Patents

Literature

32results about How to "Guaranteed production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of syrup special for moon cake

The invention relates to the field of starch sugar manufacturing, in particular to a preparation method of syrup special for moon cake. According to the method, corn starch is taken as the raw material, and the syrup is prepared through the steps such as size mixing, enzyme immersion, liquefaction, saccharification, glucoside conversion, decolorization, filtering, ion exchange, concentration, blending and the like. The prepared syrup comprises 20-25% of maltobiose, 12-17% of maltotriose, 15-20% of maltotetraose, 8-12% of tetrasaccharide-above, 3-5% of oligoisomaltose, 25-30% of fructose, and less than 3% of glucose. The syrup special for moon cake produced through the method is sucrose-free; the sweetness is slightly lower than that of the sucrose; the sweet taste is mild and pure, cool and refreshing; and the syrup is provided with a sweet flavor peculiar to honey, and has the advantages that the oil return property is obvious, the moisture retention property is good, the starch retrogradation is prohibited, the shelf life and the quality guarantee period of products are effectively prolonged, and the like.

Owner:BAOLINGBAO BIOLOGY

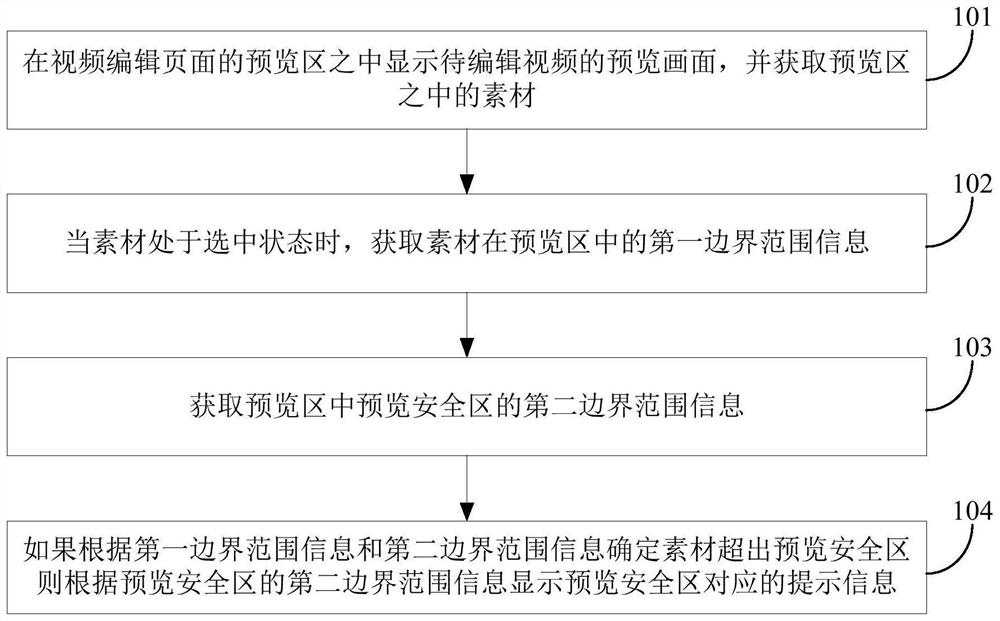

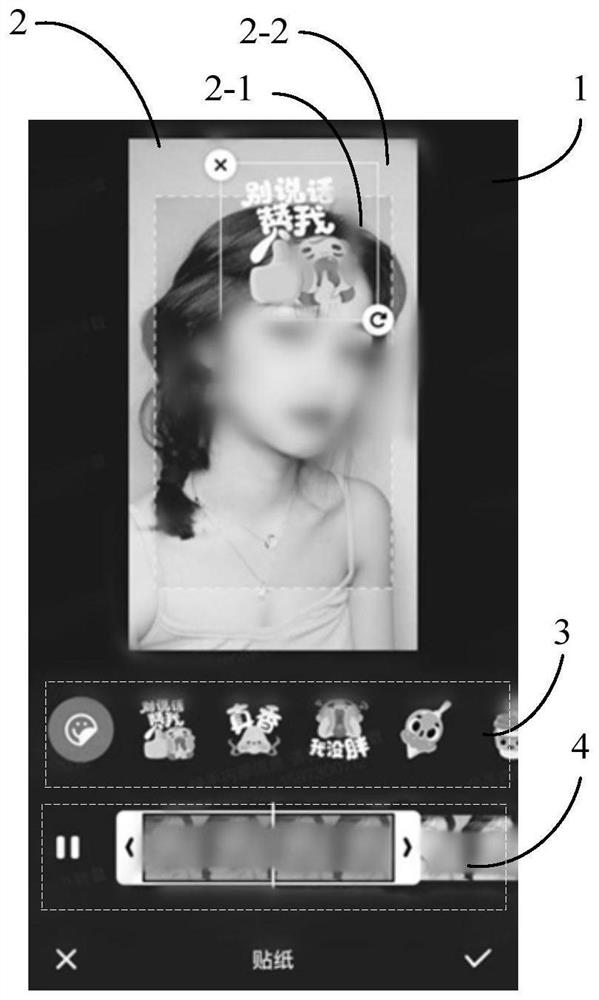

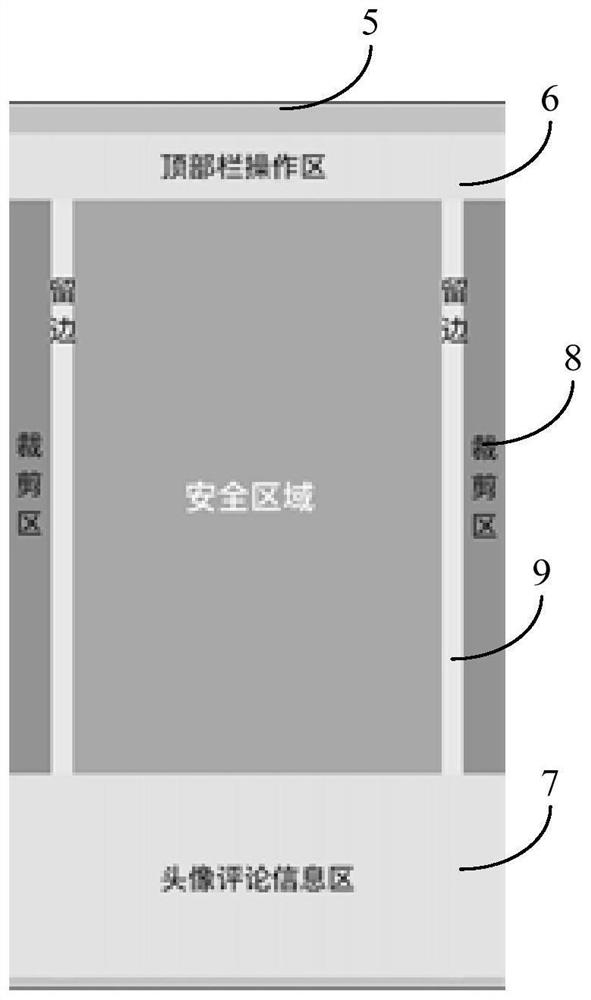

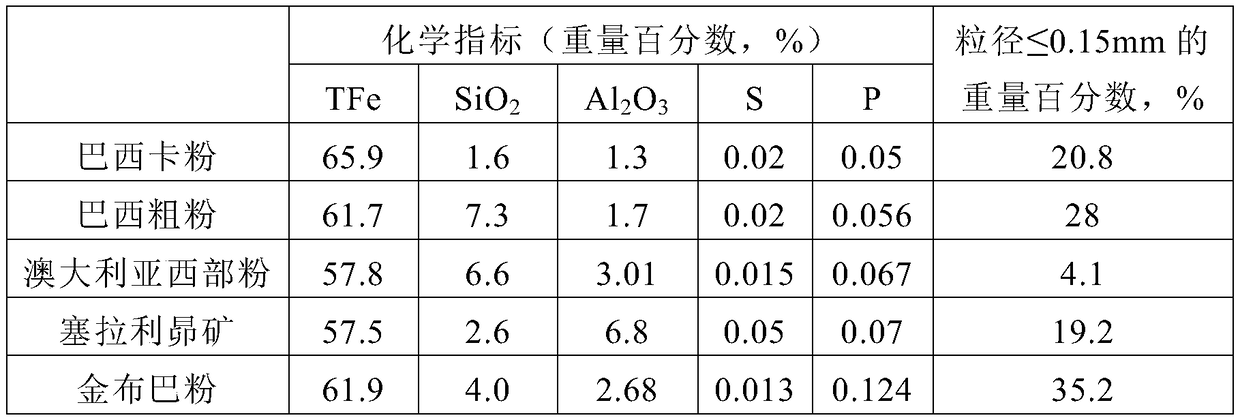

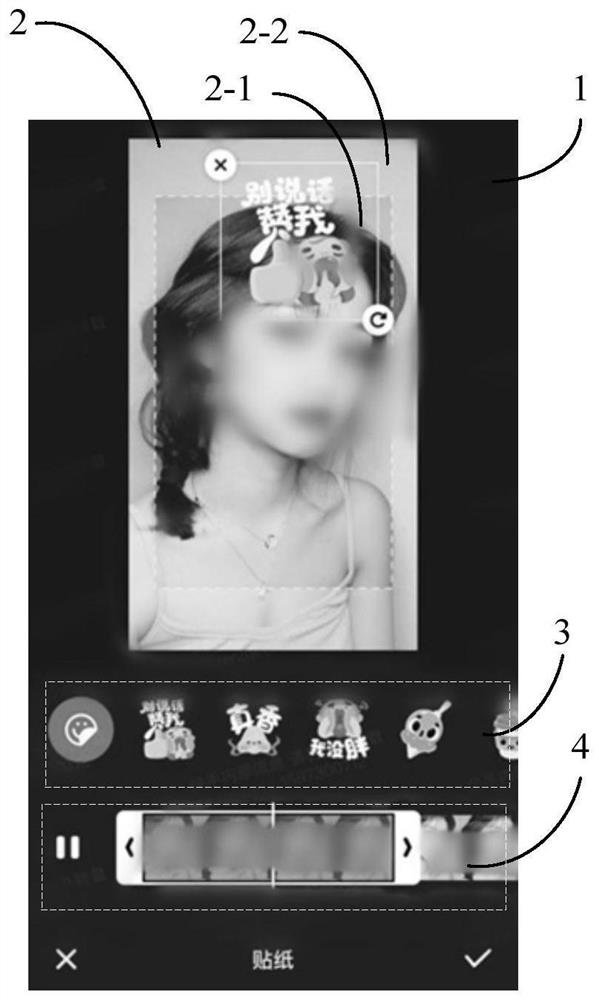

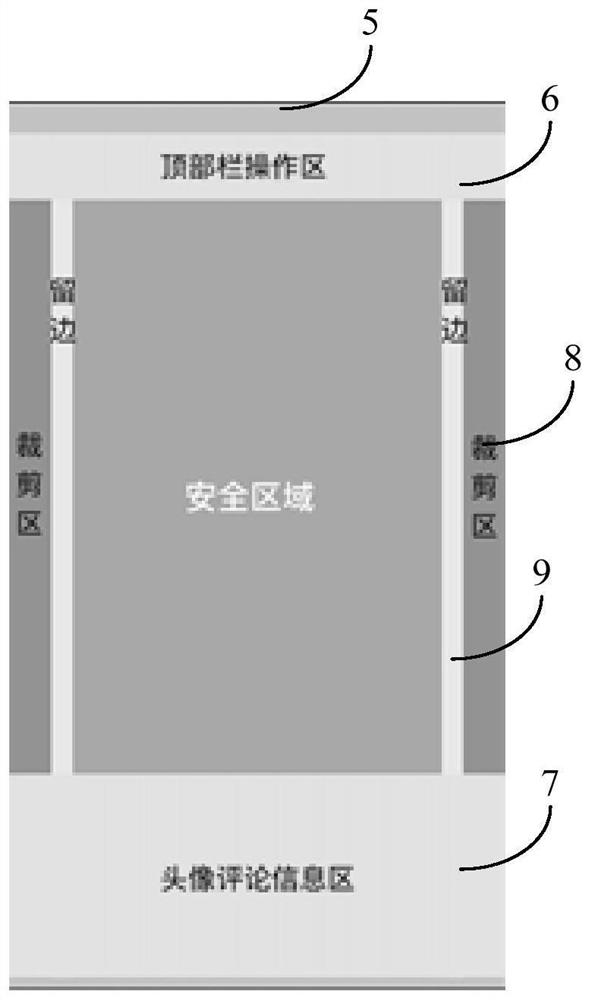

Video editing prompting method and device and electronic equipment

ActiveCN111770381ASatisfy the viewing effectGuaranteed production requirementsElectronic editing digitised analogue information signalsCarrier indicating arrangementsSafety zoneVideo production

The invention relates to a video editing prompting method and device, electronic equipment and a storage medium, and relates to the technical field of software application, and the method comprises the steps: displaying a preview image of a to-be-edited video in a preview region of a video editing page, and obtaining materials in the preview region; when the material is in the selected state, obtaining first boundary range information of the material in the preview area; acquiring second boundary range information of a preview safety area in the preview area; and if it is determined that the material exceeds the preview security area according to the first boundary range information and the second boundary range information, if so, displaying prompt information corresponding to the previewsafety area according to the second boundary range information of the preview safety area, by prompting when the added material exceeds the preview safety area, the made video can meet the watching effects of more users, and the watching experience of video watching users is improved while the making requirements of the video making users are ensured.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

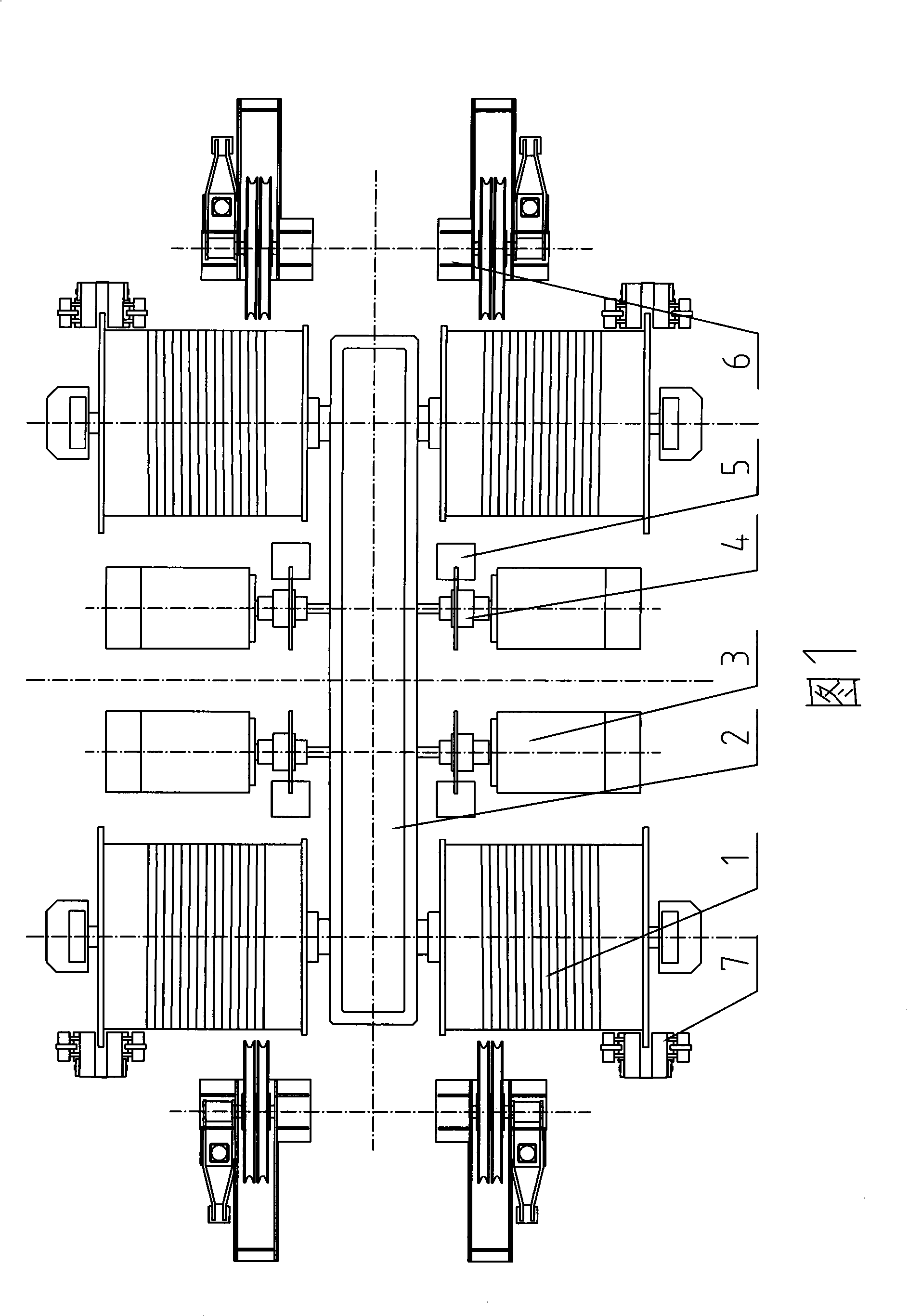

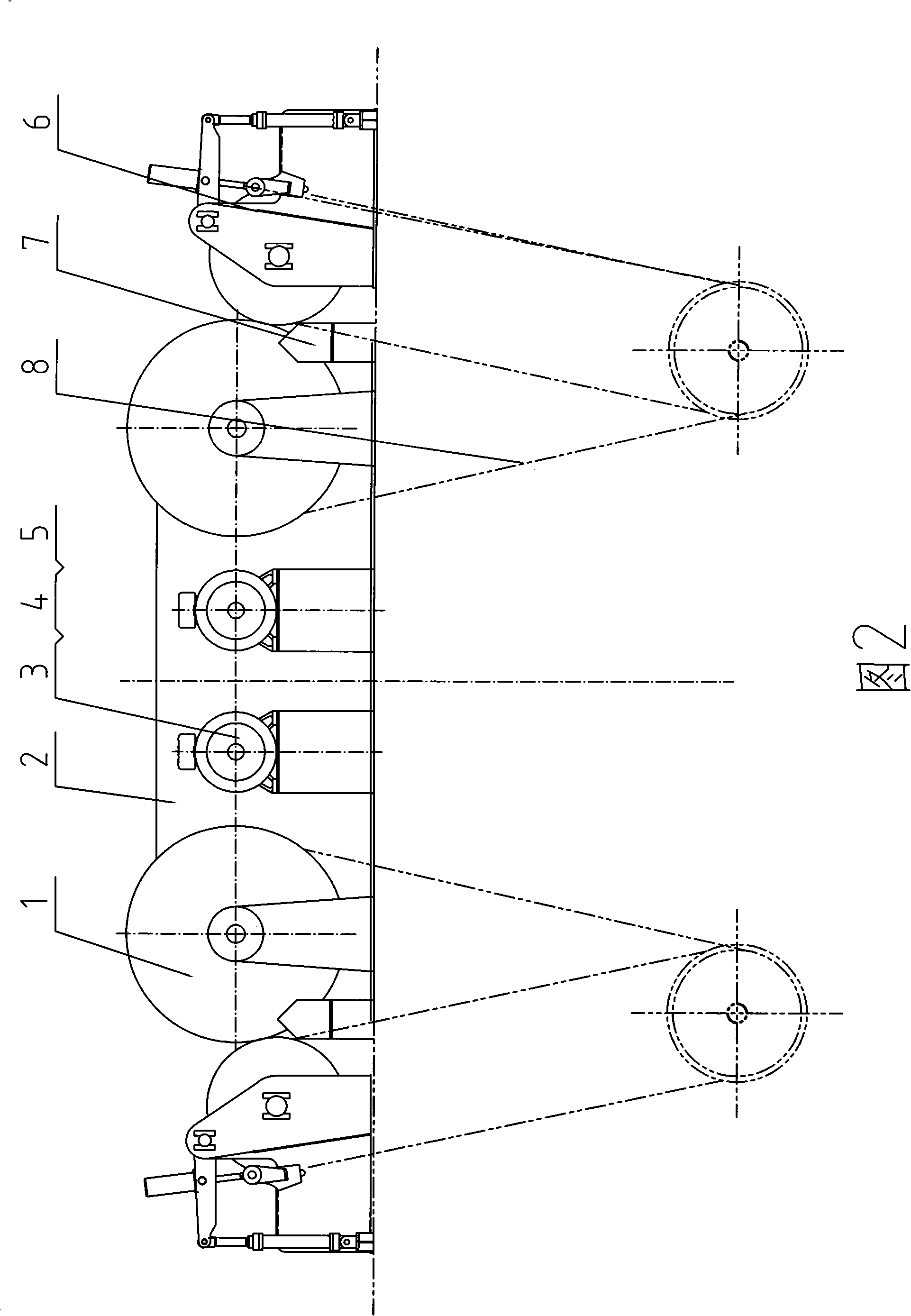

Hoisting mechanism of crane for coke pot

InactiveCN101343024AImprove reliabilityImprove securityCoke quenchingWinding mechanismsCouplingDistributed structure

The invention provides a lifting mechanism of a coke tank carrying crane, which relates to the lifting transportation and coking machinery; the lifting mechanism is composed of a winding drum group, a planetary reducer, a motor, couplings, brakes, a crown block group and a safety brake; the planetary reducer mounted on the pulley frame is provided with four input shaft ends and four output shaft ends which are symmetrically distributed. The four input shafts are arranged on the middle part of the planetary reducer and connected with the motor respectively through the couplings; the brakes are respectively mounted on the couplings; the four output shafts are arranged on both sides of the end part of the planetary reducer and connected with the single linkage winding drum group respectively; the safety brake directly acts on the winding drum edge of the single linkage winding drum group; the crown block group is mounted on the opposite side of the single linkage winding drum group. The lifting mechanism of the coke tank carrying crane has the advantages of novel structure, safety, reliability, great bearing capacity, symmetrically-distributed structure, even stress and being the lifting mechanism device of the novel coke tank carrying crane with economical and practical properties.

Owner:DALIAN HUARUI CO LTD

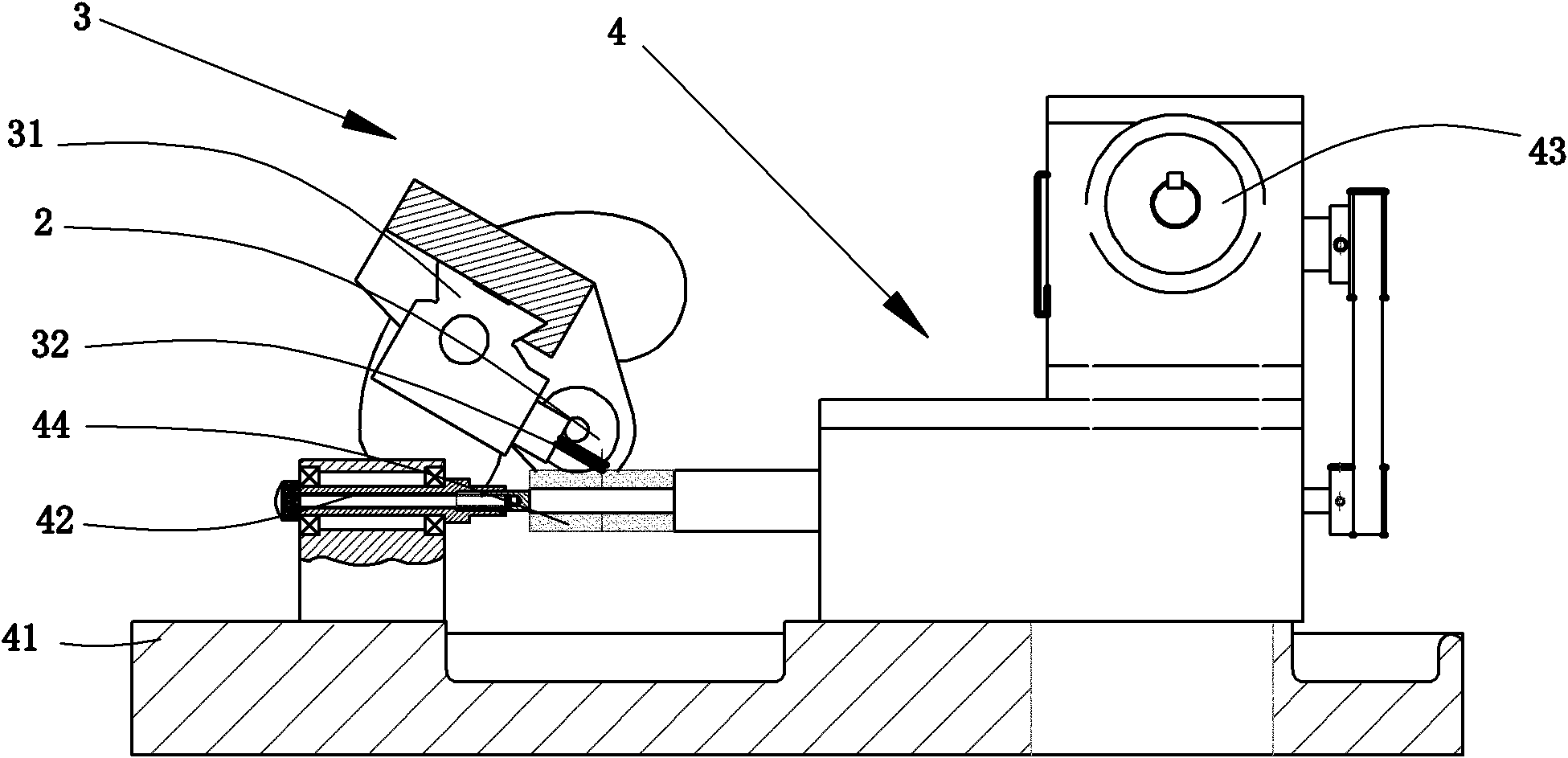

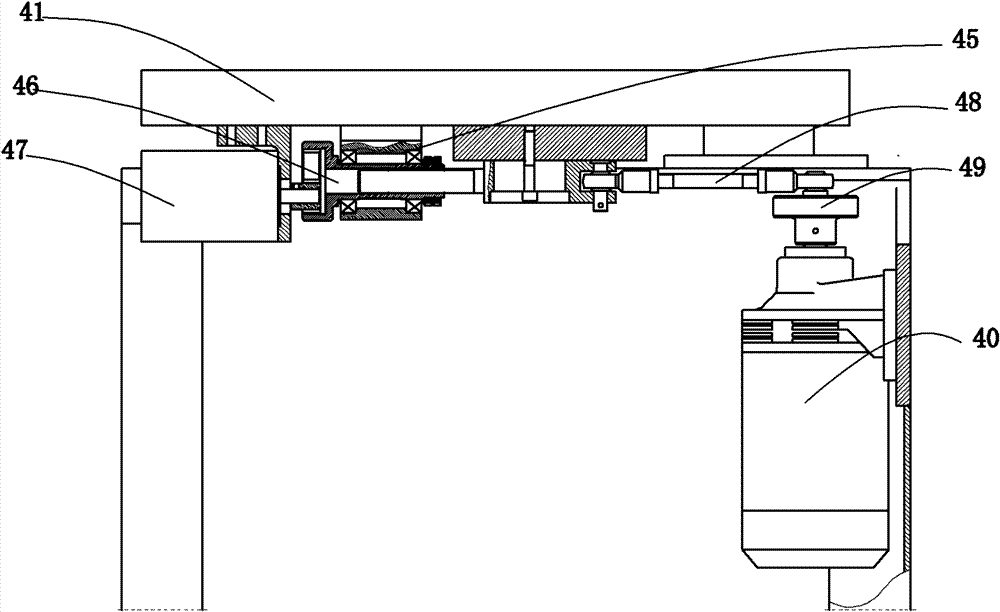

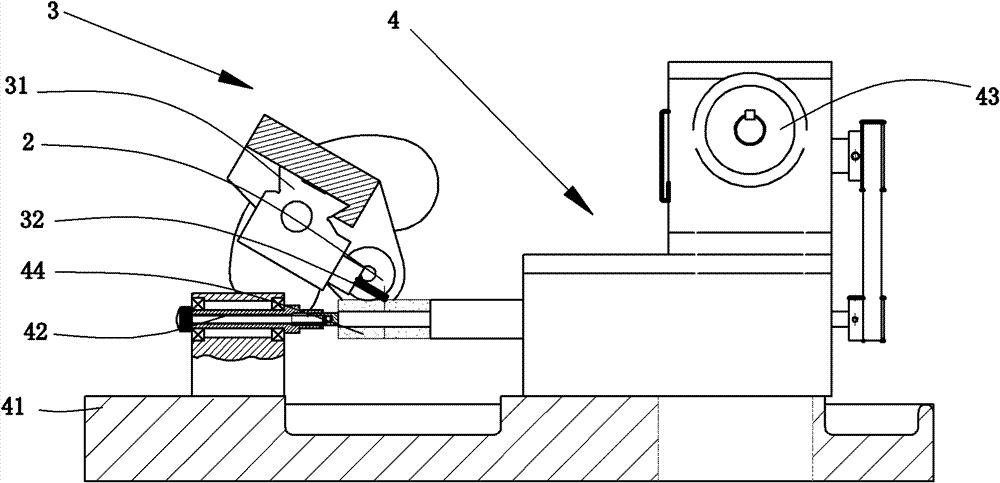

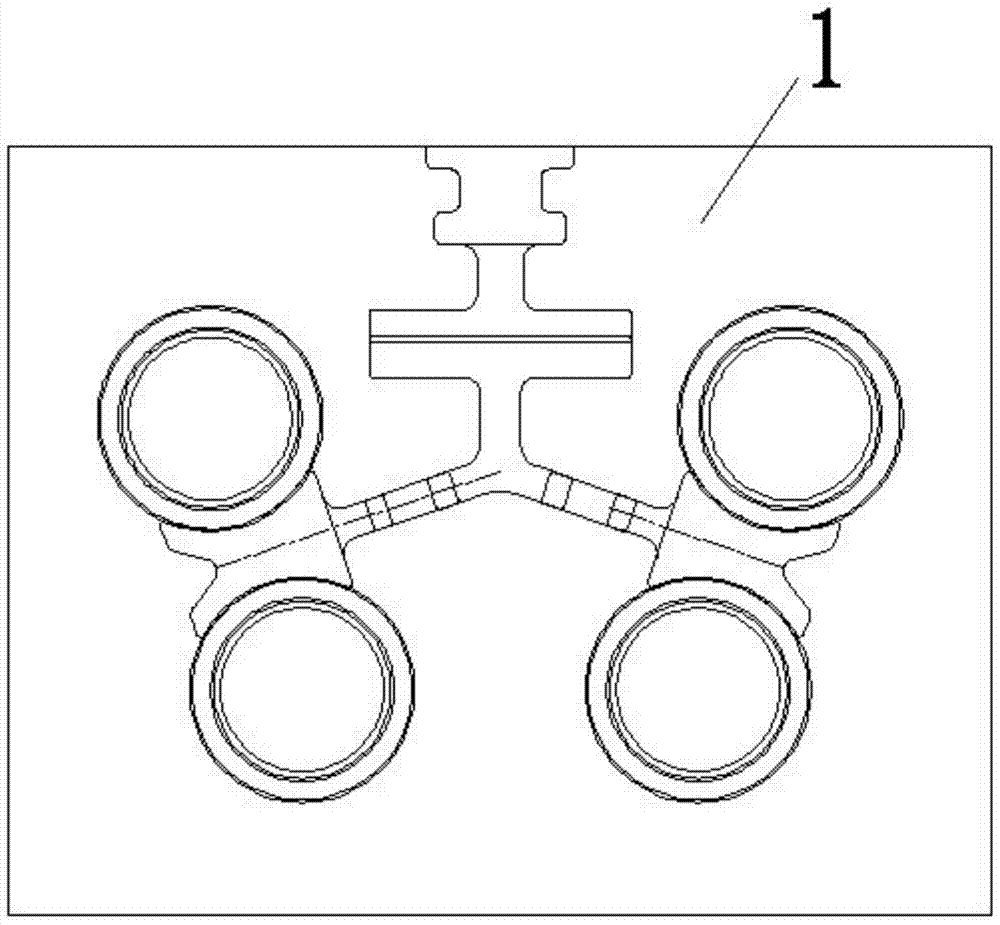

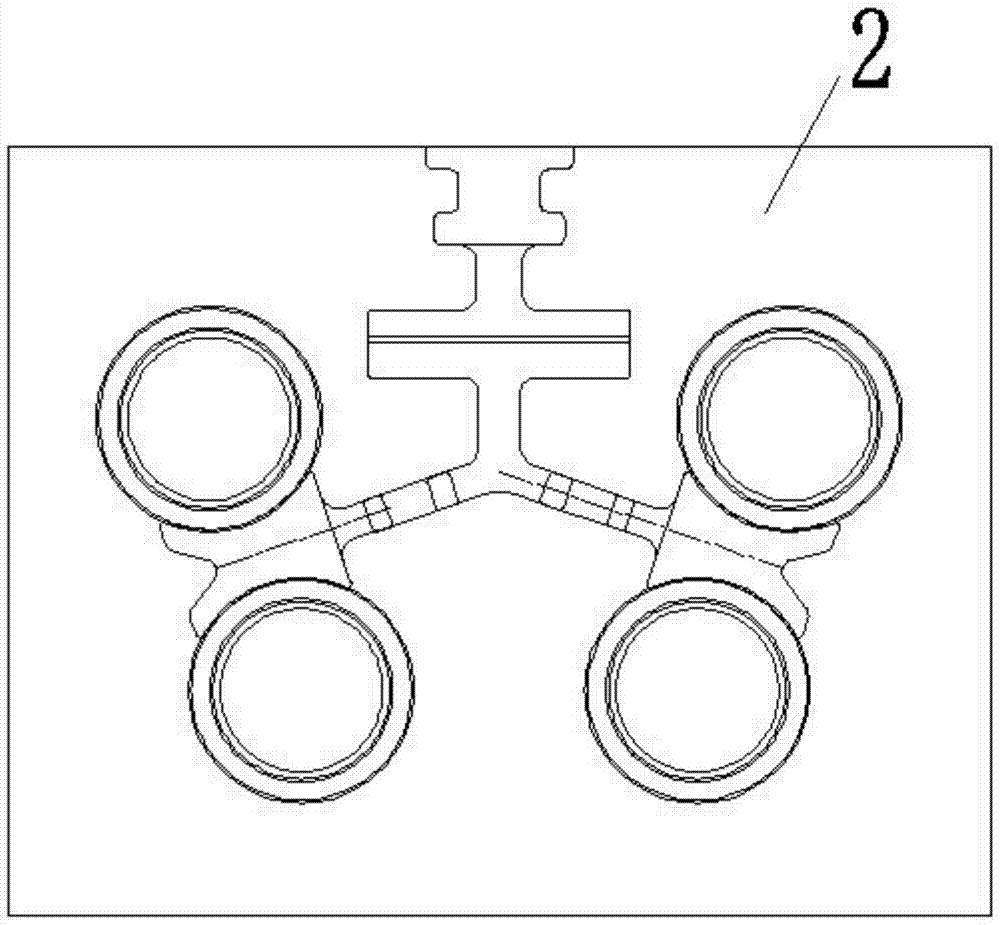

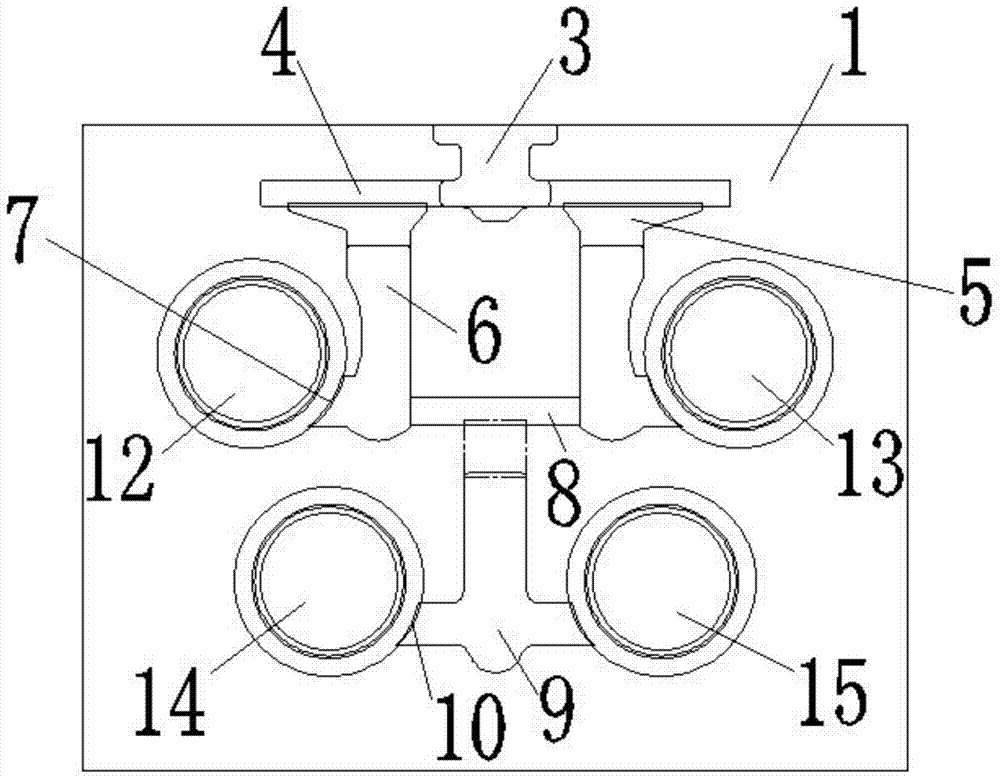

Full-automatic arc concave gem grinding machine

ActiveCN102152191AAchieve grindingRealize fully automatic arc grindingEdge grinding machinesEngineeringMechanical engineering

The invention discloses a full-automatic arc concave gem grinding machine, which comprises a rack. A transverse mounting frame is rotatably arranged at the upper side of the rack; a plurality of longitudinal aluminum ranks for clamping gem blanks are fixedly arranged on the bottom part of the mounting frame in parallel; a locking block for fixing the position of the mounting frame is arranged at the upper end of the mounting frame; guide slots are arranged at the left end and the right end of the lower side of the frame; supporting plates the two sides of which are provided with guide rails are arranged in the guide slots; the supporting plates are rotatably provided with a plurality of rotating shafts which are arranged in parallel in front and rear directions; grinding rods are fixedly arranged on the rotating shafts; guide seats are arranged at the bottom parts of the supporting plates and are provided with transverse screw holes in left and right directions; screws are sheathed inthe screw holes; the other ends of the guide seats are connected with connecting bars; longitudinal through holes are arranged at the right ends of the connecting bars; the connecting rods are connected with transverse eccentric slot wheels through the through holes; longitudinal screw holes are arranged at the middle positions of the supporting plates; lifting screws matched with the longitudinal screw holes in motions are arranged in the longitudinal screw holes; longitudinal guide holes are arranged at the two sides of the supporting plates; and guide rods are respectively sheathed in the guide holes and are arranged on the frame.

Owner:陈松军

Cultivation mediums of using flammulina velutipes mushroom dregs to produce organic hydroponic vegetables and method thereof

InactiveCN103125357AEasy to save energyImprove protectionClimate change adaptationExcrement fertilisersLivestock manureVegetable farming

The invention discloses a method of producing organic hydroponic vegetables cultivation mediums by using flammulina velutipes mushroom dregs. The method includes the steps: (1), processing medium raw materials; (2), processing medium livestock manure; (2), manufacturing microbial fermentation cultures; (4), fermenting the mediums; (5) curing the fermented medium. Under the conditions without soils, vegetables are difficult to plant. Abandoned mushroom dregs after flammulina velutipes is produced are used for fermenting with fermentation liquors, and organic hydroponic vegetablee cultivation mediums are manufactured. The used raw materials are all raw materials with organic materials, a scientific match is reasonable, vegetable planting requirements are suitable, the mushroom dregs after using and resoling by the flammulina velutipes serves as the raw materials, the mushroom dregs after fermenting which are converted into nitrogen and calcium are used. The technical problem of hydroponic cultivation is solved, and in the places without planting conditions, the method of producing the organic hydroponic vegetables cultivation mediums by using the flammulina velutipes mushroom dregs can be used for carrying out vegetable planting conveniently.

Owner:湖北富士峰生物科技有限公司

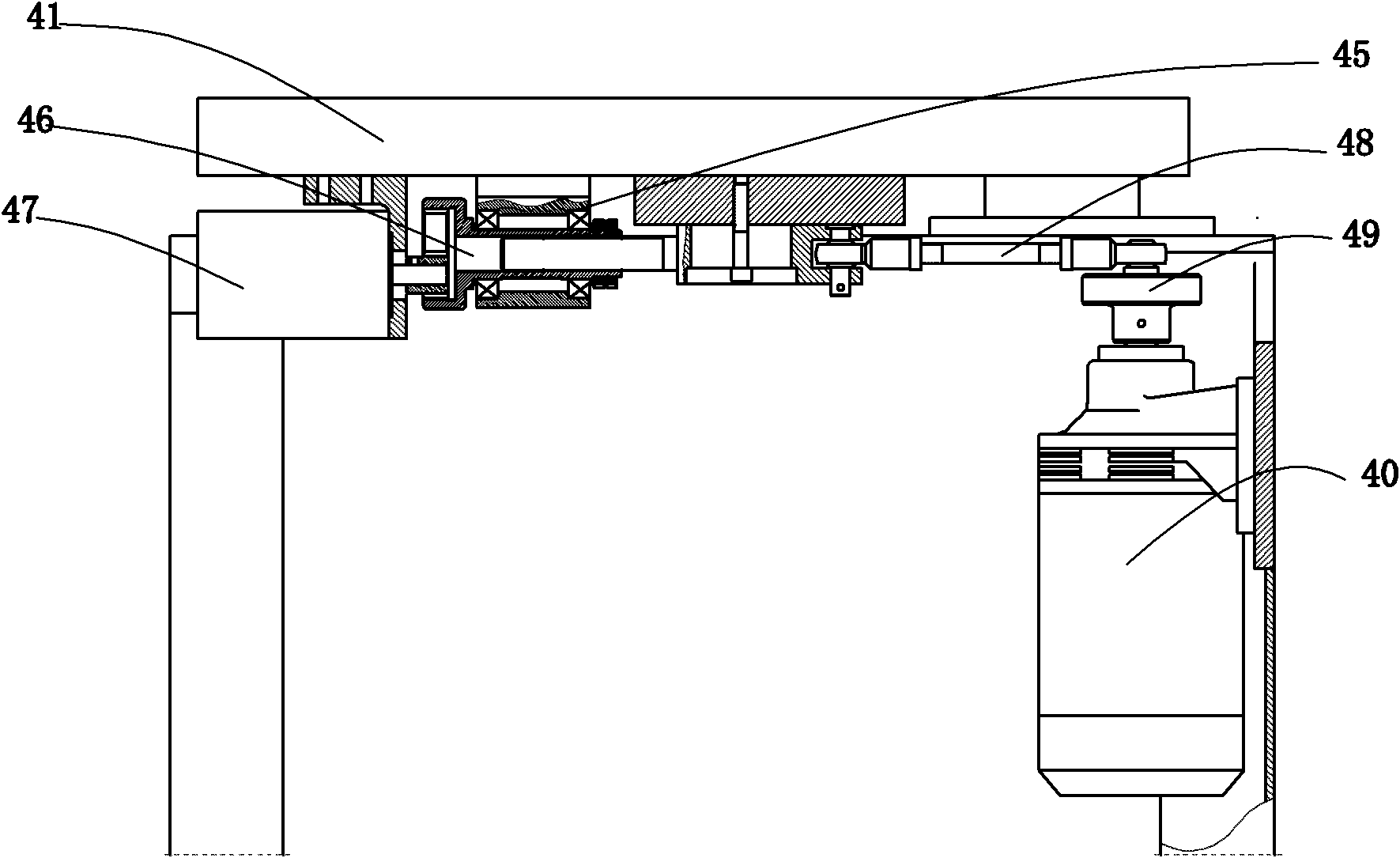

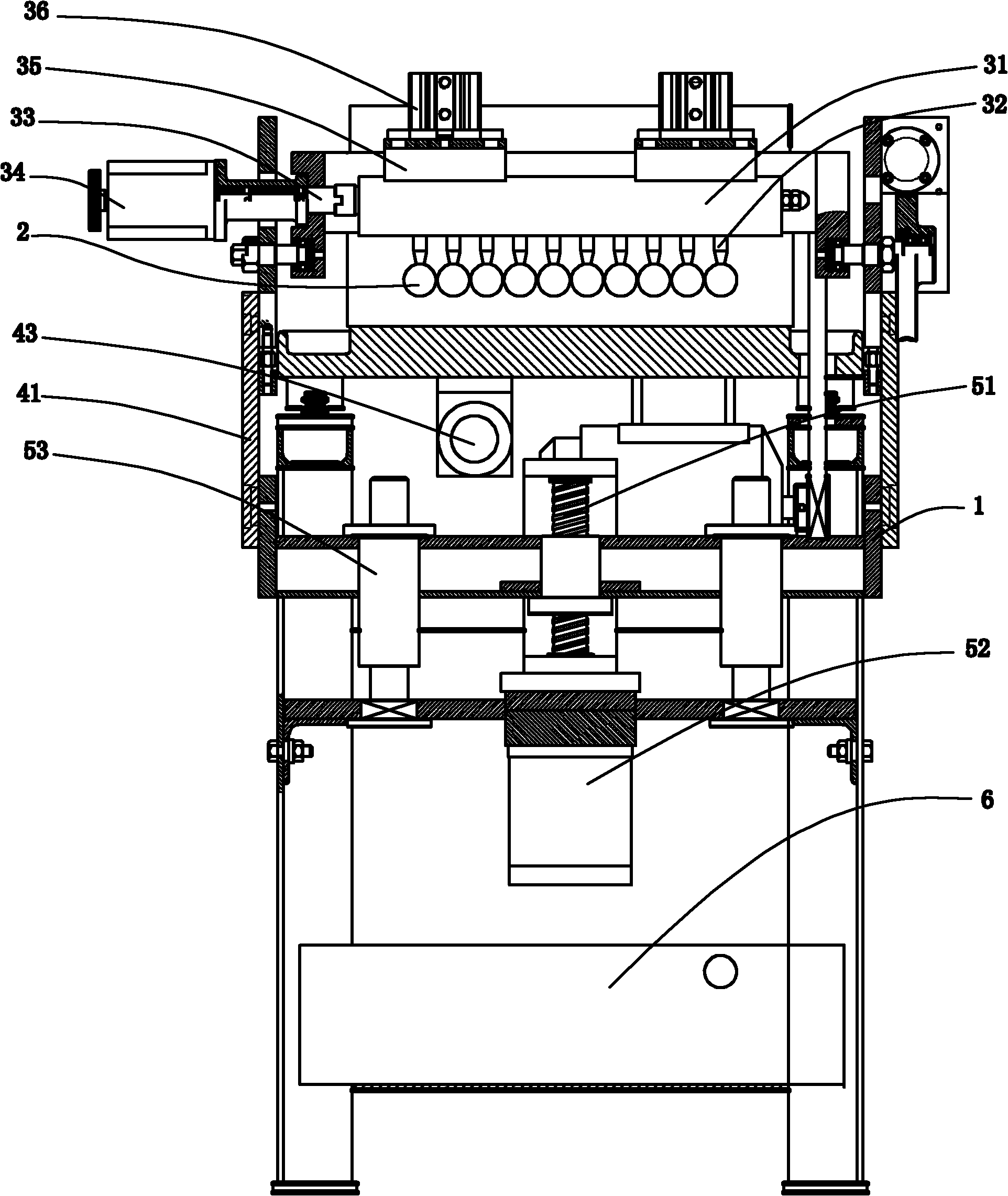

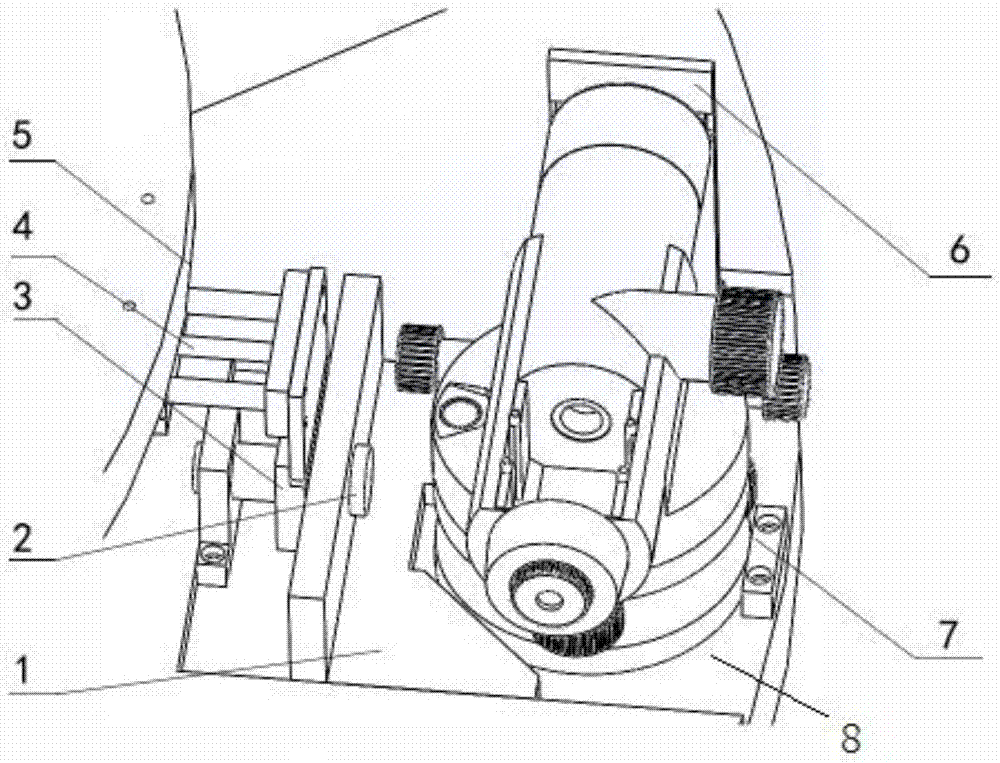

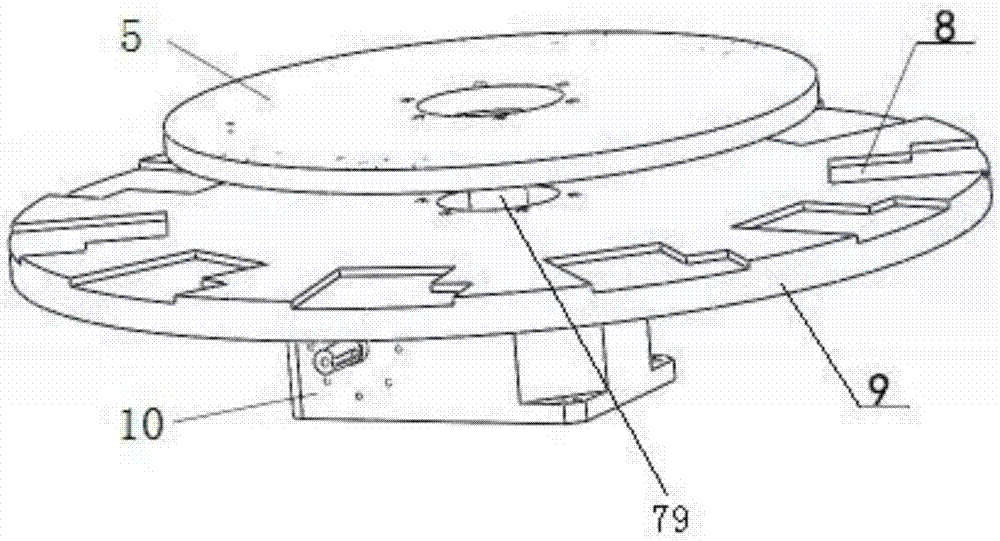

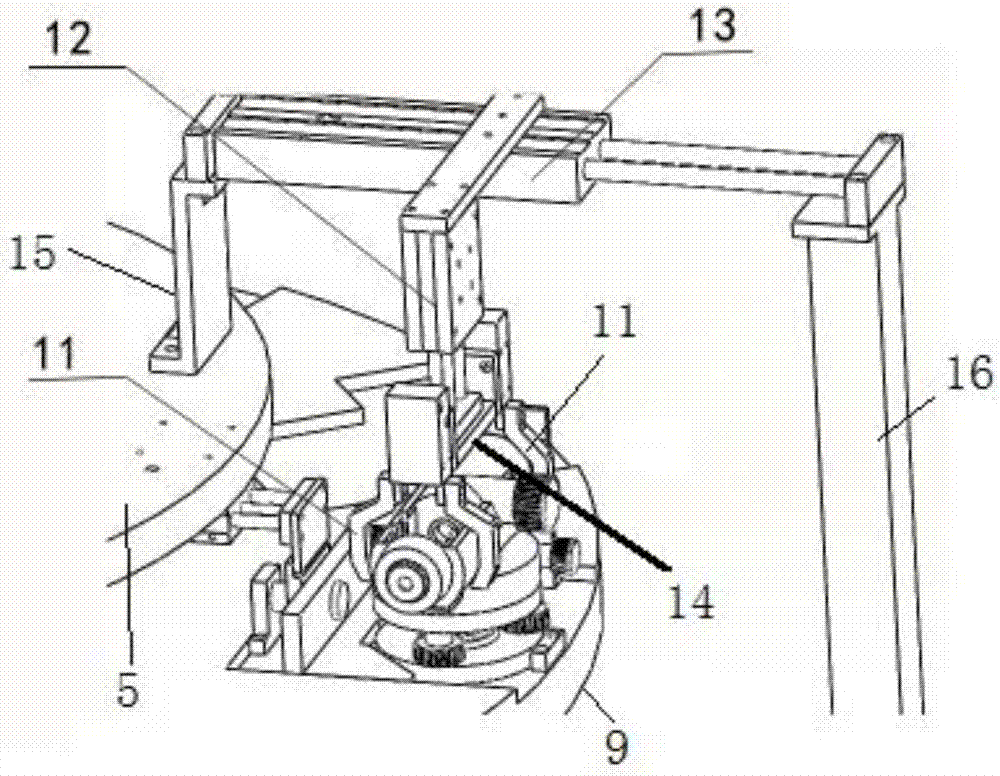

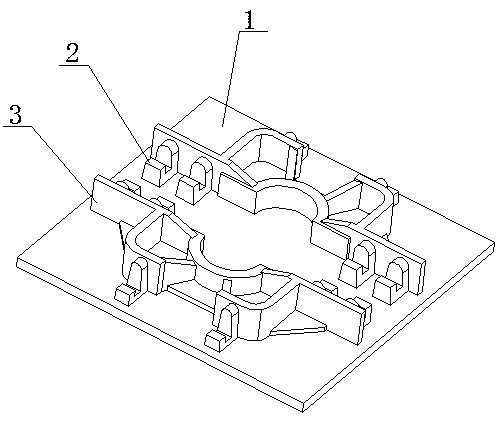

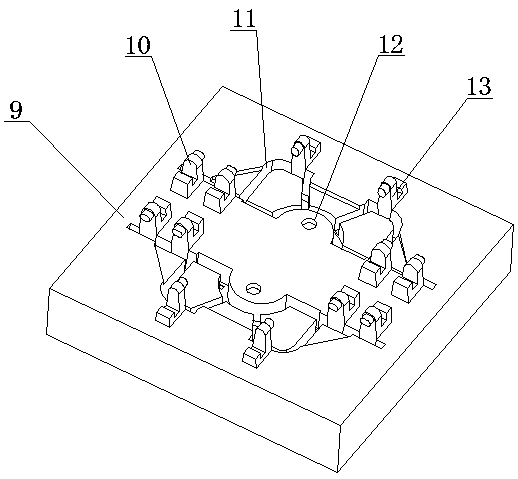

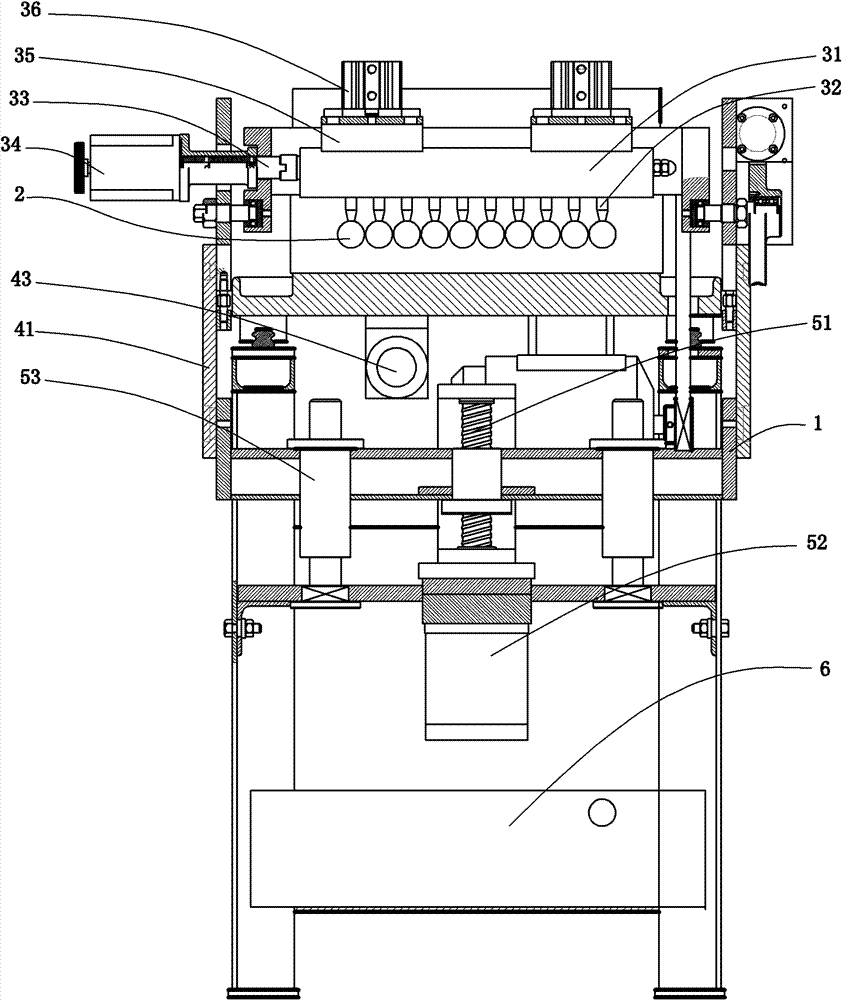

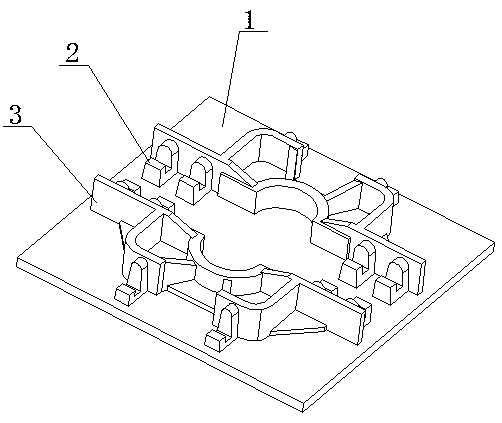

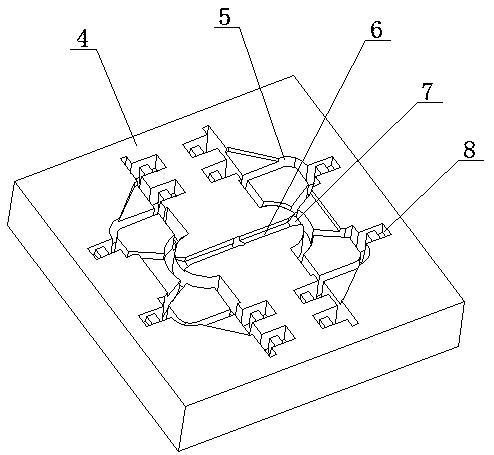

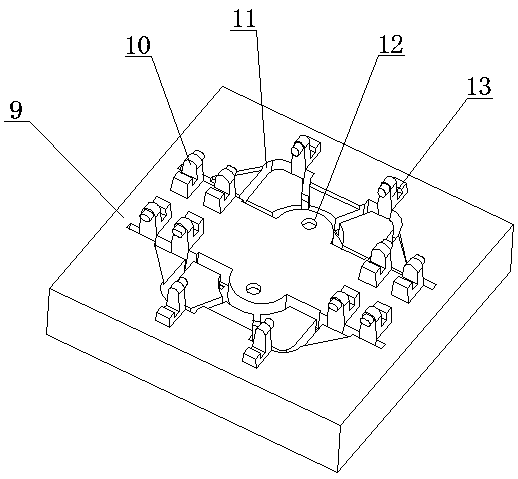

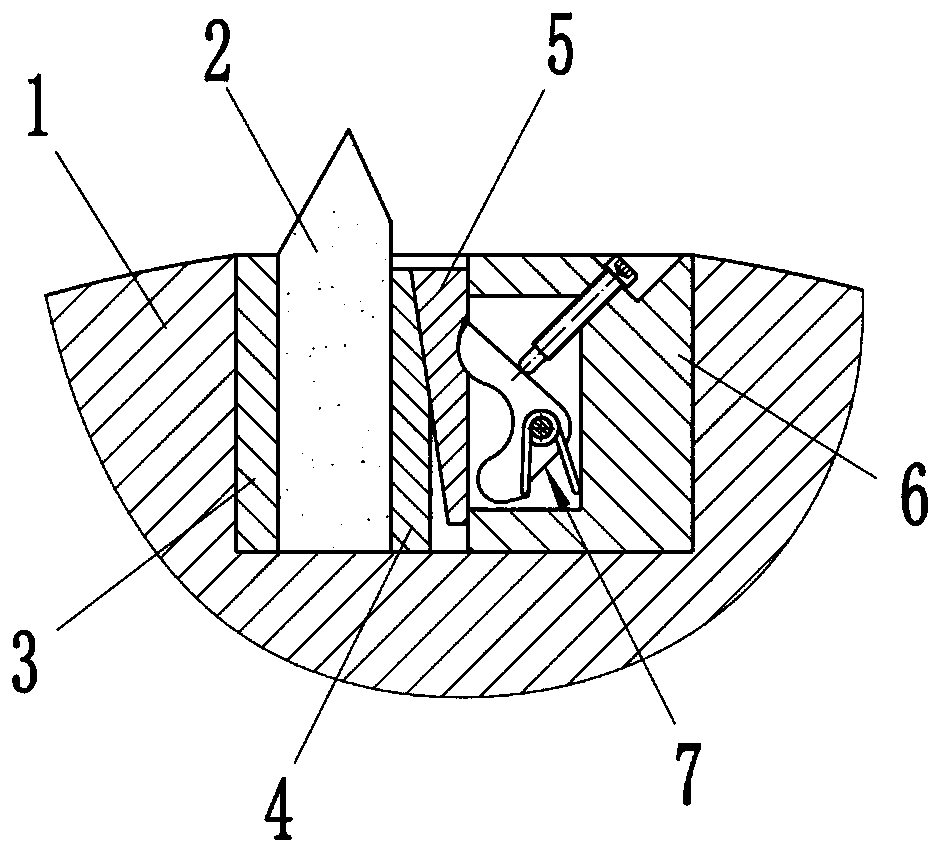

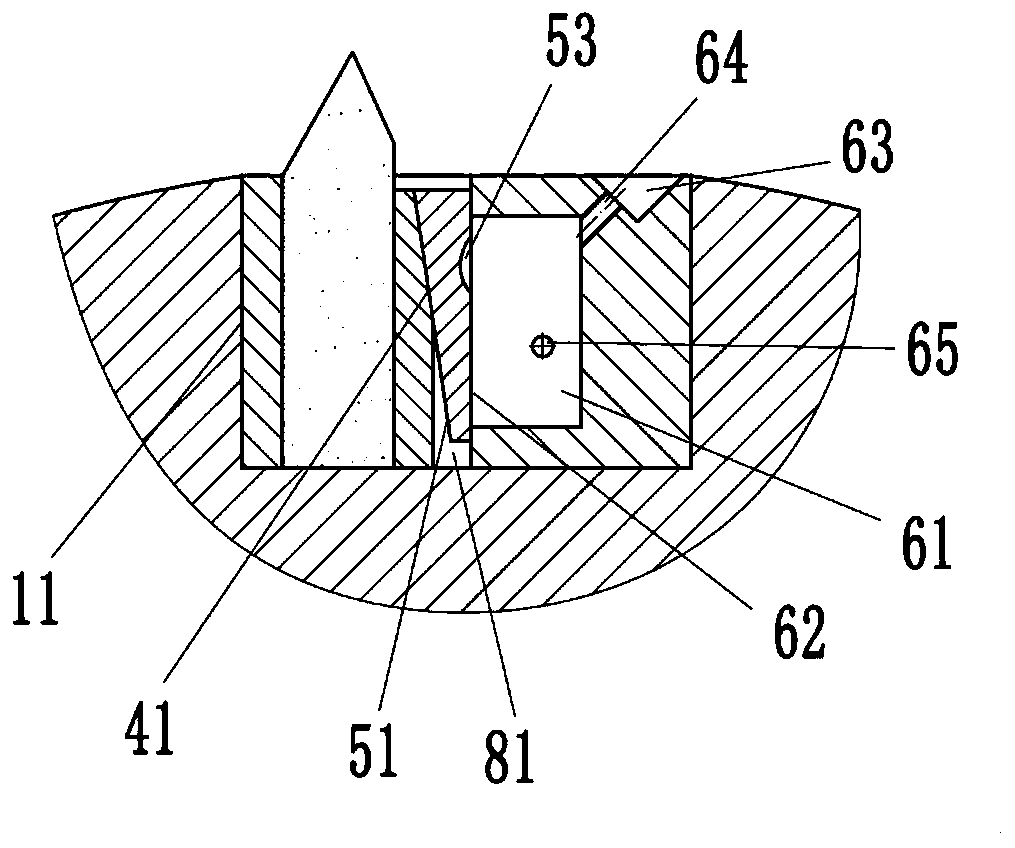

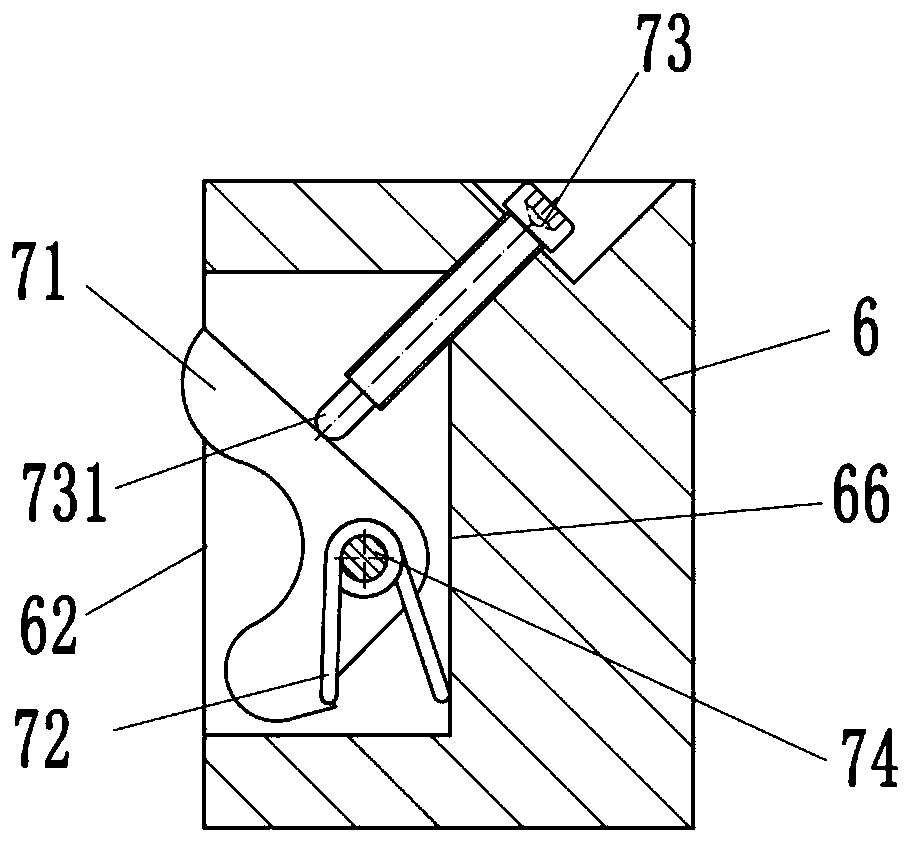

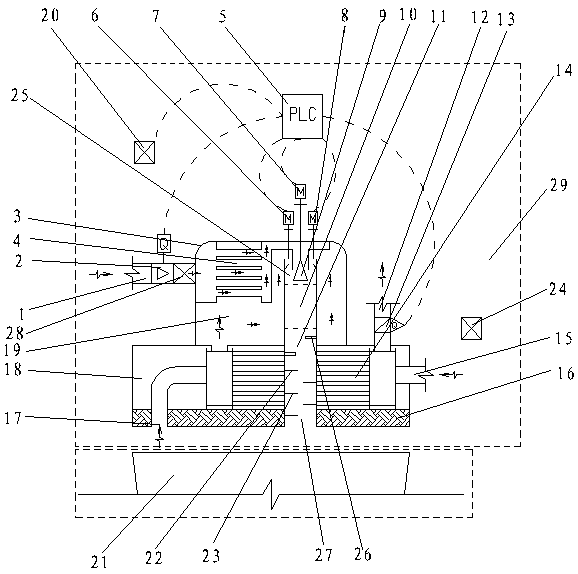

Automatic assembling system for automatic compensated level

ActiveCN107263090AImplement automatic assemblySolve problemsAssembly machinesEngineeringMechanical engineering

The invention discloses an automatic assembling system for an automatic compensated level and belongs to the technical field of automatic assembling. The automatic assembling system comprises an upper fixed supporting disc, a lower rotating supporting disc driven by a rotating shaft, multiple clamps and a base body feeding mechanism. Each clamp comprises a radial outer side stop block fixedly arranged on the upper side of the groove bottom face of a clamp installation groove, a V-shaped block correspondingly arranged on the radial inner side of the radial outer side stop block, and a clamp air cylinder arranged in the radial direction of the lower rotating supporting disc and driving the V-shaped block, wherein the clamp air cylinder is arranged on the upper fixed supporting disc. The base body feeding mechanism comprises a base body pneumatic sliding table, a base body lifting air cylinder driven by the base body pneumatic sliding table, a lifting transverse plate driven by the base body lifting air cylinder and two base body air claws arranged on the lifting transverse plate, wherein the base body pneumatic sliding table is arranged above the lower rotating supporting disc in a spaced manner. The automatic assembling system can be used for achieving automatic assembling of the level, and therefore the production efficiency of an enterprise is improved, and the labor intensity is lowered.

Owner:HEFEI UNIV OF TECH

Efficient ladle baking device

The invention provides an efficient ladle baking device. The efficient ladle baking device comprises a baking device body, a cover and a flame retardant layer, wherein the lower end of the baking device body is connected with the upper end of the cover; the lower end of the cover is connected with the flame retardant layer; the lower end of a burner composed of a conical body, a flow mixing cavity, an electronic igniter, a combustion cavity and a firing stabilizer is arranged at the lower end of the flame retardant layer, and the upper end of the burner is arranged on the upper portion inside the baking device body; the upper end of the burner is connected with an air cavity through an electric adjustment valve; an air heat exchanger is installed on the lower portion of the air cavity; one end of the air heat exchanger is connected with a smoke inlet, and the other end of the air heat exchanger is connected with a smoke outlet; an air inlet is formed in the lateral surface of the cover; the upper end of the burner is provided with a fuel gas inlet communicating with an outlet of a fuel gas heat exchanger; the conical body is arranged at the fuel gas inlet of the burner; an inlet of the fuel gas heat exchanger is connected with a fuel gas pipeline through a fuel gas valve and a flowmeter; and the ladle baking device is further provided with an intelligent control device. The efficient ladle baking device has the advantages of saving energy and labor, improving safety performance and the like.

Owner:大连新瑞晨环保科技有限公司

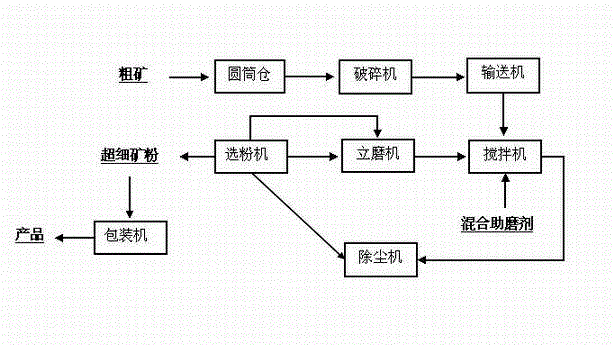

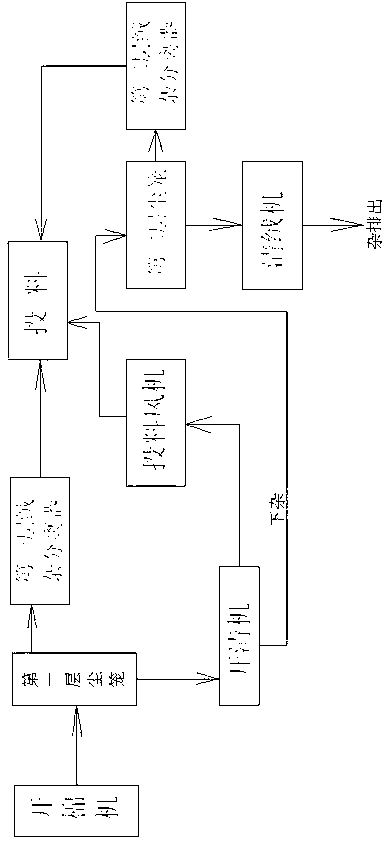

Ultrafine titanium concentrate grinding process flow

The invention discloses an ultrafine ilmenite concentrate grinding process flow, equipment is mainly composed of a cylindrical silo, a conveyer, a crusher, a mixer, a vertical mill machine, a powder selecting machine and a dust collector. The process flow is characterized in that crude ore in the cylindrical silo is conveyed to a crusher through a band conveyer for fragmenting the ore, then introducing in a mixer, simultaneously adding 0.5-0.8% of mixing grinding aid for stirring and mixing; then sending the mixing material in the vertical mill machine for grinding for a corresponding time, then sending the powder material to the powder selecting machine, screening the powder, if the power material is not qualified, sending to the vertical mill machine, and continuously repeating; screening the qualified powder material and sending into a packaging machine for packaging, and finally outputting the ultrafine ore powder products with size of 8-12mum.

Owner:昆明德道科技有限公司

Casting process for bearing seat of frame saw

InactiveCN109047667AReduce thicknessImprove casting production qualityFoundry mouldsFoundry coresMachiningMaterials science

The invention discloses a casting process for a bearing seat of a frame saw, belonging to the technical field of casting production, comprising the following steps: (1) making a mold of a mold plate;(2) making an upper sand box and a lower sand box; (3) making a first sand core insert and a second sand core insert; (4) processing a flow channel and a heat riser; (5) smelting iron; (6) closing thebox and pouring; (7) dropping sand; (8) cleaning castings and shot peening. The casting process for a bearing seat of a frame saw adopts a one-mold and two-cavity forming method, and casts two castings at one time, thereby improving the production efficiency; the production quality of the bearing seat of the frame saw can be ensured by arranging the heat riser and a fan-shaped pouring port; a mounting hole in the surface of the bearing seat of the frame saw can be molded out while producing the bearing seat of the frame saw by installing the stable and convenient first sand core insert and second sand core insert, and subsequent machining procedures are reduced.

Owner:南安市春安机械铸造有限公司

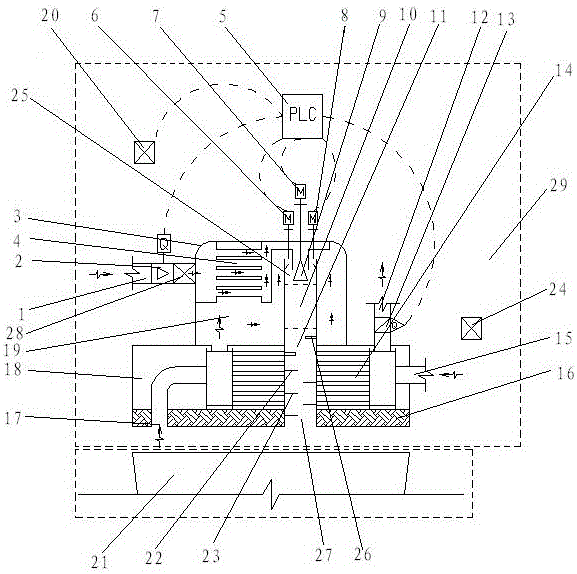

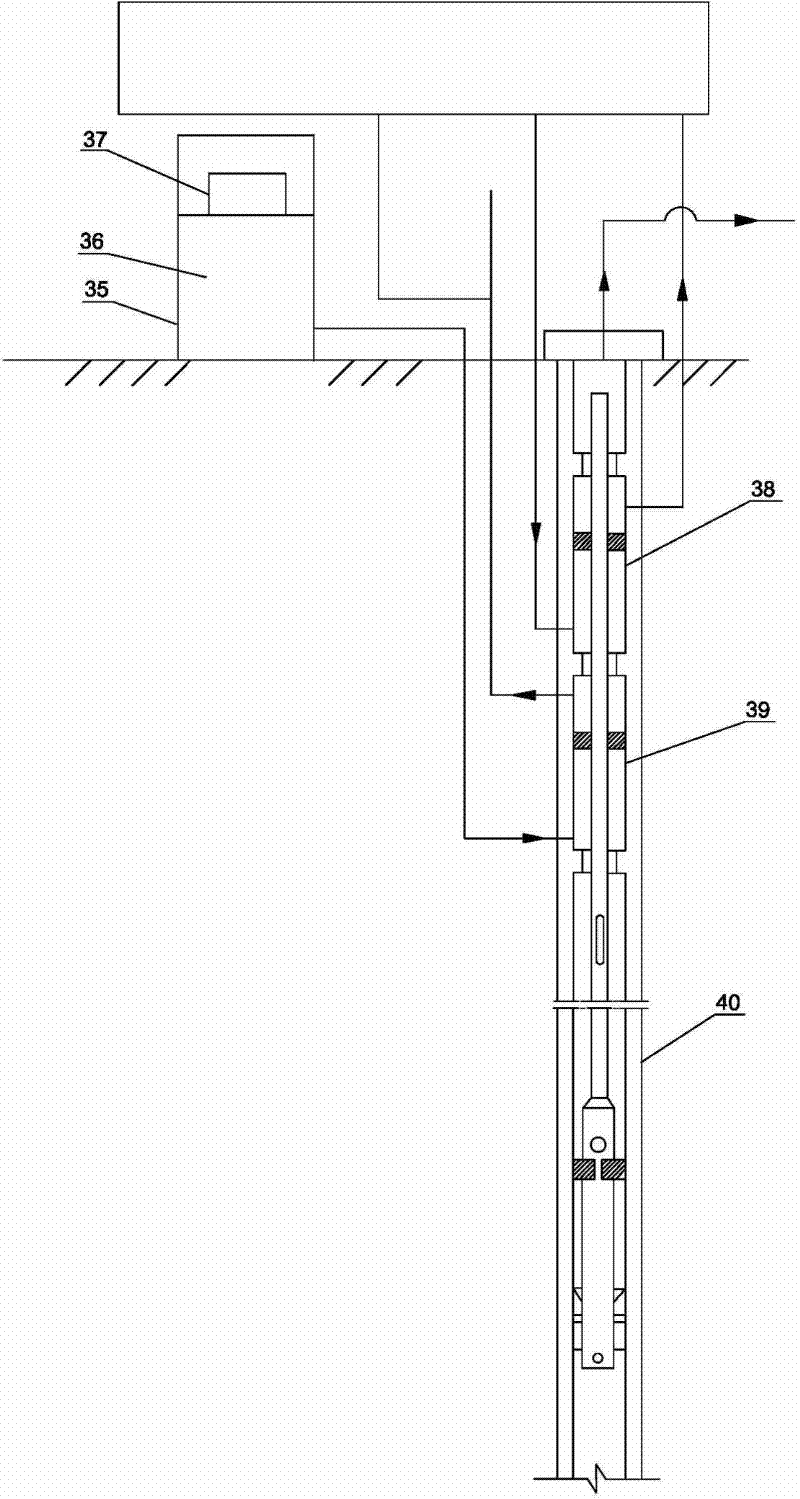

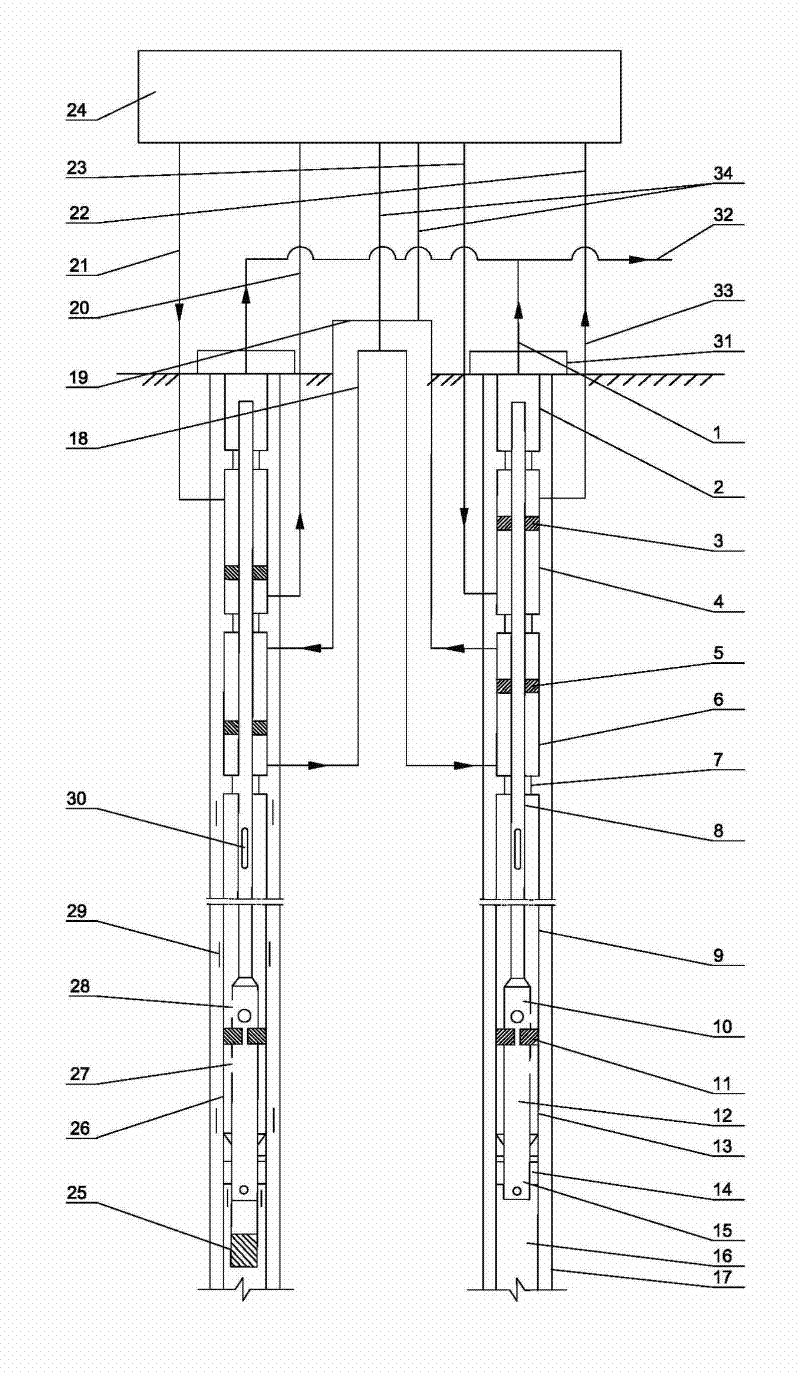

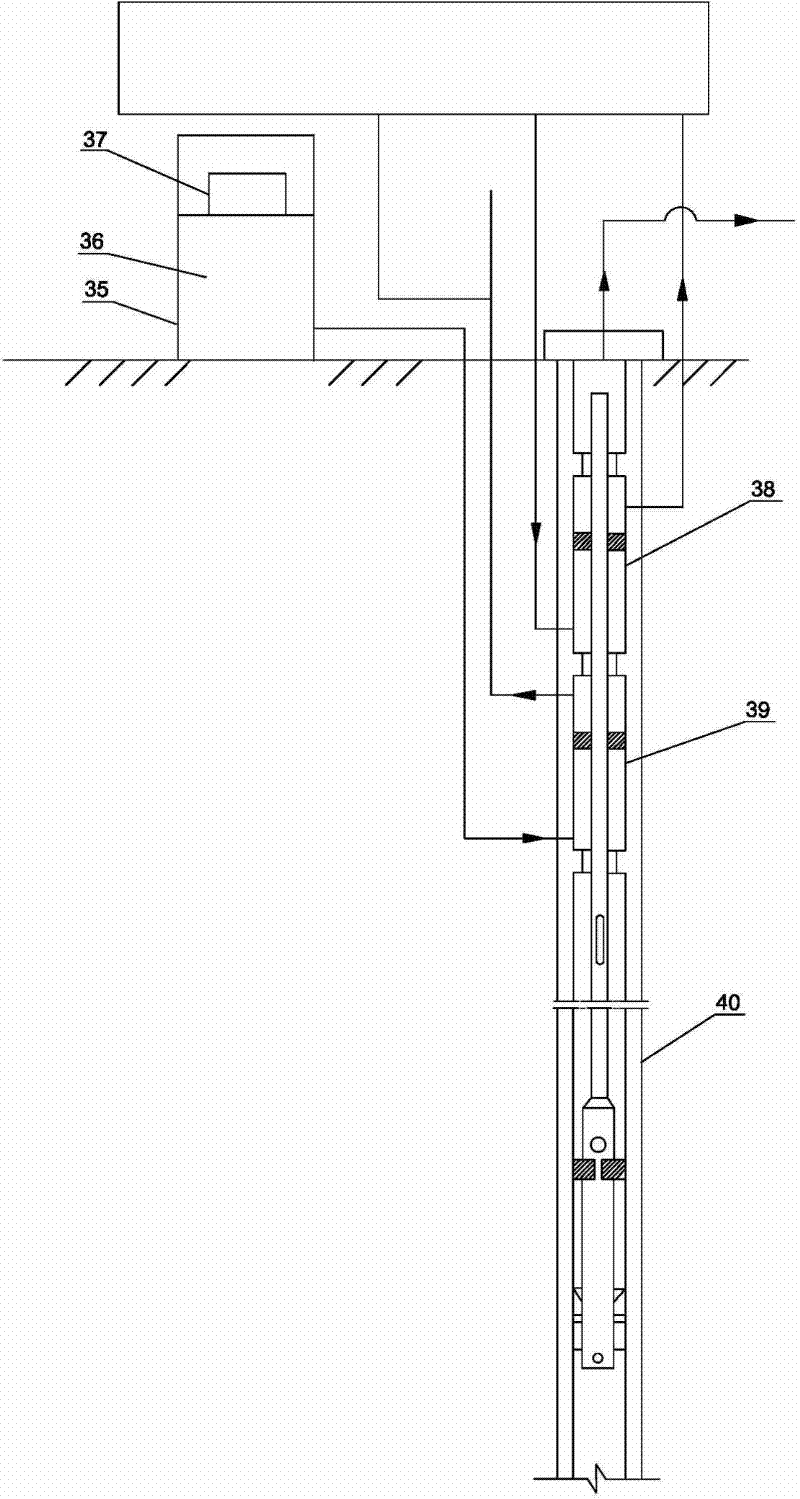

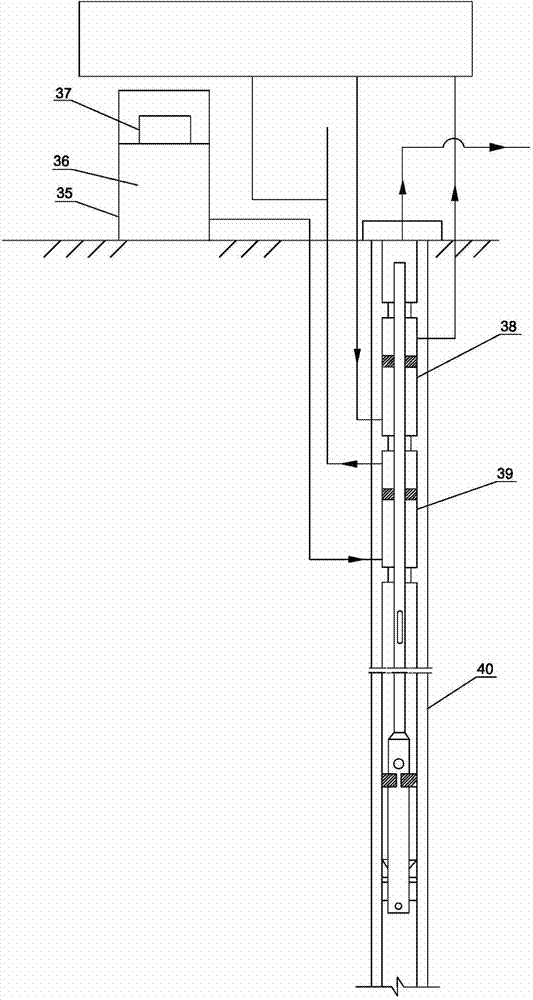

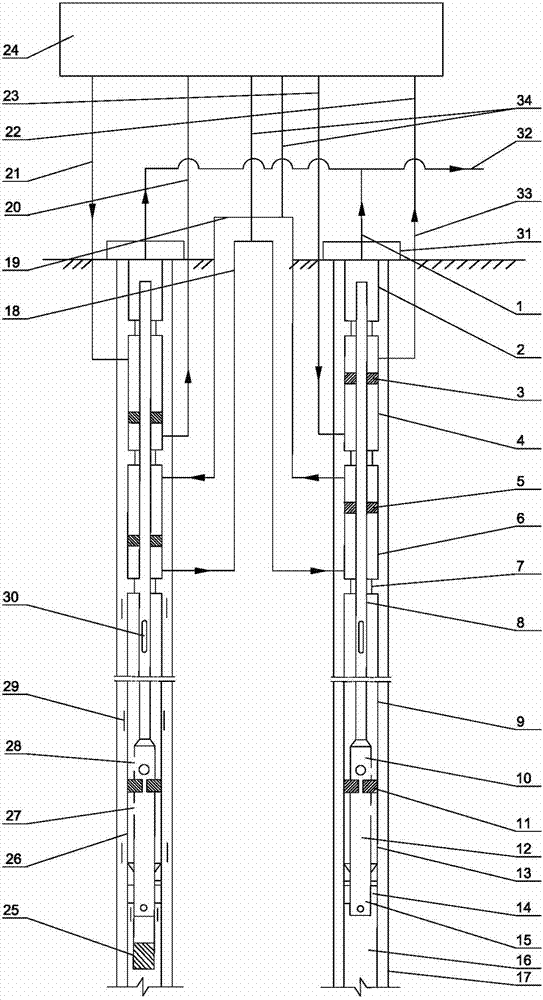

Hydraulic oil pumping system

ActiveCN102337867AImprove energy savingReasonable structural designFluid removalHydraulic cylinderHydraulic pump

The invention discloses a hydraulic oil pumping system, relating to oil extraction equipment for extracting oil from deep hard rock stratum. The invention aims at providing a balance hydraulic cylinder arranged in oil wells for converting gravity forces of an oil pumping rod and an oil pump in two oil wells and a liquid column into hydraulic pressure and serving as balance weight for balance. Simultaneously, the hydraulic power of the hydraulic pump station drives the power hydraulic cylinder in the oil well to drive the oil pump for extracting oil. Therefore, the purposes of being simple in structure, saving energy and improving work efficiency are achieved. The invention comprises at least one hydraulic oil pumping unit which comprises a power part and an oil extracting part under the power part, wherein the power part is connected with the hydraulic pump station on the ground; the structural feature is that the hydraulic oil pumping unit further comprises a balance part, wherein the balance part is connected with the power part and the oil extracting part, and a hollow oil pumping rod penetrates through the power part, the balance part and the oil extracting part.

Owner:刘学柱

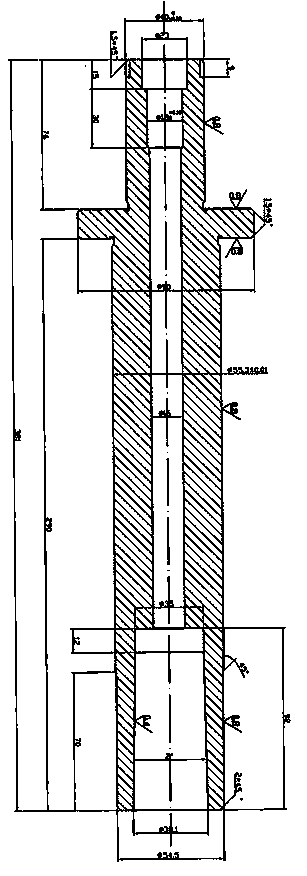

Machining method for improving ultra-accurate split spindle accuracy

The invention discloses a machining method for improving the ultra-accurate split spindle accuracy. The method includes blanking, annealing, turning a machined workpiece, milling, performing clamping machining, quenching, and grinding. According to the method, rough machining is performed on the two outer circles of a spindle for central frame erection, then the central frame is erected for performing fine machining on two-end positioning references fractionally, the accurate positioning during grinding is guaranteed, the accuracy required by design on the outer circles during outer circle grinding is guaranteed, a hole is machined firstly during sleeve machining, a special mandrel of 1: 10000 is used, the concentricities of outer circles and outer cones are guaranteed by grinding the outer circles and outer cones, the design requirements can be completely met after the split spindle matches with a sleeve, and the cost is reduced greatly.

Owner:南京紫薇精密机械有限公司

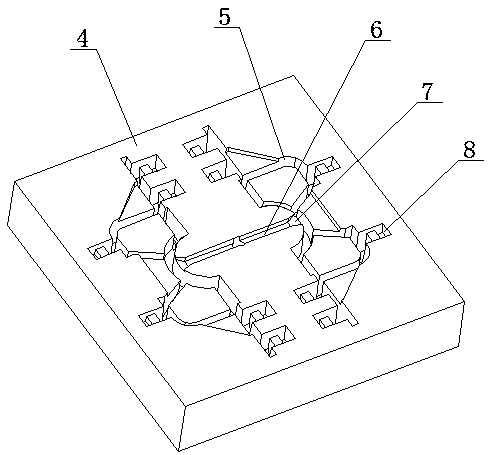

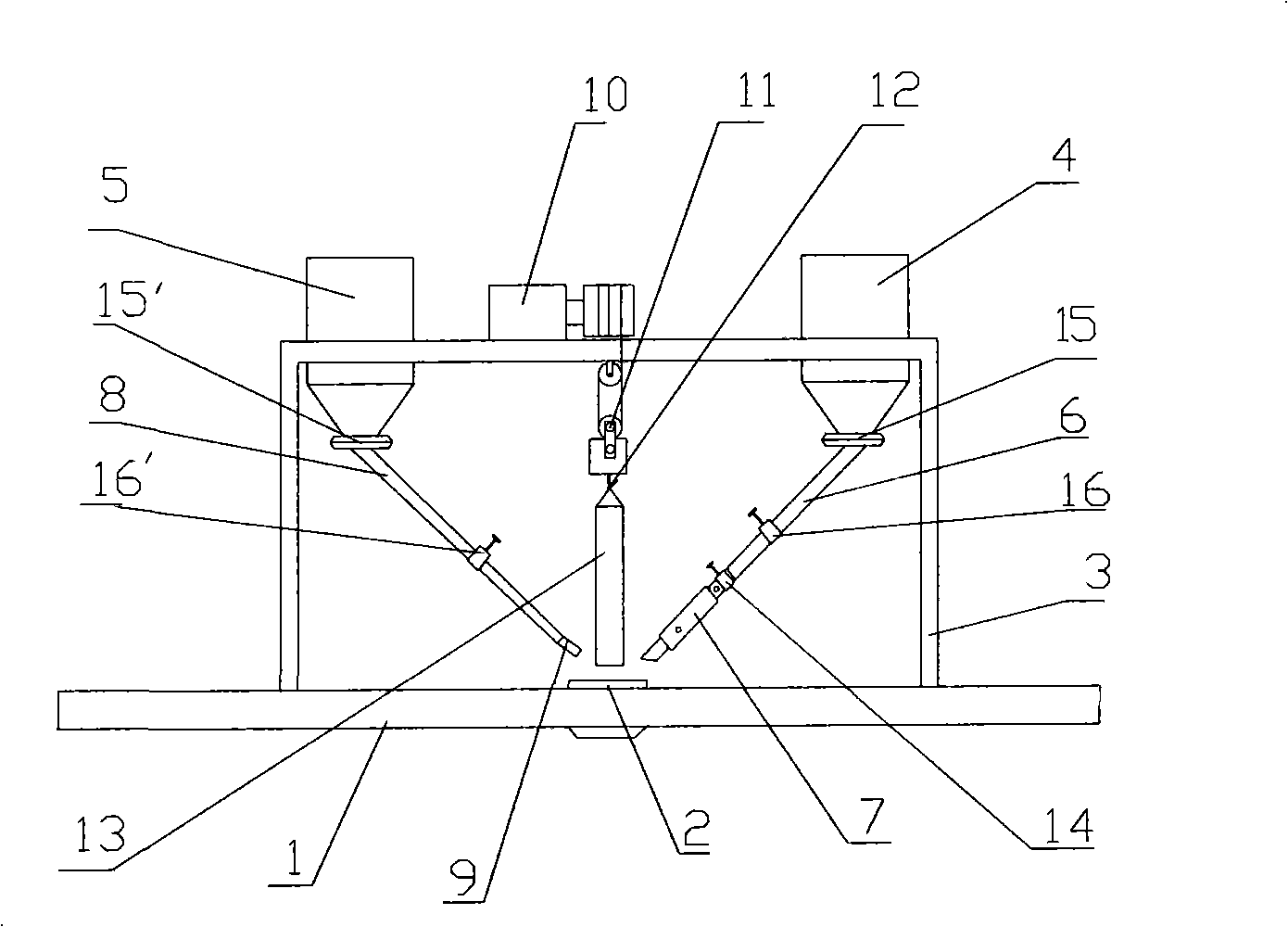

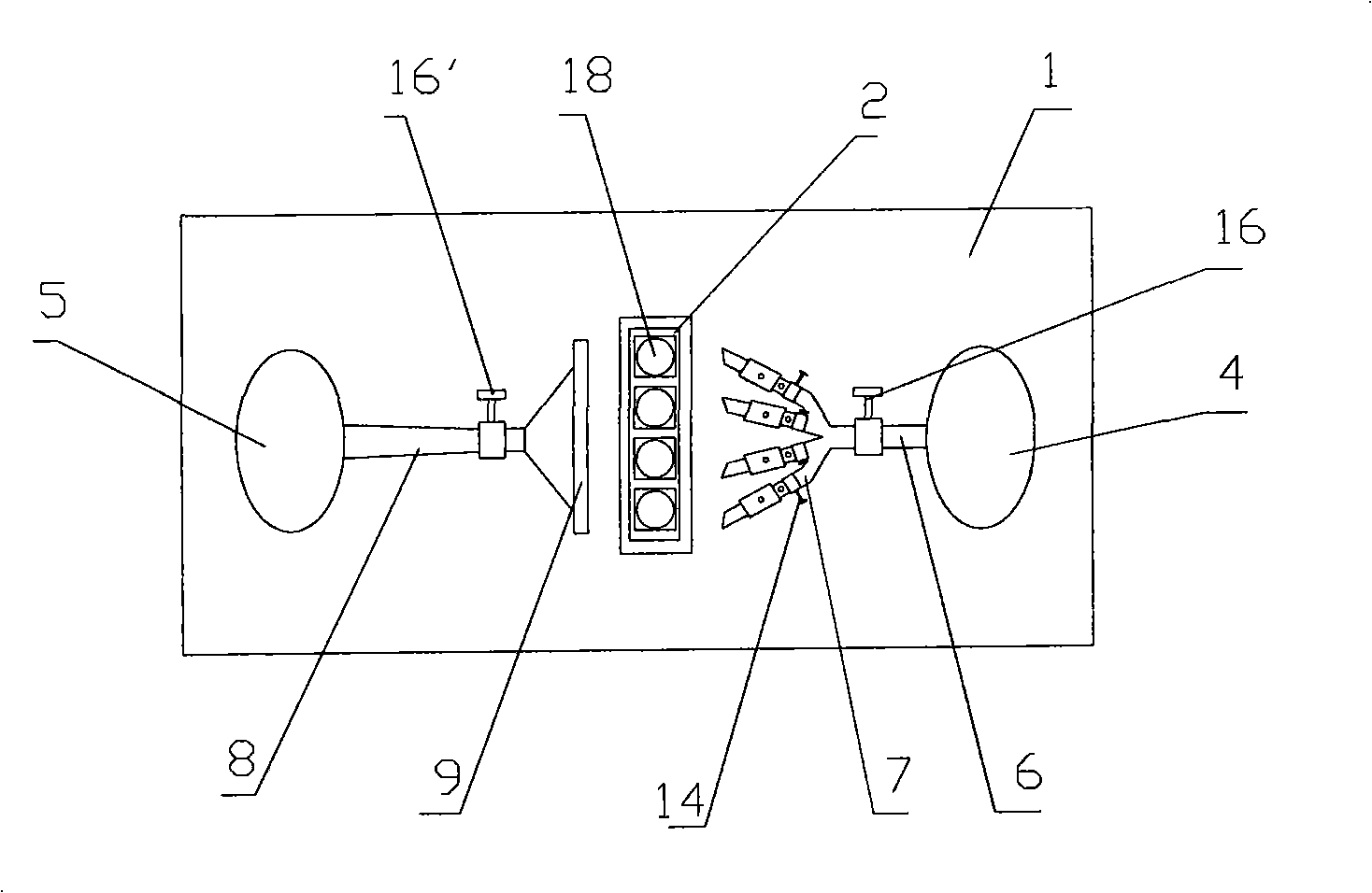

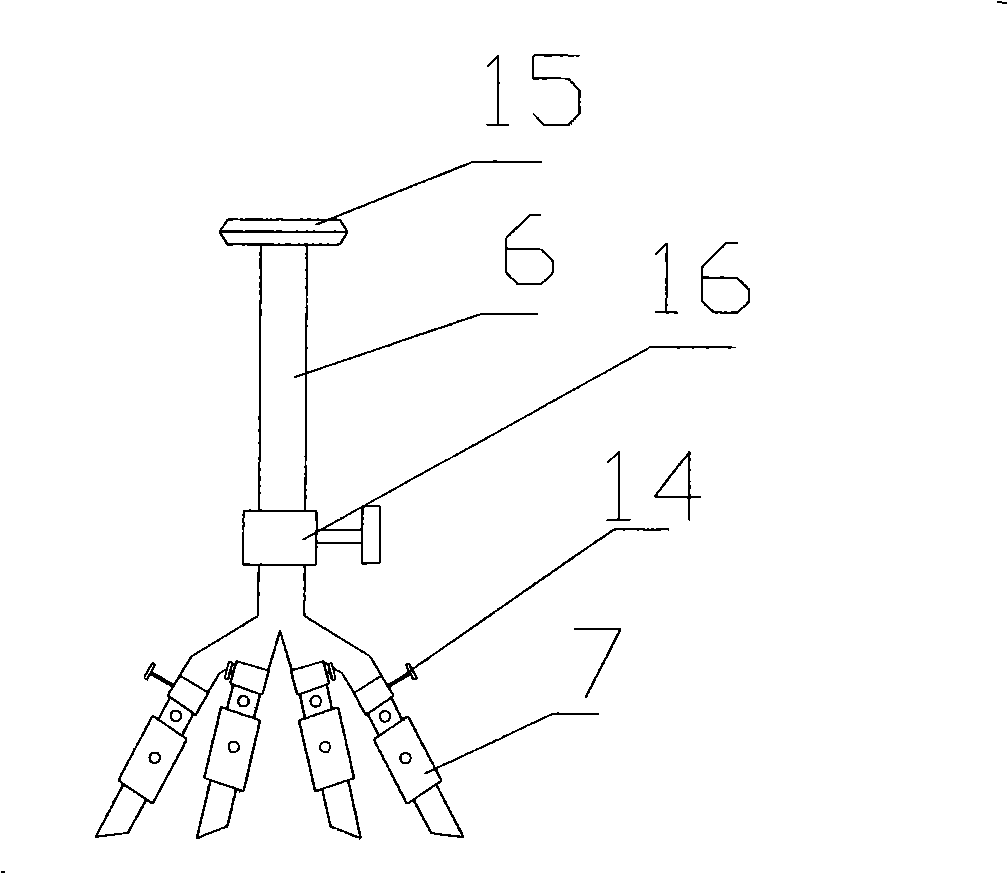

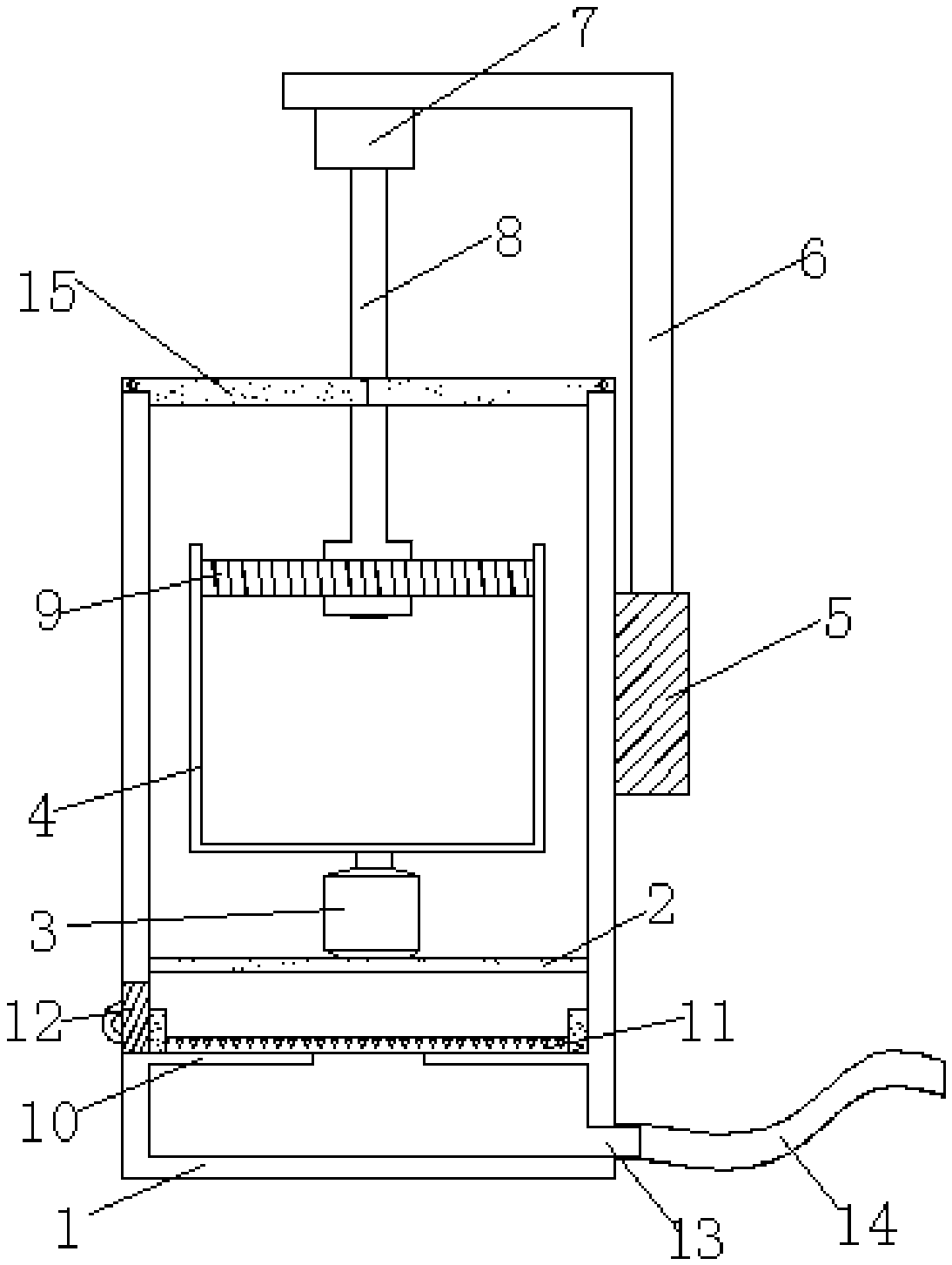

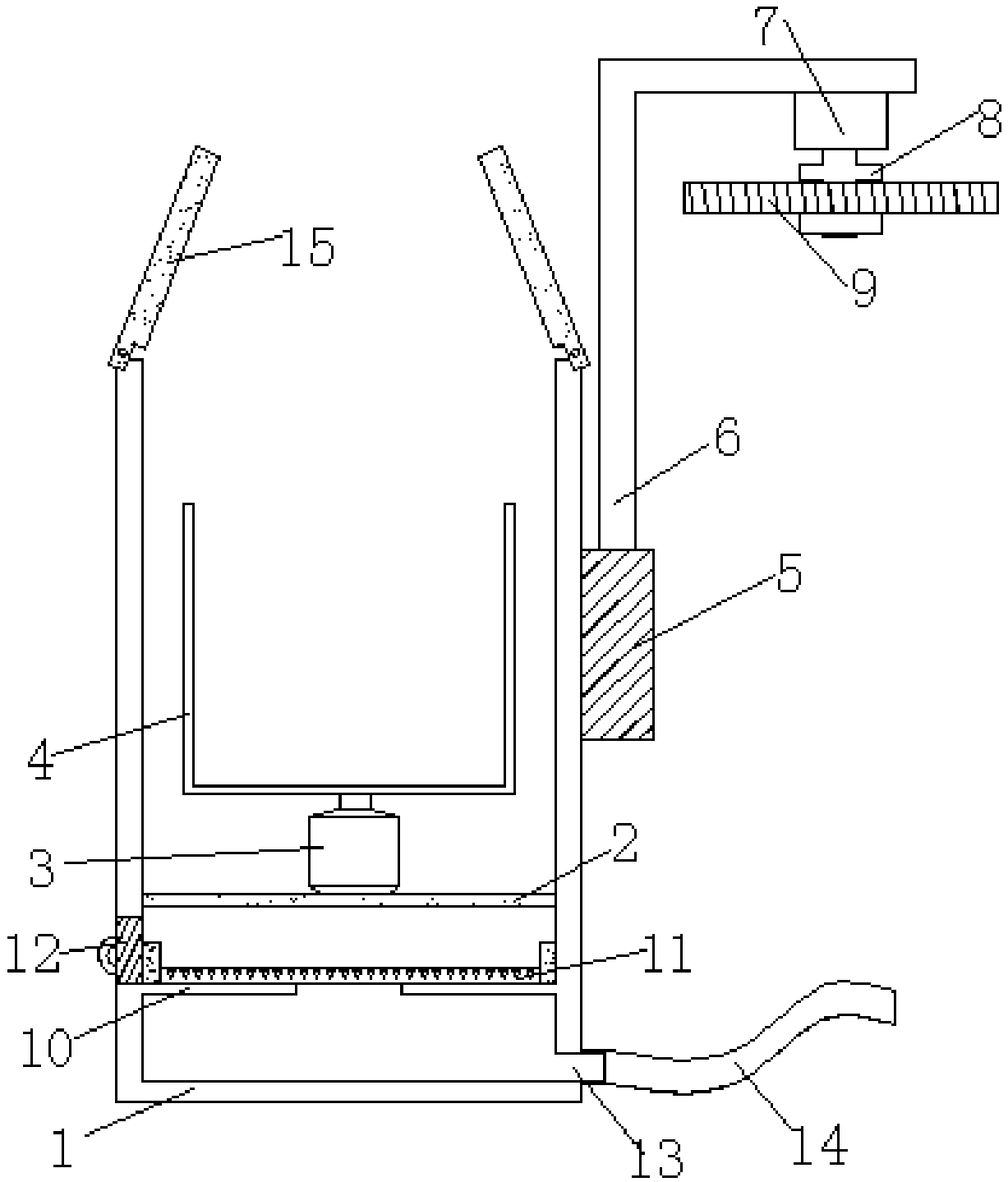

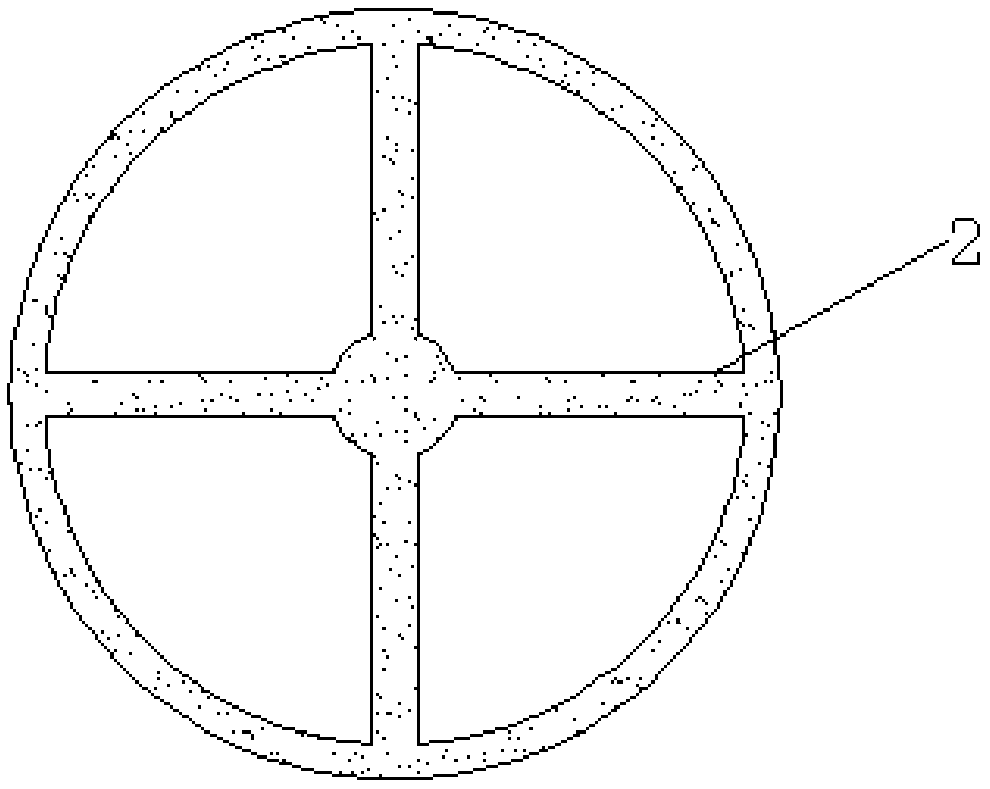

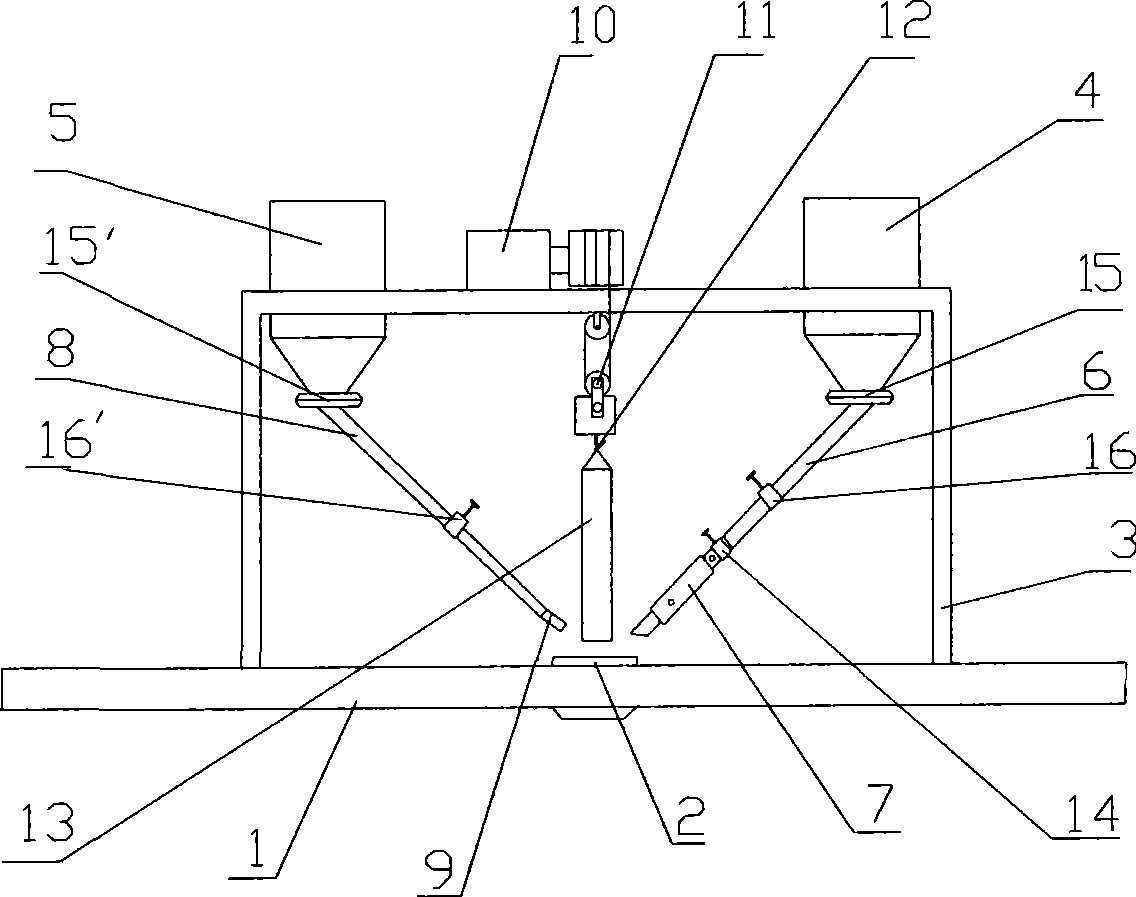

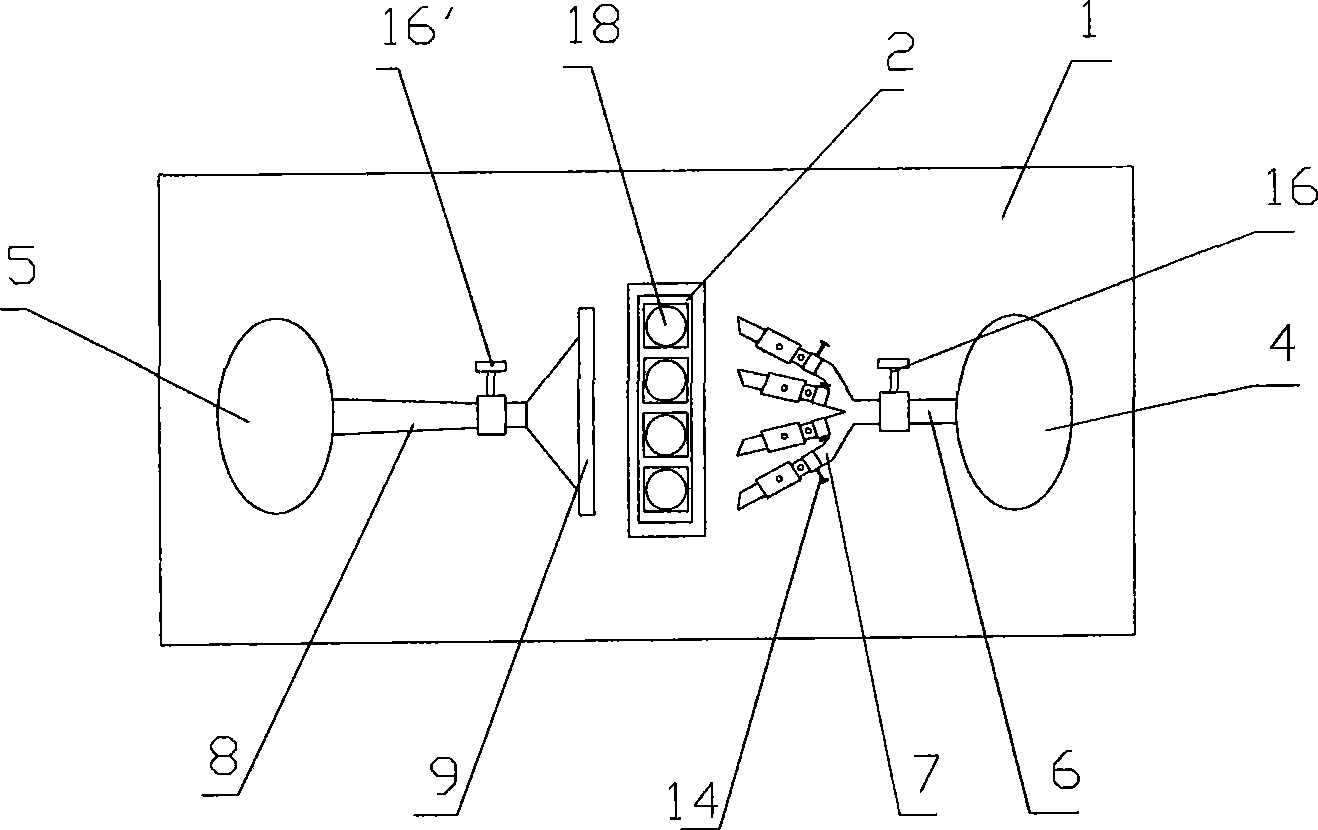

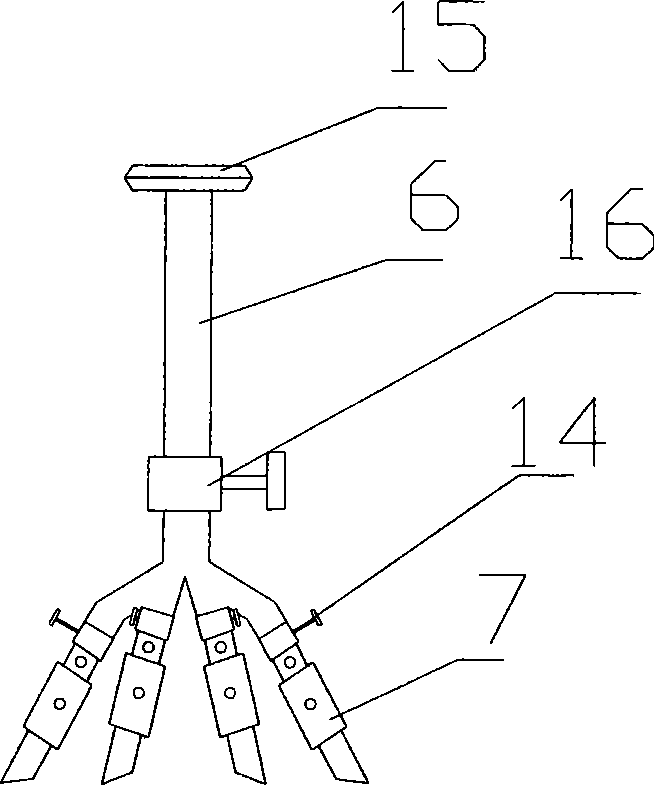

Closed type loading apparatus of SiC tank kiln car

ActiveCN101408377AOvercoming fragileGuaranteed production requirementsCharge manipulationFurnace typesProduction lineGlass cover

The invention discloses a sealing-style loading apparatus used for an SiC tank kiln car. The loading apparatus comprises a loading operation table (1) and a charging chute (2) and is characterized in that a fixing frame (3) is arranged on the loading operation table (1) and an iron scale bin (4) and a dust coke bin (5) are respectively fixed on the back side and front side of the upper part of the fixing frame (3); an iron scale discharging header pipe (6) provided with a discharging branch pipe (7) is connected at the bottom of the iron scale bin (4); a dust coke discharging header pipe (8) provided with a discharging slot (9) is connected at the bottom of the dust coke bin (5); a winch (10) provided with a hook (12) is arranged at the middle part of a beam of the fixing frame (3) on theloading operation table (1); a bushing-style fitting is suspended on the hook (12); and simultaneously a glass cover (19) for sealing operation is also arranged. The loading apparatus has high loading speed, low loading contamination and lower harm to operators; the loading can be carried out strictly according to the ratio between the iron scale and dust coke; the problems that the unloading is difficult and the SiC tank is easy to break can be solved and the operation meets the standard; and the sealing-style loading apparatus can be widely applied to the powder metallurgy production lines.

Owner:LAIWU TAIDONG POWDER TECH

Hydraulic oil pumping system

ActiveCN102337867BImprove energy savingReasonable structural designFluid removalHydraulic cylinderHydraulic pump

The invention discloses a hydraulic oil pumping system, relating to oil extraction equipment for extracting oil from deep hard rock stratum. The invention aims at providing a balance hydraulic cylinder arranged in oil wells for converting gravity forces of an oil pumping rod and an oil pump in two oil wells and a liquid column into hydraulic pressure and serving as balance weight for balance. Simultaneously, the hydraulic power of the hydraulic pump station drives the power hydraulic cylinder in the oil well to drive the oil pump for extracting oil. Therefore, the purposes of being simple in structure, saving energy and improving work efficiency are achieved. The invention comprises at least one hydraulic oil pumping unit which comprises a power part and an oil extracting part under the power part, wherein the power part is connected with the hydraulic pump station on the ground; the structural feature is that the hydraulic oil pumping unit further comprises a balance part, wherein the balance part is connected with the power part and the oil extracting part, and a hollow oil pumping rod penetrates through the power part, the balance part and the oil extracting part.

Owner:刘学柱

Dehydrating device for production of salted vegetables

The invention discloses a dehydrating device for production of salted vegetables. The dehydrating device comprises a main body, wherein a mounting frame which is horizontally placed is fixedly mountedin the main body; a motor is fixedly mounted at the middle part of the mounting frame; a discharging cylinder is fixedly connected to the output end of the motor; a rotator is fixedly mounted at themiddle part of the outer wall of the main body; and a rotating rod adopting an L-shaped structure is rotatably connected to the upper end of the rotator. The dehydrating device for production of salted vegetables disclosed by the invention has the beneficial effects that the discharging cylinder is driven by the motor, so that salted vegetables in the discharging cylinder rotate at a high speed; high-efficiency dehydrating is realized through centrifugal force; during dehydrating, definite pressure is exerted to the salted vegetables through a compressing plate, so that the dehydrating of thesalted vegetables is more thorough, and the production requirements are guaranteed; a filter residue drawer is arranged in the dehydrating device to filter sewage of the salted vegetables, and residues are remained in the filter residue drawer, so that the sewage is filtered, and the sewage is not directly drained to the environment; the filter residue drawer can be taken out, so that residues areconvenient to recover, the dehydrating device is convenient to clean, and the environment can be protected; and the dehydrating device disclosed by the invention is simple in structure, easy to operate and suitable for popularization and usage.

Owner:湖北吉姥爷农业科技股份有限公司

Cellulose ether super-multi-chain-link purified cotton producing technology

InactiveCN103343469AGuaranteed production requirementsGuarantee quality requirementsPulping with inorganic basesCelluloseEther

The invention discloses a cellulose ether super-multi-chain-link purified cotton producing technology. The technology comprises the following steps of: material preparing, namely selecting high quality cotton lower piles as raw materials, opening and screening the high quality cotton lower piles in an opener, feeding the treated cotton lower piles into a dry impurity removal device to defiber, disperse and purify, pneumatically feeding the treated cotton lower piles into a cyclone separator, performing alkali steeping in an alkali spraying mode, and feeding the treated cotton lower piles into an extruding machine to extrude and dehydrate; digesting; prebleaching, namely prebleaching a digested sizing agent, and adding liquid chlorine to the sizing agent which is delivered into a prebleaching tank from a sizing agent storage tank, wherein 0.5kg-0.8kg of liquid chlorine is added each minute according to flow, and the chlorine content before prebleaching is 0.05-0.1 g / l; bleaching; and acid treating, thus obtaining a finished product. By virtue of the purified cotton producing technology, the production cost is lowered, the yield of cellulose ether and the stability of cellulose ether product quality are improved, and the development requirements of high-quality and low-cost cellulose ethers are satisfied.

Owner:TANGSHAN SANYOU GRP DONGGUANG PULP CO LTD

Preparation method of syrup special for moon cake

The invention relates to the field of starch sugar manufacturing, in particular to a preparation method of syrup special for moon cake. According to the method, corn starch is taken as the raw material, and the syrup is prepared through the steps such as size mixing, enzyme immersion, liquefaction, saccharification, glucoside conversion, decolorization, filtering, ion exchange, concentration, blending and the like. The prepared syrup comprises 20-25% of maltobiose, 12-17% of maltotriose, 15-20% of maltotetraose, 8-12% of tetrasaccharide-above, 3-5% of oligoisomaltose, 25-30% of fructose, and less than 3% of glucose. The syrup special for moon cake produced through the method is sucrose-free; the sweetness is slightly lower than that of the sucrose; the sweet taste is mild and pure, cool and refreshing; and the syrup is provided with a sweet flavor peculiar to honey, and has the advantages that the oil return property is obvious, the moisture retention property is good, the starch retrogradation is prohibited, the shelf life and the quality guarantee period of products are effectively prolonged, and the like.

Owner:BAOLINGBAO BIOLOGY

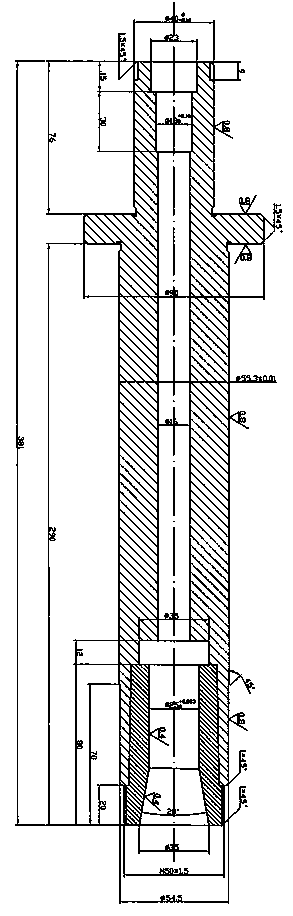

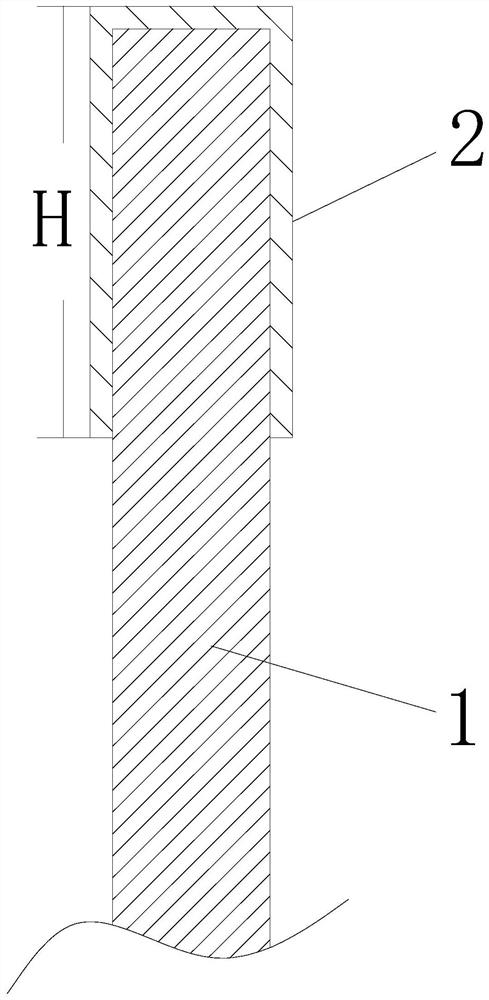

Core rod for powder metallurgy and machining process thereof

ActiveCN112170833AGood processabilityImprove toughnessPretreated surfacesFurnace typesPowder metallurgyMachining process

The invention discloses a core rod for powder metallurgy, and belongs to the technical field of core rods for powder metallurgy. The core rod comprises a core rod body, wherein a plating layer is arranged at the upper end of the core rod body. The invention further discloses a machining process of the core rod for powder metallurgy. The core rod body is made of die steel DC53, the characteristicsof good machinability and high toughness of the die steel are utilized, the core rod body with any shape and size can be machined, the problem of connection in the machining process of the core rod body can be avoided, so that the application range of machining is effectively expanded, and the machining period is shortened; the plating layer is arranged at the upper end of the core rod body, the plating layer is a thermal diffusion method carbide coating, the wear resistance and the surface roughness of the forming surface of the core rod body are improved, and the requirements of a productionproduct are met; and the toughness of the core rod body is guaranteed, the bending resistance of the core rod body after being pressed is improved, so that the physical performance of the core rod body is guaranteed, and the service life of the core rod body is prolonged.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Closed type loading apparatus of SiC tank kiln car

ActiveCN101408377BOvercoming fragileGuaranteed production requirementsCharge manipulationFurnace typesProduction lineGlass cover

The invention discloses a sealing-style loading apparatus used for an SiC tank kiln car. The loading apparatus comprises a loading operation table (1) and a charging chute (2) and is characterized in that a fixing frame (3) is arranged on the loading operation table (1) and an iron scale bin (4) and a dust coke bin (5) are respectively fixed on the back side and front side of the upper part of the fixing frame (3); an iron scale discharging header pipe (6) provided with a discharging branch pipe (7) is connected at the bottom of the iron scale bin (4); a dust coke discharging header pipe (8) provided with a discharging slot (9) is connected at the bottom of the dust coke bin (5); a winch (10) provided with a hook (12) is arranged at the middle part of a beam of the fixing frame (3) on theloading operation table (1); a bushing-style fitting is suspended on the hook (12); and simultaneously a glass cover (19) for sealing operation is also arranged. The loading apparatus has high loading speed, low loading contamination and lower harm to operators; the loading can be carried out strictly according to the ratio between the iron scale and dust coke; the problems that the unloading is difficult and the SiC tank is easy to break can be solved and the operation meets the standard; and the sealing-style loading apparatus can be widely applied to the powder metallurgy production lines.

Owner:LAIWU TAIDONG POWDER TECH

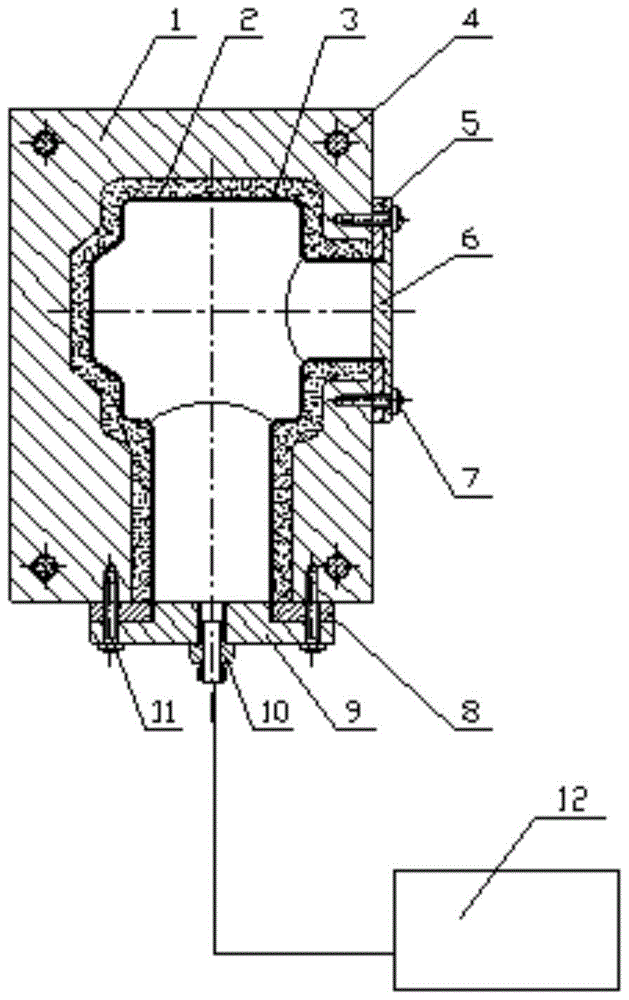

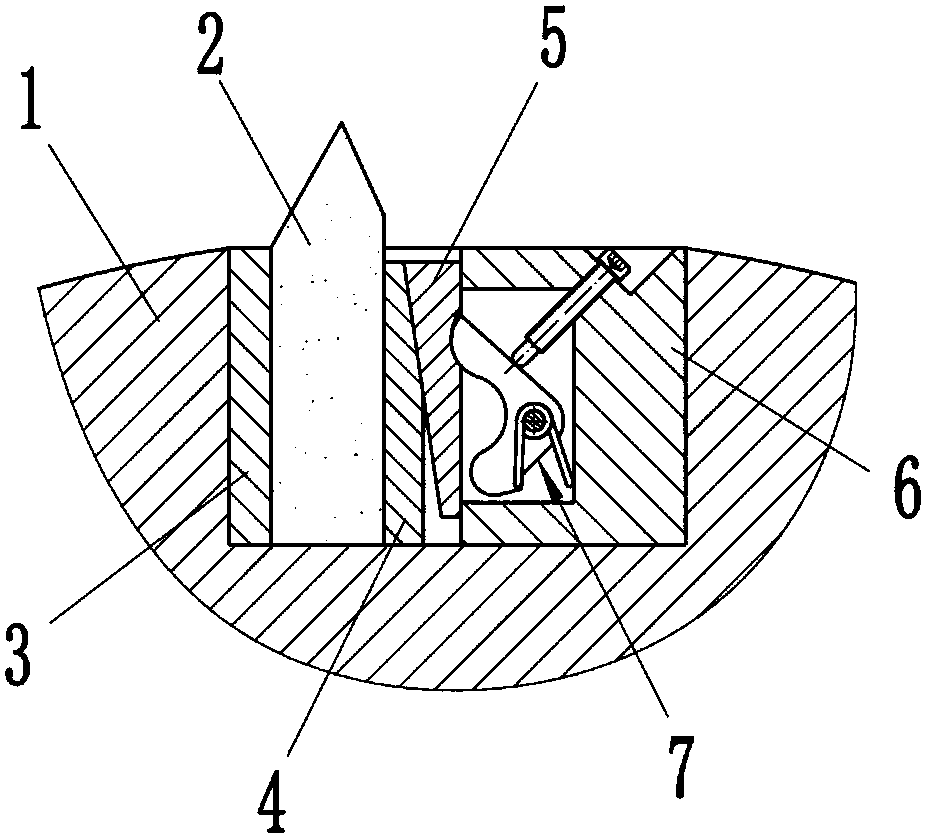

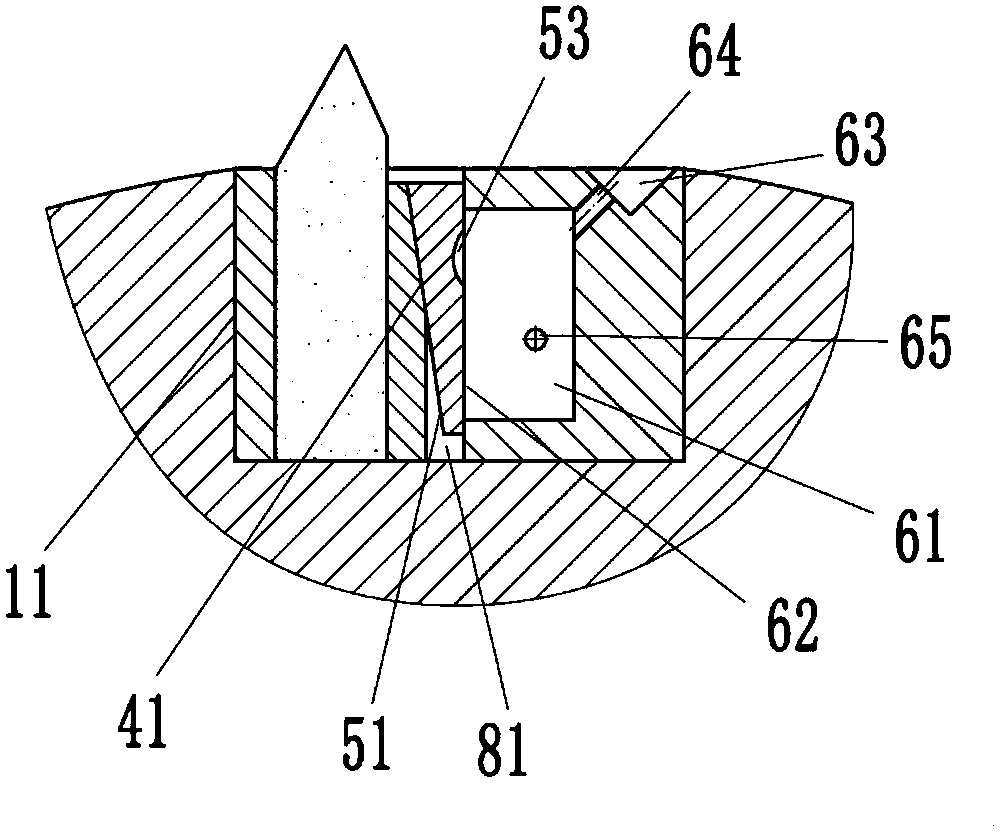

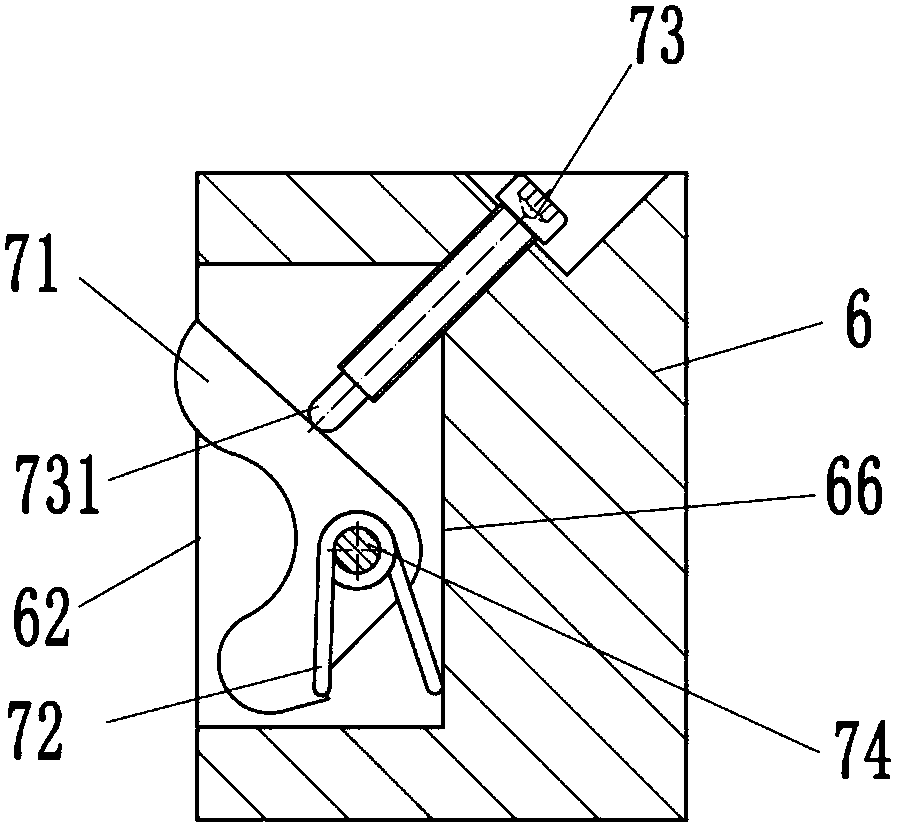

A kind of preparation method of desulfurization nozzle and its forming device

ActiveCN104760124BConsistent delivery pressureLow costCeramic shaping mandrelsCeramic shaping coresSulfurSpray nozzle

The invention relates to a preparation method and a shaping device of a sulfur removal nozzle. The preparation method of the low cost sulfur removal nozzle includes following steps: 1, firstly, smearing a release agent on the inner surface of an outer mold and the outer surface of an inner mold; 2, obtaining mixed powder by mixing materials, performing ball milling on the materials, and sieving the materials; 3, filling an interval between the outer mold and the inner mold with the powder, and using a liquid pump to inject high pressure liquid into the hollow inner mold; 4, releasing pressure; 5, drying the mixed powder; 6, obtaining the sulfur removal nozzle after sintering the powder. The shaping device of the sulfur removal nozzle comprises a shaping mold and the hydraulic pump, wherein the shaping mold and the hydraulic pump are connected through a high pressure hose, the shaping mold comprises the metal outer mold, the rubber inner mold, a first cover plate, a second cover plate and a pressurizing connector, the metal outer mold is composed of a first outer mold and a second outre mold, the rubber inner mold is arranged in an inner cavity of the metal outer mold, through holes are formed in the side wall and the bottom of the metal outer mold, a second blocking round plate is further arranged on a contact position of the second cover plate and the metal outer mold, a through hole is formed in the middle of the second cover plate, and the pressurizing connector is arranged on the outer side of the through hole in the middle of the second cover plate.

Owner:咸阳陶瓷研究设计院有限公司

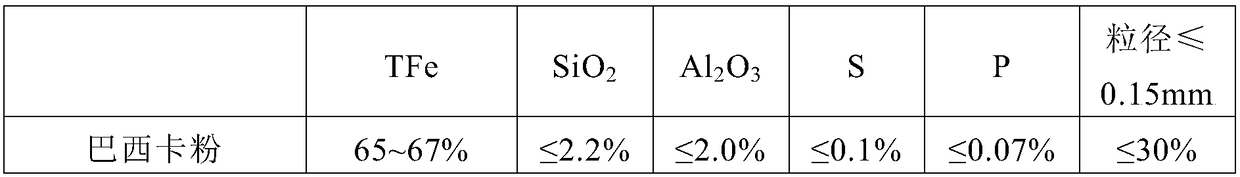

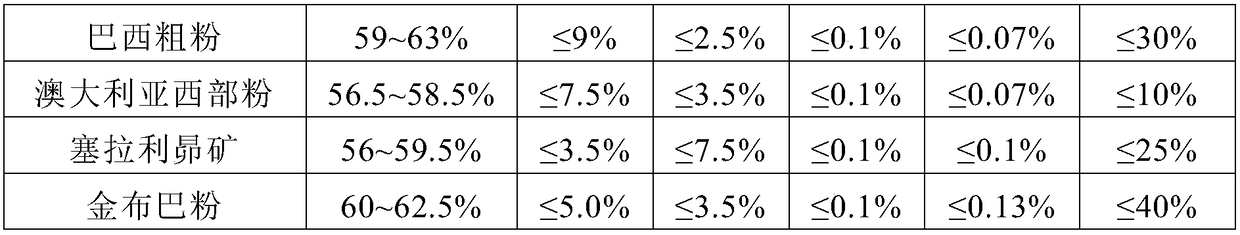

Iron ore powder mixed material suitable for HISMELT smelting reduction

The invention discloses an iron ore powder mixed material suitable for HISMELT smelting reduction. The iron ore powder mixed material suitable for the HISMELT smelting reduction comprises the following components of, by weight, 25-35% of Basica powder, 5-15% of Brazil coarse powder, 15-25% of Australian western powder, 15-25% of Sierra Leoneore and 15-25% of Jimblebar powder. The chemical indexesof the iron ore powder mixed material comprises the following components of, by weight, 61-62% of TFe, 3.5-4.3% of SiO2, 2.5-3.2% of Al2O3, less than or equal to 0.05% of S, less than or equal to 0.12% of P, and less than or equal to 22% of iron ore powder with a particle size less than or equal to 0.15 mm. A blended ore specially used for smelting reduction production of the iron ore powder is provided, the production requirements of HISMELT smelting reduction process are met while reducing the raw material cost of the iron ore powder, the charging grade and the iron yield are improved, the slag amount and ash amount are reduced, and the purposes of high yield and high metal yield are achieved.

Owner:上海慧安科技股份有限公司

Prompt method, device and electronic device for video editing

ActiveCN111770381BSatisfy the viewing effectGuaranteed production requirementsElectronic editing digitised analogue information signalsCarrier indicating arrangementsEngineeringVideo production

The present disclosure relates to a prompting method, device, electronic device, and storage medium for video editing, and relates to the technical field of software applications. The method includes: displaying a preview image of a video to be edited in a preview area of a video editing page, and obtaining a preview when the material is in the selected state, obtain the first boundary range information of the material in the preview area; obtain the second boundary range information of the preview safe area in the preview area; and if according to the first boundary range information and The second boundary range information determines that the material exceeds the preview safe area, then the prompt information corresponding to the preview safe area is displayed according to the second boundary range information of the preview safe area. It can meet the viewing effect of more users, and improve the viewing experience of video users while ensuring the production needs of video production users.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

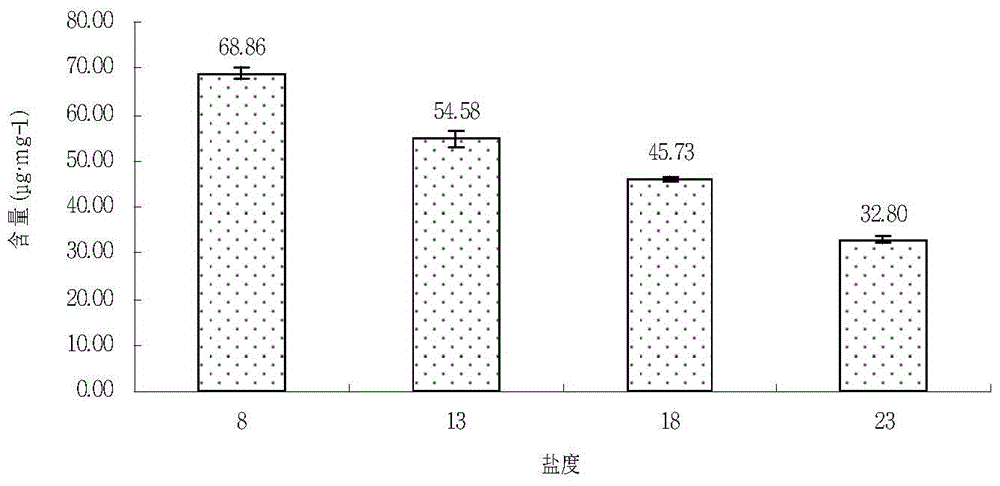

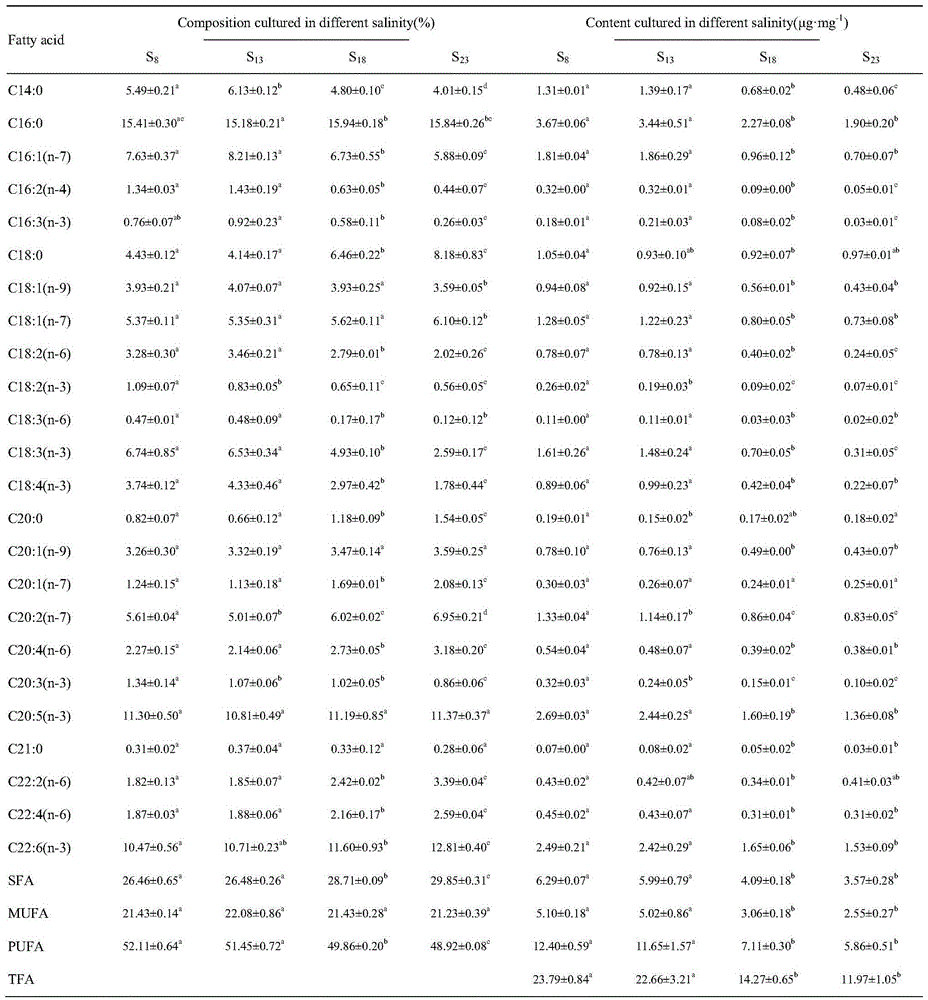

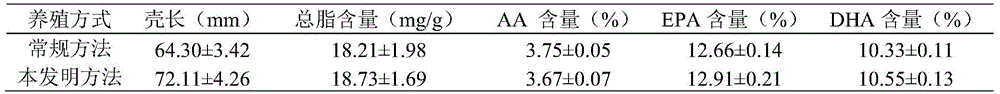

A method for improving yield and quality of razor clam cultured

ActiveCN104855320BImprove taste qualityImprove nutritional qualityClimate change adaptationPisciculture and aquariaEconomic benefitsFresh water

The invention belongs to the technical field of aquaculture, and relates to a method for improving aquaculture output and quality of sinonovacula constricta. The method for improving the aquaculture output and the aquaculture quality of the sinonovacula constricta is specially directed at the sinonovacula constricta aquaculture in a seawater enclosed pond. The method for improving the aquaculture output and the aquaculture quality of the sinonovacula constricta includes: using a water pump to pump fresh water into the aquaculture enclosed pond or replacing water in the aquaculture enclosed pond with seawater lower than 12 in salinity in April or May every year, controlling the salinity of the seawater below 13, and then throwing sinonovacula constricta larvae into the aquaculture enclosed pond. During the whole growth period of the sinonovacula constricta larvae, the salinity of the seawater in the aquaculture enclosed pond is kept below 13, and the salinity of the seawater is gradually increased to a value higher than 18 before catching is started, and then the sinonovacula constricta are fetched out of the aquaculture enclosed pond after the sinonovacula constricta larvae are bred at the salinity higher than 18 for a time longer than one month. Accordingly, the method for improving the aquaculture output and the aquaculture quality of the sinonovacula constricta achieves both high output and high taste quality in the sinonovacula constricta aquaculture, and greatly increases economic benefit of the sinonovacula constricta aquaculture.

Owner:福建省中灵农业发展有限公司

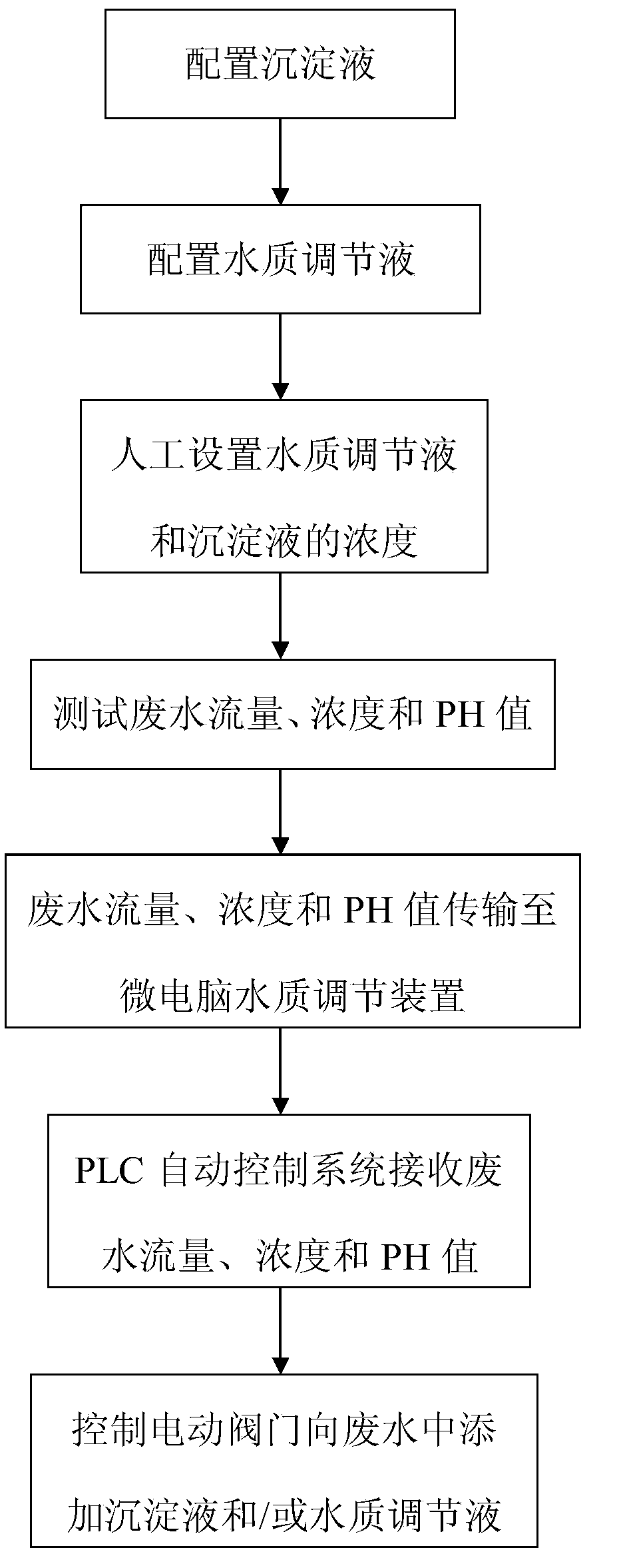

Method for adjusting stone machining wastewater quality

InactiveCN103466840AReduce environmental pollutionMaintain glossMultistage water/sewage treatmentAutomatic controlMicro computer

A method for adjusting stone machining wastewater quality comprises the following steps: providing a stone machining wastewater quality adjusting system which comprises a water quality automatic checkout device and a micro computer water quality adjusting device; arranging a deposition liquid; arranging a water quality adjusting liquid; manually setting the concentration of the water quality adjusting liquid and the deposition liquid; testing the flow, the concentration and the pH value of the wastewater in a ditch by the micro computer water quality automatic checkout device; transmitting the tested flow, concentration and pH value of the wastewater to the micro computer water quality adjusting device; and according to the set concentrations of the water quality adjusting liquid and the deposition liquid, controlling the automatic addition of the deposition liquid and / or the water quality adjusting liquid into the wastewater by the PLC automatic control system in the micro computer water quality adjusting device after the PLC automatic control system accepts the testing values of the flow, the concentration and the pH value of the wastewater. The method is capable of accurately controlling addition of the deposition liquid and the water quality adjusting liquid into the wastewater, and helps to guarantee that the wastewater is neutral, so that the water quality reaches production requirement, and has no corrosion generated on stone surfaces, so that the surface gloss of stones reaches production requirements; and also the method helps to reduce environmental pollution.

Owner:太仓中顺建筑工程有限公司

Circular pressing circular cutter

ActiveCN108501051AEasy to installGuaranteed production requirementsMetal working apparatusEngineeringWedge shape

The invention provides a circular pressing circular cutter. The circular pressing circular cutter comprises a cutter roller and a bottom roller. The cutter roller comprises a base and a fastening device. A blade is fastened in a first groove of the base through the fastening device. The fastening device comprises a first pressing strip, a second pressing strip, an extruding part, a wedge-shaped part and a reinforcing assembly, wherein the blade abuts against the right side of the first pressing strip; the left side of the second pressing strip abuts against the blade; the extruding part is fixed to the right edge of the first groove; the wedge-shaped part is blocked between the second pressing strip and the extruding part; the reinforcing assembly comprises a V-shaped part, a torsional spring and a lock screw; the V-shaped part is pivoted in a mounting groove and blocked in a second groove of the wedge-shaped part; the lock screw is connected to the extruding part; the front end of thelock screw abuts against the V-shaped part; and the V-shaped part can be driven by the lock screw to rotate, a rotating upper flap part abuts against the second groove, thus, the wedge-shaped part further extrudes the second pressing strip, then the blade is further pressed, and the blade is fixed to the cutter roller more firmly and reliably.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Full-automatic arc concave gem grinding machine

ActiveCN102152191BAchieve grindingRealize fully automatic arc grindingEdge grinding machinesPilot holeStructural engineering

The invention discloses a full-automatic arc concave gem grinding machine, which comprises a rack. A transverse mounting frame is rotatably arranged at the upper side of the rack; a plurality of longitudinal aluminum ranks for clamping gem blanks are fixedly arranged on the bottom part of the mounting frame in parallel; a locking block for fixing the position of the mounting frame is arranged at the upper end of the mounting frame; guide slots are arranged at the left end and the right end of the lower side of the frame; supporting plates the two sides of which are provided with guide rails are arranged in the guide slots; the supporting plates are rotatably provided with a plurality of rotating shafts which are arranged in parallel in front and rear directions; grinding rods are fixedly arranged on the rotating shafts; guide seats are arranged at the bottom parts of the supporting plates and are provided with transverse screw holes in left and right directions; screws are sheathed inthe screw holes; the other ends of the guide seats are connected with connecting bars; longitudinal through holes are arranged at the right ends of the connecting bars; the connecting rods are connected with transverse eccentric slot wheels through the through holes; longitudinal screw holes are arranged at the middle positions of the supporting plates; lifting screws matched with the longitudinal screw holes in motions are arranged in the longitudinal screw holes; longitudinal guide holes are arranged at the two sides of the supporting plates; and guide rods are respectively sheathed in the guide holes and are arranged on the frame.

Owner:陈松军

A new type of vibrating ring casting mold

The invention relates to a new type of vibrating ring casting mold, which includes a pressing plate, on which a module is correspondingly arranged, which is divided into an upper module and a lower module, and the lower module is arranged on the oblique inner side of the upper module, and on the pressing plate A sprue cup is provided in the middle of the upper part, and a runner is provided under the sprue cup. On the runners on both sides of the sprue cup on the positive pressure plate, there are horizontal and vertical sprues downward. An upper edge riser is provided under the horizontal and vertical sprues, and an upper inner gate is arranged on the upper edge riser, and the upper inner gate is arranged on the same horizontal line. There is an intermediate runner between the lower modules on the positive pressure plate, and a lower edge riser is provided between the lower modules on the positive pressure plate, and a lower inner gate is arranged on the lower edge riser, and the lower inner gate is arranged on On the same horizontal line, a flow blocking flange is provided on the counter pressure plate corresponding to the connection between the intermediate runner and the lower flange riser. The invention has reasonable structural arrangement, high product quality and high qualified rate.

Owner:宜兴高泰克精密机械有限公司

Casting process of frame saw bearing seat

InactiveCN109047667BReduce thicknessImprove casting production qualityFoundry mouldsFoundry coresEngineeringMachining

The invention discloses a casting process for a bearing seat of a frame saw, belonging to the technical field of casting production, comprising the following steps: (1) making a mold of a mold plate;(2) making an upper sand box and a lower sand box; (3) making a first sand core insert and a second sand core insert; (4) processing a flow channel and a heat riser; (5) smelting iron; (6) closing thebox and pouring; (7) dropping sand; (8) cleaning castings and shot peening. The casting process for a bearing seat of a frame saw adopts a one-mold and two-cavity forming method, and casts two castings at one time, thereby improving the production efficiency; the production quality of the bearing seat of the frame saw can be ensured by arranging the heat riser and a fan-shaped pouring port; a mounting hole in the surface of the bearing seat of the frame saw can be molded out while producing the bearing seat of the frame saw by installing the stable and convenient first sand core insert and second sand core insert, and subsequent machining procedures are reduced.

Owner:南安市春安机械铸造有限公司

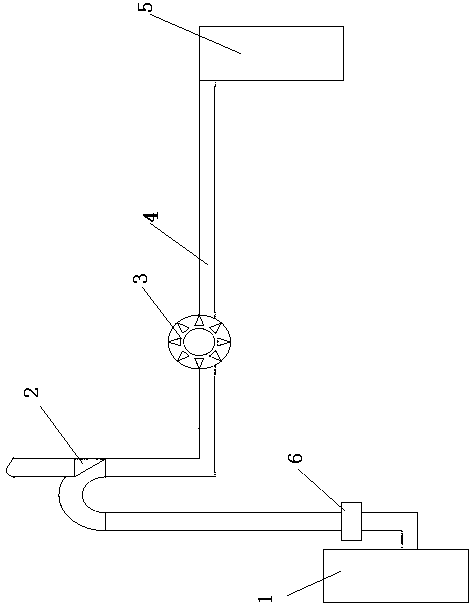

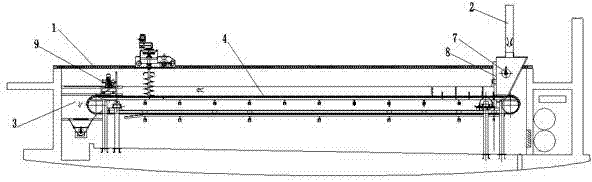

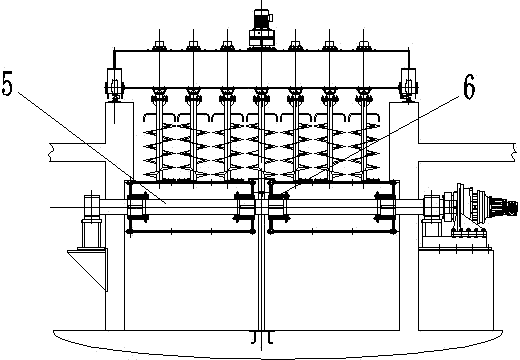

Movable germinator

InactiveCN104194986ACompact structureAvoid difficulty in dischargingMalt preparationMechanical engineering

The invention relates to a movable germinator which comprises a bed body (1), wherein a feed opening (2) is formed in one side of the bed body (1); a discharge opening (3) is formed in the other side of the bed body; a movable conveying belt (4) between the feed opening (2) and the discharge opening (3) is arranged in the bend body (1). According to the movable germinator, a traditional fixed screen plate is replaced by the movable conveying belt, material is conveyed very conveniently owing to the arrangement of the movable conveying belt, a spreading machine is not needed to be arranged, the material is fed only through the feed opening, and uniform distribution of malt is realizedautomatically with the moving of the movable conveying belt, so that the structure is more compact. The movable conveying belt of the movable germinator can move the material step by step to the discharge opening so as to automatically discharge the material without the need of a discharge machine; and all parts of the movable conveying belt discharge material at the discharge opening, thus avoiding the defect that material is difficult to discharge by the traditional fixed screen plate.

Owner:YANGZHOU XIANYE GRP

A round pressing round cutter

ActiveCN108501051BEasy to installGuaranteed production requirementsMetal working apparatusStructural engineeringKnife blades

The invention provides a circular pressing circular cutter. The circular pressing circular cutter comprises a cutter roller and a bottom roller. The cutter roller comprises a base and a fastening device. A blade is fastened in a first groove of the base through the fastening device. The fastening device comprises a first pressing strip, a second pressing strip, an extruding part, a wedge-shaped part and a reinforcing assembly, wherein the blade abuts against the right side of the first pressing strip; the left side of the second pressing strip abuts against the blade; the extruding part is fixed to the right edge of the first groove; the wedge-shaped part is blocked between the second pressing strip and the extruding part; the reinforcing assembly comprises a V-shaped part, a torsional spring and a lock screw; the V-shaped part is pivoted in a mounting groove and blocked in a second groove of the wedge-shaped part; the lock screw is connected to the extruding part; the front end of thelock screw abuts against the V-shaped part; and the V-shaped part can be driven by the lock screw to rotate, a rotating upper flap part abuts against the second groove, thus, the wedge-shaped part further extrudes the second pressing strip, then the blade is further pressed, and the blade is fixed to the cutter roller more firmly and reliably.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Efficient ladle baking device

The invention provides an efficient ladle baking device. The efficient ladle baking device comprises a baking device body, a cover and a flame retardant layer, wherein the lower end of the baking device body is connected with the upper end of the cover; the lower end of the cover is connected with the flame retardant layer; the lower end of a burner composed of a conical body, a flow mixing cavity, an electronic igniter, a combustion cavity and a firing stabilizer is arranged at the lower end of the flame retardant layer, and the upper end of the burner is arranged on the upper portion inside the baking device body; the upper end of the burner is connected with an air cavity through an electric adjustment valve; an air heat exchanger is installed on the lower portion of the air cavity; one end of the air heat exchanger is connected with a smoke inlet, and the other end of the air heat exchanger is connected with a smoke outlet; an air inlet is formed in the lateral surface of the cover; the upper end of the burner is provided with a fuel gas inlet communicating with an outlet of a fuel gas heat exchanger; the conical body is arranged at the fuel gas inlet of the burner; an inlet of the fuel gas heat exchanger is connected with a fuel gas pipeline through a fuel gas valve and a flowmeter; and the ladle baking device is further provided with an intelligent control device. The efficient ladle baking device has the advantages of saving energy and labor, improving safety performance and the like.

Owner:大连新瑞晨环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com