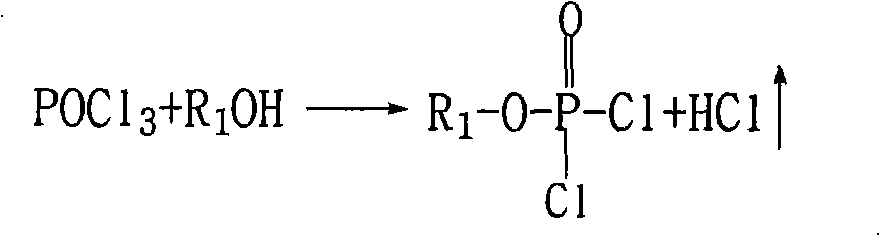

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: drop into 1mol phosphorus oxychloride, 3 ‰ carbon tetrachloride catalysts in four-necked flask, turn on stirring, drip 1mol ethylene glycol from separatory funnel, control temperature 20 ± 10 ℃, drop rate is controlled at 2-3h, absorb the HCl gas generated during the dropwise addition with water, and keep stirring at 20-25°C after the dropwise addition, and the reaction ends when no HCl gas is released. Continue to stir for another half an hour, then add about 2 mol of absolute ethanol (excessive amount) dropwise, control the dropwise addition within 2-3 hours, absorb the released HCl gas with water, after the dropwise addition, continue to react until no HCl gas is released, continue to stir for half a day Hour ends. Using the same method as ordinary flame retardants, after pickling, alkali washing, water washing and distillation, a light yellow viscous liquid is obtained. Liquid chromatography analysis showed that its molecular weight was 1250, its phos...

Embodiment 2

[0024] Embodiment 2: drop into 1mol phosphorus oxychloride, 3‰AlCl in four-necked flask 3 Catalyst, turn on the stirring, add 1.8mol of absolute ethanol dropwise from the separatory funnel, control the temperature at 20-30°C, add dropwise for 2-3h, and absorb the HCl gas released during the dropwise addition with water. When no HCl gas is released, the reaction is complete. Continue to stir at this temperature for half an hour, then add 1 mol of ethylene glycol dropwise to it, keep dropping at 20-25°C for about 2.5 hours, and absorb the released HCl gas with water. When no HCl gas was released, the reaction ended, and after stirring for 1 hour, post-treatment was carried out. After acid washing, alkali washing, water washing and distillation, viscous liquid is obtained. Liquid chromatography analysis shows that its molecular weight is 1315, its phosphorus content is 18.7%, and its hydroxyl value is 19.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com