Machining method for improving ultra-accurate split spindle accuracy

A processing method and a split-type technology are applied in the processing field of improving the accuracy of ultra-high-precision split-type spindles, which can solve the problems of difficult spindle replacement and high processing costs, and achieve the effects of improving accuracy, ensuring production requirements, and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

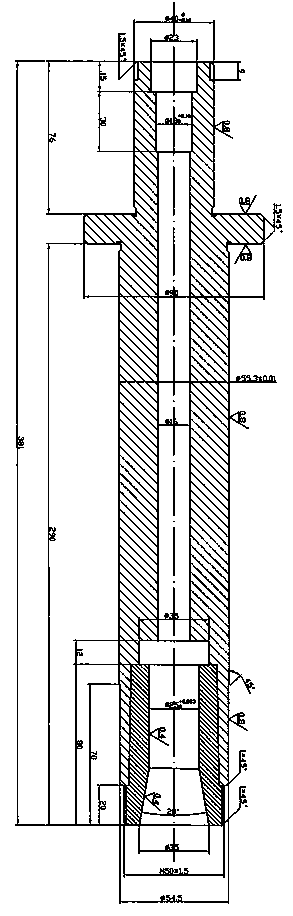

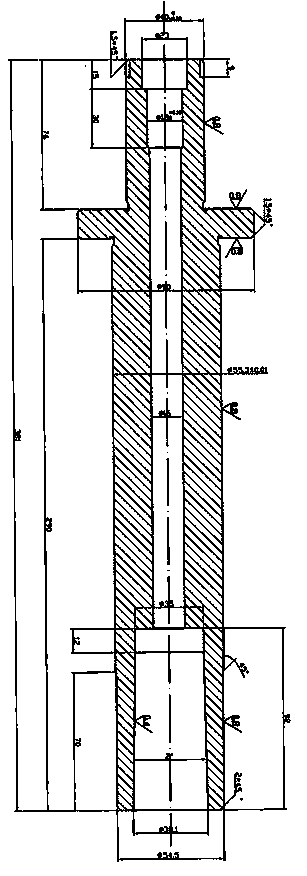

Image

Examples

Embodiment 1

[0021] Spindle blanking, annealing, the processed workpiece is raised for turning, milling and clamping, then heat treatment, and then grinding.

[0022] The grinding steps are as follows:

[0023] (1) Roughly grind the outer circles of the two first, and put 0.45 margin

[0024] (2) Clamp and polish the outer circle, set up the center frame, and grind the positioning datum at both ends

[0025] (3) Coarsely grind the outer circle and inner cone of each part with 0.09 coarse grinding amount

[0026] (4) Aging stress relief treatment

[0027] (5) Intensively study the positioning datum at both ends to ensure that the out-of-roundness of the positioning datum at both ends is within 0.001

[0028] (6) Finely grind the outer circles of each part to the size, after grinding, the concentricity of each outer circle is 0.001, and the cylindricity is 0.001

[0029] (7) The outer circle is used as the reference, and the runout between the inner cone and the outer circle is detected ...

Embodiment 2

[0035] Spindle blanking, annealing, the processed workpiece is raised for turning, milling and clamping, then heat treatment, and then grinding.

[0036] The grinding steps are as follows:

[0037] (1) Roughly grind the outer circles of the two first, and put 0.46 allowance

[0038] (2) Clamp and polish the outer circle, set up the center frame, and grind the positioning datum at both ends

[0039] (3) Coarsely grind the outer circle and inner cone of each part with 0.1 coarse grinding amount

[0040] (4) Aging stress relief treatment

[0041] (5) Intensively study the positioning datum at both ends to ensure that the out-of-roundness of the positioning datum at both ends is within 0.001

[0042] (6) Finely grind the outer circles of each part to the size, after grinding, the concentricity of each outer circle is 0.001, and the cylindricity is 0.001

[0043] (7) The outer circle is used as the reference, and the runout between the inner cone and the outer circle is detecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com