Preparation method and preparation system of alkyl carbonate

An alkyl carbonate and preparation system technology, applied in the chemical industry, can solve the problems of high cost, complex synthesis process and the like, and achieve the effects of fast speed, simple reaction device and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

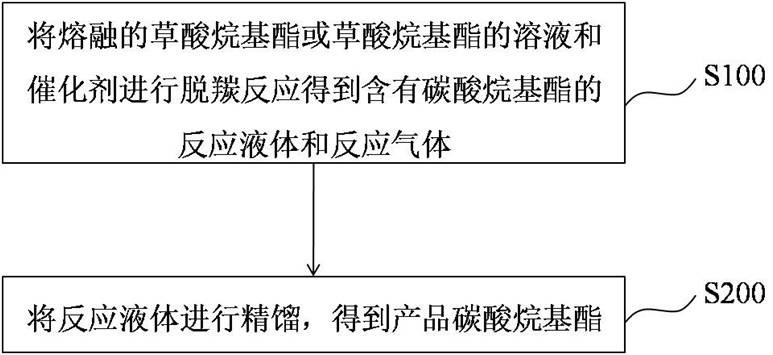

[0067] The present embodiment provides a kind of preparation method of alkyl carbonate, such as figure 1 shown, including:

[0068] S100 Decarbonylation reaction step: decarbonylation the molten alkyl oxalate or the solution of the alkyl oxalate and the catalyst at a temperature between 50°C and 160°C and a pressure between 0.5bar and 5bar Reaction obtains reaction gas and the reaction liquid containing alkyl carbonate;

[0069] S200 Rectification treatment step: performing rectification on the reaction liquid to obtain the product alkyl carbonate.

[0070] In some embodiments, the molecular formula of the alkyl oxalate is R-O-COCO-O-R', wherein both R and R' have carbon atoms between 1 and 8.

[0071] In some embodiments, the catalysts include rhodium carbonyl catalysts, which are liquid at normal temperature and pressure.

[0072] In some embodiments, a heating and melting step is also included: heating and melting the alkyl oxalate to obtain molten alkyl oxalate.

[0073]...

Embodiment 2

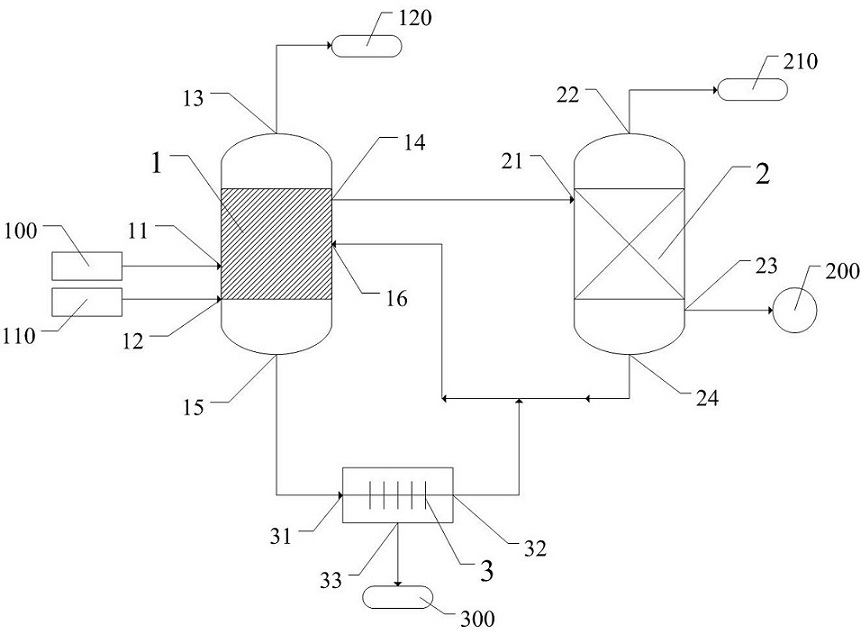

[0080] The present embodiment provides a kind of preparation system of alkyl carbonate, such as figure 2 Shown, comprise: reactor 1, rectification unit 2 and solid-liquid separation unit 3, wherein:

[0081] Reactor 1 is used for decarbonylation reaction of alkyl oxalate and catalyst to obtain reaction liquid and reaction gas 120, including: reaction raw material inlet 11, used for feeding reaction raw material 100 into the reactor, including molten oxalic acid alkane The solution of base ester or alkyl oxalate; Catalyst inlet 12, is used to pass into catalyst 110 in the reactor; Reaction gas outlet 13, is used for exporting reaction gas; Reaction liquid outlet 14, and the liquid inlet 21 of rectifying device 2 connected, so that the reaction liquid enters the rectification device 2 for rectification; the catalyst outlet 15 is connected with the fluid inlet 31 of the solid-liquid separation device 3, so that the fluid containing solid impurities enters the solid-liquid separa...

Embodiment 3

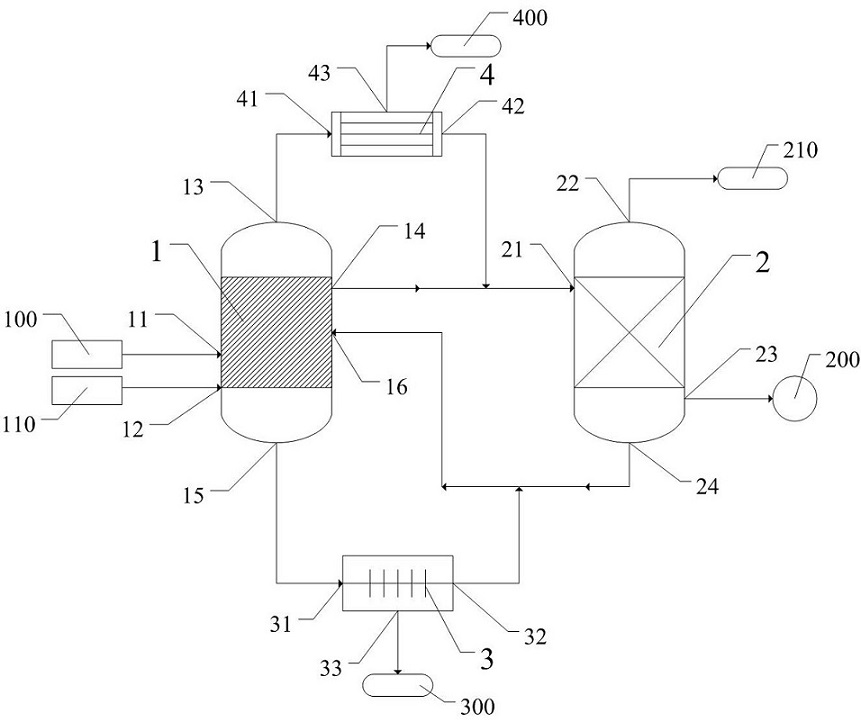

[0090] This embodiment takes the preparation of product dimethyl carbonate as an example to illustrate the preparation method and preparation system of the alkyl carbonate of the present invention. In this embodiment, the reaction raw material alkyl oxalate is dimethyl oxalate (molecular formula R-O-COCO-O -R', R and R' are all alkyl groups with 1 carbon atom), the reactor 1 in the preparation system of this embodiment is a stirred tank reactor, the rectification device 2 is a packed rectification tower, and solid-liquid separation Device 3 is a plate-and-frame filter press, and cooling separation device 4 is a shell-and-tube heat exchanger. The connections between these devices are as follows: image 3 shown. The preparation method comprises steps:

[0091] Decarbonylation reaction: heat dimethyl oxalate to 50°C~60°C, the solid dimethyl oxalate melts into a liquid state, enters reactor 1 through the reaction raw material inlet 11, and the dimethyl carbonate solution containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com