Iron ore powder mixed material suitable for HISMELT smelting reduction

A technology of iron ore powder mixing, which is applied in the field of iron ore powder mixing, to achieve the effects of reducing raw material costs, high metal yield, and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

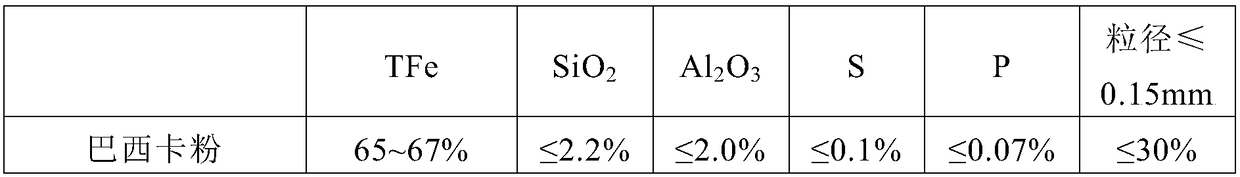

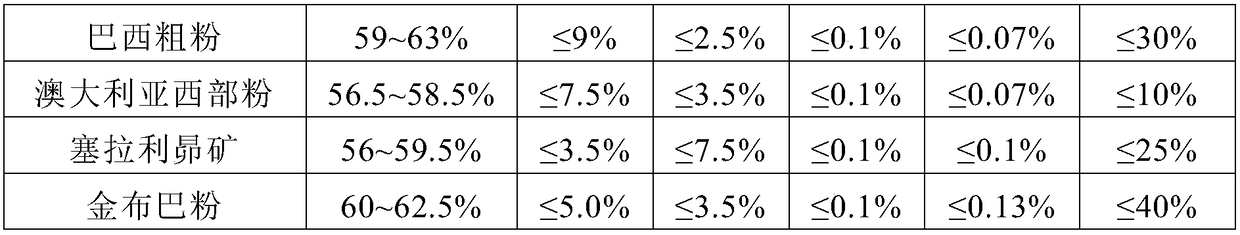

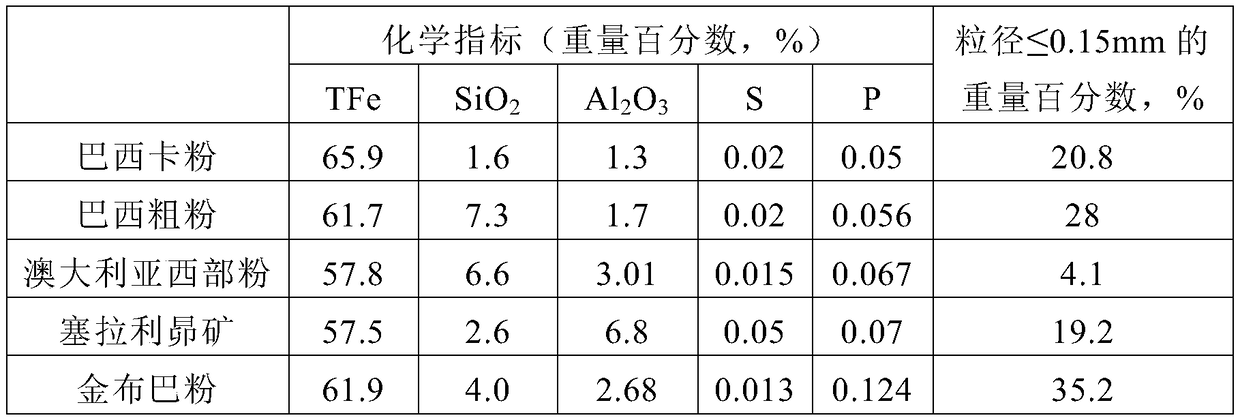

[0032] The iron ore powder mixture composition and weight percentage of the present embodiment are as shown in Table 1, and the chemical indexes of various iron ores in the mixture formula are as shown in Table 2, and various iron ores are obtained through the use of intelligent mixing materials. The processing equipment carries out batching and mixing production to obtain iron ore powder mixing. The chemical indicators of each chemical element, compound and particle size in the iron ore powder mixture obtained in this embodiment are shown in Table 3.

[0033] The iron ore powder mixing product produced in this embodiment has been applied in an enterprise in Shandong, and the iron ore powder mixing is used to produce molten iron using the HISMELT smelting reduction process. TFe: 61.5%, SiO 2 : 3.8%, Al 2 o 3 : 2.5%, S: 0.02%, P: 0.011%, the proportion of particle size less than 0.15mm is 31.5%, melting temperature 1245 ℃) the production index after application is compared, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com