Efficient terminalization preparation method for hydroxyl terminal nano diamond for biological application

A nano-diamond, terminal technology, applied in diamond and other directions, can solve the problems of slow process, low yield of diamond nano-powder, inefficiency, etc., to achieve the effect of fast speed, shorten the free path of molecular motion, and avoid aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

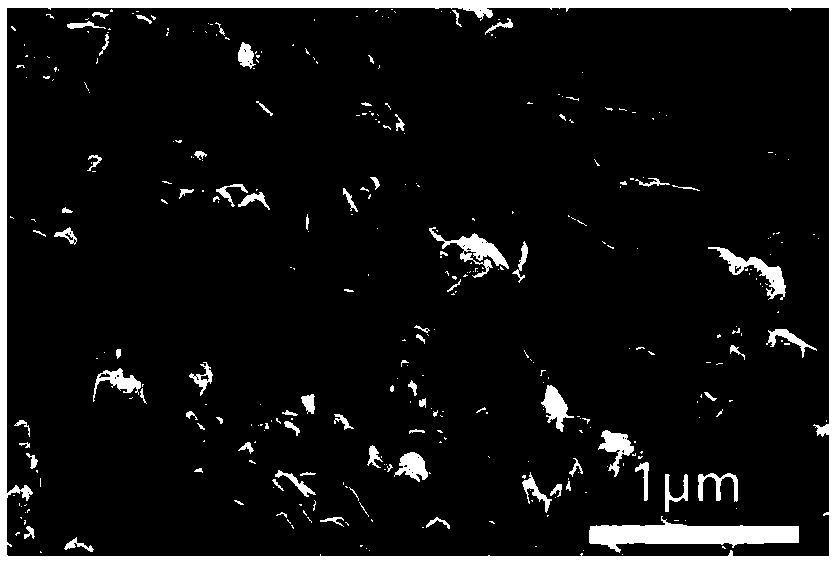

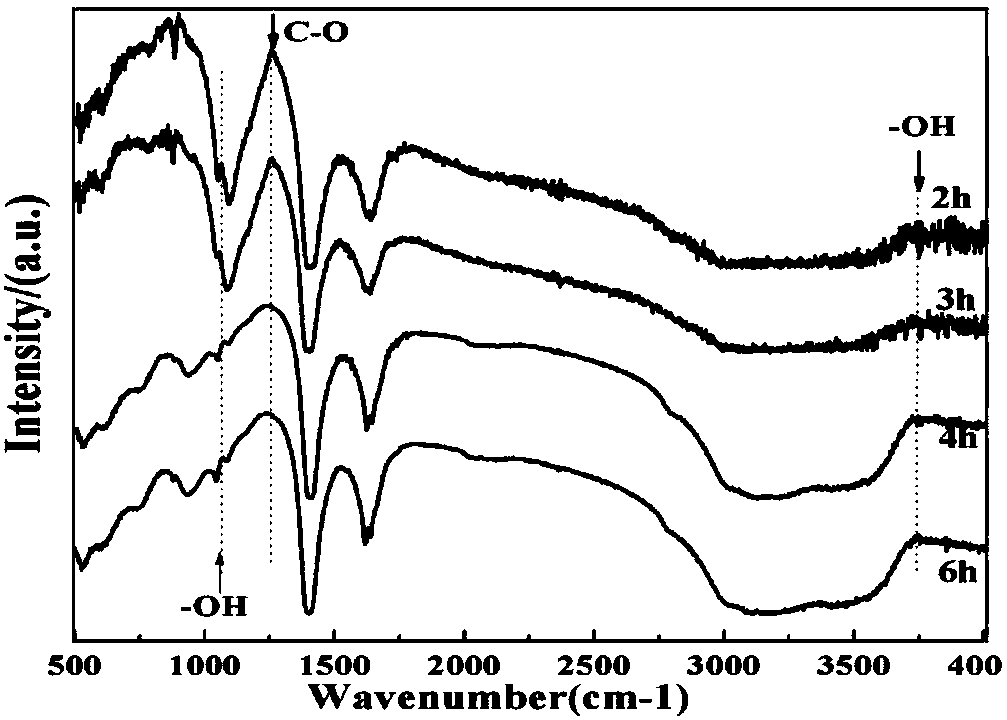

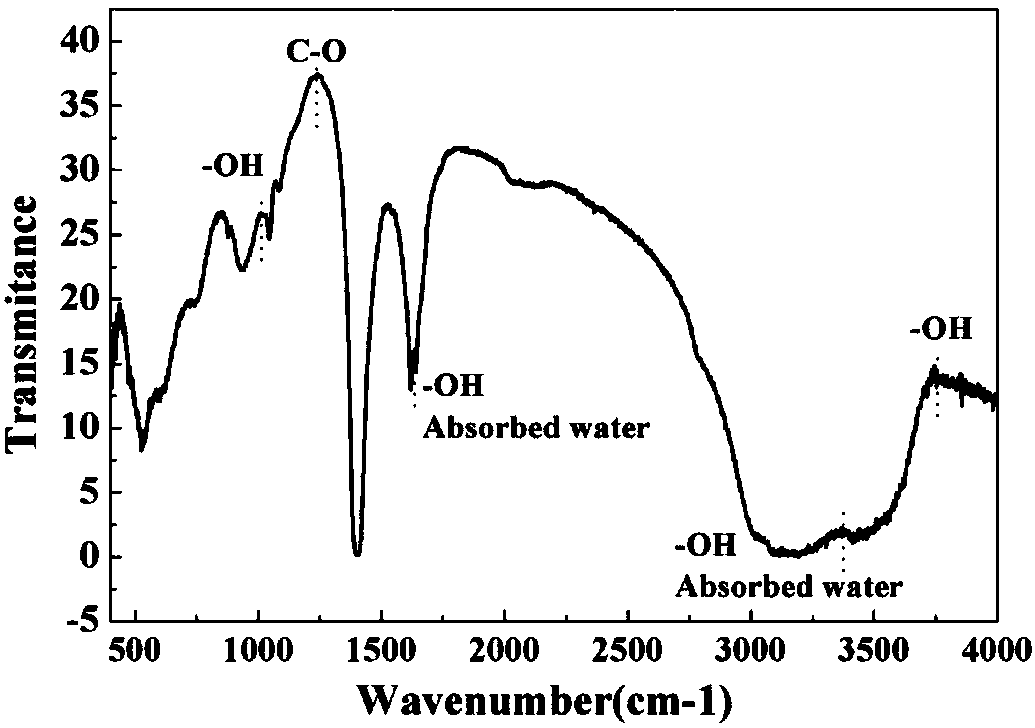

Image

Examples

specific Embodiment approach 1

[0033] (1) Take a 100nm diamond powder sample and place it in HCl: H 2 SO 4 = Boil in a mixture of 1:5 for 2 hours, acid boil for 3 times, and then rinse with deionized water; then place in acetone solution and absolute ethanol for 15 minutes for ultrasonic cleaning, and place in a ventilated drying box to dry Ventilated drying at 60°C for 2 hours to obtain dry and pure nano-diamond powder. (2) 5g of nano-diamond powder, and 0.5mol / L Lithium Aluminum Hydride dissolved in THF solution are stirred into a suspension and placed in the reactor together to ensure that the volume of the mixed suspension is 80% of the volume of the reactor . (3) Assemble the reactor and close the outer steel jacket of the reactor. Then it was placed in a constant temperature heating box, and the temperature was set at 100°C. Start timing from reaching the set temperature, and set the constant temperature time to 1 hour. After the constant temperature time is terminated, when the temperature of th...

specific Embodiment approach 2

[0034] (1) Take a 100nm diamond powder sample and place it in HCl: H 2 SO 4 = Boil in a mixture of 1:5 for 2 hours, acid boil for 3 times, then rinse with deionized water; then place in acetone solution and absolute ethanol for ultrasonic cleaning for 10-15 minutes each, and place in a ventilated drying oven Air-dried at 100°C for 1 hour to obtain dry and pure nano-diamond powder. (2) 10g of nano-diamond powder is stirred with a solution of 1mol / L Lithium Aluminum Hydride dissolved in THF to form a suspension and placed in the reactor together to ensure that the volume of the mixed suspension is 80% of the volume of the reactor. (3) Assemble the reactor and close the outer steel jacket of the reactor. Then it was placed in a constant temperature heating box, and the temperature was set at 100°C. Start timing from reaching the set temperature, and set the constant temperature time to 2 hours. After the constant temperature time is terminated, when the temperature of the ste...

specific Embodiment approach 3

[0035] (1) Take a 100nm diamond powder sample and place it in HCl: H 2 SO 4 = Boil in a mixture of 1:5 for 2 hours, acid boil for 3 times, then rinse with deionized water; then place in acetone solution and absolute ethanol for ultrasonic cleaning for 10-15 minutes each, and place in a ventilated drying oven Air-dried at 200°C for 15 minutes to obtain dry and pure nano-diamond powder. (2) 15g of nano-diamond powder is stirred with a solution of 2mol / L Lithium Aluminum Hydride dissolved in THF to form a suspension and placed in the reactor together to ensure that the volume of the mixed suspension is 80% of the volume of the reactor. (3) Assemble the reactor and close the outer steel jacket of the reactor. Then it was placed in a constant temperature heating box, and the temperature was set at 100°C. Start timing from reaching the set temperature, and set the constant temperature time at 4 hours. After the constant temperature time is terminated, when the temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com