Movable germinator

A germination box and malt technology, which is applied in the preparation of malt, beer brewing, biochemical equipment and methods, etc., can solve the problems of difficulty in discharging, long discharging journey, and waste of malt, so as to avoid difficulty in discharging and ensure Connection strength, effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

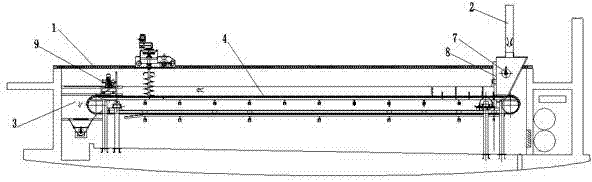

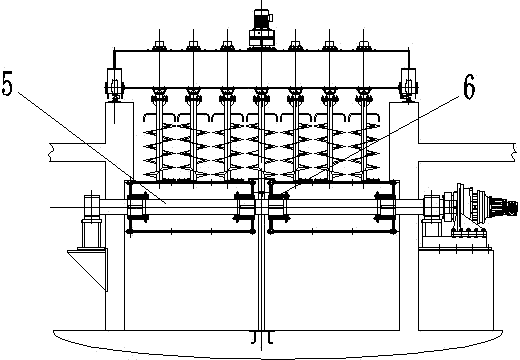

[0024] Germination feeding action of the present invention: open the moving conveyor belt 4, the malt flows into the feeding device through the feeding port 2, and the feeding device is equipped with a screw auger 7, which can evenly distribute the malt on both sides until the inner width of the germination box , The malt passes through the feed gate 8 device, which unifies the height of the feed and ensures the uniform ventilation and germination quality of the malt entering the box. After the whole germination box was covered with malt, the moving conveyer belt 4 stopped rotating, and the whole cloth action was completed.

[0025] During the germination period, it is necessary to adjust the fresh air louvers and exhaust louvers for ventilation, cooling in summer and heating in winter. Turn the wheat to replenish water to ensure the effective growth of malt.

[0026] Germination discharge action: after the germination cycle is over, the discharge action: first move the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com