Drying device for textile thread production

A drying device and textile thread technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of incomplete drying, difficult drying, poor drying effect, etc., and improve the efficiency of drying effect, increase efficiency, increase the effect of sound frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

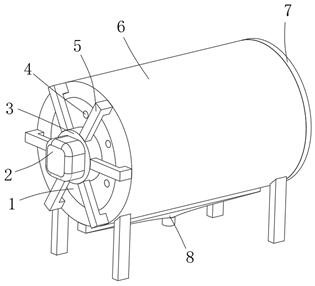

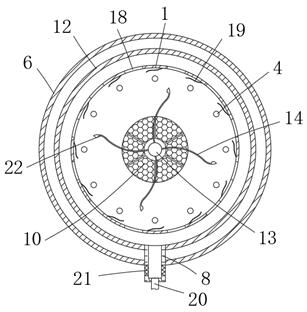

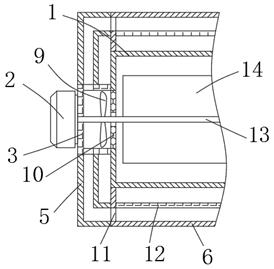

[0029] refer to Figure 1-4 , a drying device for textile thread production, comprising a drying cylinder 1, six ring-shaped and uniformly distributed wire holes 4 corresponding to each other are opened at both ends of the drying cylinder 1, and the side outer wall of the drying cylinder 1 is fixedly connected with The outer cylinder 6, and the side inner wall of the outer cylinder 6 is fixedly connected with an inner partition cylinder 12, the inner partition cylinder 12 includes a shell 15 and an inner tank 17, and a semiconductor cooling chip 16 is fixedly connected between the outer shell 15 and the inner tank 17, and the semiconductor cooling chip The heating surface of 16 is in contact with the shell 15, and the side inner wall of the drying cylinder 1 is connected with a rotating shaft 13 through a bearing, and the side outer wall of the rotating shaft 13 is fixedly connected with four annular evenly distributed arc-shaped leaves 14, and the arc-shaped leaves 14 arc The...

Embodiment 2

[0038] refer to figure 2 , a drying device for textile thread production. Compared with Embodiment 1 in this embodiment, the side inner wall of the drying cylinder 1 is fixedly connected with annular reeds 19 evenly distributed.

[0039] When the present invention is in use: compared with Example 1, when the air is compressed to generate sound, it can drive the reed 19 to produce violent vibrations, and then the sound in the drying cylinder 1 can be amplified, and then the water precipitation in the textile thread can be further improved. Efficiency further improves the drying effect.

Embodiment 3

[0041] refer to Figure 5 , a drying device for textile thread production. Compared with Embodiment 1, the side wall of the inner compartment 12 in this embodiment is fixedly connected with circularly distributed baffles 26, and the baffles 26 are all inclined downward.

[0042] When the present invention is in use: compared with Embodiment 1, after the humid air after the arc-shaped leaf 14 rotates to drive the drying to hit the inner compartment 12, the arc-shaped leaf 14 can make the air flow between the arc-shaped leaf 14 and the inner compartment The vortex is generated at the angle between 12, which can increase the contact time between the air and the inner compartment 12, improve the effect of liquefying the moisture in the air, and make the moisture in the air liquefy more fully.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com