Hydraulic oil pumping system

A hydraulic and oil pumping technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of large floor area, low pumping load, complexity, etc., to achieve larger floor area, less Small footprint and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

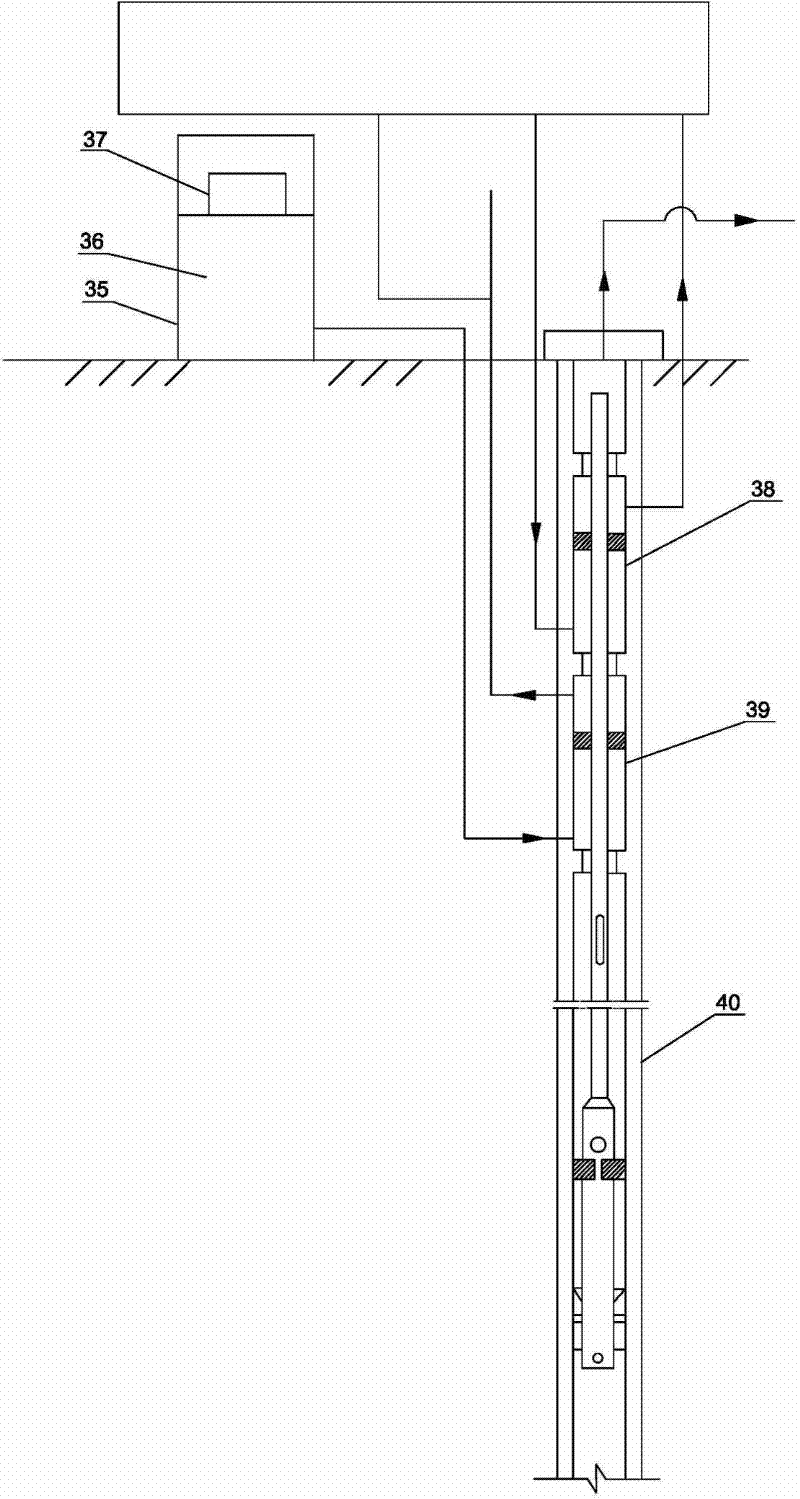

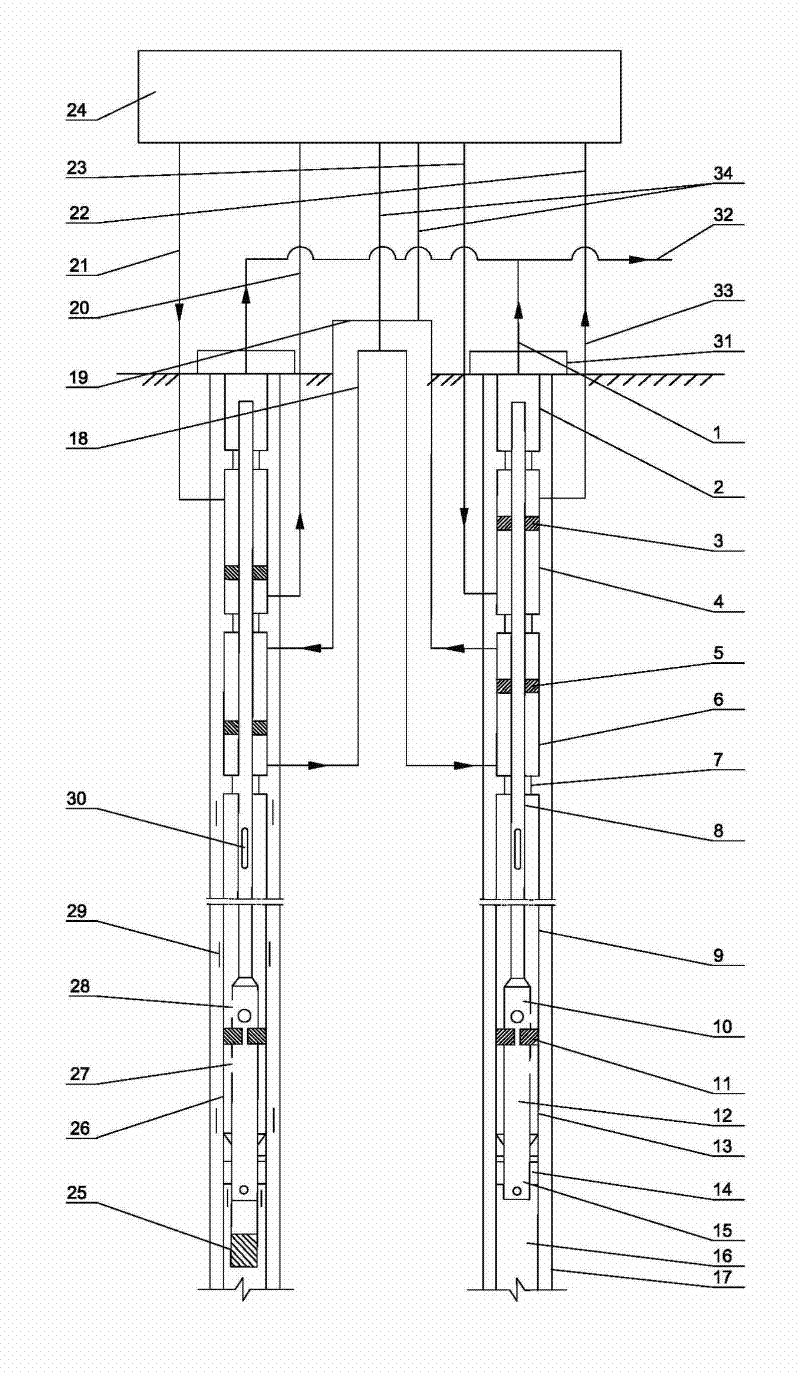

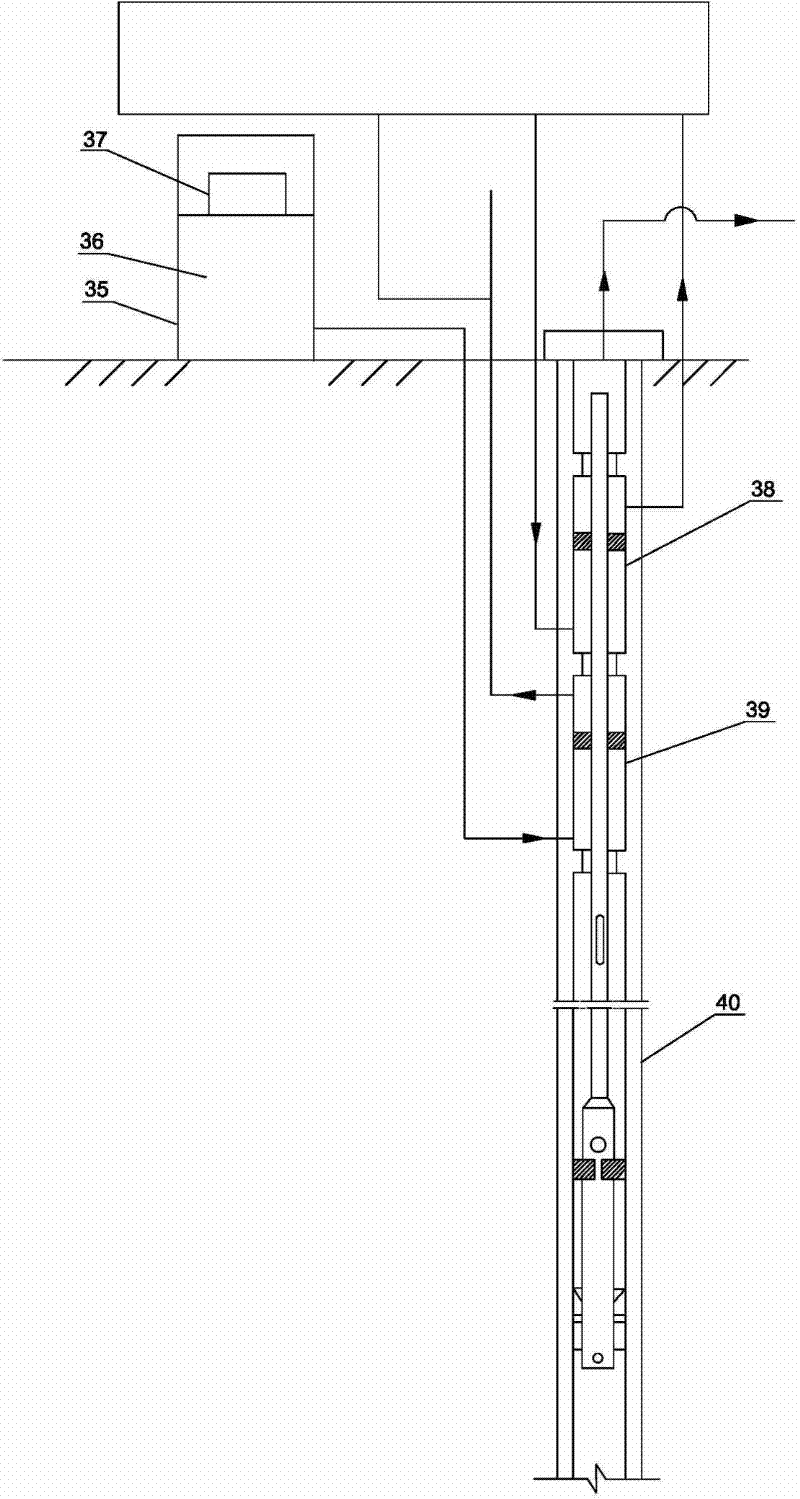

[0025] The present invention includes at least one hydraulic pumping unit, the hydraulic pumping unit includes a power unit 38 and an oil production unit 40 below the power unit 38, the power unit 38 is connected to the hydraulic pump station 24 on the surface, The main points of its structure are: it also includes a balance part 39 , the balance part 39 is connected with the power part 38 and the oil production part 40 , and a hollow sucker rod 8 passes through the power part 38 , the balance part 39 and the oil production part 40 .

[0026] The balance part 39 is located between the power part 38 and the oil production part 40 .

[0027] Further, the oil production unit 40 includes an oil well pump 26, the pump barrel 13 of the oil well pump 26 is provided with a plunger 11, and the plunger 11 is fixed on the hollow rod 12 in the pump barrel 13, and the bottom of the plunger 11 is The hollow rod 12 is provided with a communication port 27; the upper and lower parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com