Core rod for powder metallurgy and machining process thereof

A technology of powder metallurgy and processing technology, which is applied in the field of powder metallurgy mandrel and its processing technology, can solve the problems of insufficient scope of application, high processing cost, high difficulty, and high hardness of alloy materials, so as to improve the scope of application, guarantee requirements, The effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

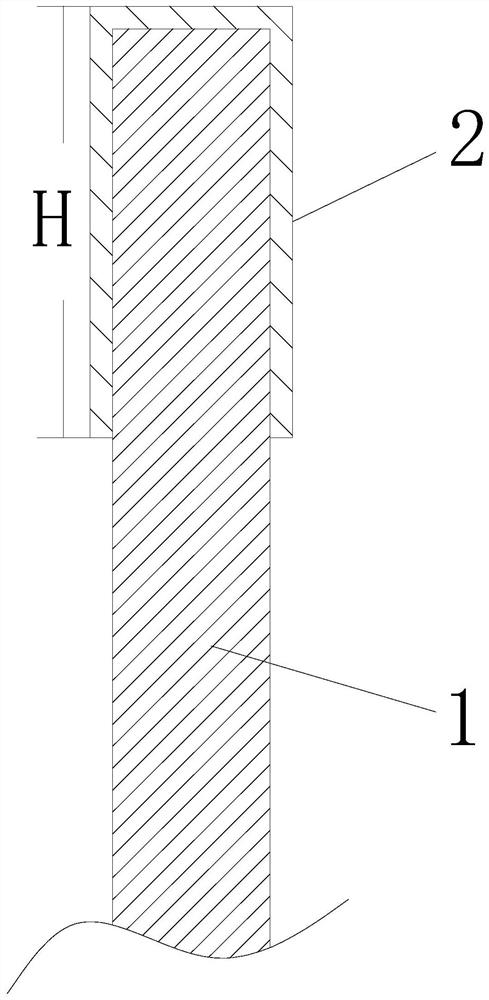

[0033] see figure 1 , the present invention provides the following technical solutions: a mandrel for powder metallurgy, comprising a mandrel body 1, the upper end of the mandrel body 1 is provided with a coating 2.

[0034] Specifically, the mandrel body 1 is a component of die steel DC53.

[0035] By adopting the above-mentioned technical scheme, the mandrel body 1 is made of die steel DC53, and the mandrel body 1 of any shape and size can be processed by utilizing the characteristics of good machinability and high toughness of the die steel, which can avoid the occurrence of The problem of connection, thus effectively improving the scope of application of processing and shortening the processing cycle;

[0036] Specifically, the coating 2 is a thermal diffusion carbide coating, the hardness of the coating 2 is greater than HRA89, and the friction coefficient of the coating 2 is less than 0.2.

[0037] By adopting the above technical scheme, the wear resistance and surface...

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is:

[0053] Further in the present invention, the processing technology of described powder metallurgy mandrel, comprises the following steps:

[0054] (1), mandrel body 1 adopts mold steel DC53 component;

[0055] (2), surface polishing is carried out to mandrel body 1;

[0056] (3), the upper end of the mandrel body 1 is sprayed with 30 microns of thermal diffusion hardening treatment coating;

[0057] (4), 180 ℃, constant temperature drying 1.5h,

[0058] (5), high temperature treatment at 1300°C for 3 hours;

[0059] (6) Tempering at low temperature for 2.5 hours;

[0060] (7) The thermal diffusion hardening treatment coating is a chrome diffusing agent;

[0061] (8), the height H of coating 2 is 2.3 times of product height;

[0062] (9) The coating 2 is a carbide coating by thermal diffusion method.

Embodiment 3

[0064] The difference between this embodiment and embodiment 1 is:

[0065] Further in the present invention, the processing technology of described powder metallurgy mandrel, comprises the following steps:

[0066] (1), mandrel body 1 adopts mold steel DC53 component;

[0067] (2), surface polishing is carried out to mandrel body 1;

[0068] (3), the upper end of mandrel body 1 is sprayed with thermal diffusion hardening treatment coating 40 microns;

[0069] (4), 180 ℃, constant temperature drying 1.5h,

[0070] (5), high temperature treatment at 1500°C for 4 hours;

[0071] (6) Tempering at low temperature for 3 hours;

[0072] (7) The thermal diffusion hardening treatment coating is a chrome diffusing agent;

[0073] (8), the height H of coating 2 is 2.3 times of product height;

[0074] (9) The coating 2 is a carbide coating by thermal diffusion method.

[0075] To sum up, the mandrel body 1 of the present invention is made of die steel DC53, and the mandrel body 1 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com