Full-automatic arc concave gem grinding machine

An arc-shaped concave and fully automatic technology, which is applied in the direction of machine tools, grinding machines, grinding/polishing equipment, etc. suitable for grinding the edge of workpieces, can solve the problem that the quality and output of jewelry cannot meet market demand, and crystal jewelry has no arc surface, etc. problems, to achieve consistent specifications and quality, and to ensure the effect of output requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

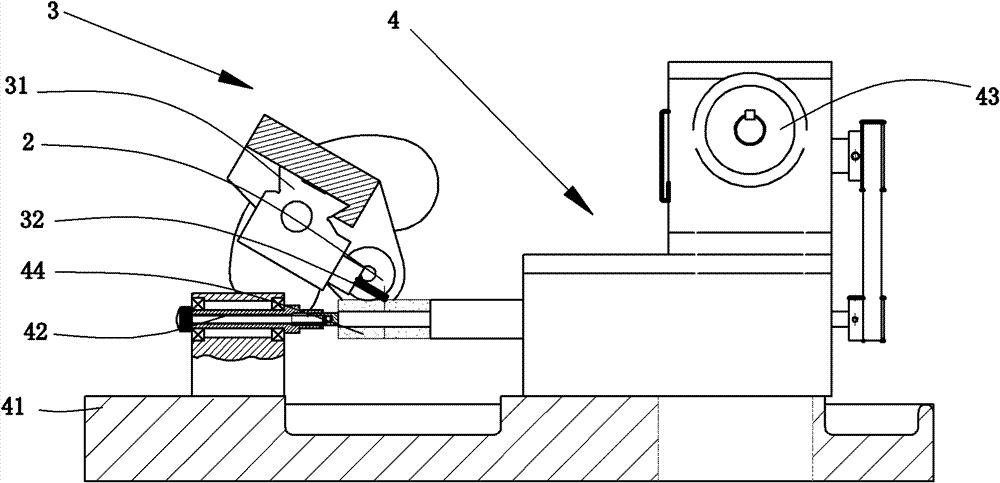

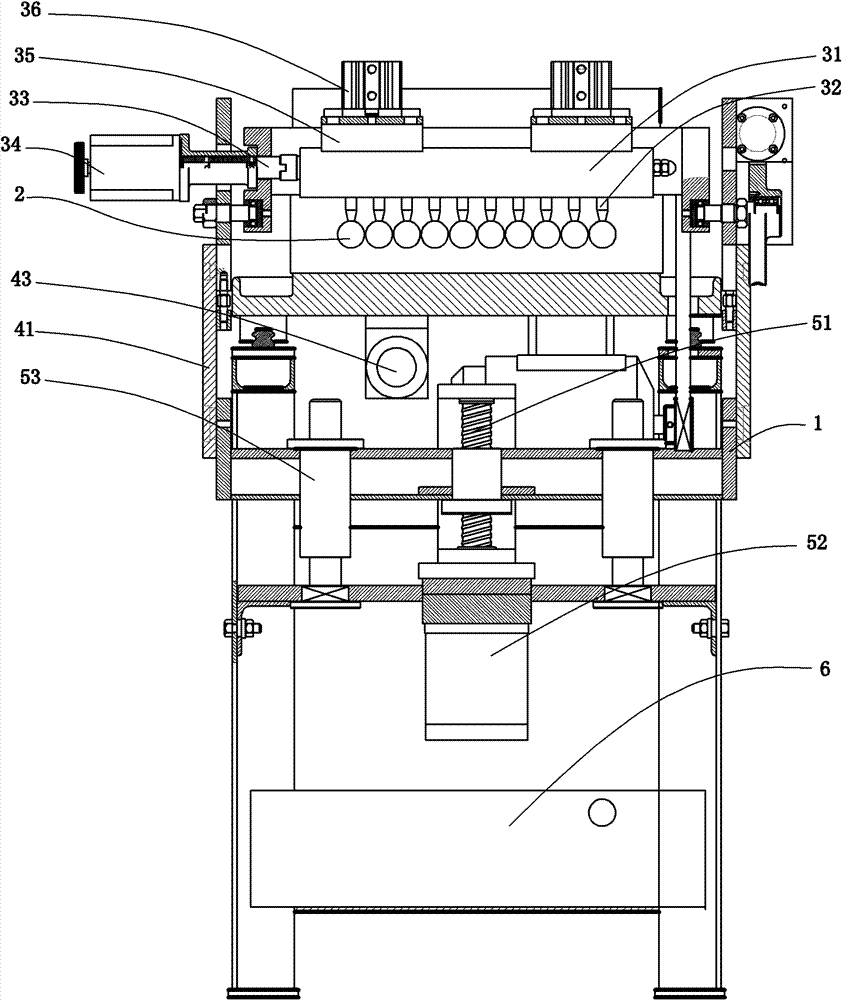

[0017] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

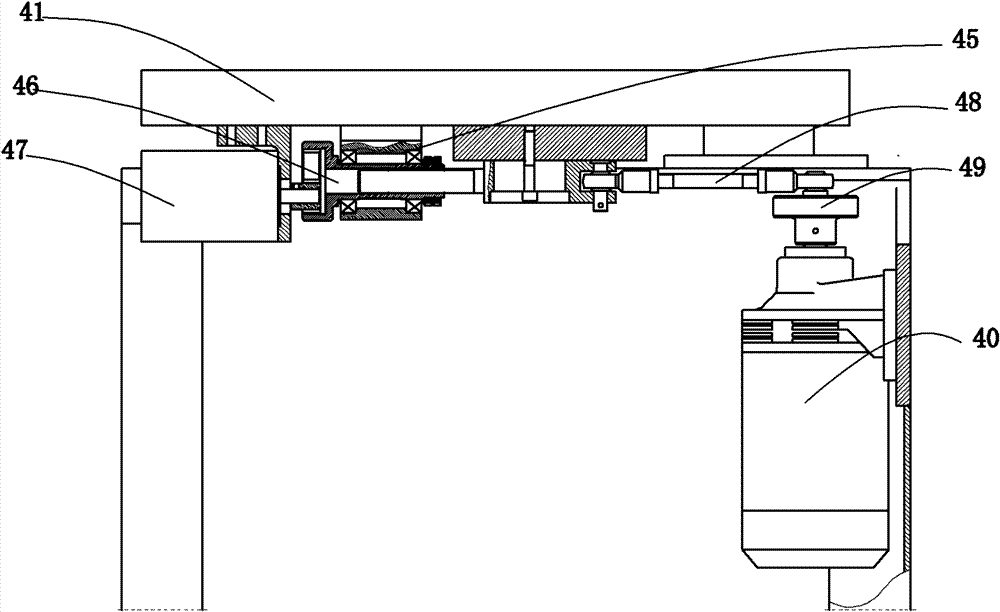

[0018] Such as figure 1 As shown, the full-automatic curved concave gem grinding machine of the present invention includes a frame 1, a positioning mechanism 3 and a grinding mechanism 4, and the grinding operation of the gemstone blank 2 is completed through the cooperative action of the positioning mechanism 3 and the grinding mechanism 4, wherein the frame 1 adopts a frame structure, the positioning mechanism 3 is installed on the upper side of the frame 1, and it is used to clamp and fix the gem blank 2, and the polishing mechanism 4 is installed in the middle of the frame 1 corresponding to the position of the gem blank.

[0019] The positioning mechanism 3 includes a horizontal mounting frame 31 installed on the frame 1, and several (generally ten, consistent with the number of grinding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com