Method for preparing hypericins

A hypericin and water extraction technology, applied in organic chemistry, quinone separation/purification, etc., can solve problems such as unfavorable large-scale production, difficult product extraction, troublesome extraction agent configuration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

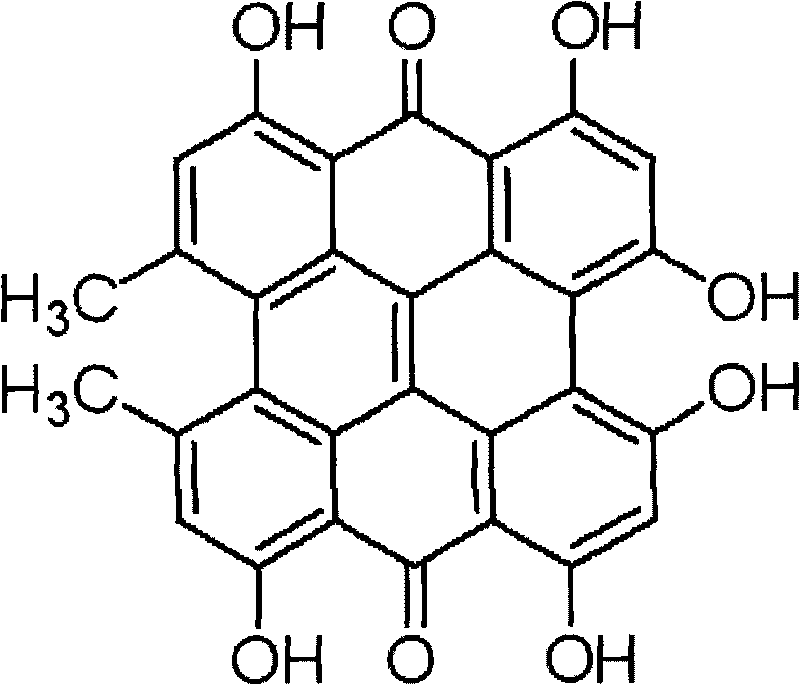

Image

Examples

Embodiment 1

[0028] Grind 20kg of fresh Hypericum perforatum (hypericin content 0.028%), add 200L saturated lime water to soak, heat to 40°C and stir for 1 hour, filter while hot, cool the filtrate to room temperature, add hydrochloric acid to adjust the pH to 6.1; the above solution is passed through the column The SA-5B resin column with a volume of 5L is used for saturated adsorption, and the resin is eluted with 40L water and a sufficient amount of 40% ethanol solution until the effluent is transparent, and then the hypericin eluate is eluted with 50L pure ethanol, and concentrated under reduced pressure; The obtained extract was mixed with neutral alumina and put on the column, eluted with 30% ethanol until the effluent was transparent, eluted twice with 70% ethanol until the effluent was transparent, and concentrated the second eluate to the original volume under reduced pressure 1 / 10, standing to crystallize; the crystals were recrystallized three times with cyclohexane to finally ob...

Embodiment 2

[0030] Grind 20kg of fresh Hypericum perforatum (0.031% hypericin content), add 220L of saturated lime water, soak and heat to 45°C and stir for 1.5 hours, filter while hot, cool the filtrate to room temperature, add hydrochloric acid to adjust the pH to 6.6; the above solution is passed through the column The HPD600 macroporous resin column with a volume of 5L is used for saturated adsorption, and the resin is eluted with 45L of water and a sufficient amount of 50% ethanol solution until the effluent is transparent, and then the hypericin eluate is eluted with 70L of 90% ethanol, and concentrated under reduced pressure; The obtained extract was mixed with neutral alumina and put on the column, eluted with 35% ethanol until the effluent was transparent, eluted twice with 80% ethanol until the effluent was transparent, and concentrated the second eluate to the original volume under reduced pressure 1 / 11, standing for crystallization; the crystals were recrystallized 4 times with...

Embodiment 3

[0032] Grind 20kg of fresh Hypericum perforatum (hypericin content 0.030%), add 240L saturated lime water to soak, heat to 50°C and stir for 2 hours, filter while hot, cool the filtrate to room temperature, add hydrochloric acid to adjust the pH to 7; the above solution is passed through the column The HZ-841 macroporous resin column with a volume of 5L is used for saturated adsorption, and the resin is eluted with 50L water and a sufficient amount of 60% ethanol solution until the effluent is transparent, and then the hypericin eluate is eluted with 75L 80% ethanol, and the eluent is decompressed. Concentrate; the obtained extract is mixed with neutral alumina and put on the column, eluted with 40% ethanol until the effluent is transparent, eluted twice with 90% ethanol until the effluent is transparent, and the second eluent is concentrated under reduced pressure to The original volume was 1 / 12, and it was crystallized upon standing; the crystal was recrystallized five times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com