Method for obtaining high-purity chlorine by efficiently utilizing magnesium chloride residues in low-temperature vacuum system

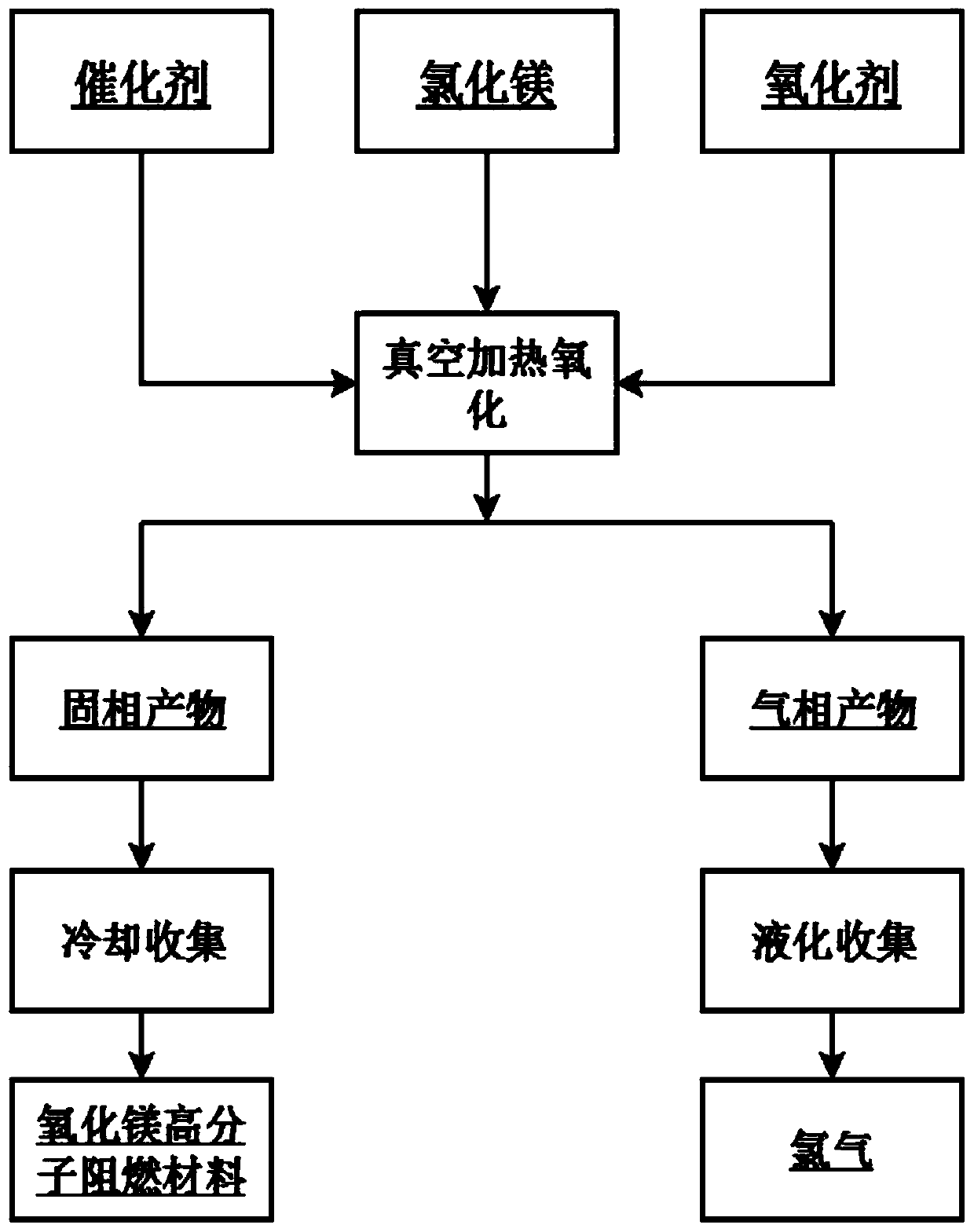

A low-temperature vacuum, high-purity chlorine technology, used in the preparation of chlorides, chlorine/hydrogen chloride purification, chemical instruments and methods, etc., can solve the problems of high reaction temperature requirements, insufficient purity, slow reaction rate, etc., and achieve fast reaction rate. , Improve the purity of the product and the effect of sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

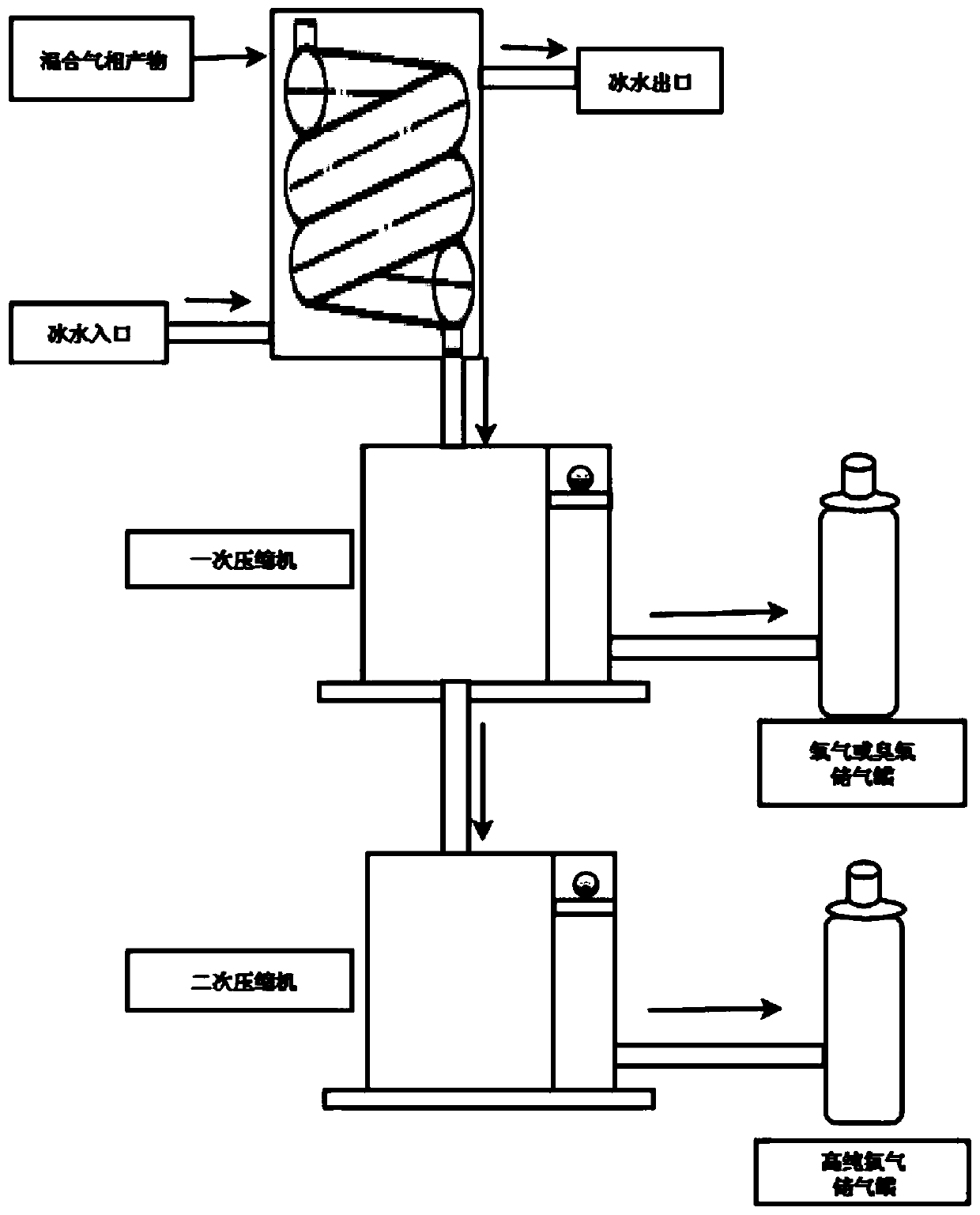

[0036] Import 75kg of molten magnesium chloride waste residue into a vacuum oxidation furnace and add 0.5% catalyst for vacuum heating and oxidation. During the oxidation process, the vacuum degree is controlled to 40Pa; the oxidation temperature is 800°C; the reaction time is 20min. Pressure, the first stage pressure is 5.5MPa, the second stage pressure is 7MPa.

[0037] The oxidizing agent is ozone. The catalyst is composite active magnesium oxide.

[0038] The feed rate of the described oxidizing agent is to feed the oxidizing agent at a rate of 0.8kg / min.

Embodiment 2

[0040] Import 82.5kg of molten magnesium chloride waste residue into a vacuum oxidation furnace and add 0.5% catalyst for vacuum heating and oxidation. During the oxidation process, the vacuum degree is controlled to 75Pa; the oxidation temperature is 650°C; the reaction time is 40min. The liquefaction pressure, the first stage pressure is 6MPa, the second stage pressure is 8MPa.

[0041] The oxidizing agent is ozone. The catalyst is composite active magnesium oxide.

[0042] The feed rate of the described oxidizing agent is to feed the oxidizing agent at a rate of 0.5kg / min.

Embodiment 3

[0044] Import 90kg of molten magnesium chloride waste residue into a vacuum oxidation furnace and add 0.5% catalyst for vacuum heating and oxidation. During the oxidation process, the vacuum degree is controlled at 110Pa; the oxidation temperature is 400°C; the reaction time is 60min. In the purification device, the liquefaction temperature is controlled to be 11° C., and the liquefaction pressure is controlled. The pressure of the first stage is 6 MPa, and the pressure of the second stage is 9 MPa.

[0045] The oxidizing agent is ozone. The catalyst is composite active magnesium oxide.

[0046] The feed rate of the described oxidizing agent is to feed the oxidizing agent at a rate of 0.5kg / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com