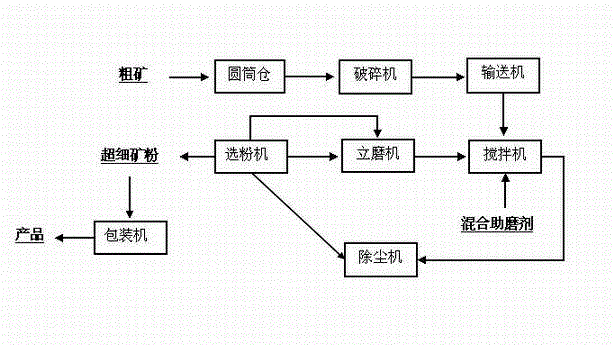

Ultrafine titanium concentrate grinding process flow

A process flow, technology of titanium concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail with specific embodiments in conjunction with the accompanying drawings.

[0011] An ultrafine titanium concentrate grinding process, which is mainly composed of a silo, a conveyor, a crusher, a mixer, a vertical mill, a powder separator and a dust removal device, and is characterized in that: The coarse ore is transported to the crusher by the belt conveyor to crush the mineral, and then enters the mixer, and at the same time adds a mixed grinding aid for stirring and mixing; then the mixed material is sent to the vertical mill for grinding, and the grinding time is corresponding Finally, the powder material is sent to the powder classifier, and the powder is screened, and the unqualified powder material is sent back to the vertical mill, and the process is repeated continuously. The qualified powder will be sent to the packaging machine for packaging, and finally produce ultra-fine mineral powder products.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com