Vacuum process for cracking dimethyl dichlorosilane hydrolysate

A technology of dimethyldichlorosilane and vacuum process, applied in the direction of silicon organic compounds, etc., can solve the problems of low level of automation control, damage to mechanical seals, equipment blockage, etc., to reduce the amount of operating labor, low operating costs, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

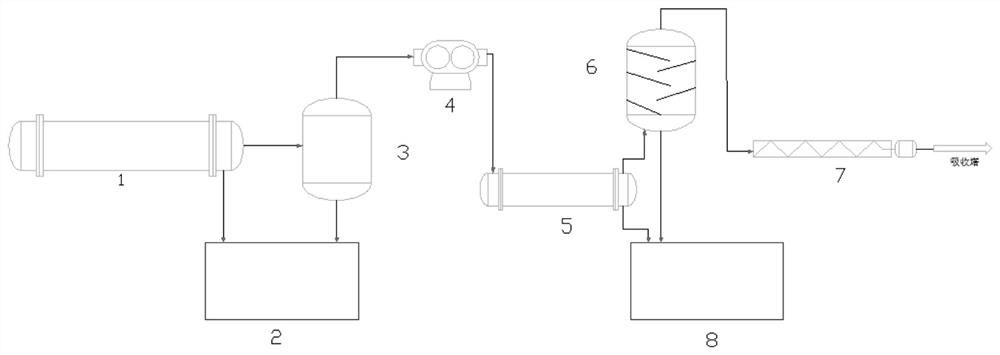

[0022] Vacuum device suitable for dimethyldichlorosilane hydrolyzate cracking, heat exchanger A 1, collection tank 2, hydrocyclone separation tank 3, Roots vacuum unit 4, heat exchanger B 5, buffer tank 6, screw vacuum unit 7. Effusion tank 8, heat exchanger A 1 is connected to separation tank 3, separation tank 3 is connected to Roots vacuum unit 4, Roots vacuum unit 4 is connected to heat exchanger B 5, heat exchanger B 5 is connected to buffer tank 6 connection, the buffer tank 6 is connected to the gas absorption tower through the screw vacuum unit 7.

[0023] The heat exchanger A 1 is also connected to the collection tank 2 , the hydrocyclone separation tank 3 is also connected to the collection tank 2 , the heat exchanger B 5 is also connected to the liquid accumulation tank 8 , and the buffer tank 6 is also connected to the liquid accumulation tank 8 .

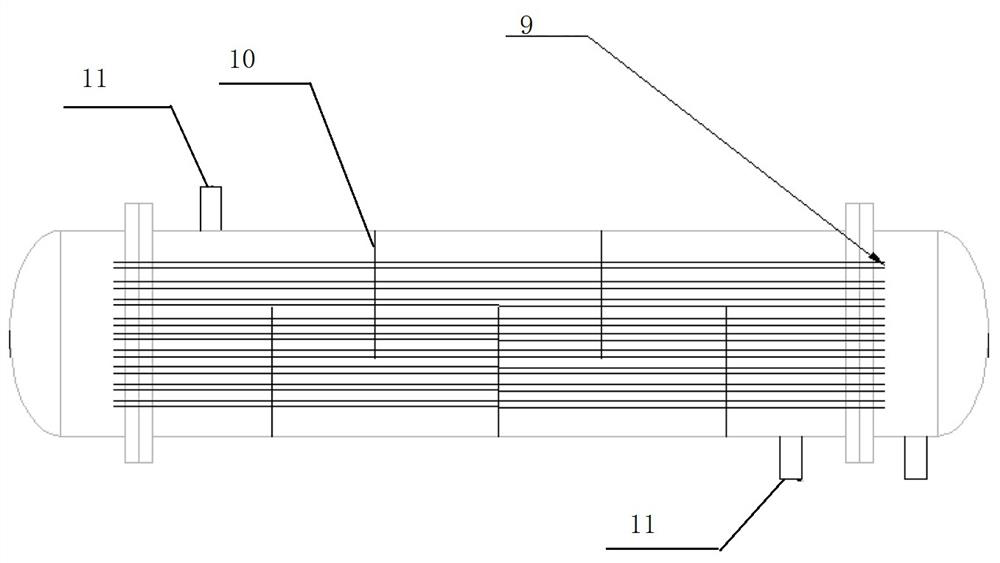

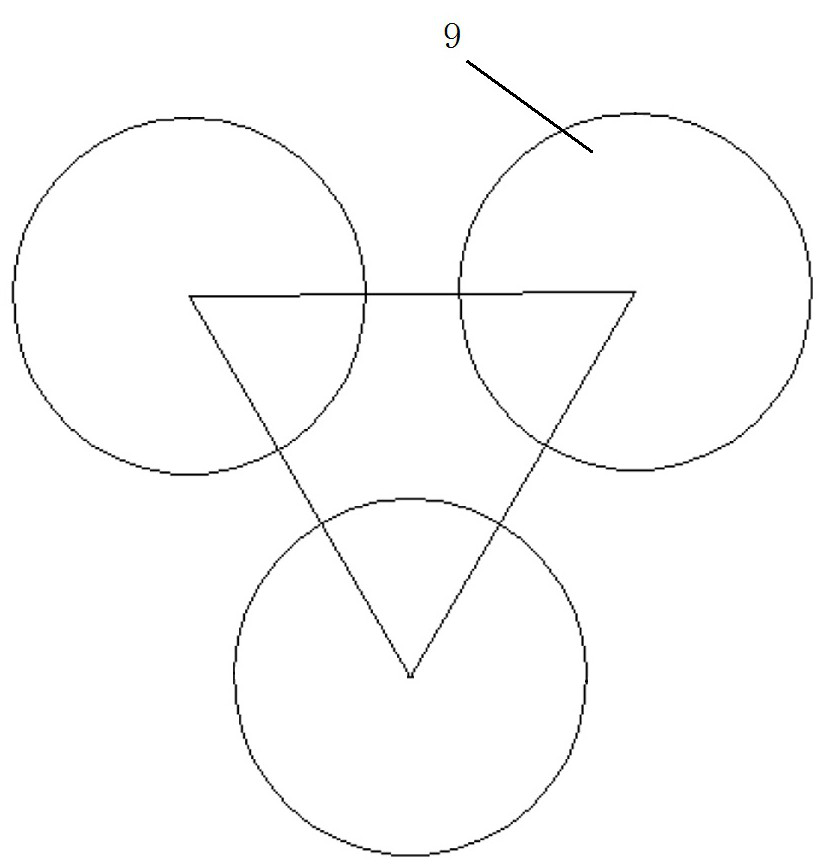

[0024] Heat exchanger A 1 is a single-tube fixed tube-sheet heat exchanger with an inner diameter of 0.6m. There are ...

Embodiment 2

[0027] The device and structure are the same as in Example 1, except that the diameter of the heat exchange tubes is Φ35mm and the length is 1.5m. The board spacing is 0.3m.

Embodiment 3

[0029] The device and structure are the same as in Example 1, except that the diameter of the heat exchange tube is Φ40mm and the length is 1.6m. The board spacing is 0.3m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com