Method for preparing resorcinol-formaldehyde aerogel

A technology of resorcinol and formaldehyde gas, applied in chemical instruments and methods, colloidal chemistry, colloidal chemistry and other directions, can solve the problems of limiting the application of resorcinol-formaldehyde aerogel, and achieve fast reaction rate and shorten the reaction time. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Preparation of resorcinol-formaldehyde airgel by ultraviolet light initiation method

[0025] First configure 30ml of resorcinol-formaldehyde solution with a certain concentration. The solution is composed of: 0.9706g of resorcinol, 0.05mol / L sodium carbonate solution of 0.88ml, and 1.33ml of formaldehyde solution. Stir to make it fully mixed, 60 Place in water at ℃ for 30 minutes, cool to room temperature, add 10wt% photoinitiator 659, mix well, transfer 0.1ml to a small container and seal it, use a wavelength range of 250-720nm, a distance of 2cm, and a light intensity of 18.26w / cm 3 Irradiated by a high-pressure mercury lamp. The time at which a solution loses fluidity is defined as the gel time. Resorcinol-formaldehyde airgel prepared after 35 min. The specific surface area of resorcinol-formaldehyde airgel is 433m 2 / g, the total pore volume is 4.77cm 3 / g, the average pore diameter is 2.996nm.

Embodiment 2

[0026] Embodiment 2 Utilizes ultraviolet photoinitiation method to prepare resorcinol formaldehyde airgel

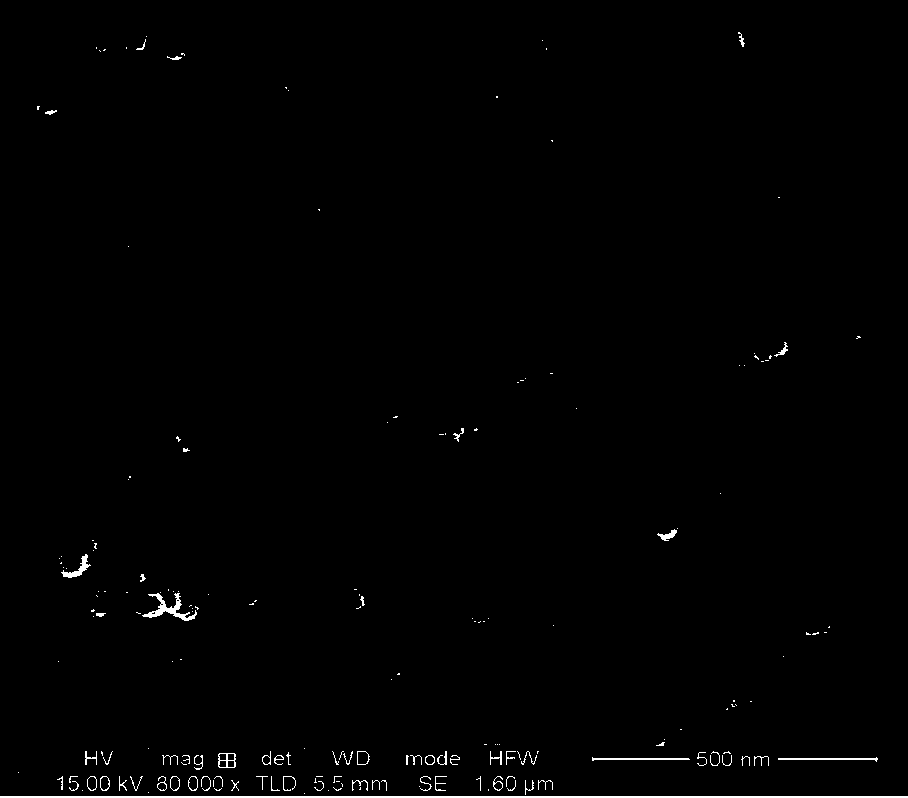

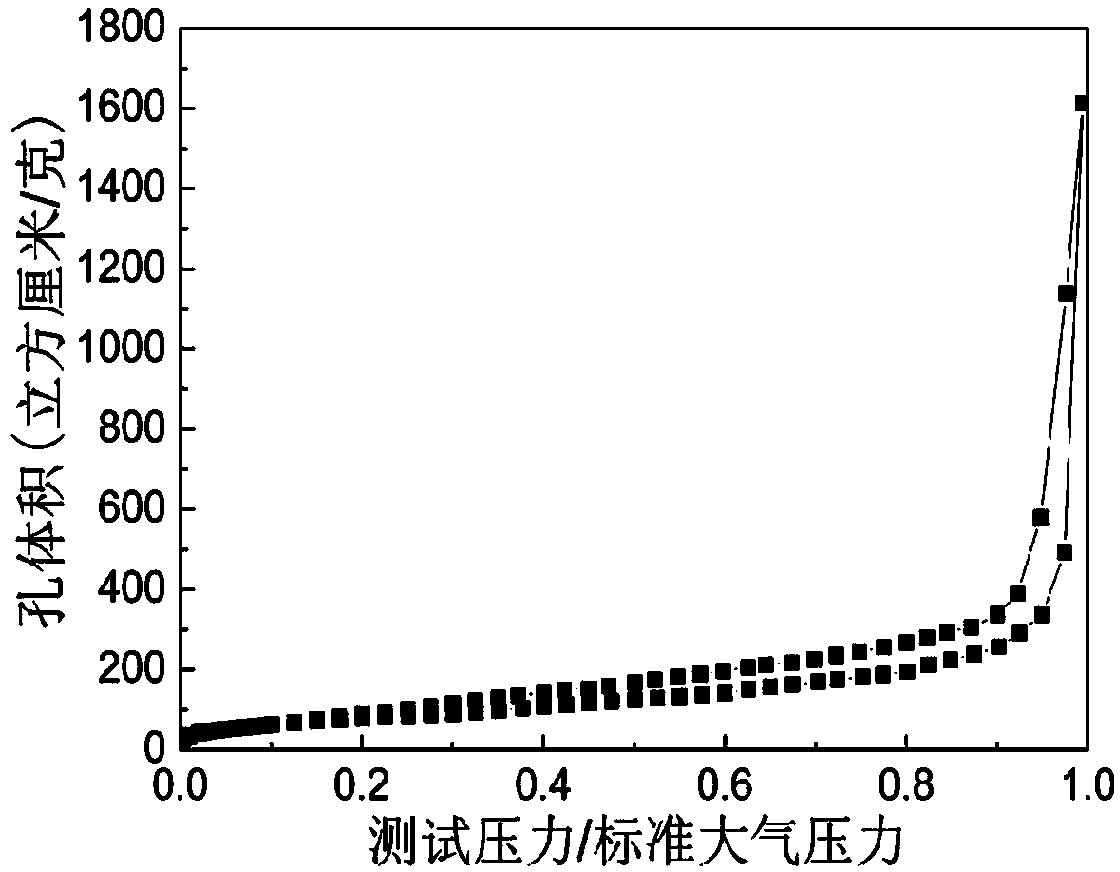

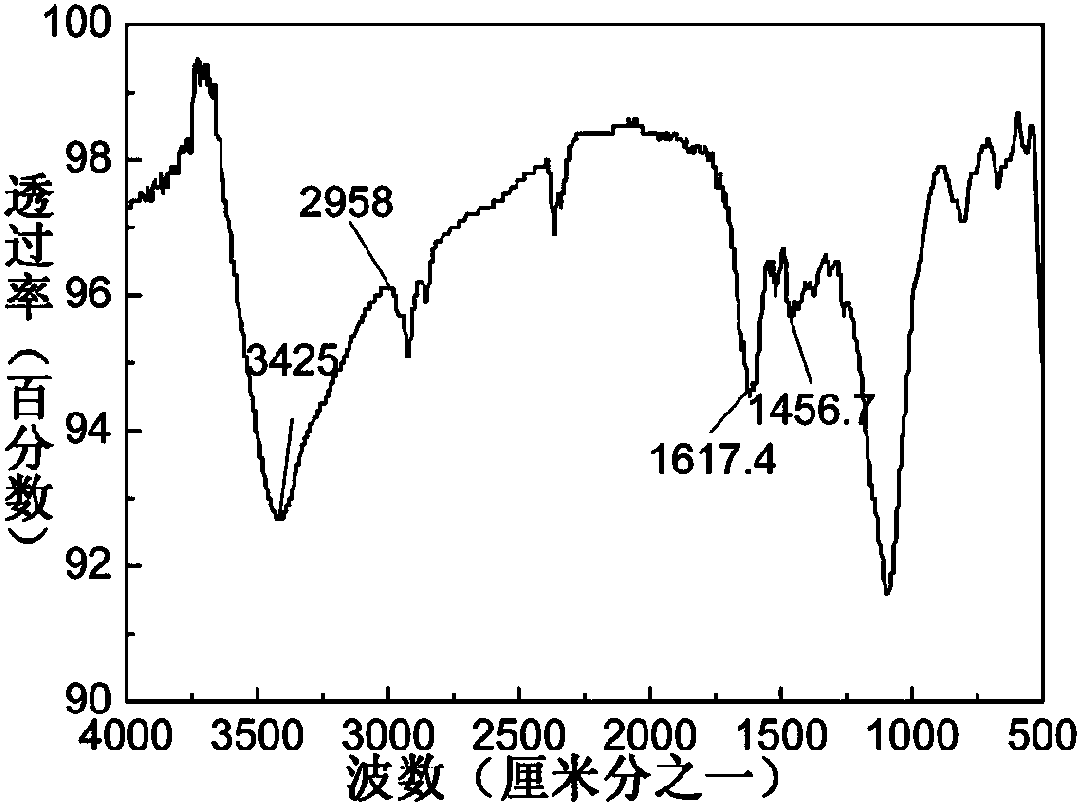

[0027] According to the preparation process of the resorcinol-formaldehyde airgel described in Example 1, the difference is that the water bath storage time in the parameters is 40 minutes, and the resorcinol-formaldehyde airgel is prepared in 15 minutes. The prepared resorcinol formaldehyde airgel has a specific surface area of 294m 2 / g, the total pore volume is 2.502cm 3 / g, the average pore diameter is 2.384nm. figure 1 It is the scanning electron microscope image of the sample. It can be seen from the figure that the RF prepared by the ultraviolet photoinitiation method has a certain network structure and a certain pore structure. figure 2 As the adsorption-desorption curve of the sample, the specific surface area, total pore volume and average pore diameter can be calculated with the adsorption software. image 3 It is the infrared spectrum curve of the sampl...

Embodiment 3

[0028] Example 3 Preparation of resorcinol-formaldehyde aerogel by ultraviolet light initiation method

[0029] Referring to the preparation process of the resorcinol-formaldehyde airgel described in Example 1, the difference is that the water bath standing time in the parameters is 50 minutes. Resorcinol-formaldehyde airgel prepared in 25 minutes. The specific surface area of resorcinol-formaldehyde airgel is 260m 2 / g, total pore volume 2.370m 3 / g, the average pore diameter is 3.996nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com