Full-automatic lug cutting machine

An ear cutting machine, a fully automatic technology, applied in the field of automatic tab cutting machines, can solve the problems of labor-intensive, low safety, low efficiency, etc., and achieve the effects of improving production efficiency and safety performance, simple structure and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

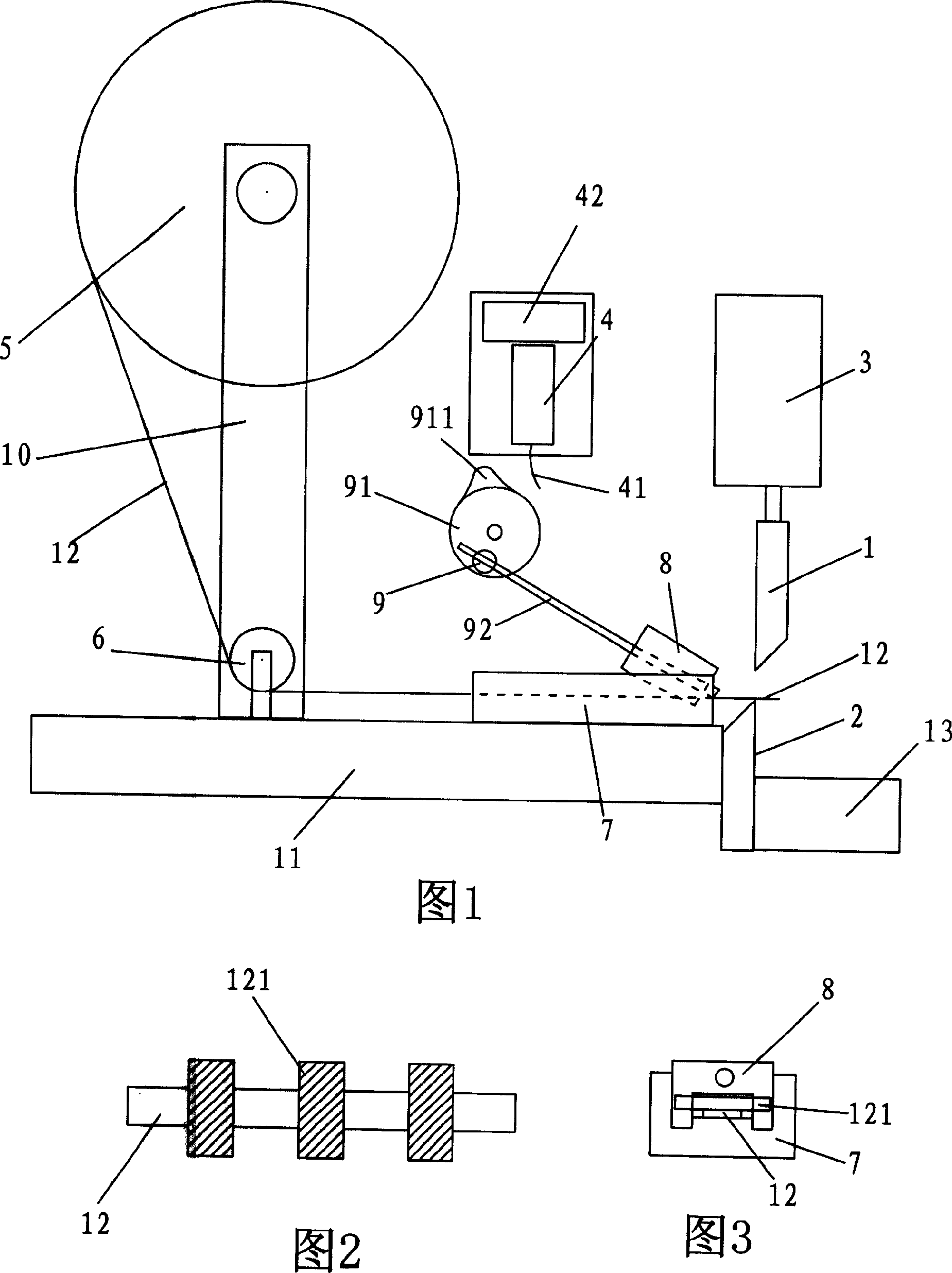

[0013] Referring to Figures 1 to 3, the fully automatic tab cutting machine according to the embodiment of the present invention is provided with a pneumatic cutter 1, a fixed knife 2, a cylinder 3, a counting and cutter control switch 4 and a feeding device, and the pneumatic cutter 1 is installed on the cylinder 3 Above, the fixed knife 2 and the cylinder 3 are installed on the workbench 11, the cylinder 3 is connected with the counting and cutting knife control switch 4, and the counting and cutting knife control switch 4 is touched when the feeding device sends the lug base belt 12 to the position, and the counting and cutting The switch 41 on the knife control switch 4 starts the cylinder 3, and the cylinder 3 drives the pneumatic cutter 1 to cut the pole ear.

[0014] The feeding device of the embodiment of the present invention can be provided with a frame 10, an unwinding frame 5, a guide wheel 6, a guide groove 7, a feeding slider 8, a crank connecting rod 9 and a moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com