Casting process of frame saw bearing seat

A casting process and bearing seat technology are applied in the field of frame saw bearing seat casting technology, which can solve the problems of large impact force between bearings and bearing seats, increase processing procedures and difficulty, reduce the service life of bearing seats, etc. Reduce the effect of cooling too fast and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described below in conjunction with the accompanying drawings, and the following embodiments and descriptions are only used to explain the present invention, but not as a limitation to the present invention.

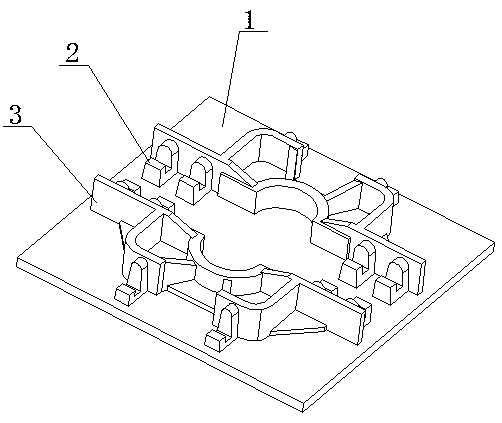

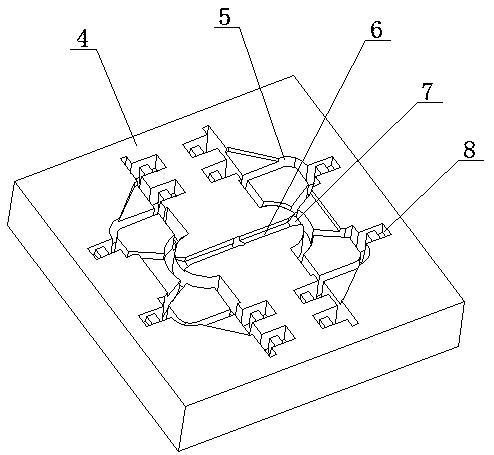

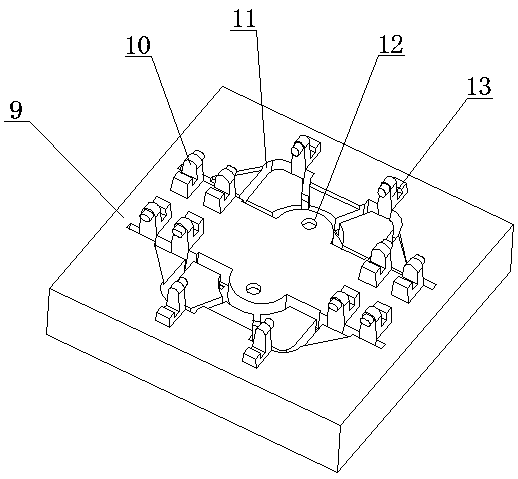

[0033] A casting process for a frame saw bearing seat. The sand mold structure used for casting the frame saw bearing seat 17 includes an upper sand box 4, a lower sand box 9, a sand core insert 13 and a sand core insert 2 10, and an upper sand box 4 Covered on the lower sand box 9 to form a main cavity structure, both the upper sand box 4 and the lower sand box 9 are provided with an insert groove 8 matching the shape of the sand core insert 13 and the sand core insert 2 10, The upper sand box is provided with a pouring runner 6, a vertical runner 14, and a sprue cup 15, and the vertical runner 14 is connected with the pouring runner 6 and the sprue cup 15, and the pouring runner 6 and the main cavity structure are provided with The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com