Organic surface modification halloysite nano-tube and method for making same

A technology for organicizing halloysite and halloysite nanotubes, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc. problem, to achieve the effect of easy product, fast reaction rate and product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

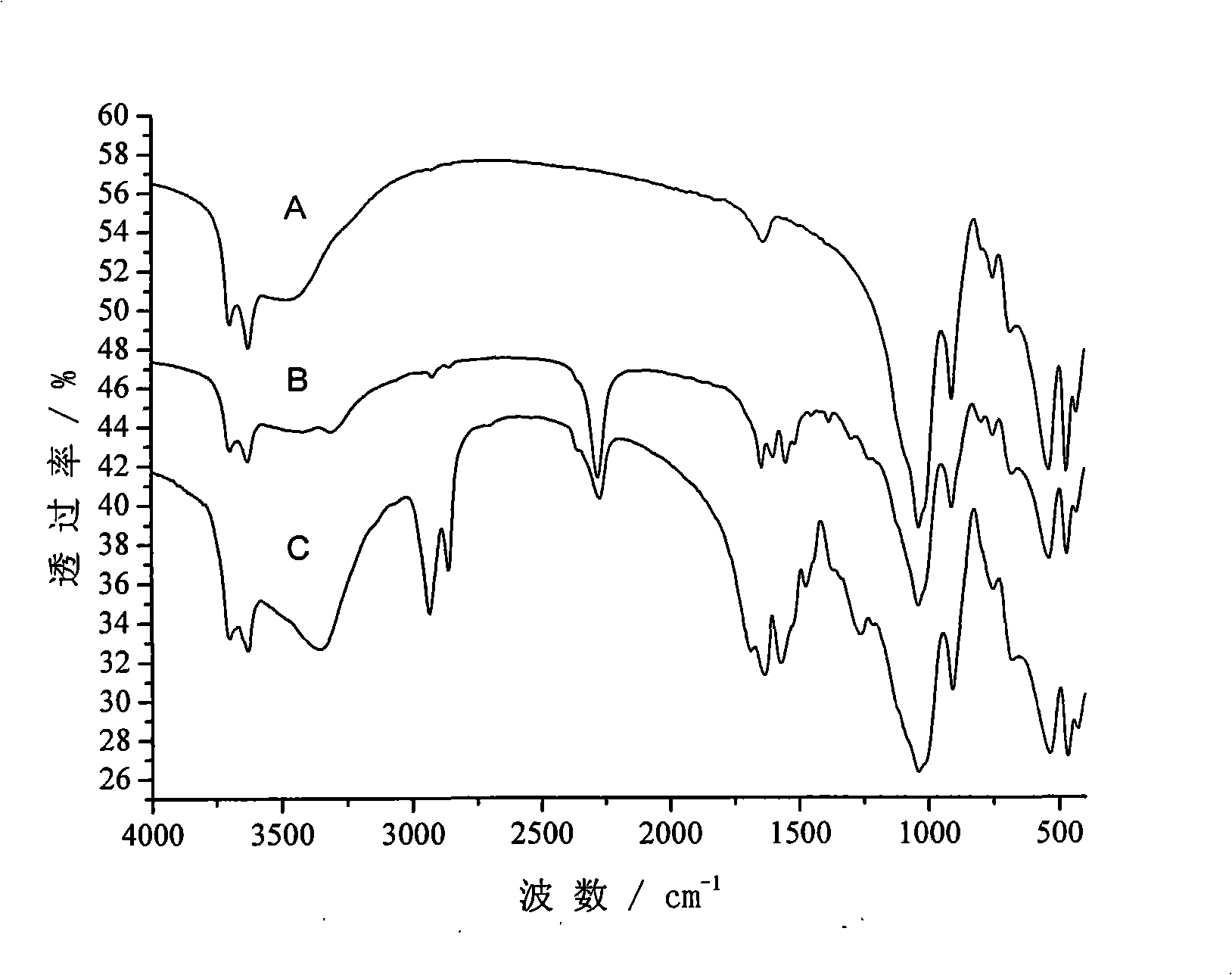

Image

Examples

Embodiment 1

[0029] The halloysite nanotube raw material is first crushed and ground, and then sieved with a 250-mesh sieve to obtain the halloysite nanotube powder. Weigh 2 grams of halloysite nanotube powder and dry it in vacuum at 80° C. for 12 hours, then disperse it into 50 grams of acetone, and ultrasonically disperse it for 1 hour under the condition of 1000 W power. 5 g of toluene-2,4-diisocyanate and two drops of dibutyltin dilaurate were added to the obtained suspension, and the reaction was irradiated by ultrasound at a temperature of 60° C. and a power of 1000 W for 2 hours. After the system was cooled, it was filtered and washed three times with 60ml of acetone. The resulting pink powder was vacuum-dried at 50°C for 12 hours, and then packaged and stored in a dry place.

Embodiment 2

[0031] The halloysite nanotube raw material is first crushed and ground, and then sieved with a 250-mesh sieve to obtain the halloysite nanotube powder. Weigh 1 gram of halloysite nanotube powder and dry it in vacuum at 80°C for 12 hours, then disperse it into 30 grams of acetone, and disperse it ultrasonically for 1 hour under the condition of 1000W power. Add 0.5 g of hexamethylene diisocyanate and two drops of dibutyltin dilaurate to the obtained suspension, and react with ultrasonic irradiation for 3 hours at a temperature of 70° C. and a power of 1000 W. After the system was cooled, it was filtered and washed three times with 60ml of acetone. The resulting pink powder was vacuum-dried at 50°C for 12 hours, and then packaged and stored in a dry place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com